15 years one-stop China custom CNC machining parts factory

35 |

Published by VMT at Oct 31 2025 | Reading Time:About 3 minutes

35 |

Published by VMT at Oct 31 2025 | Reading Time:About 3 minutes

Tungsten boasts the highest Tungsten melting point (3422°C), making it an unrivaled high-temperature tungsten and ideal for critical refractory metal properties where extreme thermal resistance and pure tungsten components are essential.

In the relentless pursuit of peak performance in extreme environments, only a handful of materials can truly stand the heat. Tungsten, with its staggering melting point—the highest of all metals—stands alone at the summit. But what does this scientific marvel mean for your toughest engineering challenges, and how can you reliably harness its extraordinary power?

Understanding the precise properties of high-temperature tungsten is not merely an academic exercise. It is fundamental to designing and manufacturing components that perform flawlessly in the most demanding applications, from aerospace to medical devices. This guide delves into the specifics of tungsten's thermal resistance, explores its key applications, and details the specialized tungsten machining required to leverage its full potential.

At China VMT CNC machining factory, we recognize the critical need for precision and reliability when working with such an extraordinary material. We will share our expertise as a leading tungsten parts manufacturer, offering insights into overcoming machining tungsten challenges and delivering superior tungsten CNC machining parts.

Tungsten holds the unparalleled distinction of having the highest melting point among all metals, approximately 3422°C, making it indispensable for extreme high-temperature applications. This exceptional thermal resistance is attributed to its strong metallic bonds, stable crystal structure, and unique physical properties like extreme hardness and high density, which allow it to retain structural integrity where other refractory metals fail.

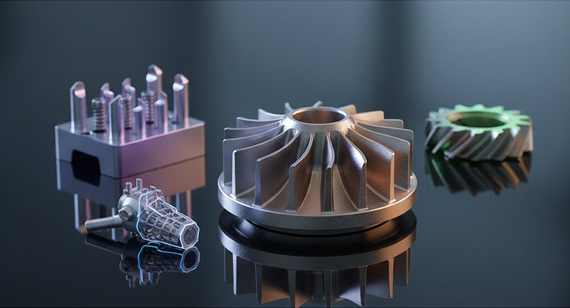

Its critical applications span aerospace (rocket nozzles, heat shields), medical (X-ray targets, radiation shielding), industrial furnaces (heating elements), and evaporation technology. Machining tungsten, however, presents significant challenges due to its inherent hardness and brittleness. Specialist manufacturers like China VMT CNC leverage advanced CNC machining, specialized tooling, and stringent quality control to produce precise, high-purity tungsten components. Partnering with such experts ensures reliable performance, technical support, and superior solutions for demanding thermal environments, driving innovation across various high-tech industries.

Tungsten's Unique Physical Properties

Tungsten (W) stands apart in the periodic table, primarily for its exceptional thermal characteristics. Beyond its impressive tungsten melting point, it exhibits a suite of properties that are crucial for high-performance applications. These include extreme hardness, high density, and remarkable tensile strength at elevated temperatures.

In our experience, these inherent properties directly translate into the material's resistance to wear, deformation, and thermal shock. This combination is why high-temperature tungsten is indispensable in environments where other metals would simply fail or degrade rapidly. Its unique atomic structure contributes significantly to this robustness.

The Science Behind High Melting Point

The extraordinary tungsten melting point stems from its strong metallic bonds. Tungsten atoms possess a very stable body-centered cubic (BCC) crystal structure and a large number of valence electrons. These electrons are delocalized, forming a strong "electron sea" that tightly binds the atoms together.

Overcoming these robust interatomic forces requires an immense amount of thermal energy. This strong bonding network explains why tungsten has such high thermal resistance and retains its structural integrity even when exposed to extreme heat. It is a testament to the fundamental physics governing material behavior.

