15 years one-stop China custom CNC machining parts factory

42 |

Published by VMT at Oct 30 2025 | Reading Time:About 3 minutes

42 |

Published by VMT at Oct 30 2025 | Reading Time:About 3 minutes

Brass density is crucial for precision engineering, directly impacting part weight, performance, and manufacturing costs. Understanding brass alloys and their specific densities is vital for material selection, effective CNC machining brass, and ensuring high-quality brass cnc machining parts in a reputable cnc machining factory.

Beyond its golden gleam, the true power of brass lies in its density. Slight variations can profoundly impact your part's weight, performance, and ultimately, your project's bottom line. At China VMT, we know that mastering brass density is the first step towards manufacturing high-performance, cost-efficient components.

Stop guessing your material's true potential. Discover how our deep technical expertise and advanced material density measurement techniques provide unparalleled precision in every brass machining project. This guide will walk you through the essential science and practical applications.

Brass density is a critical factor in precision engineering, profoundly impacting part weight, performance, and manufacturing costs. Its value varies significantly based on specific alloy compositions—primarily copper and zinc ratios, and other additives—as well as manufacturing processes like casting or cold working. Accurate material density measurement, often utilizing methods like Archimedes' principle, is crucial for quality control, adhering to industry standards, and preventing costly material overruns. Understanding these nuances enables optimal material selection for diverse applications, from aerospace to electrical components, ensuring designs meet precise weight and performance targets. Partnering with a specialized manufacturer capable of expert material consultation and precise CNC machining is essential to leverage brass density for high-performance, cost-efficient components.

What is brass density?

Brass density refers to the mass per unit volume of this versatile metal, typically measured in grams per cubic centimeter (g/cm³) or pounds per cubic inch (lb/in³). It's a fundamental physical property, crucial for engineers.

This value isn't constant across all brass types; it varies significantly based on the specific brass alloys and their elemental composition. The precise combination of copper and zinc, along with other alloying elements, dictates its exact density.

The density of brass typically ranges from 8.4 to 8.73 g/cm³ (8400–8730 kg/m³), depending on its composition. Brass is an alloy mainly composed of copper (Cu) and zinc (Zn), and its density varies based on the ratio between these two elements and any additional alloying elements (like tin, lead, or aluminum).

Here’s a quick overview:

| Type of Brass |

Copper (%) |

Zinc (%) |

Approx. Density (g/cm³) |

| Cartridge Brass (70/30) |

70 | 30 | 8.53 |

| Yellow Brass (65/35) |

65 | 35 | 8.47 |

| Red Brass (85/15) |

85 | 15 | 8.75 |

| Naval Brass (60/39/1 Sn) |

60 | 39 | 8.44 |

| Leaded Brass (59/40/1 Pb) |

59 | 40 | 8.50 |

In summary:

Why brass density matters?

Understanding brass density is critical for accurate engineering calculations, especially concerning part weight and material selection. For example, in aerospace or automotive applications, precise weight control directly impacts fuel efficiency and performance.

Density also influences material costs, as parts are often purchased by weight. Knowing the exact density helps in accurate material estimation, reducing waste and optimizing budgets during brass machining. In our experience, overlooking this can lead to costly material overruns.

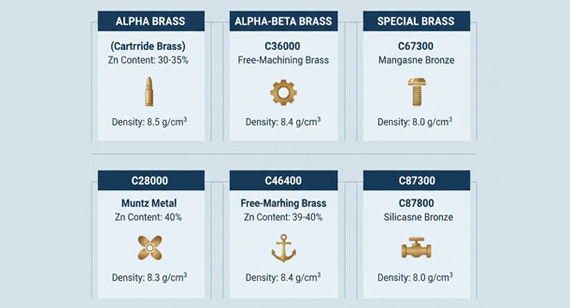

Common brass alloys & densities

Brass is an alloy primarily composed of copper and zinc, but its properties can be significantly altered by varying the ratio of these elements and adding others. Different brass alloys possess distinct densities, which directly impacts their applications and machinability.

