15 years one-stop China custom CNC machining parts factory

Home / Services / Swiss CNC Machining /

Professional Customized Swiss CNC Machining Services in China

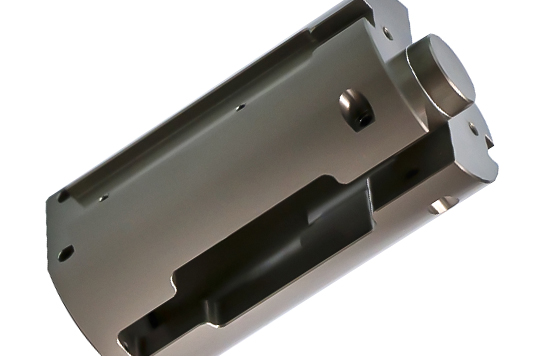

As a leading Swiss CNC machining service provider in China, VMT brings 20 years of professional experience in delivering high-precision part solutions for industries such as aerospace, medical, and automotive. Equipped with advanced Swiss-type CNC machines, we are capable of machining precision components with diameters up to 20 mm and lengths up to 800 mm, achieving tolerances of ±0.01 mm. We work with a wide range of materials, including stainless steel, aluminum alloys, brass, and engineering plastics like PEEK. From prototype development to mass production of up to 100,000 pieces, VMT offers one-stop machining services including turning, milling, and drilling — all backed by ISO 9001 and IATF 16949 certifications for quality you can trust.

Professional advantages:

Ideal for machining precision shafts, connectors, and other small, complex components, our Swiss CNC services are tailored to meet your most demanding requirements. Feel free to contact our engineering team for a customized solution that fits your project perfectly.