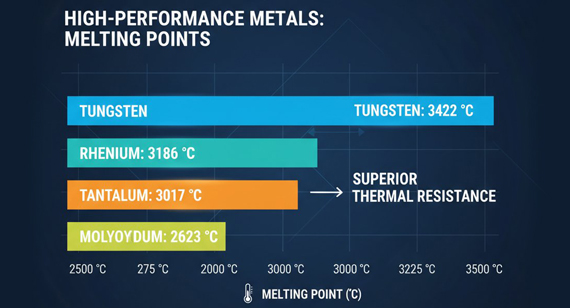

Comparing Refractory Metals

Tungsten belongs to the group of refractory metals, which are defined by their exceptional resistance to heat and wear. This group also includes molybdenum, tantalum, and rhenium, all known for their high melting points and stability. However, tungsten consistently leads this class in terms of thermal endurance.

When evaluating refractory metal properties for specific high-temperature tungsten applications, it's essential to compare their key characteristics. While each has its niche, tungsten often emerges as the material of choice when the absolute highest temperature capability is required.

Here is a comparison of common refractory metals:

| Metal |

Melting Point (°C) |

Density (g/cm³) |

Thermal Conductivity (W/m·K) |

Hardness (HV) |

| Tungsten | 3422 | 19.25 | 173 | 3430 |

| Molybdenum | 2623 | 10.28 | 138 | 1530 |

| Tantalum | 3017 | 16.69 | 57 | 873 |

| Rhenium | 3186 | 21.02 | 48 | 2450 |

Official Melting Point Value

The officially recognized melting point of pure tungsten is approximately 3422 degrees Celsius (6192 degrees Fahrenheit, or 3695 Kelvin). This precise value is a cornerstone for engineers designing components for extreme thermal environments. It represents the temperature at which solid tungsten transitions to its liquid state.

This figure is consistently used in material science and engineering handbooks worldwide. It highlights tungsten's status as the metal with the highest known melting point, a fundamental property influencing its wide array of high temperature tungsten applications.

Impact of Purity on Melting Point

The stated tungsten melting point of 3422°C refers specifically to pure tungsten components. Even trace amounts of impurities can significantly affect this value. Impurities, such as oxygen, carbon, or other metallic elements, tend to lower the melting point.

In our manufacturing processes, maintaining high purity is paramount to ensure the material performs as expected. We adhere to strict material certifications to guarantee that the tungsten used for our parts meets or exceeds industry standards for purity, safeguarding its thermal resistance and mechanical properties.

Experimental Measurement Techniques

Determining the tungsten melting point accurately involves specialized high-temperature calorimetry and pyrometry techniques. These methods are designed to measure temperatures far beyond the capabilities of conventional thermometers. For instance, optical pyrometers are often used to measure the intense radiation emitted by superheated tungsten.

These experimental techniques require controlled environments, such as vacuum or inert gas furnaces, to prevent oxidation at high temperatures. Such rigorous measurements ensure the reliability of the reported data, which is critical for material specification and product design in demanding high temperature tungsten applications.

Aerospace and Defense Needs

The aerospace and defense sectors heavily rely on the unique refractory metal properties of tungsten. Components exposed to extreme heat and rapid temperature changes, such as rocket nozzles, missile components, and heat shields, frequently incorporate tungsten. Its high tungsten melting point ensures structural integrity under intense thermal stress.

For these critical applications, the precision of tungsten machining is non-negotiable. Our expertise in creating complex pure tungsten components provides the reliability needed for mission-critical parts that operate in environments where failure is not an option.

Medical and Imaging Devices

Tungsten's high density and atomic number make it invaluable in medical applications, particularly in radiation shielding and X-ray targets. Its ability to effectively block radiation while maintaining high thermal resistance is crucial in these sensitive environments. Components like collimators in radiotherapy equipment and anode targets in X-ray tubes utilize tungsten.

The extreme precision demanded by medical devices often calls for advanced tungsten machining techniques. We provide tungsten CNC machining parts that meet stringent medical-grade specifications, ensuring both performance and patient safety.

High-Heat Industrial Furnaces

In high-temperature industrial furnaces, tungsten serves as an essential material for heating elements, radiation shields, and crucibles. These applications leverage tungsten's exceptional thermal resistance to maintain stable operations in environments reaching thousands of degrees Celsius. Its durability significantly extends the lifespan of furnace components.