Knowing these common brass alloys is key to effective material selection for any project requiring brass cnc machining parts. Each variant offers a unique balance of strength, corrosion resistance, and workability.

Alpha brass properties

Alpha brasses contain less than 37% zinc and are characterized by a face-centered cubic crystal structure. These alloys are known for their excellent cold working properties, making them highly ductile and malleable.

Common examples include Cartridge Brass (C26000) and Admiralty Brass (C44300). They are often used in applications requiring deep drawing, such as ammunition casings, musical instruments, and decorative items.

Their density typically ranges from 8.47 to 8.73 g/cm³, depending on the exact zinc content. This consistency makes them predictable for material density measurement.

Alpha-beta brass properties

Alpha-beta brasses, also known as duplex brasses, contain between 37% and 45% zinc. These alloys have a mixed alpha and beta crystal structure, which provides a good balance of strength and ductility.

These brass alloys are typically hot workable and are excellent for processes like extrusion and hot forging. Naval Brass (C46400) and Muntz Metal (C28000) are prime examples.

Their density generally falls between 8.35 and 8.47 g/cm³. This slightly lower density compared to alpha brasses is due to the higher zinc content, which is less dense than copper.

Special brass variations

Special brass variations incorporate additional alloying elements beyond copper and zinc to enhance specific properties. These elements might include lead, tin, aluminum, manganese, or nickel.

For instance, leaded brasses like Free-Machining Brass (C36000) have lead added to improve machinability, which is vital for efficient CNC machining brass. High-tensile brasses often include manganese and aluminum for increased strength.

The density of these special brass alloys can vary more widely, typically between 8.2 and 8.8 g/cm³, depending on the specific additives. These variations require precise material density measurement.

Alloying elements & their impact

The primary constituents of brass are copper and zinc, and their ratio significantly impacts brass density. Copper has a higher atomic weight and density (8.96 g/cm³) than zinc (7.14 g/cm³).

Therefore, brass alloys with a higher percentage of copper generally exhibit higher densities. Conversely, increasing the zinc content tends to slightly lower the overall density of the alloy.

The addition of other elements, like lead (11.34 g/cm³), tin (7.29 g/cm³), or aluminum (2.70 g/cm³), also influences the final density. These elements are added to modify properties like machinability, strength, or corrosion resistance, but their differing densities contribute to the overall material density measurement.

Temperature effects on density

Temperature has a measurable, though often subtle, effect on the density of brass. As brass heats up, its atoms vibrate more vigorously and spread further apart, causing the material to expand.

This thermal expansion results in a slight decrease in density, as the same mass now occupies a larger volume. Conversely, cooling brass causes it to contract, leading to a slight increase in density.

For most engineering applications at room temperature, these variations are negligible. However, for extremely precise applications or processes involving significant temperature changes, such as hot forging or casting, these effects must be considered.

Manufacturing processes impact

The method used to manufacture brass can significantly affect its final density. Processes like casting, forging, and cold working each alter the material's microstructure and internal void content.

These changes directly influence the material's bulk density, which is a critical consideration for both material selection and the ultimate performance of brass cnc machining parts. A good cnc machining factory understands these nuances.

Casting vs. wrought density

Cast brass, produced by pouring molten brass into a mold, often has a slightly lower density than wrought brass. This is because casting can introduce microscopic pores or voids within the material as it solidifies.

Wrought brass, on the other hand, is mechanically worked (rolled, extruded, forged) above or below its recrystallization temperature. These processes consolidate the material, reducing porosity and leading to a denser, more uniform structure.

Therefore, for applications demanding maximum density and minimal internal defects, wrought brass alloys are typically preferred. This is an important distinction when specifying brass density.

Cold working effects

Cold working, such as cold rolling, drawing, or swaging, deforms brass below its recrystallization temperature. This process increases the material's hardness and strength by altering its grain structure.

While cold working primarily changes mechanical properties, it also slightly increases brass density. The mechanical compression forces atoms closer together, reducing any microscopic voids that might be present.

This densification contributes to the enhanced strength and fatigue resistance often observed in cold-worked brass components. It's a key factor in producing robust brass cnc machining parts.

