15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 02 25

2025 02 25 6082 aluminum alloy is a high-strength material commonly used for CNC machining parts in various industries. It is known for its excellent corrosion resistance, strong mechanical properties, and good machinability. These qualities make it perfect for custom CNC machining applications that require robust, long-lasting components. Whether you're in need of structural parts, marine components, or aerospace machinery, 6082 aluminum alloy CNC machining parts offer a versatile, reliable solution.

66

66

Read more

Read more

VMT

VMT  2025 02 24

2025 02 24 Gear manufacturing is an essential aspect of many industries, from automotive to aerospace, and even small appliances. Gears are mechanical components that transmit torque and motion between machine parts, often converting speed or direction to optimize machine function. Without gears, many of the systems we rely on would simply not work—imagine your car’s transmission, an industrial conveyor, or the mechanisms inside a clock.

66

66

Read more

Read more

VMT

VMT  2025 02 23

2025 02 23 Metal casting defects, such as porosity, shrinkage, and slag inclusions, can compromise the quality of your parts. These issues arise from various factors, including mold material, heat, and metal flow. By identifying the defect types and their causes, manufacturers can implement effective remedies to prevent them, improving the overall production process. Regular inspections and precision techniques can minimize casting defects, leading to more efficient and cost-effective manufacturing.

66

66

Read more

Read more

VMT

VMT  2025 02 22

2025 02 22 Metal casting is a manufacturing process where molten metal is poured into a mold to create parts or products. It offers unmatched versatility and can accommodate a wide range of materials, from steel to magnesium. The process can be adapted for both high-precision CNC machining services and larger industrial components. Whether it's for automotive parts or intricate jewelry, metal casting is a cost-effective and reliable solution.

66

66

Read more

Read more

VMT

VMT  2025 02 21

2025 02 21 Casting is a manufacturing process where molten material, typically metal, is poured into a mold to solidify and form a specific shape. It is widely used in the production of complex shapes that would be difficult or expensive to create using other methods, such as machining. The process involves heating a metal to its molten state, pouring it into a pre-designed mold, and allowing it to cool and solidify into the desired shape.

66

66

Read more

Read more

VMT

VMT  2025 02 20

2025 02 20 6061 aluminum is known for its excellent machinability and moderate strength, making it ideal for a wide range of general-purpose applications. In contrast, 6082 aluminum is stronger and offers better corrosion resistance, making it a more robust choice for applications requiring higher strength and durability. When deciding between these two alloys, understanding their distinct characteristics is key.

66

66

Read more

Read more

VMT

VMT  2025 02 19

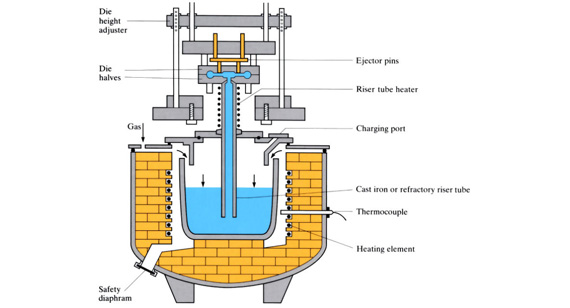

2025 02 19 Low-pressure die casting is a manufacturing process where molten metal is injected into a mold under low pressure, ensuring precise control of material flow. This process is best suited for producing high-quality castings with excellent surface finishes. By utilizing low-pressure die casting, businesses can achieve parts with superior mechanical properties, reduced porosity, and enhanced durability—an ideal solution for industries requiring high-precision components.

66

66

Read more

Read more

VMT

VMT  2025 02 18

2025 02 18 The casting process involves pouring molten metal into a mold to shape a part. Choosing the right casting method depends on factors such as the part's complexity, material type, and volume requirements. For high-precision CNC prototype machining and casting CNC machining parts, it's essential to understand the pros and cons of each method to make informed decisions that lead to successful production outcomes.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!