15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 11 17

2022 11 17 High-speed CNC engraving machining is widely used in the machining of precision CNC parts. In daily use, some problems will inevitably occur. Today, VMT CNC machining summarizes some of the problems that are easy to occur in the process of high-speed CNC engraving and machining. Let's take a look Which are there?

66

66

Read more

Read more

VMT

VMT  2022 11 14

2022 11 14 Summary of CNC parts processing technical requirements, tolerance requirements, and assembly requirements!

66

66

Read more

Read more

VMT

VMT  2022 11 12

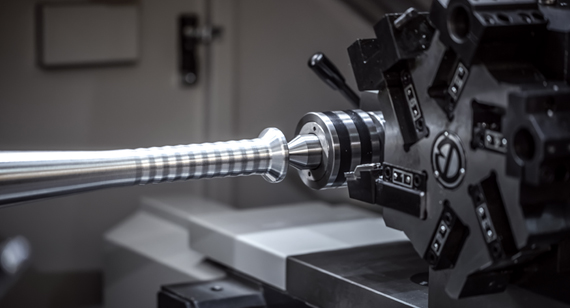

2022 11 12 A basic method of deep hole drilling machining, drilling is often carried out on drilling machines and lathes, and can also be carried out on boring machines or milling machines. The machining accuracy of drilling is low, generally only reaching IT10, and the surface roughness is generally 12.5-6.3 μm. After drilling, reaming and reaming are often used for semi-finishing and finishing.

66

66

Read more

Read more

VMT

VMT  2022 11 11

2022 11 11 During the execution of a 3-axis CNC milling program, the two rotary axes of the 5-axis machine tool are used to fix the cutting tool in an inclined position, and the name of the 3+2 CNC machining technology also comes from this, which is also called the positioning 5-axis machine tool.

66

66

Read more

Read more

VMT

VMT  2022 11 10

2022 11 10 Material cost is a certain main difference. The main difference lies in the different labor costs, transportation costs, consumption costs and taxes of each company. So how do these CNC machining factories calculate?

66

66

Read more

Read more

VMT

VMT  2022 11 09

2022 11 09 Some people say that first learn three-axis, and then go to four-axis, five-axis CNC machining center, what is the difference between these types of machine tools?

66

66

Read more

Read more

VMT

VMT  2022 11 08

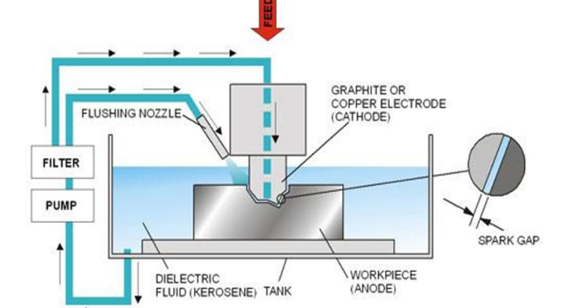

2022 11 08 EDM, also known as Electrical Discharge Machining (EDM) or EDM, is one of the four most popular CNC machining methods, alongside CNC milling, CNC turning and grinding.

66

66

Read more

Read more

VMT

VMT  2022 11 07

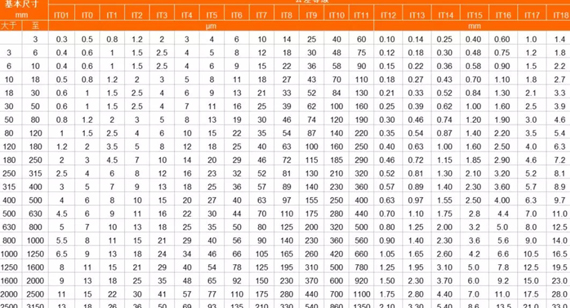

2022 11 07 According to different functions of product parts, the CNC machining accuracy that needs to be achieved is different, and the selected CNC machining form and CNC machining technology are also different. This article introduces the CNC machining accuracy that can be achieved by several common CNC machining forms such as turning, milling, planing, grinding, drilling, and boring.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!