15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 12 30

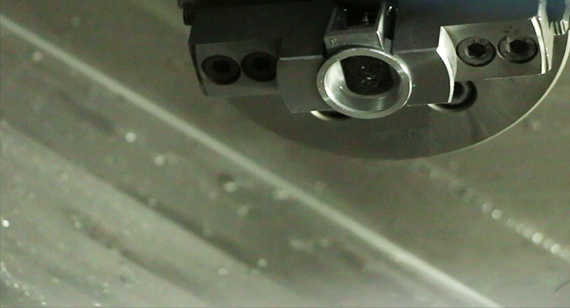

2023 12 30 CNC machining is a high-precision, high-efficiency processing method that is widely used in the manufacturing of various precision parts. However, during the CNC machining and assembly process of aluminum alloy precision parts, abnormal noise problems sometimes occur, which not only affects the smooth progress of the processing process, but may also have a negative impact on the accuracy and performance of the parts.

66

66

Read more

Read more

VMT

VMT  2023 12 29

2023 12 29 In the process of precision parts processing, thread processing is a key link. However, due to the influence of various factors, fine-tuning problems may occur in the processed threads, such as loose threads, over-tightening, or accuracy deviations. These problems will not only affect the assembly and performance of parts, but may also cause safety accidents. Therefore, it is crucial to solve the fine-tuning problems caused by threads.

66

66

Read more

Read more

VMT

VMT  2023 12 28

2023 12 28 In today's manufacturing industry, CNC machining technology has become a key means of manufacturing precision parts. However, although precision machined parts can achieve extremely high accuracy and surface quality during CNC machining, they often encounter challenges during salt spray testing. This article will delve into this issue, analyze the reasons why CNC machining parts are difficult to pass the salt spray test after oxidation, and propose corresponding solution strategies.

66

66

Read more

Read more

VMT

VMT  2023 12 27

2023 12 27 In the manufacturing field, numerical control machining (CNC) technology has become a key means of manufacturing precision parts. However, for many small CNC machining factories, stable mass production of precision machined parts is a huge challenge. This article will delve into this issue, analyze the difficulties faced by small CNC machining factories in stably mass producing precision machined parts, and propose corresponding solution strategies.

66

66

Read more

Read more

VMT

VMT  2023 12 26

2023 12 26 In the field of precision CNC machining, it is crucial to ensure high precision and high quality of parts. However, in the actual production process, especially after precision machined parts undergo oxidation and conductive treatment, a thorny problem is often encountered - oil stains are difficult to completely remove.

66

66

Read more

Read more

VMT

VMT  2023 12 25

2023 12 25 In the manufacturing industry, numerical control machining has become a key technology for precision parts manufacturing. However, for small CNC machining factories, when a set of products contains 40 precision machined parts, they will face a series of technical and resource challenges. This article will explore this problem in depth, analyze the reasons and propose corresponding solution strategies.

66

66

Read more

Read more

VMT

VMT  2023 12 24

2023 12 24 Reliability testing of outdoor aluminum CNC machined parts is of great significance to improving product quality, reducing production costs and enhancing market competitiveness. In order to ensure product reliability and stability, it is necessary to strengthen the monitoring and management of the production process, optimize product design and technical processes, and conduct regular reliability testing and evaluation.

66

66

Read more

Read more

VMT

VMT  2023 12 23

2023 12 23 There are still some potential risks after the thread of CNC machined parts passes the stop gauge, such as surface quality risk, stress concentration risk and dimensional accuracy risk. To ensure product performance and longevity, appropriate precautions need to be taken to reduce these risks.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!