A common issue we see is premature failure of lesser materials in these harsh furnace environments. Using pure tungsten components manufactured to exacting standards dramatically improves efficiency and reduces downtime, offering a superior return on investment for industrial clients.

Evaporation and Coating Technology

Tungsten is a material of choice in thin-film deposition processes, particularly for evaporation boats and filaments. Its high tungsten melting point allows it to operate at temperatures necessary to vaporize various materials for coating substrates, without itself degrading. This ensures high-purity coatings for electronics, optics, and decorative finishes.

The longevity and consistent performance of these tungsten components are vital for continuous production. Our factory specializes in producing reliable and precise tungsten parts for these advanced coating technologies, contributing to superior product quality in industries ranging from semiconductors to automotive.

Challenges of Tungsten Fabrication

Machining tungsten presents significant challenges due to its unique refractory metal properties. Tungsten is extremely hard and brittle at room temperature, making it difficult to cut and prone to chipping or cracking. Its high density also requires robust machinery and specialized cutting tools. These machining tungsten challenges demand deep experience and advanced techniques.

Without precise control over cutting parameters, tool geometry, and cooling, achieving the desired tolerances and surface finish is nearly impossible. Many manufacturers struggle with the material's unforgiving nature, leading to high scrap rates and extended production times.

Precision CNC for Tungsten Parts

At China VMT CNC machining factory, we have honed our processes for precision CNC for tungsten parts. We utilize state-of-the-art multi-axis CNC machines coupled with specialized tooling, such as diamond-tipped or carbide inserts, specifically designed to withstand tungsten's abrasive nature. Our engineers develop custom machining strategies for each component.

This advanced approach allows us to overcome typical machining tungsten challenges, delivering complex geometries and extremely tight tolerances. Whether it's intricate internal features or external profiles, our tungsten CNC machining parts meet the most demanding specifications.

Achieving Superior Surface Finish

Achieving a superior surface finish on tungsten components is critical for many high temperature tungsten applications, especially where friction, wear, or vacuum integrity are concerns. Poor surface finish can lead to micro-cracks, reduce part longevity, and affect performance. Our process incorporates specialized finishing operations.

We employ precise grinding, lapping, and polishing techniques, often in conjunction with advanced coolants, to minimize tool wear and prevent surface defects. Our rigorous quality control ensures that the surface roughness meets the exact requirements of each engineering design, enhancing the overall thermal resistance and reliability of the pure tungsten components.

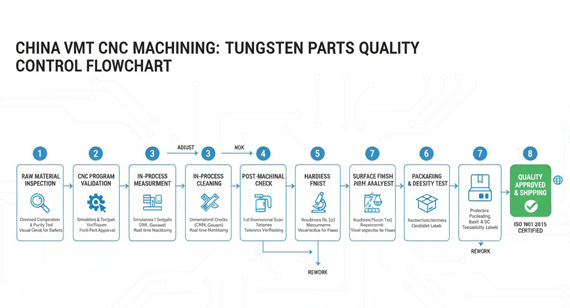

Quality Control for Tungsten Components

Quality control is an integral part of our tungsten machining process, not an afterthought. For every batch of tungsten parts, we implement stringent inspection protocols from raw material verification to final dimensional checks. This commitment ensures the integrity and performance of every tungsten component we produce.

We utilize advanced metrology equipment, including CMMs (Coordinate Measuring Machines) and optical comparators, to verify critical dimensions and tolerances. Adherence to international standards like ISO 9001 and AS9100 for aerospace components underscores our dedication to unparalleled quality in every tungsten CNC machining parts we deliver.

