15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

135 |

Published by VMT at Mar 15 2024

135 |

Published by VMT at Mar 15 2024

Common Issues in Plastic Product Structural Design and Their Impact on CNC Machining Parts Manufacturing

Plastic products, integral to modern industry, find extensive applications across various fields. In the realm of CNC machining part manufacturing, the structural design of plastic products significantly influences product performance, processing efficiency, and lead time delays. This article explores several common issues in plastic product structural design, analyzing their impact on CNC machining part production and lead times, while proposing specific solutions and recommendations.

I. Issue of Design Complexity

The complexity of structural design in plastic products is a crucial factor affecting CNC machining efficiency and lead times. Complex designs often necessitate additional machining processes and extended processing times, increasing the risk of lead time delays. For instance, plastic parts with intricate internal structures may require more cutting and polishing operations, lengthening processing time and potentially escalating tool wear and maintenance costs.

Solutions and Recommendations:

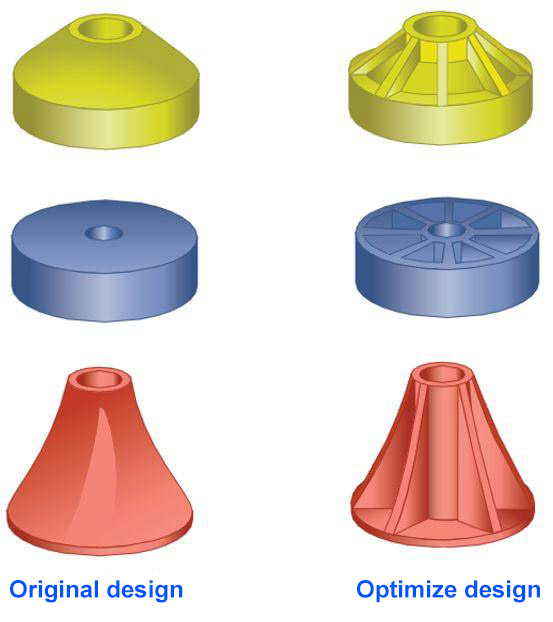

Modular Design: Break down complex product structures into simpler modules, design and machine them separately, and then assemble them. This approach reduces the machining difficulty of individual components, enhancing processing efficiency.

Simplify Design Features: Avoid overly complex design features, such as deep holes or thin walls, to reduce machining difficulty and time.

Use CAD/CAM Software: Leverage advanced CAD/CAM software for assisted design, simulating machining processes, predicting potential issues, and optimizing designs.

II. Material Selection Issue

The choice of material for plastic products is crucial for both processing performance and the final product's properties. Different plastic materials exhibit varying characteristics in terms of hardness, toughness, wear resistance, and thermal stability, directly impacting the difficulty and efficiency of CNC machining. For instance, high-hardness or high-toughness plastic materials may require advanced tooling and machining parameters, potentially increasing processing costs and extending lead times.

Solutions and Recommendations:

Define Performance Requirements: Clearly define the required performance of the product, such as hardness, toughness, and wear resistance, at the design stage to facilitate the selection of suitable plastic materials.

Consider Machinability: Choose plastic materials that are easy to machine, possessing good cutting characteristics and thermal stability to reduce machining difficulty and costs.

Collaborate with Suppliers: Establish close collaborations with plastic material suppliers to stay informed about the latest material advancements and applications, enabling the timely adoption of suitable new materials.

III. Tolerance Fit Issues

The reasonableness of tolerance fits in plastic product structural design is crucial for assembly and performance. Inappropriate tolerance fits may lead to difficulties during assembly and even result in suboptimal product performance. In such cases, rework or redesign may be necessary, increasing the risk of lead time delays and additional costs.

Solutions and Recommendations:

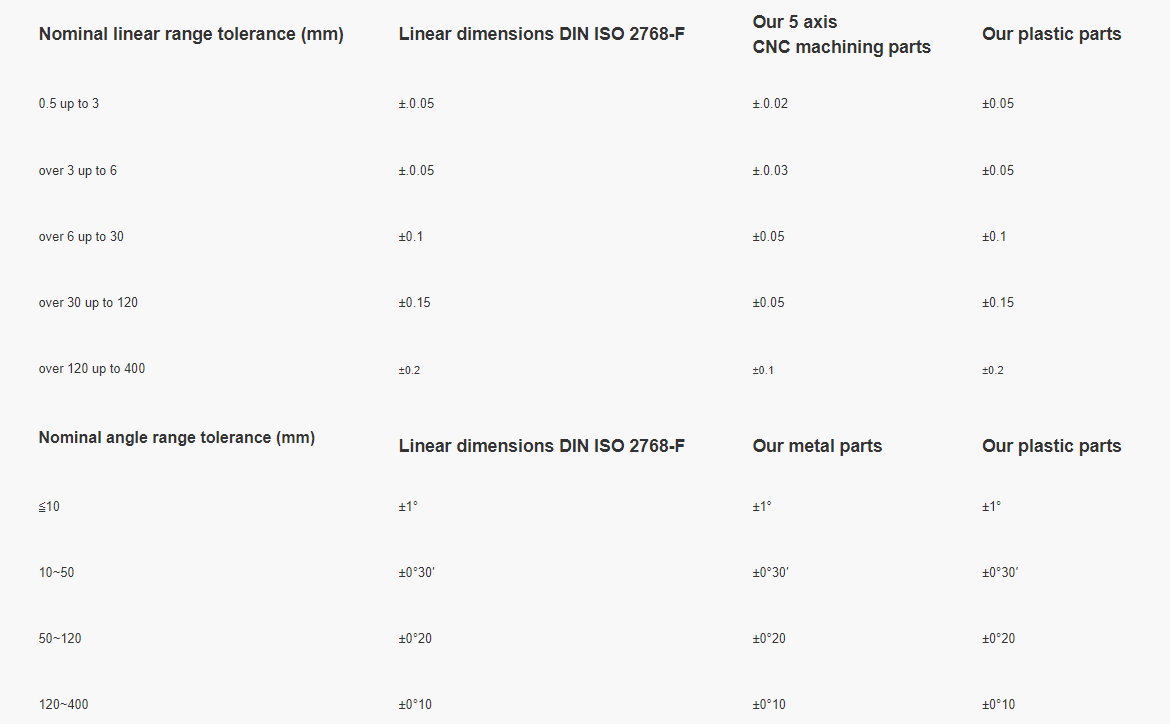

Establish Strict Tolerance Standards: Develop strict tolerance standards based on product performance requirements and assembly specifications to ensure that clearances between components fall within reasonable ranges.

Utilize Advanced Measurement Equipment: Employ advanced measurement equipment to precisely measure machined components, ensuring that tolerances align with design requirements.

Establish Feedback Mechanism: Implement a feedback mechanism during assembly to promptly identify and address tolerance fit issues, avoiding impacts on overall product performance.

IV. Surface Treatment Issues

Surface treatment of plastic products significantly affects their appearance, wear resistance, and corrosion resistance. However, certain surface treatment methods may be incompatible with the characteristics of plastic materials or may lead to quality issues during machining. For instance, some plastic materials may exhibit poor adhesion or surface roughness deviations during processes like painting or electroplating, requiring additional treatment or rework and increasing the risk of lead time delays.

Solutions and Recommendations:

Select Appropriate Surface Treatment Methods: Choose surface treatment methods compatible with the characteristics of the plastic material, such as painting, electroplating, anodizing, etc.

Pre-treatment of Components: Prior to surface treatment, perform necessary pre-treatment on plastic components, such as cleaning, degreasing, and rust removal, to ensure optimal treatment results.

Control Surface Treatment Processes: Strictly control process parameters and environmental conditions during surface treatment to ensure stable and reliable treatment quality.

V. Thermal Expansion Issue

Plastic products may undergo thermal expansion or contraction with temperature changes, potentially altering clearances between structural components. Failure to adequately consider this factor during design may lead to diminished product performance or damage during use. Therefore, in the structural design of plastic products, it is crucial to predict and control the effects of thermal expansion to ensure product stability and reliability.

Solutions and Recommendations:

Predict Thermal Expansion: Early in the design process, predict the temperature range and thermal expansion of the product during use to incorporate appropriate clearances in the design.

Use Materials with Good Thermal Stability: Select plastic materials with good thermal stability to minimize the impact of temperature changes on product structures.

Design Compensating Structures: Integrate compensating structures at critical points, such as using elastic elements or adjustable connections, to absorb deformations and stresses caused by thermal expansion.

VI. Impact on CNC Machining Factories

Issues in plastic product structural design not only affect product performance and processing efficiency but also have profound implications for CNC machining factories in terms of production planning, resource utilization, and cost control. Lead time delays may prevent factories from completing orders on time, impacting customer satisfaction and the company's reputation. Additionally, design issues may lead to additional processing costs, tool wear, and maintenance costs, further increasing operational expenses for the factory.

VII. Solutions and Recommendations

To address issues in plastic product structural design, solutions and recommendations can be proposed in the following areas:

Optimize Design Processes: Introduce advanced design software and tools to improve design efficiency and quality, reducing design errors and rework rates.

Select Materials Reasonably: Based on product performance and processing requirements, choose suitable plastic materials to lower processing difficulty and costs.

Optimize Tolerance Fits: Consider the reasonableness of tolerance fits in the design, ensuring that products can be smoothly assembled.

Improve Surface Treatment Methods: Choose compatible surface treatment methods and implement pre-treatment to enhance the quality of surface-treated plastic products.

Consider Thermal Expansion Factors: Adequately consider the effects of thermal expansion during design, incorporating compensating structures and selecting materials with good thermal stability.

In conclusion, issues in plastic product structural design have a significant impact on CNC machining part production and lead times. By optimizing design processes, selecting materials wisely, optimizing tolerance fits, improving surface treatment methods, and considering thermal expansion factors, the risk of lead time delays can be effectively reduced, enhancing product quality and processing efficiency. Additionally, this requires CNC machining factories to strengthen communication and collaboration with design departments, ensuring the feasibility and practicality of design solutions.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!