15 years one-stop China custom CNC machining parts factory

99 |

Published by VMT at Nov 01 2025 | Reading Time:About 3 minutes

99 |

Published by VMT at Nov 01 2025 | Reading Time:About 3 minutes

Pure tin has a precise melting point of 231.93°C (449.47°F), a critical aspect of its tin material properties and essential for reliable tin processing considerations in advanced manufacturing.

In precision manufacturing, a single degree can define success or failure. For critical applications, understanding the exact melting point of tin isn't just academic—it's paramount. The reliable performance of components, from microelectronics to aerospace parts, hinges on stable tin material properties.

Dive deep into the science and practical implications of tin's thermal behavior. Discover how meticulous material control can elevate your designs and ensure the integrity of your products.

What is Pure Tin's Melting Point?

Pure tin, specifically the beta phase (white tin), exhibits a remarkably sharp and consistent melting point. This is one of the most fundamental pure tin thermal data points. It consistently transforms from solid to liquid at approximately 231.93°C (449.47°F).

This precise value is a cornerstone for many industrial processes. In our experience, deviations from this temperature can signal impurities or process inconsistencies. It impacts everything from material selection to the final product's reliability.

Why Tin Melting Point is Key

The melting point of tin is a critical parameter for design and manufacturing engineers. It directly influences material selection, processing temperatures, and the operational limits of components. Ignoring its nuances can lead to catastrophic product failures.

For instance, in electronic assemblies, the accurate melting point of tin ensures proper solder joint formation. It prevents issues like cold joints or thermal damage to sensitive components during reflow. Understanding this critical tin material property is non-negotiable.

Pure Tin vs. Alloys: Differences

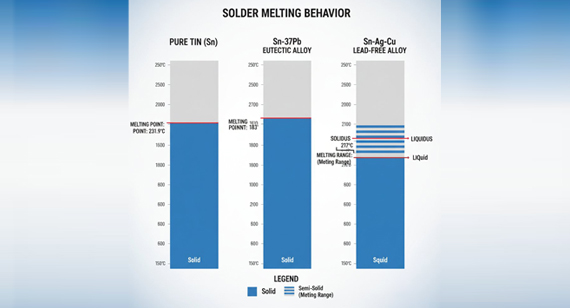

While pure tin has a single, distinct melting point, tin alloys behave differently. The addition of other elements fundamentally alters the thermal characteristics, creating a melting range rather than a sharp point. This distinction is vital for tin processing considerations.

Different tin alloys are engineered for specific applications, each with unique tin alloy melting temperature ranges. Their varied compositions offer tailored properties like strength, ductility, or electrical conductivity.

Common Tin Alloys Overview

Numerous tin alloys are utilized across industries, each offering a distinct balance of properties. Common alloying elements include lead, silver, copper, bismuth, and antimony. These additions influence not only the tin alloy melting temperature but also mechanical strength and corrosion resistance.

For example, Sn-Pb alloys (traditional solder) have a lower melting point than pure tin. Lead-free solders, like Sn-Ag-Cu alloys, generally have higher melting temperatures and a wider melting range, which presents different tin processing considerations.

Eutectic Point Significance

The eutectic point is a unique characteristic in some tin alloys where the specific composition melts and solidifies at a single, lowest possible temperature. This behavior mimics that of a pure metal, exhibiting a sharp melting point. Eutectic tin properties are highly valued.

Eutectic alloys simplify processing by avoiding a "pasty" range during melting or solidification. This property is particularly crucial in soldering applications, where a quick and clean phase transition is desired to prevent component movement or void formation.

Standard Measurement Methods

Accurate determination of the melting point of tin and its alloys is fundamental for quality control and material characterization. Industry relies on highly precise thermal analysis techniques. These methods provide pure tin thermal data that validates material specifications.

Understanding these techniques is paramount for anyone involved in tin processing considerations. It helps ensure that raw materials and finished tin cnc machining parts meet rigorous performance standards.

DSC: Differential Scanning

Differential Scanning Calorimetry (DSC) is a widely used thermal analysis technique. It measures the heat flow into or out of a sample as a function of temperature or time. For tin, the melting process is an endothermic event, absorbing heat.

DSC provides precise data on the onset, peak, and end temperatures of melting. It also quantifies the enthalpy of fusion, offering comprehensive pure tin thermal data crucial for material identification and purity assessment.

DTA: Differential Thermal

Differential Thermal Analysis (DTA) is another robust method for determining melting points. DTA measures the temperature difference between a sample and an inert reference as both are subjected to the same controlled temperature program. The melting of tin causes a temperature differential.

Similar to DSC, DTA identifies the temperatures at which phase transitions occur. While DSC quantifies energy changes, DTA focuses on the temperature differences, providing valuable insight into the tin melting point and thermal behavior.

Factors Affecting Accuracy

Even with advanced equipment, several factors can influence the accuracy of melting point measurements. Sample preparation, heating rate, and instrument calibration are all critical. A small error can lead to significant processing issues.

