15 years one-stop China custom CNC machining parts factory

156 |

Published by VMT at Sep 15 2025 | Reading Time:About 4 minutes

156 |

Published by VMT at Sep 15 2025 | Reading Time:About 4 minutes

Aluminum alloys 4032 and 2618 are common choices in industries like automotive, aerospace, and high-performance engineering. Each alloy has its own advantages and disadvantages, and choosing the wrong alloy can increase machining costs, reduce durability, and shorten the life of your CNC machined parts.

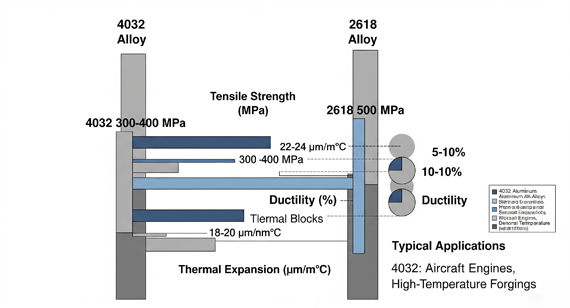

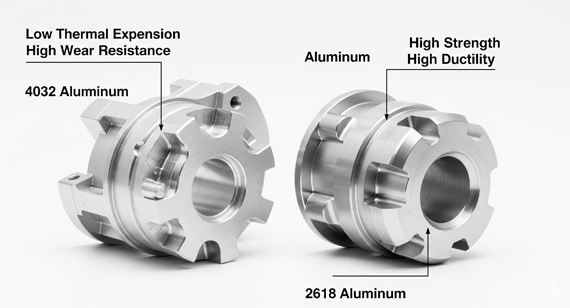

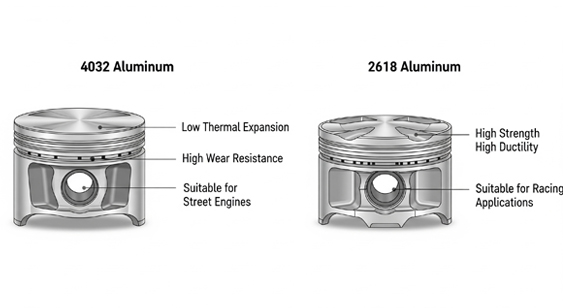

Understand the composition, properties, advantages, and limitations of each alloy to choose the right material for your project. 4032 aluminum alloy is a high-silicon alloy prized for its excellent wear resistance, dimensional stability, and low thermal expansion. On the other hand, 2618 aluminum alloy is known as a high-strength aluminum with excellent toughness, making it ideal for forged pistons and extreme performance applications.

This article provides a detailed comparison of 4032 and 2618 aluminum alloys. Learn which aluminum best meets your machining needs and how VMT CNC machining services can help you transform your designs into reliable, high-precision parts. If you're considering using 4032 forged aluminum pistons or 2618 forged alloy for your high-performance engine, this guide will help you save time, money, and avoid mistakes.

The differences between 4032 aluminum alloy and 2618 aluminum alloy lie in their composition and properties. 4032 alloy, with its higher silicon content, offers improved wear resistance and dimensional stability, while 2618 alloy offers superior strength and toughness, making it suitable for high-temperature, high-stress applications like racing engines. Choosing which aluminum alloy to use depends on whether you need durability or demand extreme performance.

Now that you have a quick overview of the differences between 4032 and 2618 aluminum alloys, let's take a deeper look at each material. Understanding the composition, properties, and applications of these alloys will help you make the right choice for your CNC machined parts. Let's first take a closer look at 4032 aluminum alloy.

4032 aluminum alloy is a high-silicon aluminum grade (around 11–13% silicon) that offers an excellent balance of strength, wear resistance, and dimensional stability. The higher silicon content makes it harder and less prone to thermal expansion compared to lower-silicon alloys, which is why it is widely used in automotive, aerospace, and precision CNC machined parts. Unlike pure aluminum, which is soft and less durable, 4032 alloy maintains tight tolerances under heat and stress, making it an excellent choice for high-performance pistons, engine components, and aerospace fittings.

A common application is the 4032 piston alloy, where reduced expansion means quieter operation and better reliability under moderate stress. Compared to 2618 forged aluminum, 4032 forged aluminum typically offers longer service life and better wear properties but sacrifices some toughness under extreme loads. Because of its stability, 4032 aluminum alloy is often chosen for projects where precision and durability matter more than maximum strength.

If you’re designing CNC machined parts that demand excellent machinability and cost efficiency, 4032 Al alloy is often the smarter option. At VMT CNC machining services, we help clients evaluate whether 4032 alloy properties fit their needs or whether a stronger grade like 2618 alloy is more suitable. Learn more about our aluminum CNC machining services here.

