15 years one-stop China custom CNC machining parts factory

Home / Resources / Material / Titanium CNC Machining /

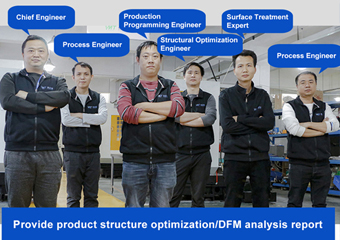

Professional Custom Titanium Alloy CNC Machining Team

24/7 CNC Machining Facility with Samples Ready in 7-10 Days

For critical components requiring the ultimate strength-to-weight ratio, superior corrosion resistance, and biocompatibility, titanium alloy is the unmatched choice. Our dedicated titanium CNC machining team, expertly mastering the properties of this tough material, provides lightweight, long-lasting, reliable, and durable precision component solutions for applications in aerospace, high-end medical, and racing. Make your products stand out.

VMT specializes in producing high-precision, complex titanium CNC machined parts. Certified to ISO9001 and IATF16949, VMT offers a one-stop service from prototyping to mass production. Leveraging advanced CNC equipment and a dedicated team, we craft high-strength, corrosion-resistant titanium parts with unmatched precision and consistency. We offer CNC milling, turning, and other services, with flexible pricing tailored to the project stage, meeting stringent tolerances and ensuring fast delivery. We continuously optimize our processes to meet your diverse production needs and provide strong support for project success.

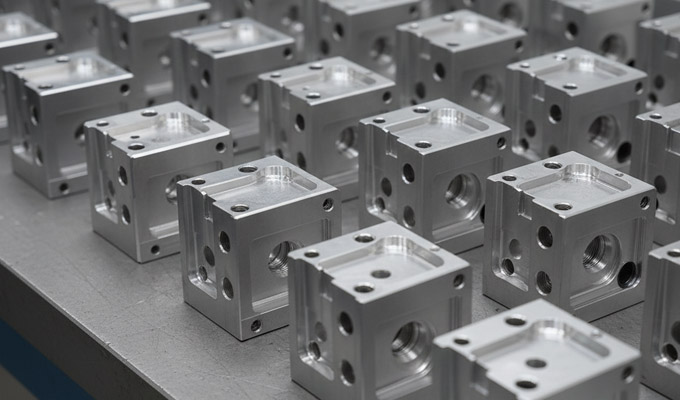

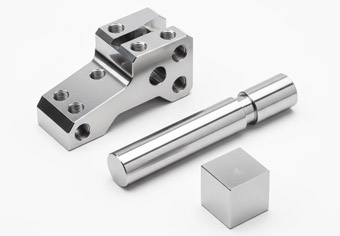

Titanium CNC Machined Prototypes

From titanium alloy prototype development to mass production, we leverage our proven rapid precision machining capabilities to provide professional titanium parts CNC machining services for over 1,000 customers. Equipped with 100 advanced machines and a team of over 12 professional engineers, we provide manufacturability analysis and a dedicated proofing team, supporting 24/7 prototyping. Through 12 rigorous quality inspection processes and specialized testing equipment, we ensure that each prototype meets design requirements for dimensional accuracy and performance, and provide authoritative test reports.

High-Volume Custom CNC Machined Titanium Parts Manufacturing

As your project progresses from prototype verification to mass production, we offer cost-effective, efficient, and stable mass customization solutions for steel parts. Professional design-for-manufacturing (DFM) reduces design costs, and a robust material inventory (such as carbon steel and alloy steel) reduces raw material procurement costs and lead times. We implement comprehensive statistical process control (SPC) and rigorous quality procedures, including first-article inspection, routine inspection, and final-article inspection, to ensure high consistency in critical dimensions and performance between the first and 10,000th parts, ensuring smooth production assembly. Once you complete titanium alloy verification at VMT, you can seamlessly transition to mass production. We ensure high consistency in process, quality, and data from prototype to mass production, significantly shortening your production cycle and mitigating the technical and management risks associated with switching suppliers.

