15 years one-stop China custom CNC machining parts factory

57 |

Published by VMT at Sep 27 2025

57 |

Published by VMT at Sep 27 2025

Are you facing challenges in material selection for high-temperature or moderately corrosive environments, perhaps grappling with the trade-off between performance and budget? Many engineering projects risk overspending on premium alloys or compromising on durability by selecting unsuitable grades. Before committing to your next stainless steel, understand why 409 stainless steel, often overlooked, presents a unique blend of characteristics that could be your ideal, cost-effective solution for demanding thermal and corrosive applications. Unlock the secret to balancing budget and performance with expert insights into this versatile material.

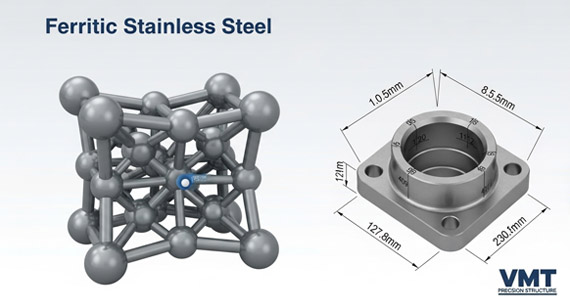

409 stainless steel is a ferritic stainless steel grade primarily recognized for its excellent high-temperature oxidation resistance and good weldability, particularly in applications where aesthetic finish is secondary to functionality and cost-effectiveness. It is commonly employed in environments exposed to fluctuating temperatures and mild corrosive conditions, offering a durable solution without the higher cost associated with more alloyed stainless steels. Its ferritic structure contributes to its magnetic properties and resistance to stress corrosion cracking.

Understanding 409 stainless steel begins with its classification and fundamental characteristics. As a ferritic grade, it stands apart from austenitic steels like 304, offering distinct advantages and limitations rooted in its metallurgical structure. For engineers and procurement managers seeking optimal material solutions, a clear grasp of these basics is crucial for making informed decisions.

Chemical Composition and Grade Standards of 409 Stainless Steel

The performance of 409 stainless steel is directly attributable to its carefully balanced chemical composition. It is a titanium-stabilized ferritic stainless steel, which means titanium is added to prevent sensitization—the formation of chromium carbides at grain boundaries during welding, which can lead to intergranular corrosion. This stabilization enhances its weldability and overall integrity in service. The typical chemical composition adheres to established international standards, ensuring consistent material quality and performance across applications.

| Element | Minimum (%) | Maximum (%) |

| Carbon (C) | - | 0.08 |

| Manganese (Mn) | - | 1.00 |

| Silicon (Si) | - | 1.00 |

| Phosphorus (P) | - | 0.045 |

| Sulfur (S) | - | 0.030 |

| Chromium (Cr) | 10.5 | 11.75 |

| Nickel (Ni) | - | 0.50 |

| Titanium (Ti) | 6xC | 0.75 |

| Iron (Fe) | Balance | Balance |

Classification and Characteristics of Ferritic Stainless Steel

409 stainless steel belongs to the ferritic family of stainless steels, distinguished by their body-centered cubic (BCC) crystal structure. This structure imparts several key characteristics that differentiate ferritics from other stainless steel types, such as austenitics or martensitics. Ferritic stainless steels generally possess good ductility, formability, and resistance to stress corrosion cracking. They are magnetic and typically non-hardenable by heat treatment. Their chromium content provides corrosion resistance, which is typically lower than that of austenitic grades but sufficient for many applications, especially when combined with their resistance to high-temperature oxidation. The absence of significant nickel content contributes to their lower cost compared to austenitic grades.