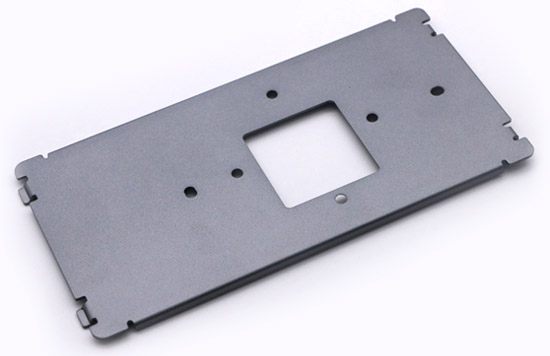

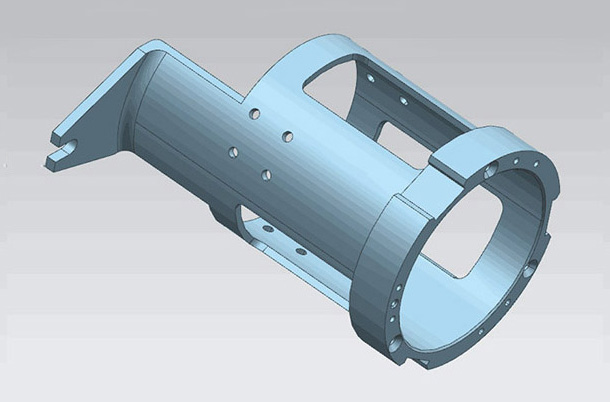

Swiss CNC Machining Parts Library

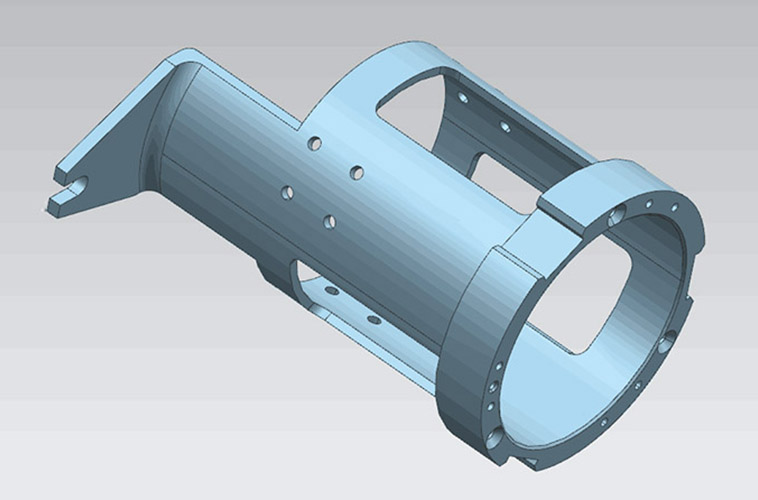

We provide professional CNC machining services for industries including medical, aerospace, automotive, and electronics, covering the full process from prototyping to mass production. With extensive experience, we deliver precision machining solutions for sectors such as industrial automation and robotics, supporting clients in fulfilling complete manufacturing needs — from design to finished product. All case studies are real, customer-authorized projects, demonstrating our commitment to quality and trust.

What is Swiss CNC Machining?

Swiss CNC machining, also known as Swiss turning or sliding headstock machining, is a high-precision CNC turning technique originally developed by the Swiss watchmaking industry for manufacturing small, complex, and ultra-precise components.

This method uses a unique sliding headstock design, where the workpiece moves axially during machining while the cutting tools remain stationary or feed radially. This configuration allows for exceptional accuracy and surface finish.

Swiss machines are computer-controlled (CNC) and typically feature multiple axes — sometimes up to 12 or more — enabling the machine to perform turning, drilling, and milling operations in a single setup. This integrated approach reduces cycle time, minimizes secondary operations, and makes it the ideal solution for high-volume, high-precision production.

Advantages and Disadvantages of Swiss CNC Machining

Advantages of Swiss CNC Machining

Disadvantages of Swiss CNC Machining

Why Choose Our Swiss CNC Machining Services?

High-Quality Parts with Tight Tolerances

As an ISO 9001-certified manufacturer, VMT delivers high-quality CNC machining parts, expertly handling complex designs. We follow international best practices, achieving dimensional tolerances as tight as ±0.0004″ (0.01mm), ensuring our products meet your exact specifications and fulfill all your requirements.

Fast Quoting and Delivery

VMT provides rapid production and delivery of CNC machining parts, enabling flexible iterations and helping you stay ahead in the market. Upload your design and receive a CNC quote within 2 hours. Our engineering team offers precise cost calculations, transparent pricing, and reduced lead times, significantly boosting your competitiveness.

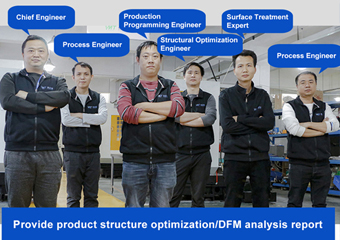

Engineering Support

Leveraging cutting-edge technology and equipment, we ensure the highest quality, precision, and performance of automotive parts. To expedite our clients' CNC machining product development and validation, we operate over 100 advanced CNC machines and a specialized rapid prototyping team. From design analysis to mass production, we can deliver within 24 hours, providing full support to ensure client success.

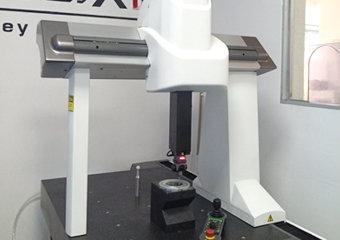

Quality Inspection

We maintain a comprehensive quality control system, including IQC, IPQC, and FQC, overseeing every stage from raw materials to final shipment. We retain inspection reports for two years and are equipped with advanced 3D and 2D measuring instruments, as well as a laboratory for precise dimension checks and material compliance. We offer CMM inspection, material testing, and certification of conformity to ensure exceptional quality.

Surface Finishing

We collaborate with surface finishing factories with over 10 years of experience, offering more than 40 surface finishingprocesses. Two senior engineers work on customizing cost-effective solutions based on your needs, strictly controlling every step to ensure a 98% product yield and outstanding surface finishingquality.

