15 years one-stop China custom CNC machining parts factory

636 |

Published by VMT at May 21 2025 | Reading Time:About 9 minutes

636 |

Published by VMT at May 21 2025 | Reading Time:About 9 minutes

In today’s high-performance manufacturing industries—especially aerospace, medical, and automotive—engineers constantly face the same challenge: finding a material that offers strength, thermal stability, chemical resistance, and dimensional precision without compromising processability. Traditional plastics often fall short in extreme environments, while metals may add unnecessary weight and cost.

This leaves manufacturers in a difficult position. Compromising on material performance can lead to product failure, increased maintenance, and higher production costs. Worse, choosing the wrong material can delay production timelines and hurt your reputation with clients expecting durability, safety, and high precision.

That’s where Ultem®, or polyetherimide (PEI), comes in. Known for its remarkable strength-to-weight ratio, flame resistance, and chemical stability, Ultem (polyetherimide) is a high-performance thermoplastic used in mission-critical applications across industries. Whether you're designing medical equipment that must withstand repeated sterilization or aerospace components that demand long-term thermal stability, Ultem offers an ideal solution. In this article, we’ll explore what Ultem (polyetherimide) is, how it performs, how it's processed, and why it’s a preferred material in precision plastic CNC machining parts and CNC machining services.

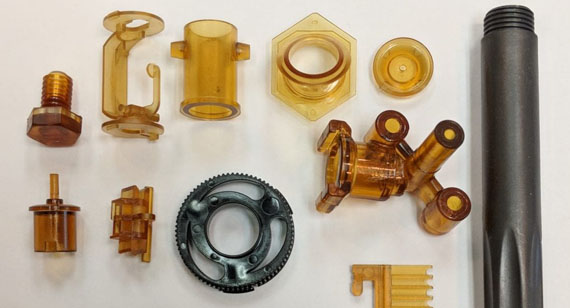

Ultem® (polyetherimide or PEI) is a high-performance, amber-to-transparent thermoplastic known for its excellent mechanical strength, thermal stability, and chemical resistance. Used in aerospace, medical, and electronics industries, it is ideal for high-precision applications. Ultem offers long-term heat resistance and is commonly used in plastic CNC machining parts due to its dimensional stability and easy machinability.

Understanding what Ultem (polyetherimide) is only scratches the surface of what makes this material a favorite in demanding industries. From its unique thermal and mechanical properties to its specialized applications in CNC machining services, Ultem continues to push the boundaries of plastic performance. Whether you're selecting materials for Ultem CNC machining parts or comparing plastic options for high-stress environments, this guide will walk you through everything you need to know. In the sections that follow, we’ll explore Ultem’s composition, processing methods, real-world use cases, and how CNC machining factories like VMT can help you turn this advanced polymer into reliable, high-quality components. To deepen your understanding, you can also check our article on plastic CNC machining parts and CNC machining services for high-performance thermoplastics.

Ultem, also known as polyetherimide (PEI), is a high-performance, amorphous thermoplastic recognized for its outstanding combination of thermal stability, mechanical strength, and electrical insulating properties. Manufactured primarily by SABIC under the brand name Ultem®, PEI is designed to function reliably in extreme environments where other plastics may degrade or fail. As a member of the polyimide family, Ultem is often chosen for its balance of processability and durability, making it ideal for precision components that demand tight tolerances and long-term reliability.

One of Ultem's most defining characteristics is its glass transition temperature of approximately 217°C (422°F), allowing it to maintain rigidity and dimensional stability at elevated temperatures. Unlike many crystalline plastics, Ultem’s amorphous structure enables it to exhibit consistent mechanical properties across a wide temperature range. This structure also supports optical clarity in some formulations, which is advantageous in specialized optical and scientific applications.

In industrial use, Ultem (polyetherimide) CNC machining is a preferred method for producing complex and high-strength parts, especially for the aerospace, medical, automotive, and electronics sectors. Due to its inherent flame retardancy, low smoke generation, and high dielectric strength, Ultem is often utilized where safety and performance cannot be compromised. When compared to other plastic CNC machining parts, Ultem stands out for its ability to endure thermal and mechanical stress over time.

Whether used for injection molding, 3D printing, or CNC machining services, Ultem delivers versatility and strength in a lightweight package. As we delve deeper into this guide, you’ll discover why CNC machining factories frequently recommend Ultem for mission-critical applications—and how you can leverage its properties to improve part performance, durability, and safety.

Yes, Ultem is the brand name for a specific type of polyetherimide (PEI). The two terms are often used interchangeably, but there is a subtle distinction worth understanding—especially if you're sourcing materials or specifying components for manufacturing.

Polyetherimide (PEI) is the generic name for the high-performance, amorphous thermoplastic in question. It was developed for applications requiring excellent thermal stability, flame resistance, mechanical strength, and dimensional stability. Ultem®, produced by SABIC (Saudi Basic Industries Corporation), is the most recognized and widely used brand of PEI on the market. In the same way that Kleenex is a brand of tissue or Teflon is a brand of PTFE, Ultem is a brand of PEI.

So when engineers and designers refer to Ultem in technical documentation, they’re usually referring to a specific formulation of PEI that meets the rigorous standards associated with the Ultem brand. These formulations come in various grades—such as Ultem 1000 (unfilled), Ultem 2300 (30% glass-filled), Ultem 9085 (used in aerospace-grade 3D printing), and Ultem 1010 (FDA-compliant and suitable for medical and food processing applications). Each grade offers unique benefits in terms of strength, thermal performance, chemical resistance, and processability.

In Ultem CNC machining parts, using certified Ultem material ensures a consistent level of quality, traceability, and performance—especially important in regulated industries like aerospace and healthcare. Plastic CNC machining parts made from generic PEI may perform similarly, but without the Ultem brand assurance, consistency and regulatory compliance could vary.

In conclusion, Ultem is a specific, branded version of PEI, widely regarded for its reliability and engineered properties. When working with CNC machining factories or sourcing from CNC machining services, be sure to clarify whether you're specifying generic PEI or the Ultem brand to ensure you get the right material for your application.

3D printing with Ultem (polyetherimide) has become a game-changer for industries that demand high-performance, functional prototypes and production-grade parts. Thanks to its outstanding mechanical strength, thermal stability, and chemical resistance, Ultem is one of the most advanced polymers used in FDM (Fused Deposition Modeling) 3D printing today. Its superior performance properties make it ideal for aerospace, automotive, medical, and industrial sectors—especially when CNC machining is not practical for complex geometries or low-volume production.