409 Stainless Steel's Physical and Mechanical Properties Overview

The physical and mechanical properties of 409 stainless steel define its behavior under various operational conditions, making it suitable for specific engineering demands. Its ferritic structure provides a distinct set of characteristics that influence its machinability, strength, and thermal response.

| Property | Value | Unit |

| Density | 7.8 | g/cm³ |

| Melting Range | 1425-1510 | °C |

| Electrical Resistivity | 0.60 | µΩ·m |

| Thermal Conductivity | 26 | W/m·K |

| Coefficient of Thermal Expansion (0-100°C) | 11.5 | µm/m·°C |

| Modulus of Elasticity | 200 | GPa |

| Property | Value (Typical) | Unit |

| Tensile Strength | 415 | MPa |

| Yield Strength (0.2% Offset) | 205 | MPa |

| Elongation (in 50mm) | 20 | % |

| Hardness (Rockwell B) | 80 | - |

409 stainless steel offers a compelling combination of properties that make it a strategic choice for specific industrial applications. Its distinct advantages, particularly in terms of high-temperature resilience and cost-effectiveness, are critical considerations for engineers designing durable and economical components.

Excellent High-Temperature Oxidation Resistance

One of the most significant advantages of 409 stainless steel is its exceptional resistance to high-temperature oxidation. While it is not designed for the most extreme high-temperature environments that superalloys might address, it performs reliably in continuous service up to approximately 675°C (1250°F) and intermittently up to 815°C (1500°F). This property is crucial in applications where components are exposed to hot gases or exhaust streams. The formation of a stable chromium oxide layer on the surface protects the underlying metal from further degradation, extending the lifespan of parts in thermally demanding conditions. This resistance to scaling and breakdown at elevated temperatures often makes it a preferred choice over carbon steels or lower-grade stainless steels in such environments.

Good Weldability and Formability

Despite being a ferritic stainless steel, 409 exhibits good weldability, a critical factor for complex fabrications. The titanium stabilization plays a key role here, mitigating the risk of intergranular corrosion that can plague unstabilized ferritic grades after welding. This allows for reliable joining of components, even for intricate designs. Its relatively low carbon content also contributes to its good ductility and formability, allowing it to be bent, drawn, and formed into various shapes with comparative ease. This versatility in fabrication reduces manufacturing complexities and broadens its application scope, from intricate automotive components to larger structural elements.

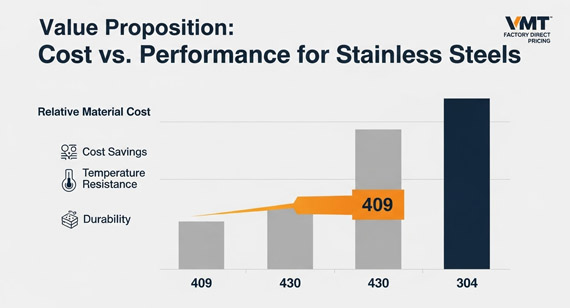

Economic and Cost-Benefit Analysis

The economic advantage of 409 stainless steel is a primary driver for its selection in many applications. Compared to higher-alloyed austenitic stainless steels like 304, 409 contains significantly less nickel, a major cost contributor. This lower alloy content translates directly into more transparent, factory-direct pricing, making it a highly cost-effective option for projects where its specific performance characteristics meet the requirements without over-engineering. For high-volume applications, these cost savings can be substantial, allowing project managers to maintain budget targets without sacrificing essential high-temperature or moderate corrosion resistance. This economic benefit, coupled with its functional performance, delivers a high-value solution, especially when sourced from a direct manufacturer like VMT CNC Machining Parts Services Factory, where supply chain transparency ensures optimal cost efficiency.

Demonstrated Corrosion Resistance Performance

While 409 stainless steel is not known for the same high levels of corrosion resistance as some austenitic grades, it offers sufficient protection against atmospheric corrosion and mild corrosive agents, particularly in automotive and industrial exhaust environments. Its chromium content provides a passive layer that resists rust and degradation from moisture and exhaust gases. However, it is important to note that 409 is susceptible to pitting corrosion in chloride-rich environments and is not suitable for marine applications or those involving strong acids or bases. Its performance in specific corrosive scenarios must be evaluated against project requirements, but for its intended uses, its corrosion resistance is entirely adequate and reliable, especially when the focus is on high-temperature oxidation.

The specific properties of 409 stainless steel make it ideally suited for applications where a balance of high-temperature stability, moderate corrosion resistance, good formability, and cost-effectiveness are paramount. Its robust performance in challenging thermal environments has established its niche across several key industries.

