15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 21 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 21 2026 | Reading Time:About 2 minutes

Choosing the correct alloy early in product development saves time, cost and headaches. For parts whose primary manufacturing demands are sheet-metal forming — extensive bending, stretching or deep drawing — and that must resist corrosive environments, Aluminum 3003 often offers the best combination of formability, corrosion resistance and cost. And only when the CNC shop’s role is limited to secondary operations such as drilling, countersinking or light contouring and further complete the parts with various surface finishes, 3003 delivers excellent outcomes for a final product. This guide explains when 3003 aluminum is appropriate for your manufacturing, how to design for it, what to expect in CNC secondary processing, finishing options and procurement advice—based on VMT’s shop experience.

Aluminum 3003 is an aluminum–manganese alloy (AlMn) that is not heat-treatable. It typically contains about 96.8 to 99% Aluminium, 1–1.5% Manganese, with small amounts of other trace elements. 3003 aluminum alloy has many advantages that make it useful for many non-structural and lightly loaded components, and key properties include:

Common use cases where 3003 truly excels include appliance interiors and panels, HVAC louvers, decorative trims, light-duty brackets and other items that need good formability, corrosion resistance and attractive finishing at a controlled cost.

For there are annealed states for these three, several heat treatment tempers of aa 6061, and strain hardening tempers of aa 3003 and aa5052 , detail properties of them you may check matweb or azom. Here I just list a relative comparison of aa 3003 vs. 5052 vs. 6061, highlighting key properties of general strength, formability, and machinability which affects their metalworking the most:

Table 1: Comparison For 3003 vs 5052 vs 6061 Aluminum Alloy’s Key Properties

| Properties | AA3003 | AA5052 | AA6061 |

| Primary Alloy |

Manganese | Magnesium | Magnesium & Silicon |

| Strength |

Low to Moderate | Medium to High | High (Heat-Treatable) |

| Formability |

Excellent | Very Good | Fair (but crack on tight bends) |

| Corrosion Resistance |

Good (Atmospheric) | Excellent (Marine) | Good (General) |

| Machinability |

Good (but gummy) | Fair (galls cutters) | Excellent |

| Heat Treatable |

No | No | Yes |

Why is Formability the key to 3003 Aluminum?

You can tell 3003 aluminum vs 6061 formability that aa3003 is far more flexible than AA6061.This is mainly because aa6061’ alloy elements of magnesium and silicon form the strengthening phase Mg2Si to heavily increase it strength while aa3003’s strengthen element of manganese won’t damage it’s plasticity. Another reason is that aa3003 can only be strengthened by physical strain while aa6061 can largely increase its yield strength by heat treatment—Artificial aging induces the precipitation of numerous fine particles to impede dislocation movement. Thus, deep drawing, spinning, and complex bending is what you can easily get from aa3003 while aa6061 for it’s high strength and far more good machinability is widely used for CNC machining into general structural parts.

Although 3003 aluminum vs 5052 formability are both good for sheet metal fabrication, and this is true for aa5052 is also good for deep drawing, spinning, and complex bending. But you can find better performance of aa5052 especially its marine grade corrosion resistance due to the more expensive Magnesium(2.2%-2.8% Mg) than aa3003’s Manganese(1.0 -1.5% Mn). Thus, 3003 aluminum sheet metal fabrication is a more affordable choice as long as your products won’t be used in the marine environment. You may use AA5052 if the part is primarily sheet metal (bent, welded, or formed) or if absolute maximum corrosion resistance is the only priority.

To maximize the benefits of 3003 aluminum’s ductility, you may follow specific Design for Manufacturing (DFM) principles. For this alloy is "soft", it behaves differently under pressure.

If aa3003 is so great for forming, why involve CNC at all? The reality of modern product design is that “forming” provides the "shape," but CNC provides the "precision."