In our experience, meticulous attention to detail during testing is essential. We follow stringent protocols to ensure that our pure tin thermal data is consistently reliable and verifiable.

Ensuring Reliable Data

To ensure reliable melting point data, adherence to international standards (e.g., ISO, ASTM) is crucial. Regular calibration of thermal analysis equipment against certified reference materials is also non-negotiable. This minimizes measurement uncertainty.

Proper sample handling, including ensuring high purity and uniform particle size, contributes significantly to accuracy. For a cnc machining factory, this diligence extends to every aspect of material verification, from incoming raw materials to finished tin cnc machining parts.

Impurities & Their Influence

Impurities are perhaps the most significant factor affecting the melting point of tin. Even trace amounts of other elements can depress the melting point and broaden the melting range. This directly impacts tin material properties.

For instance, lead in nominally "pure" tin can drastically lower the melting temperature. This phenomenon is critical for understanding tin processing considerations and preventing unexpected material behavior during manufacturing.

Pressure & Atmospheric Effects

While less common in typical manufacturing environments, changes in atmospheric pressure can subtly influence the tin melting point. Higher pressures generally lead to a slight increase in melting temperature. This is a thermodynamic principle.

For vacuum brazing or specialized applications, these pressure effects might become more relevant. However, for most tin processing considerations, ambient pressure variations are often negligible compared to impurity effects.

Heating Rate Impact

The rate at which a tin sample is heated during thermal analysis can also affect the measured melting point. Very rapid heating rates might cause a slight overestimation of the melting temperature due to thermal lag. Conversely, very slow rates might allow for more equilibrium conditions.

Choosing an appropriate, controlled heating rate is crucial for obtaining reproducible and accurate pure tin thermal data. This is a standard practice in our lab when testing incoming tin alloys.

Material Purity Control

Maintaining stringent material purity control is paramount for applications requiring a precise tin melting point. This involves rigorous supplier qualification, advanced elemental analysis (e.g., ICP-OES, XRF) of incoming raw materials, and in-process contamination monitoring.

Our cnc machining factory implements comprehensive quality checks to ensure that the tin material properties of our components meet exact specifications. This commitment to purity directly translates into consistent performance of tin cnc machining parts.

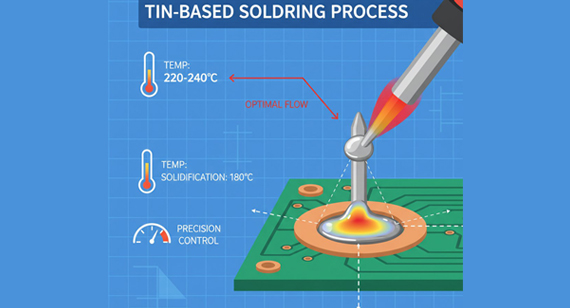

Criticality in Soldering

The tin melting point is arguably most critical in soldering applications. Solder alloys, often tin-based, must melt predictably at specific temperatures. This ensures strong, reliable electrical and mechanical connections without damaging surrounding components.

The choice of tin alloy melting temperature directly impacts the reflow profile, dwell times, and cooling rates required for successful soldering. Improper control can lead to rework, field failures, and significant cost increases.

In precision casting, particularly for specialized tin cnc machining parts, understanding the tin melting point and solidification behavior is essential. It dictates pouring temperatures, mold design, and cooling strategies. This affects the final microstructure and mechanical properties.

Controlling the melt temperature range is vital to prevent defects like shrinkage porosity or incomplete mold filling. This ensures the integrity and dimensional accuracy of the cast components.

Metallurgy & Material Science

From a metallurgical perspective, the melting point of tin is a fundamental property for understanding phase transformations. It informs the development of new tin alloys with tailored tin material properties for various demanding applications. Researchers study how different alloying elements modify the melting behavior.

This deep scientific understanding is crucial for optimizing material performance, predicting thermal fatigue, and designing components for extreme environments. It ensures that innovative tin solutions are robust and reliable.

CNC Machining Connection

While tin typically melts at lower temperatures than steels or aluminum, its melting point still has a direct connection to CNC machining processes, particularly for tin cnc machining parts. Material removal generates heat. Without proper cooling, local temperatures can exceed the tin melting point, leading to issues.

For example, when machining pure tin or low-melting tin alloys, excessive heat can cause material smearing, poor surface finish, or even localized melting. This necessitates precise control over cutting speeds, feed rates, and coolant application in our cnc machining factory.

Table: Considerations for CNC Machining Tin Alloys

| Consideration |

Impact on Machining |

Solution/Approach |

| Low Melting Point | Risk of localized melting, smearing | Optimized cooling, low cutting speeds |

| Softness/Ductility | Built-up edge formation, poor chip evacuation | Sharp tools, specific geometries |

| Thermal Conductivity | Efficient heat dissipation vs. retention | Balanced coolant strategy, tool material |

| Alloy Composition | Affects hardness, chip breakability | Tailored tool paths, coatings |

Our Tin Material Expertise

At China VMT CNC machining factory, our expertise extends far beyond just machining. We possess profound knowledge of tin material properties, including its precise melting point and how it behaves under various conditions. This deep technical insight is vital for delivering superior tin cnc machining parts.