Certifications and Patents

We are certified by ISO9001:2015, IATF16949, and SGS, and hold 12 patents. With state-of-the-art CNC technology, we ensure precise and efficient CNC machining part machining, meeting your highest expectations for size, performance, and strength, and providing exceptional service.

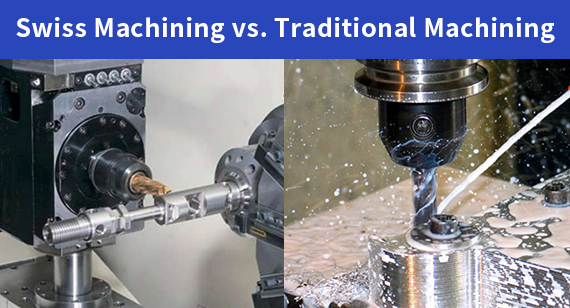

Comparison Between Swiss CNC Turning and Conventional CNC Turning

| Comparison Aspects |

Swiss CNC Turning | Traditional CNC urning |

| Workpiece support | Guide bushings | Chuck or collet only |

| Workpiece movement | Axial workpiece movement (Z axis) | Workpiece rotates and is fixed, tool moves |

| Precision and accuracy | Higher (±0.005 mm) | General (±0.02mm) |

| Number of operations | Multiple tasks in one setup | May require multiple setups |

| Productivity | Suitable for large batches of small parts |

Suitable for small to medium batches of general parts |

| Setup time |

Faster setup times |

Longer setup time |

| Applicable part size |

Small, slender parts (1-32 mm diameter) |

Medium to large parts (no strict diameter limit) |

| Complexity |

Ideal for complex parts |

More suitable for simple parts |

| Material waste |

Minimize waste |

May cause more waste |

| Tooling |

Use multiple tools simultaneously |

Single tool operation |

| Workpiece size |

Limited to smaller diameters |

Larger diameter |

Custom Swiss CNC Machining Materials

VMT offers a comprehensive inventory of metals and engineering plastics to meet the diverse and specialized requirements of Swiss CNC turning. Our material experts work closely with you to recommend the most suitable machining solution based on your part’s functional needs — such as strength, temperature resistance, and corrosion resistance — ensuring the optimal balance between performance and cost.

Swiss Machining Metal Materials

VMT offers custom precision Swiss CNC machining services for a wide range of metal materials, covering everything from prototyping to mass production. Leveraging the properties of high-strength metals, we meet the customized requirements of various applications, ensuring each part delivers both exceptional precision and long-lasting durability.

Swiss Machining Plastic Materials

VMT offers custom precision Swiss CNC machining services for a wide range of engineering plastics, supporting everything from prototyping to full-scale production.Thanks to the excellent machinability and versatile properties of plastics, we deliver cost-effective, customized solutions for industries such as medical, electronics, and more — ensuring both performance and efficiency in every component.

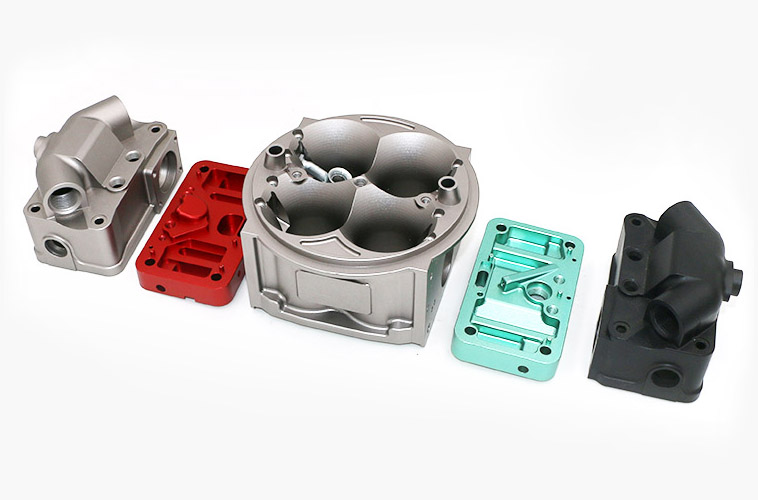

Custom Swiss CNC Machined Surface Finishing

VMT offers 40+ professional surface finishing services designed to significantly enhance the corrosion resistance, hardness, and visual appeal of your components.

