15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

1472 |

Published by VMT at Oct 06 2021

1472 |

Published by VMT at Oct 06 2021

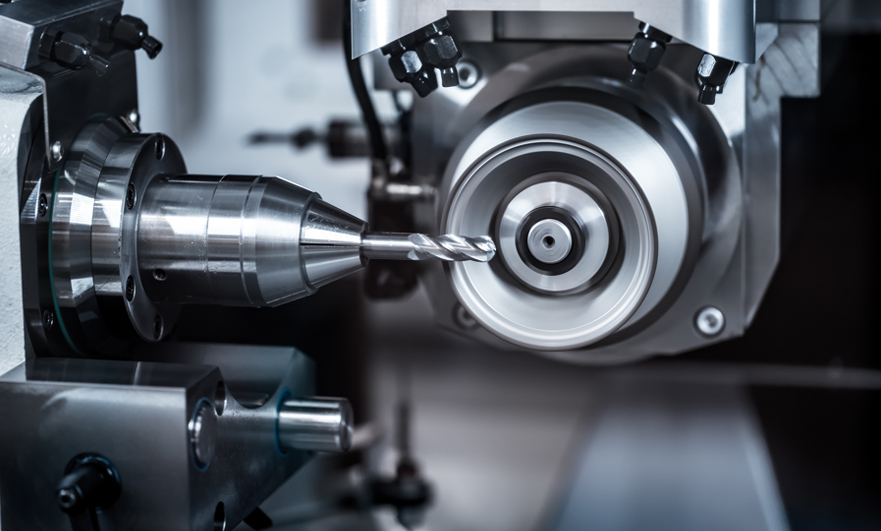

Hole milling is a common milling machine processing technology, CNC thread machining is also a common processing, this article will describe how to reasonably perform spiral interpolation on a CNC milling machine? What is spiral CNC milling?

What is spiral CNC milling?

Spiral CNC milling is a three-axis linkage of a CNC machine tool, which uses a thread milling cutter to perform spiral interpolation milling to form a thread. The tool moves in a circular motion on the horizontal plane and moves a thread pitch linearly in the vertical plane. Used to produce spiral parts such as helical gears, spiral groove milling cutters, twist drills and oblique cam grooves.

What is spiral interpolation?

A type of CNC milling technology that can replace drilling when creating holes. Helical interpolation is a fast, economical and universal operation. It is programmed by using CAM software to add z-axis motion to simple circular interpolation commands, including synchronous circular motion on X and Y axes and The axial feed is performed on the z-axis with the defined pitch.

Use of spiral interpolation

1. Spiral CNC milling: Use a milling cutter to mill threads down the spiral, which is very suitable for machining threads in hard materials such as titanium.

2. Generate holes: Spiral CNC milling is a simple way to open existing holes or make flat-bottomed holes instead of using a drill.

3. Circular ramp: Cut into the depth before machining features such as grooves or grooves, and even use it to start cutting the contour to cut the tool into the depth.

Spiral interpolation program example

The helical interpolation program is programmed through arcs. The helix is a series of G03 arc commands that create shapes when the arc is curled and descended. During the operation, the X, Y, and Z axes move at the same time. Their programming is also unique. Here are their programming examples:

N6 T0606 (40MM end mill);

M06;

G90 G54 G21 G17 G80 G43;

S1000 M03;

G00 X0.0 Y0.0

Z1.0 M08;

G01 Z0.1 F200.0;

G03 X60.0 Y0.0 Z-2.0 R30.0;

G03 X0.0 Y0.0 Z-4.0 R 30.0;

G03 X60.0 Y0.0 Z-6.0 R30.0;

G03 X0.0 Y0.0 Z-8.0 R30.0;

G03 X60.0 Y0.0 Z-10.0 R30.0;

G03 X0.0 Y0.0 R30.0;

G03 X60.0 Y0.0 R30.0;

G00 X30.0 Z1.0;

Z50.0 M09;

G53 X0.0 Y0.0 Z0.0 M05;

G40;

M01;

Summarize

The spiral CNC milling process can process holes of different diameters and high quality with only one tool, which not only reduces the tool change time, but also saves the finishing process and greatly improves the work efficiency.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!