15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

352 |

Published by VMT at Nov 13 2021

352 |

Published by VMT at Nov 13 2021

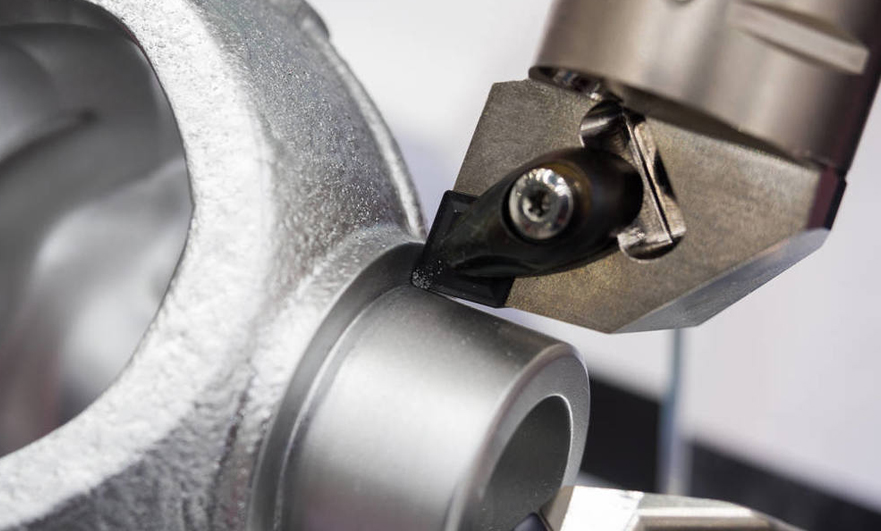

The milling cutter is one of the tools of CNC milling. The milling cutter is mainly used for CNC machining of planes, steps, grooves, forming surfaces and cutting workpieces on the milling machine. What do you know about CNC milling cutters? If you also have questions about CNC milling cutters, then you can follow our article to understand it!

1. The consideration factors and principles of CNC milling speed

The milling speed of CNC milling is too high, and the efficiency of CNC milling may not be significantly improved. On the contrary, it will accelerate the wear of the tool, thereby increasing the cost of the tool and the time cost of CNC milling; if the milling speed is too low, the efficiency of CNC milling will change significantly. Time will be wasted because of the difference, so choosing the appropriate CNC milling speed (or the number of spindle revolutions) is the correct way to give full play to the maximum benefit of the tool and the efficiency of CNC milling.

1. Timing to reduce the speed of CNC milling:

a.) To maintain the life of the CNC milling cutter, or if the tip strength of the angle milling cutter is small.

b.) When milling and cutting CNC milling parts with unstable installation.

c.) When the material of CNC milling parts is hard.

d.) CNC machining of high alloy materials, such as high nickel, high manganese and other materials.

e.) When sparks are emitted from the tool.

f.) Heavy cutting or cutting tool.

g.) When cutting black-skin parts or black-skin castings containing sand.

h.) When using high-speed steel cutters.

2. Timing to increase the speed of CNC milling:

a.) To obtain high-precision CNC machining surfaces.

b.) When the milling machine has good rigidity and the CNC milling parts are installed firmly.

c.) When the material of CNC milling parts is soft.

d.) During light cutting CNC milling.

e.) When the cutting agent is filled and the cooling condition is good.

f.) When using wear-resistant tools such as carbides.

2. Common problems of CNC milling cutters and their corresponding

1. How to solve the early wear of the milling cutter?

Answer: Wear is caused by improper speed, improper method and lack of tool maintenance. The solution is as follows:

a.) Reduce the cutting speed.

b.) If it is up-cut milling, change it to down milling.

c.) Increase the feed rate.

d.) Change dry milling to wet (using cutting fluid) and use it with a vortex tube gun to reduce the tool temperature to avoid overheating of the tool.

e.) If you are using a re-grinding end mill, the roughness of the CNC milled parts should be increased.

2. How to solve the tool breakage when cutting in or pulling out the CNC milling part?

Answer:

a.) It can be improved by reducing the feed rate and shallower cutting depth;

b.) Shorten the cutting edge to the minimum necessary length.

3. How to solve the tool breakage during normal CNC machining?

Answer:

a.) Use circular interpolation (NC machine tool), or temporarily stop (temporarily) feed.

b.) Passivation of CNC milling tools;

c.) Replace the clamp or spring chuck;

d.) Decrease (decrease) the feed before and after the direction change

e.) Change the high-blade count tool to a low-blade count;

f.) Improve chip evacuation and prevent chip blocking;

g.) Change dry CNC milling to wet (using cutting fluid);

h.) Use with vortex tube gun to reduce tool temperature to avoid tool overheating;

i.) When the liquid supply direction of wet milling is supplied from the front, change it to supply the liquid from the oblique rear or laterally above, and the coolant flow rate should be sufficient.

5. How to solve the partial breakage of the cutting depth interface?

Answer:

a.) Change down milling to up milling.

b.) Reduce the cutting speed.

6. How to solve the big chipping of the cutting edge?

a.) Reduce the feed rate of CNC milling processing;

b.) Change the number of high-edge tools to the number of low-edge tools;

c.) Improve chip evacuation and prevent chip blocking;

d.) Perform passivation chamfering or increase chamfering

3. Common problems encountered during CNC milling

1. The chips are short and thin, but there are sticky chips

Answer:

a.) Increase the cutting speed.

b.) Increase the feed rate or require cutting allowance.

c.) Carry out micro-round passivation treatment.

d.) Change from up milling to down milling.

e.) Change to wet type (using cutting fluid) and use it with a vortex tube gun to reduce the temperature of the tool to avoid overheating of the tool.

2. Concave and convex marks appear on the surface smoothness of CNC milled parts.

a.) Low-blade number tools change to high-blade number to improve surface fineness.

b.) Reduce the amount of feed.

3. The finishing size is too small

Answer:

a.) Reduce the cutting allowance.

b.) Increase the cutting speed.

c.) Replace the chuck or spring chuck.

d.) Change from up milling to down milling.

e.) Reduce the cutting depth of the end mill.

Summarize

These are some common problems and solutions in CNC milling. I hope this article can help you. VMT has 11 years of experience in CNC milling. If you need CNC machining services, you can contact us. We look forward to your new CNC milling project.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!