.

2618 aluminum alloy is a high-strength, low-silicon aluminum grade designed for extreme performance. Unlike 4032 alloy, which emphasizes stability, 2618 alloy delivers superior toughness, fatigue resistance, and heat resistance. This makes it a preferred choice for racing engines, aerospace parts, and forged pistons that face intense loads and high temperatures.

Because it has very little silicon, 2618 Al alloy expands more with heat and wears faster than 4032 aluminum grade. However, its strength and ductility allow it to withstand extreme stress without cracking, making it the go-to option in motorsports and defense applications.

At VMT CNC machining services, we often recommend forged 2618 aluminum when clients need maximum strength under high stress, even if that means shorter part life compared to 4032 alloy. Check our aluminum CNC machining expertise here

.

The main difference between 4032 aluminum alloy and 2618 aluminum alloy is dimensional stability vs. extreme strength. The table below highlights their key pros and cons.

| Alloy |

Advantages |

Disadvantages |

| 4032 Aluminum Alloy |

- High silicon → excellent wear resistance - Low thermal expansion → stable dimensions - Quieter piston operation - Longer service life - Better machinability for CNC parts |

- Less ductile than 2618 - Not suitable for extreme racing conditions |

| 2618 Aluminum Alloy |

- High strength and ductility - Superior fatigue and heat resistance - Ideal for forged pistons & aerospace - Withstands extreme stress |

- Wears faster due to low silicon - Expands more with heat → needs larger clearances - Lower machinability → higher machining costs |

At VMT CNC machining services, we help customers decide between 4032 forged aluminum for stability and longevity, and 2618 forged aluminum for strength under extreme loads. Discover our CNC machining solutions here

.

When selecting aluminum alloys for high-performance applications such as automotive engines, aerospace components, and CNC machined parts, 4032 aluminum alloy and 2618 aluminum alloy are two of the most widely considered options. Both alloys belong to the wrought aluminum-silicon-copper family but differ significantly in composition, strength, thermal stability, and wear resistance. Understanding their composition, mechanical properties, thermal behavior, and physical properties helps engineers and manufacturers choose the right material for CNC machining services and precision components.

4032 Aluminum Alloy vs. 2618 Aluminum Alloy: Composition

| Alloy |

Key Elements |

Characteristics of Composition |

| 4032 Aluminum Alloy |

~11–13% Silicon, 0.8–1.3% Copper, 0.8–1.3% Magnesium, 0.5–1.0% Nickel, Balance Aluminum | High silicon content improves wear resistance, hardness, and thermal expansion stability. |

| 2618 Aluminum Alloy |

~2.0–2.8% Copper, 1.3–1.8% Magnesium, 0.15–0.25% Iron, 0.9–1.5% Nickel, Balance Aluminum | Lower silicon, higher copper and magnesium for superior high-temperature strength and fatigue resistance. |

Key Takeaway:

4032 Aluminum Alloy vs. 2618 Aluminum Alloy: Mechanical and Thermal Properties

| Property |

4032 Aluminum Alloy |

2618 Aluminum Alloy |

| Tensile Strength |

~380 MPa | ~440 MPa |

| Yield Strength |

~315 MPa | ~370 MPa |

| Hardness (HB) |

~120–130 | ~85–95 |

| Elongation |

~1–2% (low ductility) | ~10–12% (high ductility) |

| Fatigue Resistance |

Moderate | Excellent |

| Thermal Conductivity |

~155 W/m·K | ~120 W/m·K |

| Coefficient of Thermal Expansion |

Lower (better stability) | Higher (more expansion under heat) |

| Working Temp. Limit |

~250–300°C | ~300–400°C |

Key Takeaway:

4032 Aluminum Alloy vs. 2618 Aluminum Alloy: Physical Properties

| Property |

4032 Aluminum Alloy |

2618 Aluminum Alloy |

| Density |

~2.68 g/cm³ | ~2.80 g/cm³ |

| Machinability |

Excellent (silicon aids cutting) | Good (more ductile, slightly harder to machine) |

| Corrosion Resistance |

Better (higher silicon improves resistance) | Moderate (requires protective coatings in harsh environments) |

| Wear Resistance |

Excellent | Moderate |

| Surface Finish |

Naturally smoother due to silicon | Requires more finishing processes |

Key Takeaway:

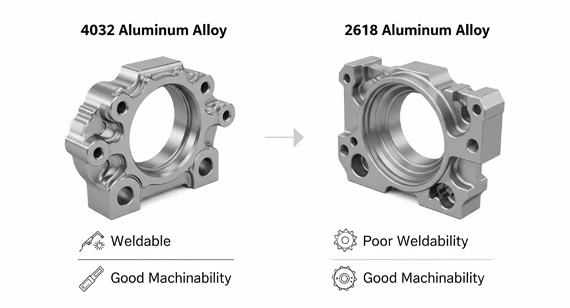

Machinability

4032 Aluminum Alloy

2618 Aluminum Alloy

Verdict: 4032 is easier and faster to machine with a better surface finish, while 2618 needs more tool management.

