15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 12 13

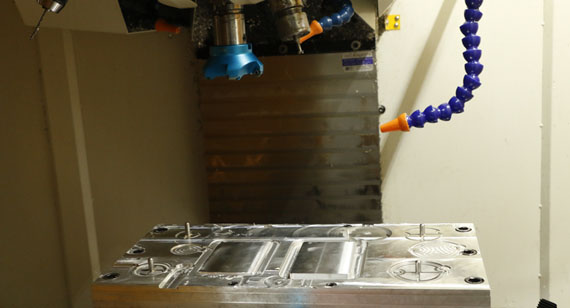

2022 12 13 Fixtures are always used in CNC machining now. Fixtures are mainly used as auxiliary tools for controlling position or movement (or both) to help us better CNC machining parts, so what should we pay attention to when using fixtures for CNC machining? The following VMT summarizes 7 points for attention.

66

66

Read more

Read more

VMT

VMT  2022 12 12

2022 12 12 The so-called vibrating tool means that the changing cutting force in the CNC machining process acts on the tool and the workpiece, resulting in vibrating tool.

66

66

Read more

Read more

VMT

VMT  2022 12 10

2022 12 10 CNC machining error refers to the degree of deviation between the actual geometric parameters (geometric scale, geometric shape and mutual orientation) of the part after machining and the ideal geometric parameters.

66

66

Read more

Read more

VMT

VMT  2022 12 09

2022 12 09 10 common surface treatment methods of CNC parts, take you to understand the process flow and technical characteristics of different surface treatment processes, and choose the surface treatment suitable for your CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2022 12 08

2022 12 08 Sand blasting is a process of cleaning and roughening the surface of the substrate by the impact of high-speed sand flow, and has been widely used in many industrial fields. The surface of many CNC parts in daily life is not a mirror surface, but a somewhat rough "frosted" effect. This "textured" effect is liked by many people. This is a very common process in metal finishing called sandblasting.

66

66

Read more

Read more

VMT

VMT  2022 11 30

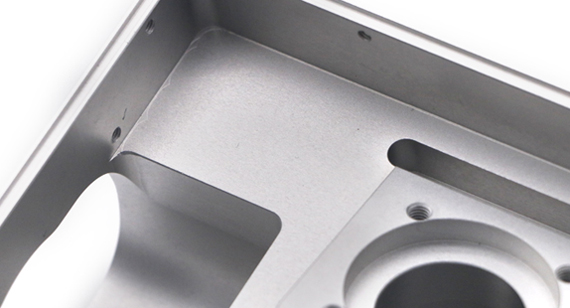

2022 11 30 The accuracy of CNC machining is the degree to which the three geometric parameters of the actual size, shape, and position of the machined part surface conform to the ideal geometric parameters required by the drawings. The ideal geometric parameters, in terms of size, are the average size; in terms of surface geometry, they are circles, cylinders, planes, cones, and straight lines; for the mutual position between surfaces, they are parallel and perpendicular , coaxial, symmetrical, etc.

66

66

Read more

Read more

VMT

VMT  2022 11 22

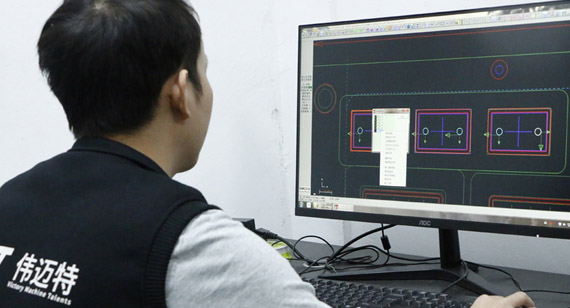

2022 11 22 The design drawing of CNC machining parts is one of the main bases for product processing in an enterprise. The design drawing of parts has a very important relationship with the precision and quality of CNC machining products.

66

66

Read more

Read more

VMT

VMT  2022 11 21

2022 11 21 In the field of CNC machining parts industry, plastics are often used as raw materials for further processing. Now there are many types of plastics on the market, so what kind of plastic should I choose when CNC machining parts?

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!