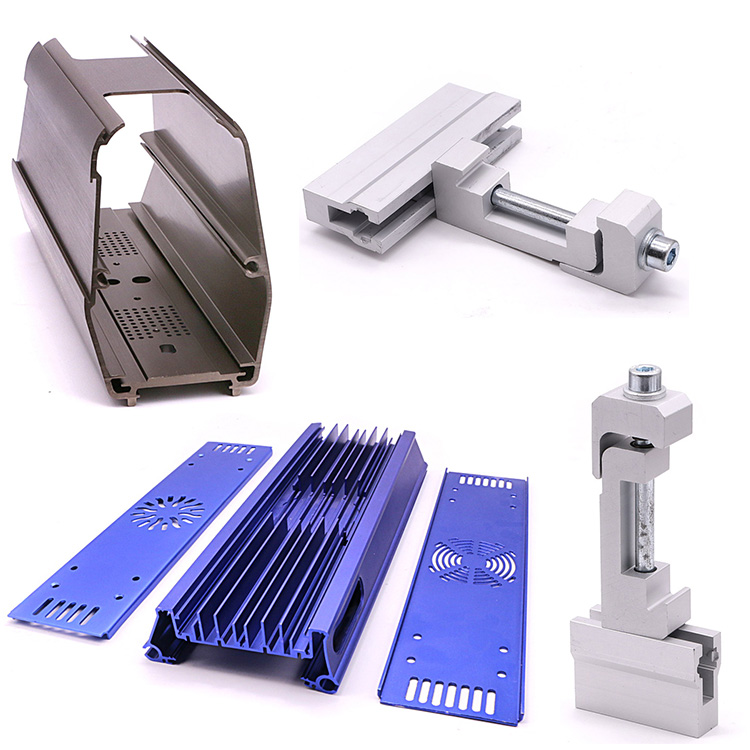

Sheet metal processes like stamping or bending usually have tolerances of ±0.2mm to ±0.5mm. For many applications—such as mounting high-end electronics, creating airtight seals, or interlocking mechanical assemblies—this isn't precise enough. So, for your already formed 3003 aluminum parts, you can use CNC as an auxiliary process to:

In the CNC workshop, 3003 aluminum is often described as "gummy" or "sticky." Because it is soft and has a lower melting point during friction, it tends to weld itself to the cutting tool, leading to Built-Up Edge (BUE) and poor surface finishes.

At VMT, we use several strategies to ensure high-quality CNC results on aa3003, and these strategies may be taken for your reference:

Once the aa3003 part is formed and CNC-machined, a further processing step is finishing. 3003 aluminum reacts well to various finish treatments, and here you can check the options and effects by each one from below table:

Table 2: Surface Finishing Options for 3003 Aluminum

| Finishing Option |

Effect on 3003 Aluminum |

Best Use Case |

| Clear Anodizing |

Provides a protective oxide layer. May appear slightly "milky" compared to 6061. | Corrosion protection for HVAC or enclosures. |

| Color Anodizing |

Absorbs dyes well, but colors may be less "vibrant" than on 6xxx series. | Identification or decorative trims. |

| Powder Coating |

Excellent adhesion. Completely hides the grain of the metal. | Consumer appliances and outdoor equipment. |

| Brushing/Satin |

Hides minor scratches from the forming process. | High-end kitchenware and decorative panels. |

| Chromate Conversion |

Excellent for paint adhesion and electrical conductivity. | Internal electronic brackets. |

When sourcing 3003 aluminum for a project that involves both forming and CNC machining, you can keep these three practical tips in mind:

Aluminum 3003 wins on its formability and cost-efficiency. It is the ideal choice when your product's integrity relies on complex sheet-metal shapes, and your precision needs are handled by secondary CNC operations.

Need expert advice on your next 3003 aluminum project? Contact the VMT team today. Our combined expertise in sheet metal forming and precision CNC machining ensures your design transition from CAD to reality is seamless and cost-effective.

A consumer appliance company required a control panel and internal bracket system for a new countertop appliance. The panels needed a premium appearance, corrosion resistance for kitchen environments, and moderate forming. The material was specified as 3003-O sheet, thickness 1.0 mm, volume 8,000 parts.

Will 3003 anodize well?

Yes — 3003 can be anodized, but the presence of manganese and other alloying elements can make dye uptake less uniform and produce different shades versus high-purity alloys. Always run color samples before full production.

What temper should I specify for bending?

If your design requires tight bends or deep draws, specify O temper (annealed). If you specify H14/H16, expect greater springback and less ductility — this may require larger bend radii and adjusted tooling.

Is CNC machining 3003 likely to create burrs or tool-weld issues?

Aluminum can form built-up edge (BUE) and long stringy chips; that is manageable with sharp tooling, proper feed/speed, good chip evacuation and air or mist cooling. Burrs are common around drilled holes and milled edges — specify deburring or chamfering on the drawing or plan for a secondary deburring operation.

For thin sheet parts, should I use PEM inserts or tapped holes?

For thin sheets under ~3 mm where thread engagement is shallow, use PEM self-clinching fasteners, rivet nuts or threaded inserts to ensure reliable assembly strength. Tapped threads in thin 3003 often fail to provide durable torque resistance.

Can I machine holes before forming to save time?

It’s ok but not recommended for the holes in blanks may shift or distort during forming. For tight positional tolerances, plan for post-form drilling and use punched locator holes for fixture alignment.

How do I avoid tearing during drawing for processing 3003 aluminum?

Control blank holder pressure, die radius and lubrication. Design part geometry with gradual transitions and add reliefs at high-strain points. Use 3003-O for maximum drawability.