Key Role in Automotive Exhaust Systems

The automotive industry is perhaps the most significant user of 409 stainless steel. It is extensively employed in exhaust manifolds, catalytic converter casings, mufflers, and exhaust pipes. The material’s excellent high-temperature oxidation resistance allows it to withstand the intense heat cycles and corrosive exhaust gases without rapidly degrading. Its good weldability enables the production of complex exhaust geometries, while its cost-effectiveness helps manufacturers manage vehicle production costs. The ability to endure constant heating and cooling, along with vibrations, makes 409 an indispensable material for ensuring the longevity and performance of automotive exhaust systems globally.

Heat Exchanger and Furnace Component Applications

Beyond automotive, 409 stainless steel finds considerable use in industrial heat management systems. It is an effective material for components within heat exchangers, furnace linings, and industrial ovens where temperatures can fluctuate. Its resistance to scaling and deformation at elevated temperatures ensures efficient heat transfer and operational reliability over extended periods. For specific parts like baffles, ducts, and combustion chamber components, 409 provides the necessary thermal stability without the prohibitive costs of higher-grade alloys, making it a pragmatic choice for a range of thermal processing equipment.

Potential Uses for Containers and Structural Components

In less demanding structural applications where moderate corrosion and elevated temperatures are a factor, 409 stainless steel can also be considered for containers and certain structural elements. For instance, in agricultural equipment or some industrial enclosures that are exposed to outdoor elements or moderate heat, 409 offers a durable and cost-effective alternative to carbon steel, providing enhanced longevity. While not suited for heavy-load bearing structures or highly corrosive environments, its balance of properties makes it a viable material for internal components or secondary structures requiring some level of environmental resistance.

Success Stories in Other Engineering Fields

The versatility of 409 stainless steel extends to various other engineering fields. It has been successfully implemented in parts for some home appliances, such as specific components in ovens or dryers, and in certain elements of agricultural machinery that encounter variable weather conditions. Its application often stems from situations where mild atmospheric corrosion resistance is needed, coupled with a requirement for decent formability and a favorable cost profile. Each application leverages its particular strengths to provide a reliable and economical solution for specific engineering challenges, often enabled by precision machining and fabrication from experienced manufacturers.

Selecting the correct stainless steel grade is a critical decision that impacts performance, longevity, and cost. By comparing 409 stainless steel with other commonly used grades like 304 and 430, engineers can better understand where 409 offers a distinct advantage and where alternative materials might be more suitable. This comparative analysis is essential for optimizing material choice against specific project requirements.

Comparing with 304 Stainless Steel: Performance and Cost Trade-offs

304 stainless steel is an austenitic grade, well-known for its excellent corrosion resistance, formability, and good weldability. It contains a higher percentage of chromium and, crucially, nickel, which imparts its austenitic structure and enhanced corrosion resistance. This makes 304 suitable for a broader range of corrosive environments, including some chemical processing applications. However, the higher alloy content, particularly nickel, makes 304 significantly more expensive than 409.

When comparing the two, 409 is the clear choice for applications primarily driven by high-temperature oxidation resistance, especially in exhaust systems, where its cost-effectiveness is a major benefit. 304, while possessing good high-temperature strength, is not necessarily superior to 409 in terms of high-temperature oxidation resistance in non-aggressive atmospheric conditions, and its higher cost makes it an uneconomical choice for such specific applications if 409 performs adequately. For general corrosion resistance in more aggressive chemical environments, 304 is superior.