Why Choose Ultem for 3D Printing?

Ultem’s ability to withstand high temperatures—up to 217°C (422°F) continuous use temperature—combined with its flame retardant properties (V-0 rating), make it ideal for parts that must comply with strict safety and regulatory standards. It is also resistant to a wide range of chemicals, including alcohols, acids, and hydrocarbons. This means Ultem-printed parts maintain integrity in environments where other plastics would degrade.

Furthermore, Ultem has a high strength-to-weight ratio, making it suitable for lightweight structural components. Unlike other plastics used in 3D printing, Ultem provides excellent dimensional stability, which ensures that parts maintain their shape and tolerance under stress or fluctuating temperatures. These qualities are critical when producing functional prototypes or end-use components.

Equipment and Material Considerations

Not every 3D printer can handle Ultem. Due to its high melting point (typically above 340°C or 644°F), Ultem requires an industrial-grade 3D printer with a high-temperature print head, heated bed, and enclosed heated build chamber. Materials like Ultem 9085 and Ultem 1010 are the most commonly used grades in additive manufacturing. Ultem 9085 is widely used in aerospace applications due to its flame, smoke, and toxicity (FST) rating, while Ultem 1010 is FDA-compliant and biocompatible—ideal for food processing and medical device prototyping.

Benefits for CNC Machining Services and Factories

When parts are too complex or costly to machine conventionally, 3D printing with Ultem provides an efficient alternative. CNC machining factories often combine Ultem CNC machining with additive processes to reduce waste, lower tooling costs, and speed up production timelines. This hybrid manufacturing approach is especially beneficial for plastic CNC machining parts that require tight tolerances and intricate features.

In summary, 3D printing with Ultem offers unmatched performance and design freedom for engineers and manufacturers looking to create high-strength, high-heat, and chemically resistant parts. Whether used alone or alongside CNC machining services, Ultem enables innovation across a wide range of industries.

Ultem®, the commercial name for polyetherimide (PEI), is a high-performance thermoplastic known for its exceptional balance of mechanical, thermal, and electrical properties. Its robustness and versatility make it ideal for applications across aerospace, automotive, medical, and electronic industries. Whether used for Ultem CNC machining parts or in plastic CNC machining services, Ultem’s characteristics ensure durability, reliability, and regulatory compliance. In this section, we outline the core physical and mechanical properties that define this material, helping engineers and designers determine its suitability for specific industrial applications.

Typical Ultem® Properties

The following are some of the most important performance metrics for Ultem® as measured by standardized ASTM testing. These properties highlight Ultem’s value for CNC machining services, particularly in environments requiring heat resistance, high strength, and dimensional stability.

| Property |

Value |

ASTM Test Method |

| Tensile Strength |

110 MPa (16,000 psi) | ASTM D638 |

| Flexural Modulus |

3,200 MPa (464,000 psi) | ASTM D790 |

| Izod Impact Strength (Notched) |

0.9 kJ/m² (0.43 ft-lb/in) | ASTM D256 |

| Heat Deflection Temperature |

207°C (404°F) @ 66 psi / 200°C (392°F) @ 264 psi | ASTM D648 |

| Water Absorption (24-Hour Soak) |

0.25% | ASTM D570 |

These properties underscore Ultem’s capabilities in high-performance applications where many other plastics fall short. Its tensile and flexural strength make it suitable for structural components, while its heat deflection temperature and low moisture uptake support its use in high-temperature and humid environments. These characteristics are especially critical in the CNC machining factories that produce precise and durable Ultem CNC machining parts for mission-critical components.

Explore more detailed physical, thermal, and electrical characteristics in the upcoming sections to determine how Ultem can meet your product development needs.

Physical Properties of Ultem® (Polyetherimide)

Ultem® (Polyetherimide or PEI) exhibits outstanding physical properties that make it a preferred material for high-performance engineering applications. Its dimensional stability, low moisture absorption, and excellent strength-to-weight ratio contribute to its widespread use in plastic CNC machining parts. These physical traits allow Ultem to perform consistently in harsh environments, from aerospace interiors to sterilizable medical devices. This section highlights key physical metrics such as specific gravity and water absorption, which are essential for engineers and product designers choosing materials for Ultem (polyetherimide) CNC machining.

| Physical Property |

Value |

ASTM Test Method |

| Specific Gravity |

1.27 | ASTM D792 |

| Water Absorption (24-Hour Soak) |

0.25% | ASTM D570 |

Ultem’s specific gravity of 1.27 indicates a lightweight yet durable plastic, ideal for reducing mass in automotive and aerospace applications without compromising strength. This low density is especially advantageous in CNC machining services where minimizing material weight while maintaining structural integrity is critical. Additionally, the low water absorption rate (just 0.25%) ensures that Ultem retains its mechanical and thermal properties even in high-humidity or water-prone environments, making it suitable for medical, food processing, and marine uses.

Because of these dependable physical characteristics, Ultem CNC machining parts are frequently selected for precision components that require minimal deformation and high environmental resistance. For further performance insights, continue to the next sections where we explore Ultem’s mechanical, thermal, and electrical attributes in detail.

Ultem® Mechanical Properties

Ultem® (Polyetherimide) is widely respected in the CNC machining services industry for its remarkable mechanical strength and structural integrity. This thermoplastic exhibits a rare balance of high tensile strength, flexural rigidity, and impact resistance, making it a reliable material for manufacturing high-performance plastic CNC machining parts. These mechanical characteristics are crucial in industries like aerospace, automotive, electronics, and medical devices, where both dimensional stability and long-term durability are essential. Below is a detailed breakdown of Ultem’s mechanical properties based on standardized ASTM test methods.

| Mechanical Property |

Value (Typical) |

ASTM Test Method |

| Tensile Strength |

110 MPa (16,000 psi) | ASTM D638 |

| Tensile Modulus |

3.2 GPa (470,000 psi) | ASTM D638 |

| Tensile Elongation |

60–100% | ASTM D638 |

| Shear Strength |

69 MPa (10,000 psi) | ASTM D732 |

| Flexural Strength |

165 MPa (24,000 psi) | ASTM D790 |

| Flexural Modulus |

3.2 GPa (470,000 psi) | ASTM D790 |

| Compressive Strength |

140 MPa (20,000 psi) | ASTM D695 |

| Hardness (Rockwell) |

R120 | ASTM D785 |

| Izod Impact Strength |

13 J/m (Notched) | ASTM D256 |

These robust mechanical properties explain why Ultem is frequently chosen for Ultem CNC machining parts that demand extreme durability and precise tolerances. Its high tensile and flexural strength make it resistant to cracking and deformation under stress, while its elongation at break ensures flexibility when needed. The material’s impact resistance further supports its use in load-bearing or high-impact environments, such as aerospace interior structures or medical device housings.