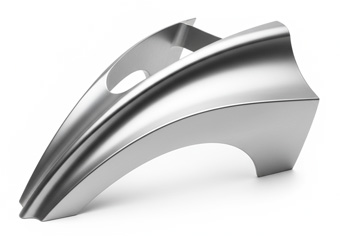

Titanium CNC Milling

Titanium alloys, with their exceptional strength-to-weight ratio and corrosion resistance, are an ideal choice for aerospace and defense, medical and surgical implants, high-end consumer goods and sports equipment, and chemical and marine engineering manufacturing. Leveraging our expertise in CNC milling, CNC turning, and 5-axis CNC machining, combined with our extensive material expertise, we offer custom high-precision, high-performance titanium CNC parts, from rapid prototyping to low-volume production.

VMT rovides titanium materials: titanium alloy TA1, titanium alloy TA2, titanium alloy TA3, titanium alloy TA4, titanium alloy TC4/Ti-6Al 4V, etc.

Advantages

Price: $$$

Delivery Time: < 10 days

Wall Thickness: 0.75 mm

Tolerance: ±0.005 in. (±0.125 mm)

Maximum Part Size: 200 x 80 x 100 cm

Disadvantages

Titanium Alloy TA1(Titanium Grade 1)

Titanium alloy TA1, also called industrial pure titanium (Grade 1 Titanium), has excellent corrosion resistance, good flexibility, and strong welding ability. It is suitable for CNC precision machining, welding, and stamping. It is widely used in making parts for aerospace, chemical, medical, and marine equipment.

Tensile strength at yield (MPa): 170–310 MPa

Fatigue strength (MPa): 240–370 MPa

Elongation at break (%): 24–35%

Hardness (Brinell): 70–100 HB

Density (g/cm3): 4.51 g/cm³

Melting point: 1660–1670°C

Titanium Alloy TA2 (Titanium Grade 2)

Titanium alloy TA2, also called industrial pure titanium Grade 2, has great corrosion resistance, strength, and weldability. It is good for CNC machining and welding. It is often used to make high-performance parts in aerospace, chemical, and medical industries.

Tensile strength at yield (MPa): 275–410 MPa

Fatigue strength (MPa): 240–260 MPa

Elongation at break (%): 20–28%

Hardness (Brinell): 160–200 HB

Density (g/cm3): 4.51 g/cm³

Melting point: 1660°C

Titanium Alloy TA3

Titanium alloy TA3, known as industrial pure titanium (medium strength type), has good strength, excellent corrosion resistance, and good formability. It is suitable for stamping, welding, and CNC machining. It is widely used to make high-performance parts such as chemical containers, marine structures, medical implants, and aerospace pipes.

Tensile strength at yield (MPa): 420–500 MPa

Fatigue strength (MPa): 240–280 MPa

Elongation at break (%): 20-25%

Hardness (Brinell): 160–200 HB

Density (g/cm3): 4.51 g/cm³

Melting point: 1660–1670°C

Titanium Alloy TA4

TA4 (Ti-3Al-1.5Mn) is called an alpha-type titanium alloy. It has higher strength and better heat resistance than pure titanium. It is suitable for CNC machining, welding, and hot forming. This material is widely used in key parts such as aircraft engine covers, ship structures, and chemical pressure containers.

Tensile strength at yield (MPa): 550–600 MPa

Fatigue strength (MPa): ≈ 240 MPa

Elongation at break (%): 15–20%

Hardness (Brinell): 210–250 HB

Density (g/cm3): 4.51 g/cm³

Melting point: 1660°C

Titanium Alloy TC4/Ti-6Al 4V

Titanium alloy TC4 (Ti-6Al-4V) is called an “alpha-beta titanium alloy.” It is known for its high strength, corrosion resistance, and heat resistance. It is suitable for CNC machining, 3D printing, and forging. This material is widely used in aerospace parts, medical implants, racing cars, and marine equipment.

