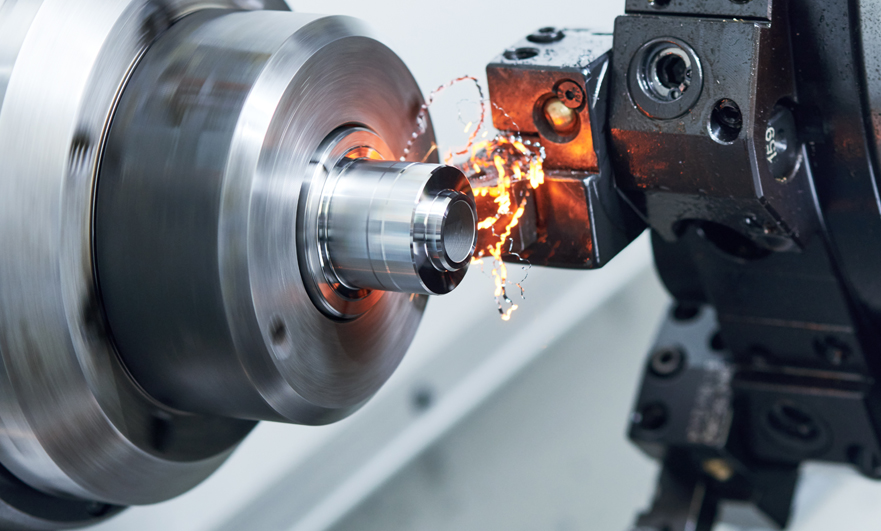

15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

133 |

Published by VMT at Oct 29 2021

133 |

Published by VMT at Oct 29 2021

Medical equipment and equipment are made of specific metals and some materials to ensure that these equipment will work normally for a long period of time and will not be corroded or affected by the environment, because this may have an impact on the rehabilitation of patients. In the numerical control mahcining and production process of medical equipment and medical equipment, various materials are needed.

Titanium is one of the most commonly used metals in the machining and manufacturing of medical devices. Because this metal has corrosion resistance and is biocompatible with human bones, it is the first choice for many people. In addition to medical equipment and equipment for internal use, it is also used to process and manufacture equipment for external use, such as surgical instruments, dental equipment, and orthopedic equipment.

There is medical grade titanium in the machining and manufacturing of medical devices. Titanium 6Al4V ELI and Titanium 6AL4V are alloys composed of 4% vanadium and 6% aluminum. Titanium alloy is harmoniously combined with the human body, so it is an ideal choice for medical device machining and manufacturing. There are many benefits of medical titanium. It is strong, but light in weight. It is an ideal choice for machining and manufacturing bulky medical equipment. Moreover, it has high corrosion resistance. At the same time, its price is very low and it is easy to afford. Medical titanium medical equipment can be used for more than 20 years.

Most surgical equipment is made of stainless steel. There are many kinds of stainless steel alloys. There are different amounts of chromium and nickel, which contribute to corrosion resistance. In fact, all kinds of stainless steel will not corrode in a special environment. It can be used for other medical equipment, such as examination tables, dental chairs, clinical scissors, pliers, etc.

Tantalum is widely used in the machining and manufacturing of medical devices. Used to manufacture simple equipment, such as marker tapes for diagnosis and composite additives in catheter plastics. Because it is high toughness and corrosion resistance. These characteristics also make metal an ideal material for implants. Tantalum has incredible dielectric properties and is easy to weld during CNC machining and manufacturing.

Titanium alloy is an alloy composed of nickel and titanium. When stress is applied due to its superelastic properties, the reaction of this metal is reversible. Shape memory (ShaeMemory) is a term used to refer to the ability of Nitinol to undergo deformation at a certain temperature and then restore its original shape at a temperature higher than its transformation temperature. Due to its unique properties and its weight, Ninino is ideal for biomedical applications such as nails, heart valve tools, complex spacer devices, bone anchors, heart valve devices, and various implants.

It is also used for CNC machining and manufacturing of positioning markers and diagnostic lines for breast tumor positioning. These devices are preferred because they are less invasive in diagnosing and treating breast cancer.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!