For applications requiring reliable, high-performance thermoplastics with repeatable results, Ultem delivers exceptional value. In the next section, we’ll explore its thermal properties, which complement these mechanical strengths to make Ultem a top choice in advanced CNC machining factories.

Thermal Properties of Ultem® (Polyetherimide)

Ultem’s outstanding thermal properties make it one of the most heat-resistant amorphous thermoplastics available for plastic CNC machining parts. These properties are especially valuable in industries that require consistent performance under high temperatures, such as aerospace, automotive, and medical device manufacturing. Its high heat deflection temperature, low thermal expansion, and resistance to thermal degradation allow for reliable, long-term use in challenging environments.

| Thermal Property |

Typical Value |

ASTM Test Method |

| Melting Point |

~217°C (423°F) | — |

| Flammability (UL 94) |

V-0 | UL 94 |

| Coefficient of Linear Thermal Expansion |

5.8 x 10⁻⁵ /°C | ASTM D696 |

| Heat Deflection Temperature (66 psi) |

200°C (392°F) | ASTM D648 |

| Heat Deflection Temperature (264 psi) |

174°C (345°F) | ASTM D648 |

| Max Continuous Operating Temp in Air |

170°C – 180°C (338°F – 356°F) | — |

Ultem’s V-0 flammability rating also positions it as an ideal material for applications demanding low flame, smoke, and toxicity performance. It maintains its mechanical strength and dimensional stability in high-heat applications, contributing to its popularity in Ultem (polyetherimide) CNC machining.

Electrical Properties of Ultem® (Polyetherimide)

Ultem® is frequently used in the electronics and electrical industries due to its strong insulating properties. Its high dielectric strength ensures safe and stable performance in electronic components, connectors, and insulators—even under high-frequency or high-voltage conditions.

| Electrical Property |

Typical Value |

ASTM Test Method |

| Dielectric Strength | 830 V/mil | ASTM D149 |

These characteristics are critical for CNC machining factories that manufacture Ultem CNC machining parts for use in complex electronic assemblies.

Optical Properties of Ultem® (Polyetherimide)

Ultem is available in transparent and translucent grades, making it suitable for components that require both mechanical strength and optical clarity. This is especially beneficial in scientific equipment, medical devices, and aerospace instrumentation where visibility and monitoring are crucial.

| Optical Property |

Typical Value |

ASTM Test Method |

| Light Transmittance |

86% (for ULTEM 1000) | ASTM D1003 |

| Haze |

<2% | ASTM D1003 |

Ultem’s optical clarity does not compromise its toughness or thermal stability, making it a superior option over materials like polycarbonate in demanding environments.

Other Properties of Ultem® (Polyetherimide)

Beyond its primary thermal, electrical, and mechanical characteristics, Ultem offers unique benefits such as low friction and exceptional sterilization compatibility. These make it a preferred material in medical, food processing, and industrial applications where hygiene and wear resistance are vital.

| Other Property |

Typical Value |

ASTM Test Method |

| Coefficient of Friction |

0.4 – 0.6 | ASTM D1894 |

| Sterilization Methods |

Steam, ETO, Gamma | — |

Ultem can withstand repeated autoclave sterilization without compromising its structural integrity, which is critical in the fabrication of medical CNC machining parts and components exposed to harsh cleaning protocols.

In the following section, we will explore how Ultem is processed—including injection molding, extrusion, and thermoforming—and how these methods influence its suitability for CNC machining services across industries.

Ultem®, or polyetherimide (PEI), stands out not just for its exceptional material properties but also for its versatility in processing. Whether you’re manufacturing complex Ultem CNC machining parts, forming durable plastic components, or preparing material for 3D printing, Ultem can be processed through multiple advanced techniques. Each method supports different product types and application requirements. The ability to process Ultem using standard thermoplastic techniques—combined with its high-performance characteristics—makes it ideal for CNC machining factories and manufacturers across aerospace, medical, and electronic sectors.

Extrusion is one of the most common processes for shaping Ultem into continuous profiles such as rods, tubes, and sheets. During extrusion, Ultem pellets are melted and forced through a die to produce long shapes with uniform cross-sections. The resulting extruded material is then cooled and cut to desired lengths.

This method is ideal for producing stock shapes used in plastic CNC machining parts, where tight tolerances and material consistency are critical. Ultem's high melt stability and excellent flow characteristics allow it to be extruded with minimal degradation, even under high heat and pressure. It is frequently used in applications requiring high strength and chemical resistance, such as industrial equipment components and semiconductor processing parts.

Thermoforming

Thermoforming involves heating Ultem sheets until pliable and then forming them into desired shapes using molds. This process is particularly useful for creating large, lightweight parts with complex geometries that don’t require the precision of CNC machining. Vacuum forming and pressure forming are common thermoforming techniques used with Ultem.

Thermoformed Ultem parts are frequently found in aerospace, automotive, and medical industries due to their excellent dimensional stability, impact resistance, and heat resistance. The process also supports rapid prototyping and short production runs, offering a cost-effective solution for custom plastic parts.

Extrusion Blow Molding

Extrusion blow molding is a process used to produce hollow Ultem components, such as containers, tanks, and enclosures. The method begins by extruding a molten tube (parison) of Ultem, which is then clamped into a mold and inflated to conform to the mold's shape.

While Ultem is not the most common material for blow molding due to its high processing temperatures, specialized equipment allows manufacturers to create robust hollow parts with excellent mechanical and thermal properties. These parts are valued in medical, laboratory, and military-grade applications where durability and chemical resistance are essential.

Injection molding is the most precise and widely used processing technique for Ultem. It enables the production of highly detailed and complex shapes with excellent repeatability. In this process, Ultem resin is melted and injected into a steel mold under high pressure. After cooling, the part is ejected, ready for use or secondary machining.

Ultem’s high heat resistance requires hot molds and careful thermal control to avoid warping or defects. Despite these challenges, injection molding is ideal for producing everything from electronic connectors to medical device housings, lighting enclosures, and aerospace interior components. Its compatibility with tight-tolerance tooling makes it especially suitable for producing Ultem (polyetherimide) CNC machining parts when precision and mechanical strength are paramount.