Weldability

4032 Aluminum Alloy

2618 Aluminum Alloy

Verdict: 2618 is superior for welding, while 4032 is mainly used where welding is unnecessary.

Quick Comparison Table

| Property |

4032 Aluminum Alloy |

2618 Aluminum Alloy |

| Machinability |

Excellent – easy cutting, smooth finish | Good – requires chip control, more tool wear |

| Tool Wear |

Low | Moderate |

| Surface Finish |

Naturally smoother | Requires finishing |

| Weldability |

Poor – high risk of cracking | Good – suitable for MIG/TIG welding |

| Post-Weld Strength |

Poor | Stronger retention of properties |

When choosing between 4032 and 2618 aluminum alloys for your project, it's crucial to understand processing costs and material prices. These factors can significantly impact your overall budget and project schedule. Let's take a closer look to help you make an informed decision.

Initial Cost Comparison

Tip: For projects with limited budgets, 4032 alloy offers a balance between performance and cost.

Long-Term Cost Benefits

Note: Consider the long-term benefits of each alloy based on the specific requirements of your project.

Machining Costs

4032 Aluminum Alloy

2618 Aluminum Alloy

Tip: If your project requires large-scale precision parts, 4032 is more cost-effective.

Market Material Prices

Note: Prices may vary depending on supplier, order quantity, and market conditions. Be sure to request quotes from multiple suppliers to ensure competitive pricing.

Quick Comparison Chart

| Factor |

4032 Aluminum Alloy |

2618 Aluminum Alloy |

| Initial Cost |

Lower | Higher |

| Long-Term Benefits |

Moderate | Higher |

| Machining Costs |

Low – Excellent machinability, less tool wear | High – Tougher, greater tool wear |

| Market Price |

$1.80–2.60/kg | $1.80–2.60/kg |

| Best Value For |

Automotive, large CNC runs, stable parts | Aerospace, racing, extreme load parts |

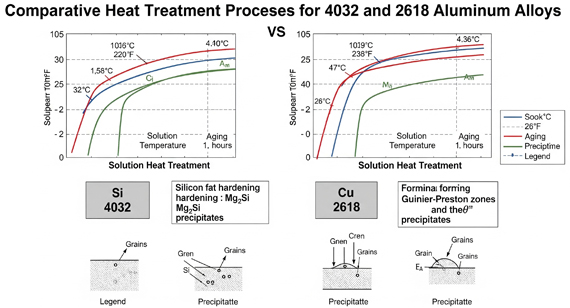

4032 Aluminum Alloy

2618 Aluminum Alloy

Quick Comparison Table

| Alloy |

Heat Treatment Process |

Primary Benefits |

Risks/Considerations |

| 4032 Aluminum Alloy |

T6, T651 | High hardness, wear resistance, dimensional stability | Overheating → microcracks |

| 2618 Aluminum Alloy |

T61, T71 | High strength, fatigue resistance, ductility | Improper aging → reduced mechanical performance |

Tip: Work closely with your CNC machining factory to determine the optimal heat treatment for your specific component. Incorrect tempering can increase material costs and cause part failure.

4032 Aluminum Alloy Applications

4032 alloy is valued for its dimensional stability, wear resistance, and machinability, making it ideal for applications that require precision under moderate stress:

Tip: 4032 is perfect when you need long-lasting, wear-resistant parts, but avoid using it in extreme high-stress applications where toughness is critical.

2618 Aluminum Alloy Applications

2618 alloy is prized for its strength, ductility, and high-temperature performance, making it the go-to choice for extreme performance:

Tip: 2618 is best for high-performance and heavy-duty applications, but keep in mind that machining costs and thermal expansion are higher compared to 4032 alloy.

Quick Comparison Table

| Alloy |

Common Applications |

Key Advantages |

Considerations |

| 4032 Aluminum Alloy |

Automotive pistons, aerospace components, CNC machined precision parts | Wear resistance, dimensional stability, excellent machinability | Less ductile, not ideal for extreme stress |

| 2618 Aluminum Alloy |

Racing pistons, aerospace/defense parts, forged high-strength components | High strength, fatigue resistance, withstands high temperature | Higher machining cost, more thermal expansion |

For high-quality 4032 or 2618 CNC machined parts, contact VMT CNC machining services to get expert advice on material selection and precision manufacturing.

