15 years one-stop China custom CNC machining parts factory

2 |

Published by VMT at Dec 04 2025 | Reading Time:About 3 minutes

2 |

Published by VMT at Dec 04 2025 | Reading Time:About 3 minutes

When you’re working with bronze for machining or manufacturing, you might worry about choosing the right alloy or misjudging its weight, which can lead to higher project costs. Bronze density often seems confusing because every alloy behaves differently. But once you understand how bronze material density works, you can pick the right bronze components with confidence and avoid expensive mistakes.

The density of bronze typically ranges from 7.4 to 8.9 g/cm³, depending on the alloy’s composition and manufacturing method. You can calculate bronze material density by dividing its mass by its volume. Knowing this helps you estimate bronze weight per cubic inch or centimeter, choose suitable bronze alloys, and control machining or casting costs.

Now that you understand the basic density range of bronze, you can dig deeper into how different alloys, compositions, and processes affect bronze metal density. This will help you select the right bronze for CNC machining, casting, or forging, and avoid issues like excess weight, poor performance, or unexpected machining costs.

The density of bronze usually falls between 7.4 and 8.9 g/cm³, depending on the alloy blend and how it is processed. When you divide the mass of a bronze component by its volume, you get its bronze material density. This helps you estimate bronze weight per cubic centimeter and choose the right alloy for CNC machined bronze parts or bronze castings.

When you look into bronze density, you’ll notice that every alloy has its own weight and behavior. This is because bronze metal density depends on the mix of copper, tin, and other elements. Knowing how these variations work helps you choose the right bronze components for machining, casting, or forging without guessing or overspending.

Definition and Calculation of Density

Density tells you how much mass fits into a given volume. For bronze, you calculate it by dividing the alloy’s mass by its volume, giving you the bronze material density in g/cm³. This simple formula helps you estimate bronze weight properties, compare different bronze alloys, and plan CNC machining, forging, or casting more accurately.

Different bronze alloys vary widely in density because each contains different amounts of copper, tin, aluminum, silicon, lead, or manganese. These changes affect bronze metal density, bronze specific gravity, and overall weight properties. Understanding these differences helps you select the right alloy for CNC machined bronze parts, bronze castings, or bronze bushings without running into cost or performance issues.

Updated Density Table of Common Bronze Alloys

| Bronze Alloy Type |

Density (g/cm³) |

Advantages |

Typical Applications / Industry Parts |

| Aluminum Bronze |

7.5 – 8.7 | Excellent corrosion resistance, high strength, great wear resistance | Marine bronze components, ship valves, pump parts, CNC machined bronze parts, aerospace bushings |

| Silicon Bronze |

8.3 – 8.9 | Superior corrosion resistance, good castability, easy to machine | Marine hardware, artistic castings, electrical connectors, industrial bronze components |

| Phosphorus Bronze |

8.7 – 8.9 | High fatigue strength, low friction, excellent spring properties | Precision gears, springs, washers, CNC machined parts for electronics |

| Lead-Tin Bronze |

8.7 – 9.3 | Self-lubricating, excellent wear resistance, good machinability | Bronze bushings, bearings, sliding components, automotive parts |

| Manganese Bronze |

8.2 – 8.9 | Very high tensile strength, good toughness, good corrosion resistance | Heavy-duty bearings, marine propellers, hydraulic components |

| High-Strength Bronze |

8.0 – 8.9 | Maintains strength under load, durable under impact | Load-bearing bronze components, structural fittings, industrial machinery parts |

| Cast Bronze |

7.8 – 8.9 | Flexible shapes, cost-effective for large parts | Bronze castings, pump housings, valve bodies, artistic components |

| Forged Bronze |

8.3 – 8.9 | Higher density, stronger grain structure, minimal porosity | Forged bronze gears, high-stress mechanical parts, aerospace components |

When you compare bronze density with other metals, you’ll see how its weight sits between lightweight materials like aluminum and much heavier ones like tungsten. Knowing these differences helps you choose the right metal for CNC machined parts, structural components, or weight-sensitive designs. It also prevents mistakes such as selecting a metal that makes your product too heavy or too expensive to process.

Metal Density Comparison Table

| Metal |

Typical Density (g/cm³) |

How It Compares to Bronze |

Common Uses |

| Density of Bronze (General Range) |

7.4 – 8.9 | Medium to high density; varies by alloy | Bushings, gears, marine parts, CNC machined bronze parts |

| Density of Aluminum |

2.6 – 2.8 | Much lighter than bronze | Aerospace parts, lightweight frames |

| Density of Titanium |

4.4 – 4.5 | Lighter than bronze but stronger | Medical implants, aircraft components |

| Density of Stainless Steel |

7.7 – 8.1 | Similar to some bronze alloys | Industrial components, kitchenware |

| Density of Copper |

8.9 | Slightly heavier than most bronze alloys | Electrical parts, plumbing |

| Density of Iron |

7.1 – 7.9 | Similar or slightly lighter than bronze | Machinery parts, automotive components |

| Density of Tin |

7.3 | Lighter than most bronze alloys | Coatings, soldering applications |

| Density of Tungsten |

19.3 | Much heavier than bronze | Counterweights, radiation shielding |

| Density of Silver |

10.5 | Heavier than bronze | Jewelry, electrical contacts |

| Density of Zinc |

7.0 – 7.2 | Generally lighter than bronze | Die-cast parts, hardware |

Bronze density isn’t fixed—it changes based on the alloy mix, added elements, manufacturing methods, cooling speed, and even internal porosity. These factors can increase or decrease bronze material density and directly affect bronze weight properties, machining behavior, and overall performance. Understanding them helps you choose the right bronze alloy for CNC machining, casting, or forging without facing unexpected weight or cost issues.

