15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Dec 11 2025 | Reading Time:About 3 minutes

0 |

Published by VMT at Dec 11 2025 | Reading Time:About 3 minutes

Electronic enclosures play a critical role in protecting network and communication equipment from electromagnetic interference, ensuring high-voltage safety for power systems, and safeguarding in-vehicle electronics from external threats. As these enclosures are increasingly used across diverse industries, the requirements for material selection, precision, surface finish, durability, and production repeatability have become more demanding.CNC machining has emerged as the preferred manufacturing solution thanks to its unmatched accuracy, consistency, and flexibility with a wide range of materials. From rapid prototyping to full-scale mass production, choosing the right CNC machining manufacturer is essential to delivering reliable electronic enclosures that meet strict quality standards.

Manufacturers specializing in CNC-machined electronic enclosures typically offer advanced 3- to 5-axis machining capabilities, comprehensive quality management systems, robust inspection equipment, and diverse finishing processes—enabling them to produce highly complex and precision-critical enclosure designs. In this article, you will find out the Top 10 CNC Machining Manufacturers for Electronic Enclosures in 2025, offering an in-depth look at their machining capabilities, industry experience, and unique competitive strengths.

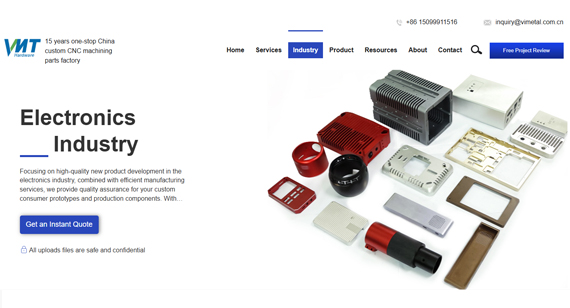

VMT isa seasoned CNC machining manufacturer with more than 15 years of professional experience, specializing in the production of high-precision custom electronic enclosures such as aluminum electronic housings. As a one-stop CNC machining factory in China, VMT has earned a strong reputation across industries such as electronics, telecommunications, medical devices, optics, and consumer electronics for consistently delivering high-quality parts with excellent accuracy and fast turnaround times.

With advanced 3-axis to 5-axis CNC machining centers, a skilled engineering team, and a strict quality control system, VMT ensures that every enclosure meets global standards and reliability requirements.

Capabilities:

VMT offers a full range of CNC machining services supporting both rapid prototyping and large-scale production:

Why Choose VMT for CNC-Machined Electronic Enclosures?

VMT has become one of the top CNC machining manufacturers for electronic enclosures thanks to several key advantages that directly benefit customers:

1. Precision Built for Electronics

Electronic enclosures require accurate dimensions, clean internal features, and stable assembly structures. VMT’s multi-axis CNC machines deliver exceptional precision, ensuring each enclosure fits internal components perfectly while maintaining performance.

2. Expertise in Complex Housing Designs

VMT has extensive experience machining thin-wall structures, heat-dissipation features, waterproof housings, and structural components, helping customers solve manufacturing challenges and optimize designs before production.

3. Wide Range of Metals and Surface Finishes

From lightweight aluminum to corrosion-resistant stainless steel and magnesium alloys, VMT offers flexible material options. High-quality surface treatments enhance both the appearance and durability of each product.

4. Strict Quality Control and Global Certifications

VMT is ISO 9001:2015 and IATF 16949 certified. Every enclosure undergoes rigorous inspection, including CMM measurement, height gauge checks, caliper verification, and functional testing, ensuring consistent quality across batches.

5. Short Lead Times and Stable Mass Production

With a well-structured production line and efficient scheduling, VMT can quickly produce prototypes and support reliable volume production, helping customers accelerate time to market.

6. One-Stop CNC Machining Service

From design review to machining, finishing, assembly, and packaging, VMT delivers seamless end-to-end support. Customers save time, reduce costs, and receive stable supply throughout the project lifecycle.

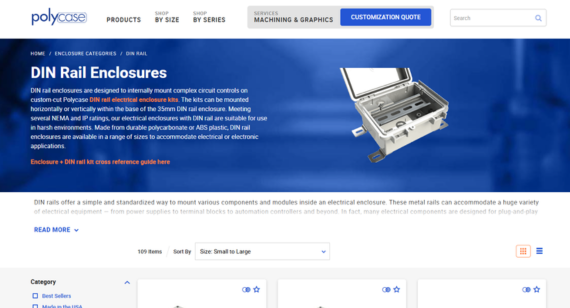

Polycase is an American enclosure manufacturer offering electronic enclosures in materials such as plastic, aluminum, steel, and stainless steel. The company provides custom CNC cutout services (machined via CNC) to achieve customized enclosures for clients. Polycase offers housings from rugged NEMA-rated enclosures to basic potting compounds, with over 2,100 ready-made variations (plastic/metal) to choose from, making it a specialized electronic enclosure company. They can also deliver standard parts quickly. However, Polycase lacks five-axis CNC machining capabilities, meaning that higher precision requirements may not be met. Their surface treatment experience is also somewhat lacking.

Capabilities:

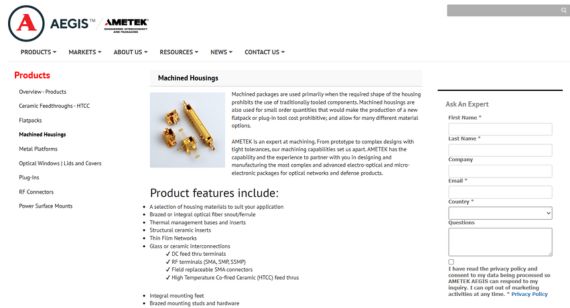

Aegis is a brand under AMETEK. AMETEK itself was founded in 1930 as American Machine & Metals. This company specializes in high-precision machined metal components, glass-metal enclosures, electrical housings, and mechanical parts with high sealing performance. They possess CNC milling, turning, automated lathes (such as Swiss-type lathes and Davenport), and metal sealing manufacturing technologies, specializing in mechanical structural components for aerospace, military, energy, and high-reliability electrical systems. Aegis' machining capabilities cover a wide range of materials including aluminum, steel, stainless steel, titanium, Kovar, and Inconel, and they excel in manufacturing complex small housings and functional seals.