Choosing between 4032 aluminum alloy and 2618 aluminum alloy depends on your project’s performance requirements, budget, and operating conditions.

Quick Recommendation:

Tip: Consult with your CNC machining factory to evaluate the best alloy based on application, volume, and thermal/structural demands. Choosing the wrong alloy can increase costs, reduce performance, or cause premature part failure.

For expert guidance on selecting the right aluminum alloy for CNC machined parts, contact VMT CNC machining services to discuss 4032 vs. 2618 alloy options.

At VMT CNC machining services, we specialize in precision machining of 4032 and 2618 aluminum alloys for industries ranging from automotive and aerospace to high-performance engineering. Whether your project requires forged 4032 aluminum for dimensional stability or forged 2618 aluminum for extreme strength, our experienced team ensures each component meets tight tolerances and superior quality standards.

We provide a full spectrum of services, including:

Why Choose VMT?

Tip: Partnering with a knowledgeable CNC machining factory ensures correct alloy selection, optimal machining parameters, and minimal material waste, saving both time and costs.

Ready to manufacture high-performance aluminum parts? Contact VMT CNC machining services today for a consultation on 4032 or 2618 alloy components.

Choosing between 4032 aluminum alloy and 2618 aluminum alloy depends entirely on your project’s performance requirements, budget, and operating conditions. 4032 alloy excels in dimensional stability, wear resistance, and machinability, making it ideal for automotive pistons, aerospace components, and precision CNC machined parts. 2618 alloy, with its high strength, ductility, and heat resistance, is the top choice for racing, high-stress, and heavy-duty applications, despite higher machining costs.

By understanding composition, mechanical and thermal properties, physical characteristics, machinability, heat treatment, and applications, engineers and manufacturers can make informed decisions that balance cost, durability, and performance.

At VMT CNC machining services, we help clients select the right alloy and provide precision machining, forging, and finishing services to ensure optimal performance for both 4032 and 2618 aluminum components. Proper alloy selection not only improves part life but also reduces production costs and avoids premature failures.

For expert guidance on 4032 or 2618 aluminum alloy CNC machined parts, contact VMT today and let our team help you choose the right material for your high-performance project.

1. 4032 vs. 2618: Which aluminum alloy is stronger?

2618 aluminum alloy is stronger than 4032 alloy, offering higher tensile strength, superior fatigue resistance, and better performance at high temperatures. 4032 alloy, while wear-resistant and dimensionally stable, is less ductile and not as suitable for extreme stress applications. Choose 2618 for high-performance, heavy-duty pistons and aerospace parts.

2. Why is 2618 aluminum typically more expensive than 4032 aluminum?

2618 alloy costs more due to its aerospace-grade strength, high ductility, and ability to withstand extreme thermal and mechanical loads. Machining 2618 also requires advanced tooling and longer processing time, adding to overall costs. 4032, with high silicon content, is easier to machine and more widely available, making it more affordable.

3. How much HP can a 4032 piston handle?

4032 pistons can handle moderate to high horsepower levels typical in street performance and naturally aspirated engines. The exact limit depends on engine design, cooling, and clearances, but 4032’s high wear resistance and low thermal expansion make it reliable for most non-racing applications. For extreme horsepower or forced induction engines, 2618 pistons are usually preferred.

4. Which piston is better?

There is no single “better” piston—it depends on application:

5. What is the best material for a high-performance piston?

For extreme performance applications, 2618 aluminum alloy is the preferred choice due to its high strength, fatigue resistance, and heat tolerance. 4032 aluminum alloy is better suited for applications requiring wear resistance, low expansion, and smoother operation under moderate stress.

6. How do I choose the right piston?

Consider your engine type, performance goals, operating temperature, and budget:

Consulting a CNC machining factory like VMT ensures the piston is machined and heat-treated correctly for your application.

7. How do 4032 and other 2xxx series compare?

4032 alloy is a high-silicon aluminum alloy, providing wear resistance and dimensional stability, while other 2xxx series alloys (like 2618) prioritize strength and ductility. 4032 is easier to machine and better for longevity, whereas 2xxx series alloys are used in extreme high-performance applications.

8. Is a forged piston better than a cast piston?

Forged pistons, whether 4032 or 2618, offer superior strength, fatigue resistance, and durability compared to cast pistons. Cast pistons are cheaper and suitable for standard engines, but they are less tolerant to high stress, high temperature, and extreme horsepower. For racing and performance engines, forged 2618 pistons are usually the top choice.

For expert advice on choosing between 4032 and 2618 pistons, or to order precision CNC machined forged pistons, contact VMT CNC machining services today.