Up next, explore the many applications and parts Ultem is commonly used for across key industries—from aerospace and medical devices to consumer electronics and everyday carry gear. Learn how CNC machining services transform this high-performance plastic into solutions for demanding environments.

Ultem®, also known as polyetherimide (PEI), is widely recognized for its high strength, thermal stability, dimensional accuracy, and resistance to chemicals and stress cracking. These properties make it a highly sought-after material across a variety of industries requiring durable, high-performance components. Whether you're manufacturing complex Ultem CNC machining parts or high-tolerance plastic components, Ultem's versatility ensures it meets the strict demands of sectors ranging from aerospace to food processing. Below is a breakdown of key industries that benefit from Ultem, along with the specific parts commonly made using this exceptional plastic.

Aerospace Industry

Ultem is extensively used in the aerospace sector due to its flame retardancy, low smoke output, and lightweight strength. Its compliance with FAR 25.853 standards makes it ideal for flight-ready components.

Applicable Parts:

These parts require materials that can withstand both high temperatures and mechanical stress, all while keeping weight to a minimum—making Ultem an ideal fit.

The automotive industry leverages Ultem for components exposed to under-the-hood heat, friction, and chemicals. Its ability to retain mechanical properties across a wide temperature range ensures durability and safety.

Applicable Parts:

Ultem parts are often machined or injection molded with high precision, supporting modern automotive designs and electric vehicle innovations.

Consumer Goods Industry

Ultem offers consumer brands the ability to deliver products that combine aesthetics with durability. Its excellent dimensional stability, along with resistance to wear and chemicals, makes it popular for lifestyle and electronic goods.

Applicable Parts:

These products benefit from Ultem’s premium feel and performance, while manufacturers appreciate its compatibility with standard CNC machining services.

Electronic and Electrical Fields

With its high dielectric strength and thermal resistance, Ultem is used extensively in electronic components requiring insulation and stability under thermal cycling.

Applicable Parts:

Ultem's excellent electrical insulation makes it ideal for complex, miniaturized devices in high-performance applications.

In medical technology, where cleanliness, precision, and strength are critical, Ultem is favored for its ability to withstand repeated sterilization and its biocompatibility.

Applicable Parts:

These components are typically produced in certified CNC machining factories where quality control and traceability are essential.

3D Printing

Ultem is one of the few high-performance thermoplastics suitable for FDM/FFF 3D printing. It’s used for both prototyping and production-ready parts.

Applicable Parts:

Ultem 9085 and 1010 grades are especially popular in additive manufacturing due to their strength-to-weight ratio and flame resistance.

Food Processing

Due to its low moisture absorption and resistance to harsh sanitizing agents, Ultem is used for components that come into direct or indirect contact with food.

Applicable Parts:

Ultem’s compliance with FDA and NSF standards makes it suitable for hygienic applications requiring regular sterilization.

EDC (Everyday Carry)

Ultem’s balance of lightweight strength and visual appeal makes it a favorite in the EDC community for producing durable and stylish gear.

Applicable Parts:

These parts are often customized and precision-machined from Ultem rods or plates using plastic CNC machining parts services.

Scientific Equipment Parts

Scientific instruments often require parts that maintain mechanical and structural integrity under repeated thermal cycling, chemical exposure, and high-precision usage. Ultem excels in these conditions due to its inherent stability, low creep, and resistance to sterilization processes.

Common Uses:

Because accuracy is vital in scientific settings, plastic CNC machining parts made from Ultem are often chosen for their ability to hold tight tolerances during both rapid prototyping and large-scale production.

Manifolds

Ultem is an outstanding choice for fluid manifolds due to its chemical resistance, transparency in some grades (ideal for flow monitoring), and strength at elevated temperatures. Whether in medical, chemical, or industrial environments, manifolds must be reliable, leak-proof, and able to endure pressure changes and cleaning chemicals.

Ultem Benefits in Manifolds:

With proper CNC machining services, Ultem manifolds are custom-engineered to exact flow paths and integration needs, offering efficient and hygienic fluid control.

Semiconductor Equipment Components

Ultem is widely used in semiconductor fabrication due to its non-conductive properties, thermal stability, and resistance to outgassing—key requirements in ultra-cleanroom environments.

Typical Components:

The semiconductor industry demands absolute precision, making Ultem (polyetherimide) CNC machining a standard practice for producing consistent, high-performance parts that meet rigorous industry regulations.

Chip Test Sockets

Chip test sockets must hold microelectronic components securely during testing, often under thermal and mechanical stress. Ultem’s excellent thermal resistance, dielectric strength, and rigidity allow it to perform well in this role.

Why Ultem is Ideal:

CNC machining factories with experience in semiconductor tooling often rely on Ultem for creating repeatable, precise chip socket assemblies that reduce product testing errors.

From aerospace to EDC tools, Ultem’s utility across industries is nearly unmatched. For more information about how Ultem (polyetherimide) CNC machining can meet your product needs, visit VMT’s plastic CNC machining services or explore CNC machining factories that specialize in high-performance thermoplastics.

Here's a clear, organized table summarizing the applications of Ultem (Polyetherimide) and their corresponding applicable parts across various industries. This format is ideal for enhancing readability and SEO relevance for terms like Ultem CNC machining parts, plastic CNC machining parts, and CNC machining services.

Ultem (Polyetherimide): Applications and Applicable Parts

| Industry |

Applicable Parts |

| Aerospace Industry |

Aircraft interior panels, ventilation ducts, seat components, pipe fittings, connectors |

| Automotive Industry |

Lighting housings, sensor enclosures, electronic control unit housings, ignition components |

| Consumer Goods |

Sports equipment, appliance housings, mobile device casings, eyewear components |

| Electronics & Electrical |

Printed circuit boards (PCBs), electrical insulators, terminal blocks, connectors |

| Medical Device Industry |

Surgical instruments, sterilizable device housings, diagnostic machine components |

| 3D Printing |

Functional prototypes, jigs, fixtures, low-volume custom components |

| Food Processing |

Food-grade molds, machine guards, conveyor guides, hygienic surfaces |

| EDC (Everyday Carry) |

Knife handles, tactical pens, flashlights, multitool housings |

| Industrial Applications |

Fluid manifolds, semiconductor fixtures, precision housings, analytical equipment parts |

| Scientific Equipment |

Laboratory instrument housings, pump components, test chambers |

| Semiconductor Equipment |

Chip test sockets, probe housings, wafer handling parts |

For CNC machining factories and OEMs looking to source durable, high-performance components, Ultem’s adaptability across industries and part types makes it an excellent candidate for CNC machining services and plastic CNC machining parts. If you need reliable, high-quality parts from Ultem or other engineering plastics, contact VMT for expert CNC machining solutions.