| Feature | 409 Stainless Steel | 304 Stainless Steel |

| Structure | Ferritic | Austenitic |

| Primary Alloy | Chromium, Titanium-stabilized | Chromium, Nickel |

| High-Temp Oxidation | Excellent (up to 815°C intermittent) | Very Good (up to 925°C intermittent) |

| General Corrosion | Good (mild environments) | Excellent (broader environments) |

| Weldability | Good (titanium stabilized) | Excellent (no pre/post heat) |

| Cost | Lower | Higher |

| Magnetic | Yes | No (non-magnetic) |

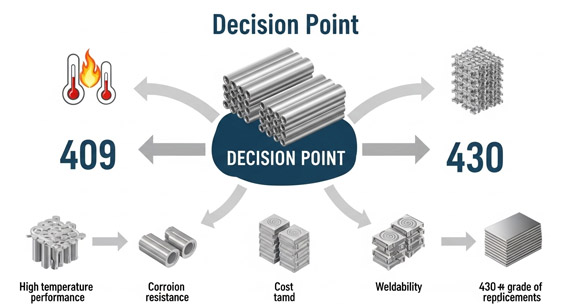

Comparing with 430 Stainless Steel: Corrosion Resistance and Toughness Differences

430 stainless steel is also a ferritic grade, similar to 409 in its basic structure and magnetic properties, but it lacks the titanium stabilization found in 409. It typically contains a slightly higher chromium content than 409 and is known for its good general corrosion resistance and formability in mild environments. However, the absence of titanium stabilization means 430 is more susceptible to sensitization and intergranular corrosion after welding, making its weldability inferior to 409 for many precision applications.

While 430 might offer marginally better general corrosion resistance in some specific non-welded applications due to its higher chromium, 409 surpasses it in high-temperature oxidation resistance and, critically, in weldability for complex fabrications. 409 is designed for more robust performance in thermal cycling applications where weld integrity is key. 430 is often chosen for decorative trims, appliance components, and kitchen utensils where welding is minimal or not subjected to high heat.

| Feature | 409 Stainless Steel | 430 Stainless Steel |

| Structure | Ferritic | Ferritic |

| Primary Alloy | Chromium, Titanium-stabilized | Chromium |

| High-Temp Oxidation | Excellent | Good (up to 870°C intermittent) |

| General Corrosion | Good | Good (slightly better) |

| Weldability | Good (titanium stabilized) | Moderate (sensitization risk) |

| Cost | Low | Low (similar to 409) |

| Key Differentiator | High-temp stability, weld integrity | Slightly better general corrosion |

How to Select Stainless Steel Grade Based on Project Requirements?

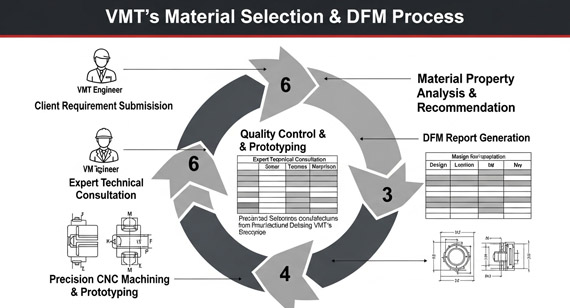

Choosing the right stainless steel grade requires a careful evaluation of several factors related to your project's specific demands. As a source manufacturer with deep technical expertise, VMT CNC Machining Parts Services Factory provides comprehensive DFM (Design for Manufacturability) reports and consultation to guide your selection.

1. Application Environment: Is the component exposed to high temperatures, corrosive chemicals, or atmospheric conditions? Quantify the temperature range and the type/concentration of corrosive agents.

2. Mechanical Properties: What are the required strength, ductility, and hardness? Does the part need to withstand significant stress, impact, or fatigue?

3. Fabrication Requirements: Does the design involve complex forming, welding, or deep drawing? The material's formability and weldability are critical considerations.

4. Cost Constraints: What is the budget for the material and manufacturing? Balancing performance with cost-effectiveness is often key, and 409 offers significant advantages in this area for specific applications.

5. Desired Lifespan and Maintenance: How long must the component last, and what are the expected maintenance cycles?

6. Aesthetic Requirements: Is surface finish critical, or is functionality the primary concern?

For projects demanding excellent high-temperature oxidation resistance, good weldability, and a cost-effective solution, especially in automotive exhaust systems or heat exchangers, 409 stainless steel is often the optimal choice. For higher general corrosion resistance, 304 is preferred. VMT's engineering team can provide expert guidance, leveraging our extensive experience in machining diverse stainless steel grades, including complex structures with 5-axis capabilities, to ensure your material selection is perfectly aligned with your project's success.