Based on your specific functional and aesthetic requirements, we provide tailored surface treatment solutions for Swiss CNC turned parts — helping to extend service life and optimize overall performance.

As-Machined Finish

The standard machined finish retains visible CNC tool marks and is the most economical and time-efficient option. Minor burrs may remain and can be removed in secondary processes.

Anodizing

Anodizing enhances the corrosion and wear resistance of aluminum parts and offers a variety of color options. Pre-treatment with sandblasting further improves surface performance and aesthetics.

Powder Coating

Powder coating applies a thick, durable, and corrosion-resistant layer through electrostatic spraying and high-temperature curing. It offers a wide range of color choices and is more durable than traditional paint.

Hard Anodizing

Type III hard anodizing uses 120-grit sandblasting as a pre-treatment to produce a thicker and more durable coating. It combines the corrosion resistance of Type II anodizing with superior wear resistance, making it ideal for high-performance applications.

Chrome Plating

Chrome plating is an electroplating process that forms a chromium layer on metal surfaces, improving wear and corrosion resistance while providing a bright, decorative finish.

Blue Zinc Plated

Blue zinc plating involves passivation of the zinc layer to form a blue-tinted protective film. It offers both rust resistance and decorative appeal.

PVD (Physical Vapor Deposition)

PVD is a vacuum coating process that creates ultra-hard metallic or ceramic coatings on the surface, combining excellent wear resistance with a decorative finish.

Electrophoresis Coating (E-coating)

Electrophoresis uses electric current to evenly deposit a paint layer onto metal surfaces, forming a matte, high-corrosion-resistant coating commonly used in automotive parts.

Nickel Plating

Nickel plating, either electrolytic or chemical, deposits a nickel layer on the surface to enhance corrosion resistance, wear resistance, and appearance. It is widely used in both industrial components and consumer products.

Laser Carving

Laser engraving uses focused laser beams to permanently mark patterns or text on the surface with high precision and no physical contact. It is suitable for metals, plastics, and various other materials.

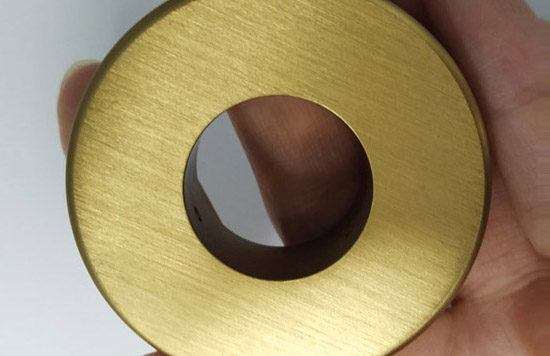

Brushed

Brushing is a mechanical process that creates fine, linear textures on metal surfaces. It offers scratch resistance and an elegant decorative appearance, often used in electronics and construction products.

Polishing

Polishing removes tool marks and smooths the surface, improving gloss and appearance while reducing surface roughness. It can achieve a range of gloss levels and surface textures.

Custom Swiss CNC Machined Parts Ordering Process

Unlike online quoting platforms, VMT operates its own manufacturing facility, allowing us to maintain full control over every stage of the machining process.

This hands-on approach ensures reliable quality, consistent performance, and gives you complete peace of mind throughout your project.

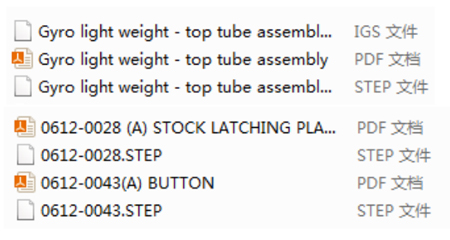

Upload Your CAD File

Upload your file directly or send your project information through the quote page. All files support NDA.

