15 years one-stop China custom CNC machining parts factory

33 |

Published by VMT at Dec 01 2025 | Reading Time:About 2 minutes

33 |

Published by VMT at Dec 01 2025 | Reading Time:About 2 minutes

If you’re choosing a material for a part's design, will you imagin that the part will maintain its shape under actual working conditions without permanent bending? Or you may think about whether it will deform under load but not break? Or you are worried that it will fail by breaking directly under extreme conditions? To answer these practical questions , you’ll need to learn about the difference between yield strength and tensile strength.

This article will guide you through the difference between yield strength and tensile strength from the perspectives of definition, stress-strain curves, and their impact on part structural design. After reading, you will understand why yield strength and tensile strength are two important evaluation references in industry.

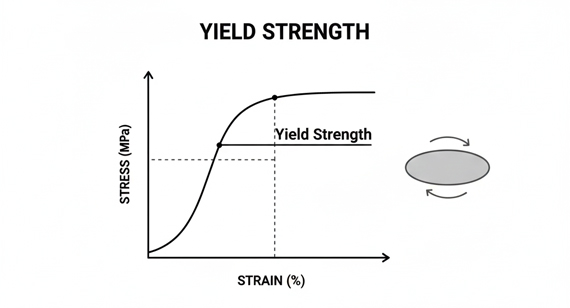

Yield strength refers to the stress a material can withstand before undergoing permanent deformation—the critical point at which a material cannot return to its original shape after bending or stretching. It corresponds to the strength against yielding criterion.

For example, a metal ruler: if bent gently, it will return to its original shape; this is the elastic stage. If bent with excessive force, it will undergo permanent deformation; this is because of stress over the yield strength.

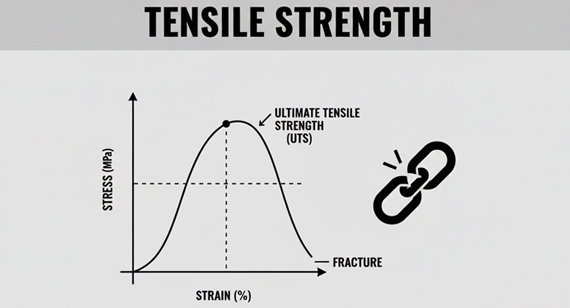

Tensile strength, also known as ultimate strength, fracture strength, or breaking strength, is the maximum stress a material can withstand before it completely fractures. It corresponds to the strength against fracture criterion.

For example, a deformed metal ruler: if forcibly bent further, it will break; this is because of stress over the tensile strength.

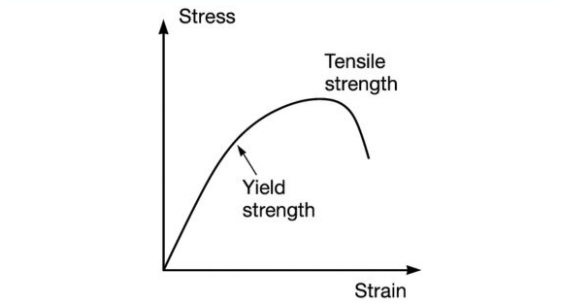

To understand the yield strength and tensile strength, you may need to learn about some basics of the stress-strain curves.

Stress refers to the external force acting on the molecules in a given material; strain refers to the extent of deformation of the material due to the external force.

Yield strength is the point on the tensile curve where it begins to deviate from linearity, showing the minimum force required to produce permanent deformation.

Tensile strength is the maximum peak value on the tensile curve, showing the maximum stress the material can withstand.

It can be seen from the figure that yield strength is always lower than tensile strength.

The zone between yield and tensile strength is the plastic deformation zone. In this zone, the material can still withstand greater forces, but its shape is no longer reversible.