Tensile strength at yield (MPa): 830–900 MPa

Fatigue strength (MPa): 510 MPa

Elongation at break (%): 10–15%

Hardness (Brinell): 330–360 HB

Density (g/cm3): 4.43 g/cm³

Melting point: 1650–1660°C

Titanium Alloy CNC Machining Parts Gallery

Titanium: Various National Standards and Equivalent Grades

We maintain a stock of over 40 certified materials, enabling rapid delivery of precision prototypes and small batch parts within 24 hours. Some of these materials are IMDS certified.

| Titanium Grade | ASTM (US) | EN (Europe) | GB (China) | JIS (Japan) | ISO | Key Properties | Typical Applications |

| TA1 | Grade 1 | 3.7035 | GR1 | TiCP-1 | ISO 5832-2 | Excellent corrosion resistance, high ductility, good weldability | Chemical equipment, heat exchangers, marine and medical parts |

| TA2 | Grade 2 | 3.7035 | GR2 | TiCP-2 | ISO 5832-2 | Balanced corrosion resistance and strength, good formability | Aerospace structures, chemical processing, medical devices, marine components |

| TA3 | Grade 3 | 3.7035 | GR3 | TiCP-3 | ISO 5832-3 | Higher strength than TA2, good corrosion resistance | Aerospace fasteners, chemical pipes, marine equipment, medical implants |

| TA4 | Grade 4 | 3.7035 | GR4 | TiCP-4 | ISO 5832-4 | Highest strength among pure titanium grades, excellent corrosion resistance | Aerospace components, pressure vessels, chemical equipment, medical implants |

| TC4 | Ti-6Al-4V | 3.7165 | GR5 | Ti-6Al-4V | ISO 5832-3 | High strength, excellent corrosion resistance, good high-temperature performance | Aerospace structural parts, medical implants, racing car components, marine devices |

Why Choose VMT?

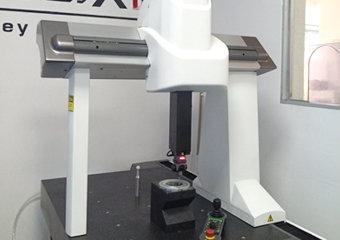

High-Quality Parts with Tight Tolerances

As an ISO 9001-certified manufacturer, VMT delivers high-quality CNC machining parts, expertly handling complex designs. We follow international best practices, achieving dimensional tolerances as tight as ±0.0004″ (0.01mm), ensuring our products meet your exact specifications and fulfill all your requirements.

Fast Quoting and Delivery

VMT provides rapid production and delivery of CNC machining parts, enabling flexible iterations and helping you stay ahead in the market. Upload your design and receive a CNC quote within 2 hours. Our engineering team offers precise cost calculations, transparent pricing, and reduced lead times, significantly boosting your competitiveness.

Engineering Support

Leveraging cutting-edge technology and equipment, we ensure the highest quality, precision, and performance of automotive parts. To expedite our clients' CNC machining product development and validation, we operate over 100 advanced CNC machines and a specialized rapid prototyping team. From design analysis to mass production, we can deliver within 24 hours, providing full support to ensure client success.

Quality Inspection

We maintain a comprehensive quality control system, including IQC, IPQC, and FQC, overseeing every stage from raw materials to final shipment. We retain inspection reports for two years and are equipped with advanced 3D and 2D measuring instruments, as well as a laboratory for precise dimension checks and material compliance. We offer CMM inspection, material testing, and certification of conformity to ensure exceptional quality.

Surface Finishing

We collaborate with surface finishing factories with over 10 years of experience, offering more than 40 surface finishingprocesses. Two senior engineers work on customizing cost-effective solutions based on your needs, strictly controlling every step to ensure a 98% product yield and outstanding surface finishingquality.

Certifications and Patents

We are certified by ISO9001:2015, IATF16949, and SGS, and hold 12 patents. With state-of-the-art CNC technology, we ensure precise and efficient CNC machining part machining, meeting your highest expectations for size, performance, and strength, and providing exceptional service.

Custom Titanium CNC Machining Capabilities

We focus on solving the machining challenges of titanium alloys such as the TA series, TC4/GR5, and TC11. Our team provides full-process services, from rapid prototyping to mass production.

CNC Machining Titanium Parts Surface Finishing Options

VMT can improve the surface finish of titanium CNC machined parts up to Ra 0.8 μm, which greatly increases their corrosion resistance, surface hardness, wear resistance, and appearance. This ensures that our titanium parts can meet the strict industry standards of aerospace, medical, marine, and chemical equipment fields.