Impurities and their role

The presence of impurities in brass can also influence its density, although typically to a lesser extent than major alloying elements. Trace elements or non-metallic inclusions can alter the material's overall mass-to-volume ratio.

Some impurities, depending on their own density, might slightly increase or decrease the brass density. More importantly, impurities can degrade other critical properties like machinability, corrosion resistance, or electrical conductivity.

This is why a reputable cnc machining factory relies on stringent material verification. Our material density measurement protocols include checking for purity to ensure consistent performance.

Measuring Brass Density Accurately

Standard measurement methods

Accurate material density measurement is fundamental to quality control and material verification for brass alloys. Several established methods are employed to determine the density of brass, each with its own level of precision and application.

These methods are crucial for ensuring that the specified brass density matches the delivered material, preventing costly errors in manufacturing. Our cnc machining factory employs these techniques diligently.

Archimedes' principle

The Archimedes' principle is one of the most common and practical methods for material density measurement. It involves immersing a brass sample in a liquid (typically water) and measuring the displaced volume.

First, the mass of the dry sample is measured in air. Then, the sample is weighed again while fully submerged in water. The difference in weight corresponds to the buoyant force, which equals the weight of the displaced water.

By knowing the density of the water, the volume of the sample can be calculated, and subsequently, its density. This method is highly effective for solid, irregularly shaped brass cnc machining parts.

Pycnometer method

The pycnometer method is often used for higher precision density measurements, particularly for powders or small brass granules. A pycnometer is a flask with a precisely known volume.

The method involves weighing the empty pycnometer, then weighing it filled with the brass sample, and finally weighing it filled with a liquid (like water or ethanol) where the brass sample is submerged.

By knowing the volume of the pycnometer and the density of the liquid, the volume and then the density of the brass sample can be accurately determined. This offers excellent precision for material density measurement.

Industrial testing equipment

Modern industrial testing equipment offers advanced and highly automated ways to measure brass density. Digital densimeters, for example, can quickly and accurately determine density using variations of the Archimedes' principle.

These machines often integrate temperature compensation and digital readouts, reducing human error and increasing throughput. X-ray diffraction and computed tomography can also be used for microstructural analysis that indirectly informs density and porosity.

At our cnc machining factory, we utilize state-of-the-art equipment to ensure precise material density measurement for all brass alloys we process. This commitment to technology underpins our quality assurance.

Importance of precision in measurement

Precision in material density measurement is paramount, especially when dealing with high-performance brass cnc machining parts. Small errors in density values can propagate into significant issues in final product performance.

For instance, an underestimation of density could lead to a part being underweight, potentially failing to meet structural requirements. Conversely, an overestimation could result in a heavier-than-expected component, affecting system balance or transport costs.

This is why, at China VMT, we adhere to strict quality control protocols. Our attention to accurate material density measurement ensures that every batch of brass alloys meets your exact specifications.

Industry standards for brass density

To ensure consistency and reliability across the industry, various standards bodies publish guidelines and specifications for brass density and related properties. Adhering to these standards is a hallmark of a trusted cnc machining factory.

Key standards include those from ASTM International (e.g., ASTM B43 for Seamless Red Brass Pipe, ASTM B135 for Seamless Brass Tube). ISO standards, such as ISO 426-1, also define copper and copper alloy specifications.

These standards provide accepted density ranges for specific brass alloys, as well as prescribed testing methodologies. Compliance assures you of the material's integrity and performance.

| Standard Body |

Relevant Brass Density Standard Examples |

Purpose |

| ASTM | ASTM B43, ASTM B135, ASTM B16 | Specifies brass alloys, forms, and properties, including density ranges. |

| ISO | ISO 426-1, ISO 6509 | Defines copper and copper alloy specifications and corrosion testing. |

| EN (European) | EN 12164, EN 12165 | Covers specific brass grades for machining and forging applications. |

Density in part design & weight

Brass density is a fundamental parameter in the initial design phase of any component. Engineers use this value to accurately calculate the expected weight of a part, which is critical for various applications.