Our engineers understand the intricate relationship between material science and manufacturing processes. We apply this knowledge to every project, from material selection to final inspection, ensuring optimal performance.

Quality Sourcing & Control

We understand that the integrity of the tin melting point starts at the source. Our rigorous supplier qualification process ensures we only procure high-purity tin and certified tin alloys from trusted partners. Each batch undergoes comprehensive material verification.

This commitment to quality sourcing, combined with in-house analytical capabilities, guarantees consistent pure tin thermal data. It ensures that the tin material properties of components we manufacture are precisely as specified, every time.

Partnering for Reliable Parts

Partnering with China VMT means gaining access to unparalleled expertise in high-precision CNC machining services. We don't just execute designs; we collaborate with our clients, providing invaluable insights into tin processing considerations. Our goal is to enhance product reliability.

From aerospace to medical devices, we deliver tin cnc machining parts with critical tolerances and consistent material characteristics. Our transparent pricing and commitment to quality make us a trusted partner for your most demanding projects.

Key Tin Melting Insights

Understanding the tin melting point is not merely academic; it is foundational to successful advanced manufacturing. Whether it's the sharp point of pure tin or the melting range of complex tin alloys, these properties dictate processing parameters and product reliability. Accurate measurement and meticulous control of material purity are non-negotiable tin processing considerations.

From soldering to precision casting and tin cnc machining parts, the nuances of tin's thermal behavior profoundly impact component performance. China VMT CNC machining factory stands at the forefront of leveraging this expertise.

Consult Our Experts

Elevate your product's performance with unmatched material precision. Contact our engineering specialists today to discuss your project's specific tin material requirements, explore our transparent pricing models, or request a consultation on how our deep technical expertise can deliver superior, high-quality tin components for your most demanding applications through our comprehensive cnc machining services.

Problem: A client in the medical device sector was struggling with inconsistent bond integrity in a new implantable sensor. Their existing supplier's tin alloy components exhibited a variable tin alloy melting temperature, leading to unpredictable solder joint quality and high reject rates during assembly. The critical nature of the application demanded absolute reliability.

Our Solution: China VMT CNC machining factory initiated a thorough material analysis of the client's existing components. Our metallurgists identified minor variations in alloy composition, directly impacting the eutectic tin properties and leading to an undesirable melting range. We then developed a custom Sn-Bi (tin-bismuth) alloy, precisely formulated to achieve a stable, low tin alloy melting temperature and a sharp eutectic point, perfectly suited for their automated reflow process. We manufactured the tiny, intricate tin cnc machining parts using our advanced CNC machining services, ensuring perfect dimensional accuracy.

Result: By supplying precisely engineered tin components with a consistent and optimized melting point, the client saw a dramatic reduction in assembly defects—over 85% within the first quarter. The improved solder joint integrity not only enhanced the reliability of their medical devices but also significantly reduced manufacturing costs and time-to-market. Our deep understanding of tin material properties and commitment to precision as a cnc machining factory proved invaluable.

What is the exact melting point of pure tin?

Pure tin consistently melts at approximately 231.93°C (449.47°F). This precise value is a fundamental aspect of its pure tin thermal data and a benchmark for industrial applications.

How do tin alloys differ from pure tin?

Tin alloys have a melting *range* instead of a single point. This range is determined by the specific alloying elements and their concentrations, altering the tin alloy melting temperature.

Why are impurities detrimental to tin?

Impurities in tin can significantly depress the tin melting point and broaden its melting range. This can lead to unpredictable material behavior and compromised performance in applications like soldering.

What is a eutectic tin alloy?

A eutectic tin alloy is a specific composition that melts and solidifies at a single, lowest possible temperature. This behavior provides a sharp transition, similar to pure metals, due to its unique eutectic tin properties.

How is tin's melting point measured?

Common methods include Differential Scanning Calorimetry (DSC) and Differential Thermal Analysis (DTA). These techniques accurately measure heat flow or temperature differences during phase transitions to determine the tin melting point.

Why is melting point critical for CNC machining?

While not melting during machining, the tin melting point informs optimal cutting parameters. Excessive localized heat during machining tin cnc machining parts can cause smearing or surface finish degradation, requiring careful tin processing considerations.

Can the heating rate affect the measurement?

Yes, very rapid heating rates can lead to a slight overestimation of the tin melting point. Controlled heating rates are crucial for obtaining accurate and reproducible pure tin thermal data during analysis.

How does VMT ensure tin quality?

China VMT CNC machining factory ensures tin quality through rigorous supplier qualification and in-house material analysis. We verify the tin material properties, including the tin melting point, to guarantee consistency for all tin cnc machining parts.