Ultem (polyetherimide), often branded under SABIC’s ULTEM® name, is a premium thermoplastic polymer used in advanced engineering applications. Known for its remarkable heat resistance, dimensional stability, and excellent electrical properties, Ultem is a standout material in industries requiring high performance under extreme conditions. However, like any material, it has both strengths and trade-offs that must be weighed depending on the application. This section outlines the advantages and disadvantages of using Ultem (polyetherimide), especially in the context of Ultem CNC machining parts and plastic CNC machining parts used across various CNC machining services.

Ultem (Polyetherimide): Advantages

Ultem offers a wide range of performance benefits, making it one of the most sought-after high-performance plastics in CNC machining, 3D printing, and injection molding. Below are its most notable advantages:

Ultem (Polyetherimide): Disadvantages

While Ultem offers numerous performance advantages, there are also limitations that should be considered, especially when selecting materials for high-volume production or cost-sensitive applications:

Despite its cost and processing demands, Ultem remains a go-to material for advanced applications where high performance, safety, and reliability are critical. If your project requires complex, high-precision plastic CNC machining parts, VMT’s expertise in Ultem (polyetherimide) CNC machining can ensure reliable outcomes with tight tolerances. Learn more about our CNC machining services for high-performance plastics today.

Here is a detailed comparison table outlining the advantages and disadvantages of Ultem (Polyetherimide). This table helps users quickly assess Ultem’s strengths and limitations for applications in Ultem CNC machining parts, plastic CNC machining parts, and other CNC machining services.

Ultem (Polyetherimide): Advantages and Disadvantages

| Advantages |

Disadvantages |

| Excellent long-term heat resistance (up to 170°C continuous use) | Requires high mold temperatures during injection molding |

| High strength and stiffness — retains mechanical properties at elevated temperatures | Sensitive to stress cracking under certain chemical environments |

| Outstanding dimensional stability | Can emit smoke or toxic fumes when burned |

| Extremely strong with high tensile and flexural properties | Surface defects and dimensional shifts can occur if not processed correctly |

| High dielectric strength — ideal for electrical applications | More expensive than other thermoplastics like ABS or polycarbonate |

| Easy to process via CNC machining, thermoforming, and injection molding | Requires careful handling during machining due to potential brittleness |

| Excellent resistance to hydrolysis — stable in hot water and steam | Limited UV resistance unless specially formulated |

| Can withstand repeated sterilization cycles (ideal for medical and food-grade applications) | May require post-processing to enhance surface finish |

| Thermoformable — adaptable to complex geometries | Availability of certain grades may be limited depending on market demand |

| Excellent resistance to environmental stress and cracking | Not suitable for applications requiring extreme ductility |

| Naturally flame-retardant with low smoke output (UL94 V-0 rated) | May need annealing to relieve internal stress in machined parts |

| Sustainable — recyclable and used in long-lasting, high-performance parts |

This table is useful for engineers, designers, and purchasing managers comparing materials for CNC machining factories. If you're sourcing durable, high-performance Ultem CNC machining parts, explore our plastic CNC machining services at VMT to see how Ultem can meet your technical and commercial needs.

When selecting materials for CNC machining, knowing the standard sizes available for Ultem (polyetherimide) helps engineers and procurement teams efficiently plan their projects and reduce material waste. Ultem is commonly supplied in sheet and rod forms, making it versatile for a wide range of plastic CNC machining parts. These stock sizes cater to diverse application needs in industries such as aerospace, medical, and electronics, where precision and performance are critical.

| Form |

Standard Dimensions |

Details |

| Sheet |

12 in x 12 in to 24 in x 48 in | Ideal for flat components, panels, and CNC-milled parts. Sheets are available in various thicknesses to support structural and non-structural applications. |

| Sheet Thickness |

0.060 in to 3 in | Multiple thickness options offer flexibility for both lightweight and high-strength applications. Thick sheets are often used for structural components. |

| Rod |

Outer Diameter: 0.250 in to 6 in | Suitable for turned and milled cylindrical parts. Rod stock is commonly used for bushings, insulators, and precision-machined components. |

Whether you're developing high-performance Ultem CNC machining parts or sourcing raw materials for custom CNC machining services, choosing the right size format can save time and cost during fabrication. If you need help selecting the proper Ultem stock for your next project, contact VMT CNC machining factory for tailored solutions.

Ultem (polyetherimide) is available in several color options to accommodate a wide range of visual, functional, and regulatory requirements across industries. Color variations help differentiate parts, meet aesthetic demands, or comply with specific application standards such as in medical or aerospace environments. These color choices do not significantly impact Ultem’s performance but may play a role in light transmission, traceability, and brand alignment in plastic CNC machining parts.

Below are the most commonly available Ultem colors used in Ultem CNC machining parts and 3D printing:

| Color |

Description & Common Uses |

| Black |

Offers excellent light-blocking properties, ideal for electronic housings, industrial parts, and applications where visibility must be minimized. Common in CNC machining factories producing sensitive equipment components. |

| Brown |

A standard choice for electrical and automotive parts; provides a neutral, technical look suitable for components that do not require light transmission. |

| Amber |

The most iconic color of Ultem, often associated with its transparent or semi-transparent form. Frequently used in aerospace and medical industries due to its high visibility and traceability. |

| Natural (Uncolored) |

Typically translucent with a pale yellow tint; preferred in food-grade and medical applications. It offers the purest material state for applications requiring low contamination and compliance with FDA or USP standards. |

Choosing the right color for your Ultem components can enhance product differentiation, improve traceability, or simply align with branding standards. At VMT’s CNC machining services, we offer expert guidance in material selection and customization to meet your specific project needs.

Ultem (polyetherimide) is available in multiple grades to suit a broad range of mechanical, thermal, and electrical requirements across industries such as aerospace, medical, and electronics. The two main categories of Ultem grades are unfilled and glass-filled, each offering unique advantages for specific CNC machining applications.