For parts subjected to stress, weight affects inertia and vibrational characteristics. In portable devices, overall product weight is a key consumer concern. Precise density data from material selection helps predict and control these factors.

In our cnc machining factory, we integrate accurate brass density data into our CAD/CAM systems, enabling optimal material usage and ensuring the final brass cnc machining parts meet precise weight targets.

Density for material selection

The choice of brass alloys is heavily influenced by the required density for an application. Different industries have unique demands where brass density plays a crucial role in material selection.

Making the right choice for brass alloys ensures that the component performs as intended, balancing factors like strength, weight, conductivity, and cost. This requires deep expertise in brass machining.

Aerospace & automotive needs

In aerospace and automotive sectors, every gram counts. Components must be robust yet lightweight to optimize fuel efficiency and performance. Brass density is a critical factor in the material selection for precision parts.

For example, brass fittings or sensors might be chosen for their corrosion resistance and specific density profile, ensuring they contribute minimally to overall weight while maintaining structural integrity. Our CNC machining brass expertise supports these demanding applications.

Brass is often used in electrical connectors and terminals due to its excellent electrical conductivity and corrosion resistance. While conductivity is paramount, the material density measurement still plays a role.

For compact or weight-sensitive electrical assemblies, selecting brass alloys with a specific density can help manage the overall weight and balance of the component. Precise brass machining ensures contact reliability.

Plumbing & marine applications

In plumbing and marine environments, brass is valued for its superior corrosion resistance against water, especially saltwater. Here, brass density might influence buoyancy in marine applications or simply provide robust, long-lasting fittings.

The specific brass alloys chosen (e.g., Naval Brass) are selected for their ability to withstand harsh conditions, and their density ensures they provide the necessary structural integrity for reliable operation.

Quality control & cost savings

Precise material density measurement is a cornerstone of quality control. By verifying the density of incoming raw brass alloys, manufacturers can confirm the material's identity and detect inconsistencies early.

This proactive approach prevents costly rework, material waste, and potential product failures down the line. In our experience as a cnc machining factory, early detection saves significant time and resources.

Moreover, accurate density knowledge allows for optimized material selection, ensuring you're not overpaying for unnecessary material properties. It directly contributes to cost savings in production of brass cnc machining parts.

Machining challenges & solutions

The density of brass alloys impacts its machinability. Generally, higher density brass (often with higher copper content) tends to be tougher and may require different cutting parameters than lower density, free-machining brass.

Factors like chip formation, tool wear, and surface finish can all be affected by brass density. For instance, denser materials may generate more heat during cutting, necessitating optimized cooling strategies during brass machining.

At China VMT, our expertise in CNC machining brass means we adjust our tooling, feed rates, and speeds precisely for each brass alloy's density and properties, ensuring optimal results and efficient production.

Aligning density with application

The process of material selection for your project begins with a clear understanding of the application's demands. Do you need lightweight components, or is structural integrity at a specific weight more important?

Knowing the required brass density will quickly narrow down your options among the various brass alloys. It ensures that the chosen material supports the functional and performance criteria of your design.

Consider the operating environment, required strength, and any electrical or thermal conductivity needs in conjunction with density. This holistic approach is key to success.

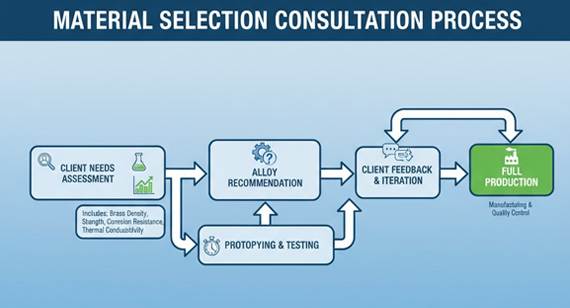

Consulting with material experts

Navigating the vast array of brass alloys and their specific properties can be complex. Consulting with material experts can provide invaluable guidance, ensuring you make the most informed material selection.