VMT offers a wide range of custom surface treatment solutions for titanium CNC machining, including passivation, sandblasting, anodizing, micro-arc oxidation, electroplating, and heat treatment. Each process is carefully designed to match the needs of different titanium CNC machined parts. These treatments help improve the durability, performance, and appearance of the parts, ensuring that every component meets the high-quality standards expected by global customers in precision CNC machining.

As Machined

Passivation

Plating

Bead blasting/Sandblasting

Polishing

Anodizing

Micro-arc Oxidation

Nitriding/Oxygenating

Flexible Turnaround Time

We customize machining lead times for all types of projects to ensure your titanium CNC machining needs are met—ranging from rapid prototyping to mass production:

Project Type

Urgent high-Precision Samples

Stainless Steel Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Advantages and Disadvantages of Titanium CNC Machining

Titanium alloy CNC machining can produce lightweight, strong, and corrosion-resistant parts, making it ideal for aerospace, medical, and marine applications.

During machining, challenges like heat buildup, tool wear, and springback can affect accuracy. We use carbide tools, advanced cooling systems, optimized cutting strategies, and rigid fixtures to solve these problems. This ensures a machining tolerance of ±0.01 mm and excellent surface finish, making our titanium alloy parts reliable for high-performance applications.

Advantages

Solution:

Disadvantages

Application of CNC Machining Titanium Parts

CNC machining of titanium parts is used in many industries. CNC machining gives precise sizes, complex shapes, and very smooth surfaces. This makes titanium a good choice for high-performance and precise parts. It meets the strict needs of important parts in different industries.

Frequently Asked Questions

What Are the Cutting Speeds and Feed Rates for Titanium?

Cutting speeds for titanium alloys typically range from 30–60 m/min for roughing and 50–100 m/min for finishing, with feed rates 0.05–0.25 mm/rev depending on tool type and part geometry.

Can Titanium be CNC Machined?

Yes, titanium can be CNC machined, but it requires special tooling, optimized cutting parameters, and advanced cooling to manage heat and tool wear.

How Difficult is it to Machine Titanium Alloys?

Titanium is moderately to highly difficult to machine due to its low thermal conductivity, high strength, and tendency to work-harden.

What is the Best Tooling for Machining Titanium?

Carbide, coated carbide, or polycrystalline diamond (PCD) tools are preferred, often with rigid setups and high-pressure coolant.

How Much Does 1 kg of Titanium Cost?

Prices vary by grade and market, but industrial titanium typically costs $8–$15 per kg.

Which Titanium Alloy is the Easiest to Machine?

Commercially pure titanium (TA1, TA2) is easier to machine than high-strength alloys like TC4/Ti-6Al-4V.

Is Titanium Easier to Machine Than Steel?

No, titanium is more difficult to machine than most steels because of low thermal conductivity and spring-back, requiring specialized tools and slower cutting speeds.

Which Grade of Titanium is Easiest to Machine?

TA1 and TA2 (grades 1 and 2) are the most machinable among common titanium alloys.

Why is Titanium so Difficult to Cut?

Titanium is hard to cut due to low thermal conductivity (heat concentrates at the cutting edge), high chemical reactivity at elevated temperatures (causing tool wear), and spring-back tendency, which requires precise machining strategies.

CNC Machining Resources

Types of Titanium Alloys: A Comprehensive Guide

Gain in-depth knowledge of the types, properties, applications, and machining techniques of titanium alloys, and apply this expertise to your titanium CNC machining projects. ...

Titanium vs. Stainless Steel: Which is the Best Choice for CNC Machining?

This article provides a detailed comparison of titanium and stainless steel, outlining their properties, advantages, disadvantages, and applications. It will help you determine whether titanium or stainless steel is the best choice for ...

Aluminum vs. Titanium: Which Metal Is Best for Your Project?

Read this article to explore the key differences between aluminum and titanium, from elemental composition and strength to cost, corrosion resistance, machinability, and industry-specific applications, helping you choose the ...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red