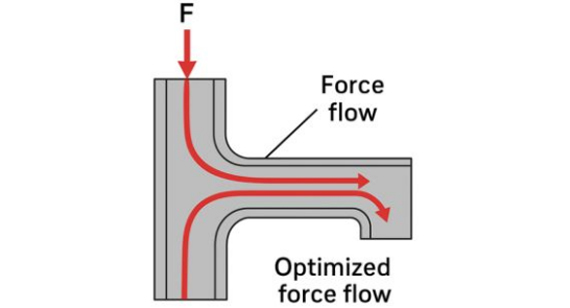

In part structural design, material selection affects the safety and effectiveness of your project. Here I divide materials into ductile and brittle materials to discuss how yield strength and tensile strength affect the structural design of parts.

For the ductile materials(controlled by yield strength )

Ductile materials emphasize plastic development, energy dissipation capacity, and seismic performance. Upon reaching the yield point, it doesn't immediately fracture but continues to develop plastically, requiring further stress until fracture (tensile strength). For ductile materials, the structure is usually controlled by the yield strength.

For the brittle materials(controlled by tensile strength)

Brittle materials emphasize crack prevention, strength, and avoiding sudden break. Upon reaching the yield point, it fractures quickly (tensile strength). For brittle materials, structures are typically controlled by tensile strength (or bending/compressive limits).

To further illustrate how yield strength and tensile strength affect part structural design to you, here I take aluminum alloy parts (ductile materials) and zinc alloy die castings (relatively brittle) as examples.

Example: Controlled By Yield Strength

Suppose you are designing an aluminum alloy (ductile)mobile phone structural component. You’ll find that aluminum alloy has good ductility and undergoes some plastic deformation before fracture—it is a "warning sign."

During the design process, you’ll consider to prevent your aluminum alloy mobile phone structural component from yielding under forcing loads; otherwise, the deformation will be irreversible.

Therefore, your design should verify the strength based on yield strength.

The yield strength and tensile strength of aluminum alloy are (e.g., 6061-T6: σy≈276 MPa, σu≈310 MPa). So, you should consider that the forces generated in the application scenario will not exceed 276 MPa.

To prevent premature yielding of your aluminum alloy mobile phone structural components, you should consider:

Example: Controlled By Tensile Strength

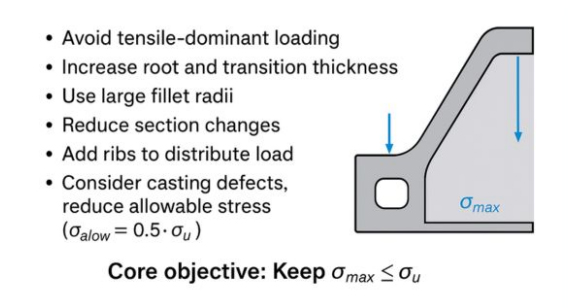

Suppose you are designing a zinc alloy die-cast part(brittle), such as a small bracket. You’ll find that it usually doesn't yield first, but may suddenly fracture brittlely directly in the tensile principal stress region—it is "without warning."

Therefore, your design focus is on tensile strength as the primary strength metric.

Taking Zamak 3 zinc alloy as an example, its yield strength and tensile strength are approximately σy≈210 MPa and σu≈280 MPa, respectively. However, due to defects such as porosity and shrinkage cavities often present in castings, the effective tensile strength may be much lower than the nominal value.

Therefore, in your design, you must ensure that the maximum equivalent principal tensile stress generated by the part in the application scenario is far below 280 MPa (and may even need to be multiplied by a defect reduction factor of 0.5–0.7).

To prevent sudden brittle fracture in zinc alloy die castings, you should:

The core objective of these measures is to keep the part away from the upper limit of fracture stress (σmax ≪ σu) under tensile principal stress, thus avoiding brittle fracture.

Beside from the above explanations and comparisons of Yield Strength and Tensile Strength in terms of definition, stress, and structural design, here noted the temperature.

Temperature changes affect both yield strength and tensile strength. As temperature increases, intermolecular forces weaken, making the material more prone to deformation/fracture; and, temperature has a greater impact on yield strength.

The table below summarizes the differences between yield strength and tensile strength.