Ultem (Polyetherimide): Properties of the Four Most Commonly Used Resins

|

Property |

ULTEM 1000 |

ULTEM 9085 |

ULTEM 1010 |

ULTEM 2200 |

| Type |

Unfilled | Unfilled, Aerospace-Grade | Unfilled, High-Temp | 20% Glass-Filled |

| Glass Transition Temp (°C) |

~217 | ~186 | ~217 | ~220 |

| Tensile Strength (MPa) |

~110 | ~70 | ~95 | ~155 |

| Flexural Modulus (GPa) |

~3.2 | ~2.3 | ~3.2 | ~6.2 |

| Flame Retardancy |

UL 94 V-0 | UL 94 V-0 | UL 94 V-0 | UL 94 V-0 |

| Chemical Resistance |

Excellent | Good | Excellent | Excellent |

| Electrical Insulation |

Excellent | Good | Excellent | Good |

| Dimensional Stability |

High | Moderate | Very High | Very High |

| Advantages |

High clarity, strength, sterilizable | Strong, lightweight, FST compliant | Ideal for autoclaving, high heat | High rigidity, strength, heat resistance |

| Applications |

Medical tools, electrical insulators | Aerospace interiors, 3D printed parts | Food tooling, medical components | Structural parts, high-load supports |

Each Ultem grade brings distinct benefits to CNC machining services, allowing manufacturers to tailor plastic CNC machining parts to specific mechanical or environmental requirements. At VMT CNC machining factories, we offer expert processing for all major Ultem grades, ensuring both performance and precision in every component.

Ultem (polyetherimide), due to its outstanding performance characteristics, is produced and marketed by several well-known manufacturers under different brand names. These brands ensure that the material is available in various grades, dimensions, and formulations to suit diverse industrial applications, particularly in Ultem CNC machining parts, plastic CNC machining parts, and high-performance components made through CNC machining services. Each brand offers consistent material quality while meeting the demanding standards of industries such as aerospace, medical, electronics, and automotive.

Ultem® (by SABIC)

Ultem® is the original and most recognized brand of polyetherimide (PEI), manufactured by SABIC. It is known for its exceptional high-temperature resistance, dimensional stability, and flame retardancy. Ultem® is available in a wide range of grades, including unfilled (like Ultem 1000) and glass-filled (like Ultem 2200), as well as specialized grades for 3D printing, food contact, or medical use. It is widely used in CNC machining factories for producing electrical connectors, medical devices, aerospace parts, and more. Ultem® maintains global certifications and regulatory compliance, which makes it a preferred choice in regulated industries.

SUSTAPEI (by Röchling)

SUSTAPEI is Röchling’s trade name for its high-quality PEI materials. This brand emphasizes excellent machinability, thermal resistance, and electrical insulation, making it ideal for plastic CNC machining parts and high-precision components. SUSTAPEI is especially popular in semiconductor manufacturing, analytical instrumentation, and electrical insulation applications due to its tight tolerances and clean-room compatibility. It is supplied in a variety of dimensions including sheets, rods, and custom extrusions, tailored for both prototyping and mass production in CNC machining services.

TECAPEI™ (by Ensinger)

TECAPEI™ is the trade name used by Ensinger for its PEI-based product line. Known for consistent quality and a broad range of stock shapes, TECAPEI™ is commonly used in demanding applications where strength, stability, and heat resistance are essential. Ensinger’s TECAPEI™ offers excellent compatibility with CNC machining and is a top choice for parts that require fine detail, such as Ultem CNC machining parts in electronics, fluid handling, and mechanical assemblies. It is also available in FDA-compliant grades and is frequently used in medical and food-processing applications.

Whether you choose Ultem®, SUSTAPEI, or TECAPEI™, each brand delivers top-tier polyetherimide solutions for a wide range of machining needs. For expert guidance and premium processing, VMT offers specialized Ultem (polyetherimide) CNC machining backed by years of experience in CNC machining services across industries.

Here is a comparison table of Ultem (Polyetherimide) common brands, including key features and applications:

| Brand Name |

Manufacturer |

Key Features |

Typical Applications |

Machining Compatibility |

| Ultem® |

SABIC |

- Original Ultem PEI material - High heat resistance - Flame retardant - Available in many grades (e.g., 1000, 2200) - FDA, ISO compliant |

- Aerospace interiors - Medical instruments - Electrical connectors - 3D printing (e.g., Ultem 1010, 9085) |

Excellent for CNC machining, injection molding, and 3D printing |

| SUSTAPEI |

Röchling |

- Excellent machinability - Stable thermal and electrical properties - Clean-room compliant - Broad dimensional range |

- Semiconductor components - Scientific equipment - Electrical insulation parts |

Well-suited for precision plastic CNC machining parts |

| TECAPEI™ |

Ensinger |

- Consistent stock shapes - Strong dimensional stability - FDA and ISO compliant grades available - High strength-to-weight ratio |

- Food processing tools - Medical device housings - Custom industrial parts |

Optimized for CNC machining, excellent dimensional control |

This table gives a clear, side-by-side comparison to help you choose the right Ultem (polyetherimide) brand for your Ultem CNC machining parts, depending on application and performance needs. For expert advice or a custom quote, visit VMT’s CNC machining services page.

ULTEM®, the trade name for polyetherimide (PEI), stands out among high-performance plastics due to its unique blend of thermal, mechanical, and electrical properties. Engineers and designers across industries—from aerospace to medical—choose ULTEM when durability, stability, and efficiency are non-negotiable. But what truly sets ULTEM apart, especially for CNC machining services and high-precision plastic CNC machining parts?

Exceptional Strength and Heat Resistance

ULTEM offers outstanding tensile strength and structural rigidity even at elevated temperatures. With a high glass transition temperature (around 217°C) and excellent heat deflection, ULTEM resists thermal degradation and mechanical deformation. This makes it an ideal choice for demanding applications in aerospace interiors, automotive lighting systems, and under-the-hood components. When weight reduction is essential without compromising strength, ULTEM performs comparably to metals in many structural roles.

High Dimensional Stability for CNC Machining

One of the main reasons CNC machining factories prefer ULTEM is its dimensional stability. Unlike other plastics that may warp or expand under machining stress or heat, ULTEM maintains tight tolerances, ensuring that CNC machined parts remain precise and repeatable. Its stiffness and low creep over time make it perfect for high-performance parts such as semiconductor sockets, medical components, and electronic insulators.

Outstanding Electrical and Flame Retardant Properties

ULTEM possesses excellent electrical insulation and naturally flame-retardant characteristics. Its low smoke emission and high dielectric strength are key factors in its use for electrical connectors, high-voltage insulators, and printed circuit board components. Additionally, it meets UL94 V-0 flammability standards without requiring additives, making it safe and reliable in critical environments.

Compatibility with Sterilization and Food Contact

In the medical and food sectors, ULTEM’s ability to withstand repeated sterilization cycles—especially steam autoclaving—is invaluable. It's resistant to hydrolysis, meaning it won't degrade in hot, moist environments. FDA-compliant and biocompatible grades are available, making it suitable for surgical tools, diagnostic equipment, and even food molds or containers.