Capabilities:

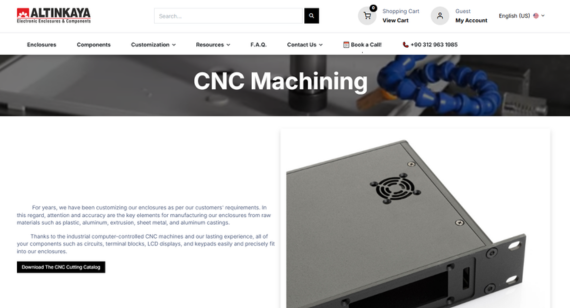

Altınkaya is an electronic enclosure and chassis manufacturer, offering products including plastic enclosures, aluminum profile enclosures, handheld device enclosures, DIN-Rail enclosures, and outdoor waterproof and dustproof enclosures. They provide CNC custom machining services (hole cutting, milling, and partial machining) and possess comprehensive capabilities in plastic injection molding, molding, sheet metal work, and profile cutting. While their CNC machine tools are primarily used for enclosure hole cutting and custom machining, they do not offer high-precision equipment such as five-axis CNC machines.

Capabilities:

CED Machining specializes in precision CNC machining, particularly for tight-tolerance parts in the electronics, medical, and industrial equipment sectors. They possess multi-axis CNC milling, CNC turning, mill-turn, and machining center combination capabilities, and are equipped with deburring, inspection systems, and laser marking equipment.

Their specialty lies in machining medium to highly complex parts, but publicly available information does not indicate they possess 5-axis machining centers.

Capabilities:

DATRON is a manufacturer of high-speed CNC machine tools, also providing rapid milling services for components in the electronics industry. Their high-speed milling machines feature high-speed spindles (up to 60,000 RPM) and support 3-axis, 4-axis, and 5-axis machining, suitable for processing aluminum, plastics, small high-precision housings, heat sinks, electronic modules, etc. Their strengths lie in high-speed cutting (HSC), micro-machining, and high-quality surface finishing of aluminum.

Capabilities:

MetalQuest is a high-precision CNC machining factory equipped with 3-axis, 4-axis, and 5-axis milling, turning, Swiss-style lathes, automated units, and robotic loading and unloading systems. Their strength lies in their high degree of automation, making them suitable for medium- to high-volume production of precision parts, including metal components for electronic devices and mechanical packaging parts.

Capabilities:

Lakeside Precision offers CNC milling, turning, multi-tasking (mill-turn), and 5-axis machining services. Its machine tools include the Mazak series (Integrex, VCN, Quick-Turn), capable of performing multi-tasking operations and handling medium to complex metal housing parts. Ideal for small to medium batches of high-precision parts (100–5,000 pieces).

Capabilities:

Protocase specializes in rapid manufacturing of electronic enclosures, housings, and CNC metal components. They possess 3-axis and 5-axis CNC milling machines and CNC lathes, and can handle aluminum, plastics, and engineered materials. Protocase's strengths lie in rapid prototyping, small-batch manufacturing, and extremely short lead times (2–3 days).

Primarily serving the R&D, laboratory equipment, and development board enclosure industries.

Capabilities:

Fibox is a globally renowned manufacturer of plastic and composite electronic enclosures, providing high-level IP/NEMA protective enclosures. Their CNC machining services primarily offer secondary processing such as drilling, grooving, and cutting to customize ABS, PC, or composite material chassis suitable for industrial, electrical, and outdoor electronic equipment. Their CNC machining focuses on custom manufacturing of standard enclosures, rather than entirely in-house machined parts.

Capabilities:

The market boasts numerous manufacturers with capabilities and expertise. While top 10 electronic housings CNC machining manufacturers are listed in this article, a traditional and comprehensive evaluation of these manufacturers remains essential.

When selecting a CNC machining manufacturer for electronic housings, prioritize partners that:

By examining their process control, inspection procedures, precision stability, and project delivery capabilities, you will be able to select a preferred manufacturer that truly meets your requirements and long-term cooperation expectations.

A European electronics company approached VMT to develop a high-precision aluminum enclosure for its next-generation communication module. The product presented a number of demanding requirements of wall thickness as low as 0.8 mm; multiple internal heat dissipation cavities; flawless surface finish to meet premium consumer electronics aesthetics.

The customer’s biggest challenge was finding a manufacturer capable of meeting all of the following:

Several suppliers had previously failed during mass production due to dimensional instability, resulting in assembly failure and high scrap rates.

Our Solution & Engineering Breakthroughs

VMT assigned a dedicated engineering team to thoroughly analyze the customer’s 3D model, identify potential manufacturing risks, and propose design-for-manufacturing improvements. Key actions included:

These engineering improvements ensured that the enclosure met all dimensional tolerances and visual appearance standards without compromising production efficiency.

Results & Customer Value

With these optimizations, VMT delivered enclosures that were not only dimensionally stable and repeatable but also visually flawless—surpassing the customer’s expectations. Key outcomes include:

This project highlights VMT’s unmatched capability in producing high-precision, appearance-grade electronic enclosures and reinforces its position as one of the most trusted CNC machining manufacturers in the global electronics industry.