Here are key quality control checkpoints in our tungsten machining process:

| Process Stage |

Quality Checkpoints |

Key Performance Indicators |

| Raw Material | Purity analysis, Material Certification | Composition, Trace Elements |

| Pre-Machining | Blank dimensions, Hardness | Dimensional accuracy, Uniformity |

| CNC Machining | Dimensional tolerance, Surface roughness | Geometric accuracy, RA value |

| Post-Machining | Micro-crack detection, Material integrity | Flaw absence, Structural soundness |

| Final Inspection | Full dimensional verification, Visual check | Critical dimensions, Aesthetic |

The Value of a Source Manufacturer

Partnering with a dedicated tungsten parts manufacturer that is also a source manufacturer, like China VMT CNC machining factory, offers distinct advantages. We control the entire production chain from raw material procurement to final inspection. This integrated approach ensures consistent quality, eliminates middlemen markups, and provides greater transparency.

In our experience, direct engagement with the manufacturing facility reduces risks associated with material authenticity and process deviations. This means you receive higher quality pure tungsten components, produced under rigorous control, without unnecessary delays or costs. Our status as a cnc machining factory specializing in high-temperature tungsten applications ensures expertise at every step.

Our Transparent Pricing Model

Understanding the true cost of complex tungsten CNC machining parts is crucial for project budgeting. We pride ourselves on a transparent pricing model that clearly itemizes costs associated with material, machining time, tooling, and quality assurance. This eliminates hidden fees and fosters trust.

Our goal is to provide cost-effective solutions for high-temperature tungsten applications without compromising on quality or precision. As a direct cnc machining factory, we can offer competitive rates while maintaining the highest standards of manufacturing excellence.

Deep Technical Support & Solutions

Navigating the intricacies of high-temperature tungsten applications requires profound technical knowledge. Our team of experienced engineers offers deep technical support from the design phase through to production. We collaborate with your R&D engineers and procurement managers to optimize designs for manufacturability and performance.

Whether it’s material selection, design for tungsten machining, or troubleshooting performance issues, our expertise provides practical, innovative solutions. We view ourselves as an extension of your engineering team, dedicated to overcoming your machining tungsten challenges and ensuring project success.

High-Quality Parts Guarantee

Our commitment to quality is unwavering. Every pure tungsten component and every tungsten CNC machining part leaving our cnc machining factory is backed by a comprehensive high-quality parts guarantee. We adhere to stringent industry standards, including ISO 9001, and can meet specific client certifications like AS9100 for aerospace and defense.

This guarantee provides our clients with confidence that their critical high-temperature tungsten applications will perform reliably and consistently. We stand by the precision, durability, and thermal resistance of every part we produce, ensuring long-term satisfaction.

Key Benefits of Tungsten

Tungsten's unparalleled tungsten melting point and exceptional refractory metal properties position it as a material of strategic importance across numerous high-tech industries. Its high density, strength, and remarkable tungsten thermal resistance ensure superior performance where extreme conditions are the norm.

For applications demanding the utmost reliability in high-temperature environments, pure tungsten components are often the only viable solution. The ability to precisely machine this challenging material is what unlocks its full potential, transforming raw properties into functional, high-performance parts.

Future Innovations and Trends

The demand for high-temperature tungsten applications continues to grow, driven by advancements in aerospace, nuclear energy, and cutting-edge electronics. Future innovations will likely focus on developing even more advanced tungsten alloys and composite materials that push the boundaries of thermal resistance and mechanical strength.

As a dedicated tungsten parts manufacturer, we remain at the forefront of these developments. We continuously invest in research and development, refining our tungsten machining techniques and expanding our capabilities to meet the evolving needs of industries that rely on this extraordinary metal.

Request a Custom Quote

Unlock the unmatched potential of precision-machined tungsten for your next high-temperature project. We invite you to request a custom quote tailored to your exact specifications. Our team will provide a transparent breakdown of costs and timelines for your specific tungsten CNC machining parts.

Simply provide your design files and requirements, and we will demonstrate how our expertise delivers value. We are committed to providing the most competitive and clear pricing in the industry.

Speak with Our Engineering Team

If you are grappling with complex machining tungsten challenges or need expert guidance on material selection for your high temperature tungsten applications, our engineering team is ready to assist. We offer comprehensive technical consultation to ensure your project’s success.