Quotation and DFM Analysis

We will send back the design for manufacturability analysis and real-time quotation within 12 hours.

Start Production

Once the order is confirmed, we will start the manufacturing process using your CAD design.

Receive Your Machining Parts

The prototype or part will be produced within a few days and sent directly to you by international courier.

12 Quality Inspection Process

Learn how VMT's quality control team maintains strict quality standards by conducting dimensional and cosmetic inspections of each order during production. If there is any problem, we will communicate and solve it as soon as possible, or solve it in your way.

DFM Analysis

Before CNC machining, engineers conduct a DFM analysis to identify and resolve potential issues in advance. This ensures optimized designs for efficient manufacturing, minimizes defects, and reduces machining costs.

Dimensional Tolerance Determination

Check whether the parts meet the specified dimensional tolerances, ensure the technical feasibility of the tolerance design, and optimize the production process to meet your quality requirements and cost-effectiveness.

Material Testing

We have long-term stable partnerships with material suppliers for decades and can provide third-party inspection reports from organizations such as SGS, CTI, and TUV.

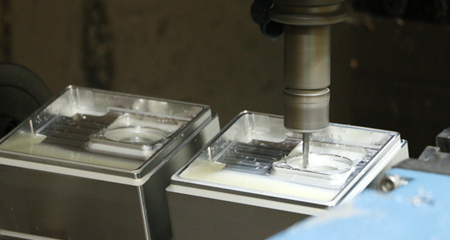

CNC Machining Production

We have a dedicated team to track order progress, maintaining detailed records for each production run. Photos and videos are transparently shared with customers, keeping you informed about the machining process.

FQC Detection

During the machining production process, dimensional tolerance inspections are conducted every two hours, and the first article is inspected to ensure it meets design and quality standards. This guarantees process stability, product consistency, and improved production efficiency.

SPC / CKP

Implement statistical analysis to monitor and control the manufacturing process and provide inspection reports.

Problem Found

If any deviations, defects, or non-compliance issues are discovered during the machining process, an immediate meeting is held to address the problem.

Problem Solving

Respond within 30 minutes, provide solutions within 2 hours, and resolve within 1 day.

OQC Detection

Before CNC parts leave the factory, 100% dimensional inspection is conducted according to customer drawings. Inspection reports are provided before proceeding to the next processing step.

Surface Finishing

In addition to conventional surface treatments, there are a variety of special surface treatments. We have a full-time SQE to follow up and control each process in the surface treatment factory. After returning to our workshop, the product appearance will be 100% inspected.

Full Inspection

QC specilists will check the parts at every step with testing equipments accordingly,like 3D / 2D project, height/thread /roughness gauge. Offering inspection report with full dimensions for each part.

Package

Many different ways to pack the goods,avoid the damage, easy to carry and enviornmentally,Accept customer customization, commonly used pearl cotton, bubble bag.

Custom CNC Machining Factory Workshop

Established in 2010 and is located in Guangming District, Shenzhen, Guangdong Province, China,has own factory cover an area of 5000 m2. We are customized machining parts manufacturer with 100 employees,can provide items within 24 hours.

100 sets machines including 4 & 5 axis imported CNC centers,turning & milling machines for fast delivery, 6 engineers who have been working for more than 20 years to provide you with free design service to ensure that parts can reach the appearance of iPhone, the accuracy of Atomic Clock, tolerance per 0.01 mm, the key procedure controlled by CPK1.68 or more. At the same time,2 engineers specialized in surface finishingcontrol the finish procedures. Passed ISO 9001:2005 & IATF 16949 & SGS in 2015.

Devoted to helping 10,000 enterprises to break through the difficulty of processing, and strive for becoming a leader in high-efficiency, high-yield, and precise parts. In the past 15 years, our business has spread to 62 countries around the world,covered military, medical, semiconductor, Telecommunication, automotive and other fields.No matter how complicated part is, or any technical problems faced with,we can find the solution and offer you with professional service.