Table: Differences Between Yield Strength and Tensile Strength

| Item | Yield Strength | Tensile Strength |

| Definition | The stress at which a material begins to undergo permanent plastic deformation. | The maximum stress a material can withstand before complete fracture. |

| Also Called | Yield Point / Yield Stress | Ultimate Tensile Strength (UTS) |

| Material Behavior | Material starts to bend or deform permanently. | Material reaches its maximum load and then breaks. |

| Relative Magnitude | Always lower than tensile strength. | Always higher than yield strength. |

| Intermolecular Forces Interpretation |

Intermolecular forces are stronger than the applied stress → bonds stretch but do not break; dislocation movement begins. | Applied stress exceeds intermolecular forces → internal bonds break, leading to fracture. |

| Effect of Temperature |

Increases in temperature weaken intermolecular bonding → yield strength decreases (material becomes easier to bend or deform). | Tensile strength also decreases with temperature, but usually less sharply than yield strength for many metals. |

| Use in Structural Design |

Critical for ductile materials (e.g., steel, aluminum). Used to prevent permanent deformation. | Critical for brittle materials (e.g., cast iron, ceramics). Used to prevent fracture. |

| Identification in Stress–Strain Curve |

Point where the curve deviates from linearity (start of plastic deformation). | Peak of the curve (maximum stress before necking and fracture). |

| Engineering Significance |

Controls shape integrity — preventing permanent bending. | Controls failure integrity — preventing catastrophic break. |

Yield strength and tensile strength determine strain of the material or parts under external forcing loads and are important references for component structural design.

VMT's professional team has extensive experience in the component structural design. Our engineers conduct professional evaluations of yield strength, tensile strength, and other mechanical properties to complete high-quality prototype designs.

Whether it's material selection, prototyping, or mass production, VMT CNC machining factory can provide fast, reliable manufacturing support for your projects. Contact VMT experts for a free consultation or quotation.

Is the yield strength of steel greater than its ultimate tensile strength?

No. Yield strength is always lower than ultimate tensile strength. The yield strength of low-carbon steel is typically about 30% to 40% lower than its ultimate tensile strength; for other steels, it depends on crystal structure, composition, alloying, etc.

How to calculate yield strength from tensile strength?

Yield strength can be estimated from tensile strength by using the 0.2% offset method. The yield strength is typically lower than the tensile strength and is determined by finding the stress at which a material undergoes permanent deformation (usually marked by a 0.2% offset strain).

What is 0.2% yield strength?

0.2% yield strength is the stress at which a material will experience permanent deformation of 0.2% strain. This is commonly used as an approximation of the yield point for materials that do not exhibit a clear elastic-plastic transition.

What is the difference between YS and UTS?

Can yield strength be higher than tensile strength?

No, yield strength cannot be higher than tensile strength. Yield strength marks the onset of permanent deformation, whereas tensile strength represents the maximum load a material can bear before breaking. Tensile strength is always greater than or equal to yield strength.

What are the three types of tensile strength?

The three types of tensile strength are:

Which metal has the highest yield strength?

Titanium alloys and tungsten generally have the highest yield strengths among metals. Titanium alloys, especially Ti-6Al-4V, are commonly used in aerospace due to their strength-to-weight ratio, while tungsten has exceptional strength at high temperatures.

What is the difference between the ratio of yield strength to tensile strength?

The ratio of yield strength to tensile strength gives insight into the ductility of a material. A higher ratio indicates that the material does not deform easily before failure, while a lower ratio suggests that the material has a greater ability to deform plastically before fracture.

What does UTS measure?

UTS (Ultimate Tensile Strength) measures the maximum tensile stress a material can withstand before breaking. It indicates the material's resistance to fracture under a stretching force.

What is the difference between tensile strength and ultimate tensile strength?

There is no difference between tensile strength and ultimate tensile strength (UTS); both terms refer to the same property, which is the maximum stress a material can handle before breaking. "Tensile strength" is the more general term, while "ultimate tensile strength" is often used in material science and engineering.