Sustainability and Long-Term Performance

Compared to metals or lower-grade plastics, ULTEM offers long-lasting durability without compromising environmental compliance. It’s recyclable in some forms and helps reduce component weight, leading to lower fuel consumption in transportation applications. These attributes support sustainability goals while reducing total cost of ownership.

VMT specializes in Ultem (polyetherimide) CNC machining, offering precision-crafted plastic CNC machining parts for industries that demand excellence. Whether you need rapid prototyping or high-volume production, our CNC machining services deliver tight tolerances, material expertise, and consistent quality.

Explore VMT CNC machining services for Ultem parts or continue reading to learn how ULTEM compares to PEEK and other advanced plastics.

When engineers and manufacturers need a high-performance thermoplastic for demanding applications, two materials often stand out: Ultem (polyetherimide) and PEEK (polyetheretherketone). Both materials are widely used in industries such as aerospace, automotive, electronics, and medical devices, offering exceptional mechanical and thermal properties. However, each has its own advantages, limitations, and ideal use cases. Choosing between Ultem and PEEK depends on your application's performance requirements, budget, and processing capabilities. In this section, we provide a comprehensive comparison of Ultem vs. PEEK based on key properties relevant to CNC machining and advanced part manufacturing.

Thermal Stability

Both Ultem and PEEK exhibit excellent high-temperature performance, but PEEK holds a slight edge in terms of overall heat resistance.

If your project involves prolonged exposure to extreme heat, PEEK may be the better option. However, Ultem still performs well in high-heat applications, especially where cost savings are crucial.

Mechanical Strength

When it comes to stiffness and tensile strength, both materials are excellent—though PEEK typically offers better toughness.

For static structural components, Ultem works exceptionally well. For parts subject to repeated mechanical stress or vibration, PEEK may be more suitable.

Chemical Resistance

Chemical exposure is often a deciding factor in material selection. Here, PEEK has the upper hand.

For highly corrosive environments, PEEK offers broader chemical compatibility.

Cost

One of the most significant differences between the two materials is their price point.

Choose Ultem when cost-efficiency is essential without sacrificing too much performance. Reserve PEEK for mission-critical applications where cost is secondary to performance.

Flame Retardancy

Both materials meet high standards for flame retardancy, but Ultem often achieves this without additives.

Both materials are suitable for use in environments requiring strict fire safety, such as aerospace and electronics.

Dimensional Stability

Precision and consistency are crucial in CNC machining. Ultem has slightly better dimensional stability due to lower moisture absorption.

For CNC machining services that demand tight tolerances and dimensional precision, Ultem CNC machining parts can offer a processing advantage.

Processability

Ease of machining and forming can influence production timelines and tooling costs.

If fast turnaround and lower tooling wear are priorities, Ultem (polyetherimide) CNC machining is a more practical choice.

Applications

Both materials serve a wide range of industries, but their ideal use cases differ based on performance needs.

| Industry |

Ultem Applications |

PEEK Applications |

| Aerospace |

Interior panels, ducts, brackets | Engine components, insulation, seals |

| Automotive |

Sensor housings, light fixtures | Under-the-hood parts, gears, pump components |

| Medical |

Surgical tools, diagnostic devices | Implants, sterilizable instruments |

| Electronics |

Connectors, PCB substrates | Semiconductor processing equipment |

| Industrial |

Manifolds, fluidic components | Bearing cages, compressor parts |

Final Thoughts

If you're weighing Ultem vs. PEEK for your next project, the choice often comes down to performance vs. cost. Ultem is a versatile and cost-effective high-performance plastic, especially valuable for plastic CNC machining parts where high heat resistance, strength, and tight tolerances are required. PEEK, on the other hand, should be chosen when extreme conditions demand maximum durability, chemical resistance, and heat tolerance.

Still unsure which material fits your project best? Contact VMT for expert CNC machining services — we’ll help you choose the right material, optimize your design, and deliver precision CNC machined parts with unmatched quality.

Precision Machining for High-Performance Ultem Parts

At VMT, we specialize in precision CNC machining of Ultem (polyetherimide)—a high-performance engineering plastic known for its outstanding thermal resistance, mechanical strength, and dimensional stability. Whether you need prototypes, small-batch production, or large-volume manufacturing, our advanced CNC equipment and expert team deliver Ultem components with tight tolerances, smooth finishes, and consistent quality.

Why Choose VMT for Ultem CNC Machining?

| Advantages |

Details |

| Material Expertise |

Extensive experience machining Ultem 1000, 1010, 2200, and 9085 resins. |

| Advanced Equipment |

High-speed CNC mills, lathes, and 5-axis machines for complex Ultem parts. |

| Tight Tolerance Capability |

Dimensional precision up to ±0.01mm, ideal for aerospace and electronics. |

| Heat-Resistant Machining |

Suitable for applications up to 170°C (Ultem) and 260°C (PEEK if needed). |

| Cleanroom-Ready Processing |

Supports medical, food-grade, and electronic applications. |

| Global Delivery |

Efficient logistics for on-time delivery across Asia, Europe, and the U.S. |

Ultem CNC Machining Capabilities at VMT

Material Grades Supported:

Sizes and Shapes: Machining from Ultem sheets, rods, and custom billets.

Part Types:

Industries We Serve with Ultem CNC Parts

| Industry |

Typical Ultem Parts |

| Aerospace |

Lightweight brackets, ducts, sensor housings |

| Medical |

Sterilizable surgical tools, diagnostic device enclosures |

| Electronics |

High-voltage insulators, connectors, circuit board carriers |

| Automotive |

Lighting housings, electronic module covers |

| Industrial |

Fluid manifolds, chemical-resistant components |

| Food Processing |

Autoclavable molds, food-grade machine parts |

Get a Quote for Ultem CNC Machining Today

Whether you’re looking for Ultem prototype machining, short-run production, or full-scale CNC part manufacturing, VMT is your trusted partner for plastic CNC machining services. Our team is ready to review your CAD files, recommend optimal tooling paths, and deliver high-performance Ultem parts that meet your exact requirements.

Contact VMT now for a fast, competitive quote on your Ultem CNC machining project.

Precision, performance, and partnership—made in every part.

Ultem® (polyetherimide) stands out as one of the most versatile, high-performance thermoplastics available for modern engineering, manufacturing, and design applications. Its unique combination of high heat resistance, exceptional mechanical strength, dimensional stability, chemical resistance, and excellent electrical insulation properties makes it an ideal material for industries ranging from aerospace and automotive to medical devices, electronics, and industrial equipment.