100+

Sets of Machine

120+

Countries Shipped

100,000+

Parts Manufactured

Typical Applications of Swiss CNC Machining

Swiss CNC machining is widely adopted across industries that demand extreme precision and complex geometries in a single setup, especially where tight tolerances and superior surface finishes are critical. Key application areas include:

Other Industry Applications

Our business has grown to now cover 62 countries worldwide. We have done products in the electronics industry, industrial industry, automotive industry, and medical industry. If you need custom CNC Machining Components parts service, we have rich manufacturing experience and can turn your ideas into products.

VMT : 5-axis CNC Machining Petrochemical Connectors Parts Project

How to process difficult 5-axis CNC machining petrochemical connectors by dismantling the process, saving materials and combining 2+3 methods, and reduce the cost to 20%?

Our engineers conduct a process review according to the customer's drawings. During the review, it is found that it is an irregular eccentric shaped part. According to the traditional processing method, it can only be produced by a 5-axis machine, and the material that needs to be purchased must be twice the outer diameter of the part. . The processing area is large, the time is long, and materials are wasted.

FAQs About Swiss CNC Machining

How much does Swiss CNC machined parts service cost?

The cost of Swiss CNC machining services depends on several factors including part complexity, material type, production volume, and required tolerances. On average, part pricing can range from $5 to $150+ per piece, depending on specifications and order size. For accurate pricing, it’s best to request a detailed quote based on your part drawing and technical requirements.

How much does Swiss CNC machining cost per hour?

Swiss CNC machining typically costs $75 to $200+ per hour, depending on the machine type, materials processed, level of automation, and the operator's skill level. High-end medical or aerospace parts may incur higher hourly costs due to stringent tolerances and inspection procedures.

What types of materials are suitable for your CNC Swiss machining?

Swiss CNC machines can handle a wide range of materials, especially those used in high-precision industries:

These materials are commonly used for producing medical devices, aerospace components, electronics, and more.

Can Swiss CNC machines create internal threads?

Yes, Swiss CNC machines are fully capable of producing precise internal and external threads, including standard, metric, and custom thread profiles. Tapping, thread milling, and single-point threading operations are supported with tight tolerances.

How do Swiss CNC machines reduce setup time?

Swiss-type lathes reduce setup time through:

How does CNC Swiss machining differ from traditional machining methods?

Swiss CNC machining differs in key ways:

Can you accept both small and large orders?

Yes. Our Swiss CNC machining services are flexible and scalable. We accept:

We tailor production strategies based on your project scope.

Can you provide samples or prototypes for testing and evaluation?

Absolutely. We offer sample runs and prototypes to help you evaluate fit, function, and quality before mass production. Prototyping also allows for design optimization and process validation.

What secondary operations or finishing services do you offer?

We provide a variety of value-added services to meet end-to-end production needs:

Do you have a minimum order quantity requirement?

We are flexible with low to high volume production and do not impose strict minimum order quantities. We welcome prototype orders and small runs to support your product development cycle.

Do you provide value-added services such as assembly or packaging of Swiss CNC turned parts?

Yes. Our full-service model includes:

These services help streamline your supply chain and reduce time-to-market.

How do Swiss CNC machines achieve their high precision and tight tolerances?

Swiss CNC machines achieve superior precision through:

Tolerances of ±0.002 mm (±0.0001 in) are routinely achieved, making Swiss CNC machining ideal for industries that require the highest levels of dimensional accuracy.

Explore Related Resources

CNC Swiss Machining vs. Traditional CNC Machining: What’s the Difference?

This article explains how CNC Swiss machining and traditional CNC machining work, highlights their respective advantages, and outlines which types of parts each method is best ...

What is Swiss Machining: How It Works and Its Advantages

This comprehensive guide explores what Swiss machining is, how it works, and the numerous advantages it offers, enabling your CNC machining services to achieve unparalleled ...

Types of Turning Operations: Definitions, Methods, Parameters, and Equipment

Read this article to learn about various types of turning operations, their applications, and how to choose the right machining method for your needs ...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red