409 stainless steel is a titanium-stabilized ferritic grade renowned for its excellent high-temperature oxidation resistance, good weldability, and cost-effectiveness. It is widely applied in automotive exhaust systems, heat exchangers, and other thermal applications where its specific properties provide a balanced solution without the higher cost of austenitic grades like 304. While offering good corrosion resistance in mild environments, its primary strength lies in high-temperature stability. VMT CNC Machining Parts Services Factory, as a source manufacturer, leverages deep technical expertise and advanced machining capabilities to deliver precision 409 stainless steel parts, offering transparent pricing and comprehensive support from design evaluation to final delivery.

Ready to optimize your project with 409 stainless steel? Leverage our deep technical expertise and transparent pricing. Contact our engineering team today for a free, no-obligation technical consultation and a precise quote for your custom CNC machined parts. With no minimum order quantity and rapid prototyping available, VMT is your trusted partner for high-value machining solutions.

Q1: What are the primary advantages of using 409 stainless steel over other grades?

A1: The primary advantages of 409 stainless steel include its excellent high-temperature oxidation resistance (performing reliably up to 815°C intermittently), good weldability due to titanium stabilization, and its superior cost-effectiveness compared to austenitic grades like 304. These characteristics make it ideal for thermal applications where budget and durability in hot environments are critical, such as automotive exhaust systems.

Q2: Is 409 stainless steel magnetic?

A2: Yes, 409 stainless steel is a ferritic grade, which means it possesses a body-centered cubic (BCC) crystal structure and is inherently magnetic. This is a distinguishing characteristic compared to common austenitic stainless steels like 304, which are typically non-magnetic in their annealed condition.

Q3: Can 409 stainless steel be welded effectively?

A3: Yes, 409 stainless steel exhibits good weldability. The addition of titanium as a stabilizing element minimizes the formation of chromium carbides in the heat-affected zone during welding. This reduces the risk of sensitization and intergranular corrosion, ensuring reliable and strong weld joints, which is crucial for complex fabrications like those found in exhaust systems.

Q4: What are the typical applications where 409 stainless steel is most commonly used?

A4: 409 stainless steel is most commonly used in automotive exhaust systems (manifolds, mufflers, pipes), catalytic converter casings, and industrial heat exchangers. It is also found in furnace components, agricultural equipment, and certain home appliances where high-temperature oxidation resistance and cost-effectiveness are important.

Q5: How does VMT ensure the quality of CNC machined 409 stainless steel parts?

A5: As a source manufacturer, VMT CNC Machining Parts Services Factory implements rigorous, full-chain quality control measures. We are ISO9001 and IATF1649 certified, ensuring adherence to strict quality management systems. Our advanced equipment, including high-precision 5-axis CNC machines, combined with our technical expertise and DFM reports, guarantee that every 409 stainless steel part meets tight tolerances and specified performance requirements.

Q6: Is 409 stainless steel resistant to corrosion?

A6: 409 stainless steel offers good resistance to atmospheric corrosion and mild corrosive agents, particularly in the high-temperature environments it is designed for. However, its corrosion resistance is not as robust as higher-alloyed grades like 304, and it is susceptible to pitting corrosion in chloride-rich solutions and not recommended for marine or highly acidic/alkaline environments.

Q7: Can VMT handle custom designs and low-volume orders for 409 stainless steel parts?

A7: Absolutely. VMT specializes in one-stop service from design evaluation to final delivery, offering comprehensive solutions for custom CNC machined parts. We have no minimum order quantity (MOQ), and our capabilities include rapid prototyping, with 24-hour service available for urgent projects, making us a flexible partner for diverse project needs.

Q8: What should I consider when deciding between 409 and 430 stainless steel?

A8: When choosing between 409 and 430 stainless steel, consider the application's primary demands. 409 offers superior high-temperature oxidation resistance and significantly better weldability due to its titanium stabilization, making it ideal for welded components exposed to thermal cycling. 430, while also ferritic and cost-effective, typically has slightly better general corrosion resistance but is more prone to sensitization after welding, limiting its use in welded, high-temperature applications.