In this guide, we’ve explored what Ultem (polyetherimide) is, how it compares to other materials like PEEK, and how its various grades—such as Ultem 1000, 1010, 2200, and 9085—meet different technical demands. We've also examined Ultem CNC machining, its use in 3D printing, the advantages and disadvantages, and the typical part types and processing methods.

Whether you’re sourcing Ultem CNC machining parts, working with plastic CNC machining parts, or comparing materials for mission-critical applications, understanding the full scope of Ultem’s properties and applications empowers you to make more informed decisions.

At VMT, we specialize in precision CNC machining services for Ultem and other advanced engineering plastics. As one of the trusted CNC machining factories in the industry, we provide technical guidance, tight-tolerance manufacturing, and tailored solutions that meet your exact specifications.

Ready to start your next project?

Contact VMT today for expert CNC machining support and custom Ultem component solutions. Let performance, precision, and partnership define your next innovation.

What is Ultem®?

Ultem® is the brand name for a high-performance thermoplastic resin known as polyetherimide (PEI). It is known for its excellent thermal resistance, strength, and dimensional stability, making it suitable for demanding applications in aerospace, medical, electronics, and automotive industries.

How Durable is Ultem®?

Ultem® is highly durable due to its high tensile strength (up to 110 MPa), impact resistance, and thermal endurance. It maintains mechanical integrity even at elevated temperatures and under stress, which makes it ideal for long-term use in extreme environments.

What is Ultem® Used For?

Ultem® is used in a variety of industries for parts like aerospace interiors, electrical connectors, medical devices, automotive lighting housings, food processing molds, and 3D-printed prototypes. It’s valued for both structural and insulating applications.

Can You Machine Ultem®?

Yes, Ultem® can be precisely machined using CNC machining services, especially in tight-tolerance applications. At VMT, we specialize in Ultem CNC machining, producing complex and highly accurate components for industrial clients.

What Are the Disadvantages of Ultem®?

Despite its advantages, Ultem® can be more expensive, difficult to mold due to its high processing temperatures, and prone to stress cracking under certain conditions. It may also exhibit surface finish challenges if not processed correctly.

What’s Special About Ultem?

Ultem® offers a rare combination of thermal endurance (up to 170°C continuous use), mechanical strength, flame retardancy, and dimensional stability, all in a lightweight thermoplastic form. It also withstands repeated sterilization and is FDA-compliant for select applications.

What is the Difference Between Ultem and PEEK?

While both are high-performance plastics, PEEK generally has higher chemical resistance and continuous use temperature, but Ultem is more affordable and easier to process. Both materials offer excellent strength and flame resistance, but differ in their thermal and chemical behavior. Explore the full Ultem vs. PEEK comparison →

What is Another Name for Ultem?

Ultem is the trademarked name for polyetherimide (PEI). Other brands of PEI include SUSTAPEI and TECAPEI™.

What is the Purpose of Polyetherimide?

Polyetherimide (Ultem) is designed for high-performance engineering applications requiring stiffness, heat resistance, electrical insulation, and chemical stability. It’s commonly used where metal replacement is needed with reduced weight.

Why is Ultem So Expensive?

Ultem is expensive due to its complex production process, high-performance properties, and low-volume specialty applications. Its superior mechanical and thermal characteristics justify the cost in critical applications.

Is Ultem a Polyetherimide?

Yes, Ultem is the brand name for polyetherimide (PEI), a type of amorphous thermoplastic resin known for its strength and stability under high heat.

Does Ultem Scratch Easily?

While Ultem has good toughness, it is still a thermoplastic and can scratch more easily than metals or harder materials. Surface coatings or fillers can be used to improve scratch resistance.

What Are the Different Types of Ultem?

The most common Ultem types include Ultem 1000 (unfilled), Ultem 2200 (glass-filled), Ultem 9085 (flame-retardant, 3D printable), and Ultem 1010 (high-temperature resistance), each tailored for specific properties and applications.

Is Ultem a Polycarbonate?

No. Although Ultem may look similar to polycarbonate in transparency, it is a polyetherimide, which offers superior thermal and mechanical performance compared to polycarbonate.

Can Ultem Be 3D Printed?

Yes. Ultem grades like Ultem 9085 and Ultem 1010 are used in high-temperature FDM 3D printing, particularly in aerospace and industrial applications. Specialized printers are required due to the high extrusion temperature.

Can Ultem Be Laser Cut?

Laser cutting Ultem is possible but challenging due to its high heat resistance and tendency to discolor or char. CNC machining is a more reliable option for intricate or high-precision Ultem parts.

Is Ultem Stronger Than G10?

Yes. Ultem generally offers higher heat resistance, tensile strength, and dielectric properties than G10, making it more suitable for high-performance structural and electronic applications.

What Printers Can Print Ultem?

Industrial-grade FDM printers like the Stratasys Fortus 450mc or Fortus 900mc are capable of printing Ultem due to their ability to maintain high chamber and nozzle temperatures.

What Are the Purposes of Polyetherimide?

Polyetherimide is used for purposes that demand thermal stability, rigidity, and chemical resistance—from medical components to aerospace parts, and even in semiconductor tooling.

Is Ultem Easy to Process?

Ultem requires high processing temperatures (above 300°C) and tight control of molding parameters. While it’s not “easy” to process like standard plastics, it’s considered manageable for experienced CNC machining factories and molders.

What Color is Ultem?

Natural Ultem is typically transparent amber, but it also comes in black, brown, and custom color grades, depending on the formulation and filler content.

Does Ultem Crack Easily?

Ultem is tough and impact-resistant, but like many amorphous plastics, it can be sensitive to stress cracking, especially under harsh chemicals or prolonged load in suboptimal environments.

What is the Common Name for Ultem?

The common name for Ultem is polyetherimide (PEI), though Ultem is often used interchangeably in the industry due to its brand recognition.

Is Ultem Amorphous or Crystalline?

Ultem is an amorphous thermoplastic, which gives it good dimensional stability, clarity, and uniform mechanical properties across various directions.

What is the Difference Between Ultem 2300 and Ultem 1000?

Ultem 2300 is a 30% glass-filled variant of PEI, offering greater stiffness and dimensional stability than Ultem 1000, which is the unfilled, general-purpose grade with maximum clarity and good machinability.

Still have questions or need custom Ultem CNC machining parts?

Contact VMT’s CNC machining experts for material selection support and project consultation.