Experts can help you weigh the trade-offs between density, cost, machinability, and performance. Their insights can prevent costly mistakes and optimize your material choices for specific brass cnc machining parts.

At China VMT, we pride ourselves on being more than just a cnc machining factory; we are your technical partners. Our engineers offer comprehensive material consultations to help you define the perfect brass alloy.

Our factory's precision expertise

As a leading cnc machining factory, China VMT combines deep material science knowledge with cutting-edge CNC machining brass capabilities. We understand that precise brass density control is fundamental to manufacturing superior components.

Our commitment to advanced material density measurement and rigorous quality control ensures that every brass machining project meets the highest standards. We leverage our experience to overcome complex manufacturing challenges.

By partnering with us, you gain access to a team that ensures material integrity from concept to final product, delivering brass cnc machining parts that precisely meet your specifications and performance expectations.

Recap of brass density importance

Mastering brass density is not merely an academic exercise; it's a critical factor in achieving precision, optimal performance, and cost-efficiency in your manufacturing projects. From initial material selection to the final CNC machining brass process, density profoundly impacts every stage.

Understanding the nuances of various brass alloys, how factors like alloying elements and manufacturing processes influence density, and employing accurate material density measurement techniques are all indispensable for success.

Partnering for optimal brass parts

Choosing the right partner for your brass machining needs is crucial. A truly effective cnc machining factory provides not only expert brass machining services but also deep material science consultation.

By aligning precise brass density considerations with advanced manufacturing capabilities, you ensure your brass cnc machining parts perform reliably and meet the strictest quality standards.

Your trusted source manufacturer

At China VMT, we stand as your trusted source manufacturer, committed to unlocking unparalleled precision and optimal performance in your brass components. Our deep technical expertise and transparent processes mitigate material-related risks and guarantee exceptional outcomes.

We empower you to make informed decisions about material selection, supported by our rigorous material density measurement and world-class CNC machining brass capabilities. Partner with us for confidence, reliability, and relief in your next project.

Ready to elevate your next project with perfectly specified and precisely machined brass components? Leverage our deep technical expertise. Contact our engineering team today for a comprehensive material consultation and a transparent, no-obligation quote tailored to your exact specifications.

How does zinc content affect brass density?

Zinc is lighter than copper.

As the percentage of zinc in brass alloys increases, the overall brass density generally decreases.

This is a key factor in material selection for weight-sensitive applications.

What is the typical density range for brass?

The typical density for common brass alloys ranges from approximately 8.35 g/cm³ to 8.8 g/cm³.

This range varies depending on the specific copper-to-zinc ratio and other alloying elements present.

Accurate material density measurement helps confirm the exact density for your batch.

Why is density important for CNC machining brass?

Density affects how easily brass alloys can be machined.

Denser, harder brass may require different cutting speeds, feeds, and tools to prevent excessive wear and ensure good surface finish.

This impacts the efficiency and quality of brass machining operations.

How do we ensure accurate brass density measurement?

At China VMT, we use standard methods like Archimedes' principle and industrial densimeters.

Our processes include precise weighing and volume determination, often with temperature compensation.

This ensures highly accurate material density measurement for all brass cnc machining parts.

What brass alloys are best for high strength?

Alpha-beta brasses, often with higher zinc content and sometimes additional elements like manganese, offer increased strength.

These brass alloys are typically hot workable and used in applications requiring robust performance.

Examples include Naval Brass (C46400).

Can density impact the cost of brass parts?

Yes, parts are often priced by weight, so accurate brass density helps in material estimation.

Choosing the right brass alloy based on its density can prevent over-engineering and material waste.

This leads to significant cost savings in manufacturing brass cnc machining parts.

What are common applications for brass components?

Brass cnc machining parts are widely used across various industries.

They are found in plumbing fixtures, electrical connectors, automotive components, and marine hardware.

Their excellent machinability and corrosion resistance make brass alloys highly versatile.

How does our factory support material selection?

Our cnc machining factory offers expert material consultation services.

We help you align brass density and other properties with your specific application needs.

This ensures optimal material selection for your brass machining projects, leveraging our deep expertise.