Leverage our deep knowledge as a leading cnc machining factory and tungsten parts manufacturer. Contact us today to discuss your project needs and discover how our precision tungsten machining services can bring your designs to life.

Problem: A client in the specialized materials processing industry faced frequent failures of their furnace heating elements, which were operating consistently at 2500°C. The existing elements, made from a conventional refractory alloy, degraded rapidly, leading to costly downtime and inconsistent product quality. They required pure tungsten components with superior tungsten thermal resistance.

Our Solution: Our engineering team collaborated closely with the client, analyzing the furnace's thermal profile and operational stresses. We designed and precision-machined custom pure tungsten heating elements, leveraging our expertise in tungsten machining. We selected a high-purity tungsten grade and applied specialized finishing techniques to enhance thermal stability and reduce internal stresses, specifically addressing machining tungsten challenges.

Result: The new tungsten heating elements demonstrated significantly extended lifespans, operating reliably for over 18 months without degradation, a five-fold increase compared to their previous components. This resulted in a 75% reduction in downtime, substantial cost savings on replacements, and a noticeable improvement in the consistency of their processed materials. Our high-quality tungsten CNC machining parts solved a critical operational bottleneck.

Call to Action:

Unlock the unmatched potential of precision-machined tungsten for your next high-temperature project. Contact our expert engineering team today for a transparent consultation and a customized quote that meets your exact specifications.

How does tungsten's melting point compare?

Tungsten has the highest melting point of all metals, reaching approximately 3422°C. This extraordinary thermal resistance significantly surpasses other refractory metals like molybdenum and tantalum, making it unique.

This property is crucial for high-temperature tungsten applications where other materials would fail. It ensures structural integrity and performance in extreme heat environments.

What are high-temperature tungsten applications?

High-temperature tungsten applications include rocket nozzles, industrial furnace components, X-ray targets, and filaments for lighting. These fields demand materials that retain strength and stability at thousands of degrees Celsius.

Tungsten's exceptional thermal resistance makes it ideal for these demanding uses. It ensures reliable performance and longevity in critical systems.

What challenges does tungsten machining pose?

Tungsten machining presents challenges due to its extreme hardness and brittleness at room temperature. This makes it difficult to cut precisely and prone to chipping. Specialized tooling and techniques are essential.

Overcoming these machining tungsten challenges requires advanced CNC machines and deep expertise. This ensures the production of accurate and high-quality tungsten CNC machining parts.

Why choose a specialist tungsten parts manufacturer?

Choosing a specialist tungsten parts manufacturer ensures access to deep expertise and specialized equipment. They understand the unique refractory metal properties and machining complexities of tungsten.

This partnership guarantees high-quality, precise pure tungsten components. It also offers technical support and cost-effective solutions for complex high-temperature tungsten applications.

How does purity affect tungsten's properties?

Purity significantly affects tungsten's melting point and overall performance. Even minor impurities can lower its thermal resistance and alter its mechanical properties. High-purity tungsten components are essential.

Maintaining high purity ensures the material achieves its maximum thermal performance. This is critical for reliable high-temperature tungsten applications.

What is tungsten's thermal resistance?

Tungsten's thermal resistance refers to its ability to withstand high temperatures without melting or deforming. Its exceptional tungsten melting point of 3422°C gives it superior resistance among metals.

This property is vital for components exposed to extreme heat. It ensures they maintain their structural integrity and functionality.

Can you make custom tungsten CNC machining parts?

Yes, as a specialized cnc machining factory, we excel in producing custom tungsten CNC machining parts. We work with clients to create components tailored to specific design and application requirements.

Our advanced tungsten machining capabilities allow for complex geometries and tight tolerances. We ensure each part meets rigorous quality standards for high-temperature tungsten applications.

What quality standards do you follow?

As a leading cnc machining factory, we adhere to strict international quality standards, including ISO 9001. We also meet specific client certifications like AS9100 for aerospace components.

These certifications guarantee the high quality and reliability of our pure tungsten components. They ensure superior performance in critical high-temperature tungsten applications.