Table: Key Factors That Influence Bronze Density

| Factor |

How It Affects Bronze Density |

Practical Impact on Parts |

| Alloy Composition |

Different mixes of copper, tin, aluminum, or lead change bronze alloy density. | Alters weight, strength, and cost for CNC machined bronze parts. |

| Alloying Elements |

Elements like aluminum lower density, while tin or lead increase it. | Helps tailor bronze components for light or heavy applications. |

| Manufacturing Processes |

Casting may cause density variation; forging increases density by compacting grains. | Cast parts may be lighter; forged bronze gears are denser and stronger. |

| Temperature and Cooling |

Faster cooling can trap internal stresses; slower cooling produces more uniform density. | Affects durability and stability of bronze bushings and mechanical parts. |

| Porosity |

More pores = lower effective density; fewer pores = higher density. | High-porosity bronze castings may weaken under load. |

Bronze’s density plays a big role in how it performs in real applications. The weight, strength, and stability of bronze components depend heavily on their bronze material density and bronze specific gravity. When you choose a bronze alloy with the right density, you ensure smoother machining, better wear resistance, and longer part life in industries like marine, industrial machinery, energy, and automotive.

Industries and Applications

1. Marine Industry

2. Industrial Machinery

3. Automotive & Transportation

4. Aerospace

5. Electrical & Electronics

6. Energy & Power Equipment

7. Art, Sculpture & Architectural Design

Tip: Each application demands a density level that matches strength, corrosion resistance, and weight requirements—choose your bronze alloy based on real operating conditions, not just price.

Customer Background & Challenges

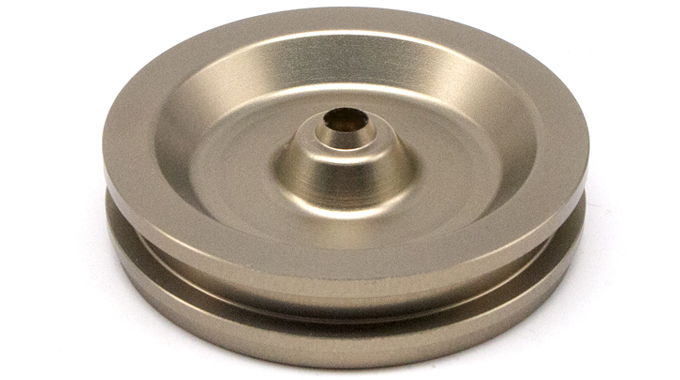

A North American industrial equipment manufacturer contacted VMT to produce a series of high-precision bronze CNC machined parts for their motion control system. These components required excellent wear resistance, thermal stability, and long-term dimensional accuracy due to their critical role in continuous mechanical movement.

Despite working with several suppliers previously, the customer struggled to achieve:

Bronze is known for its ductility and tendency to deform under cutting pressure, creating challenges such as burr formation, size inconsistency, and tool wear—issues that had caused delays and high rejection rates with their former vendors.

Our Solution & Breakthrough

VMT assembled an engineering team with extensive experience in copper-based alloys and performed a full manufacturability analysis. The project achieved success through several targeted solutions:

These technical breakthroughs enabled VMT to stabilize the machining process, eliminate deformation issues, and improve finish quality well beyond industry requirements.

Results & Customer Value

The customer experienced significant improvements in performance, quality, and cost-efficiency after partnering with VMT:

This project highlights VMT’s capability to handle challenging materials such as bronze and deliver exceptional precision, stability, and long-term value through professional CNC machining and engineering expertise.

Understanding the density of bronze is essential for choosing the right alloy, designing reliable components, and controlling machining or casting costs. Different bronze alloys—aluminum, phosphor, lead-tin, manganese, and others—have unique bronze material densities that affect strength, weight, and performance. By considering alloy composition, manufacturing methods, porosity, and cooling processes, you can optimize CNC machined bronze parts, bronze castings, and forged components for marine, industrial, automotive, or aerospace applications.

1. Is bronze denser than brass?

Bronze is usually slightly denser than brass, depending on the alloy composition. Bronze typically ranges from 7.4–8.9 g/cm³, while most brass alloys are around 8.4 g/cm³.

2. Which is heavier, brass or bronze?

It depends on the specific alloy. Some brass alloys can be heavier than certain bronze alloys, but most standard bronze alloys are slightly denser than common brass.

3. What is the density of bronze in pounds per cubic inch?

The density of bronze is approximately 0.27 to 0.32 lb/in³, depending on the alloy.

4. Why do we no longer use bronze?

Bronze is still used, but in many modern applications, steel, aluminum, and specialized alloys have replaced it due to cost, availability, or specific strength-to-weight requirements.

5. What are the three densest metals?

The densest common metals are tungsten (~19.3 g/cm³), gold (~19.3 g/cm³), and platinum (~21.4 g/cm³).

6. Are there any metals that do not rust?

Yes. Metals like aluminum, titanium, and stainless steel are highly corrosion-resistant. Bronze is also resistant to corrosion, especially in marine environments.

7. Which has a greater density, bronze or copper?

Copper is slightly denser than most bronze alloys. Copper’s density is about 8.9 g/cm³, while bronze ranges from 7.4 to 8.9 g/cm³ depending on the alloy.