15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 20 2026 | Reading Time:About 4 minutes

0 |

Published by VMT at Jan 20 2026 | Reading Time:About 4 minutes

This article is intended for engineers and manufacturing customers in the CNC machining and metalworking fields. From here, you can get a clear understanding that: what is the basics about aluminum alloy 5052? How does aluminum alloy 5052 strengthen its strength? What are processing ways to alloy 5052’s annealed O, H12, H18, H24, H32, H34 tempers? What are the pros and cons as well as uses for each temper? About several manufacturing ways, what you may pay attention to when you deal with the processing? Below information will assist you in making decisions regarding quotations, process selection, and quality control.

5052 is an aluminum-magnesium alloy (Al-Mg series), with magnesium (Mg, approximately 2.2–2.8%) as the main alloying element and a small amount of chromium (Cr, approximately 0.15–0.35%). Magnesium is the main strengthening agent, and chromium inhibits grain recrystallization and improves durability. As a typical non-heat-treatable aluminum alloy (Aluminum Association Industry Standards), its strength is primarily enhanced through cold working (strain hardening, such as cold rolling and cold drawing). Its key properties include:

Due to these excellent characteristics, 5052 aluminum can be found in applications such as ship components, fuel and oil tanks, pressure vessels, truck/trailer panels, appliance housings, electronic and instrument enclosures, HVAC, and food equipment. For the above uses, a wide range of supply forms also allows it to be adapted to various processing methods:

Only tempers starting with T (such as T4, T6, T7) undergo heat treatment through solution treatment and aging (precipitation hardening). The number after T represents a specific heat treatment combination/solution.

AA 5052 aluminum is cold-worked (physically extruded/drawn), and its strength variations stem from the combination of the degree of cold working (H) and the degree of annealing. H1x refers to pure cold hardening, H2x refers to partial annealing/tempering after cold hardening, and H3x usually refers to stabilization after cold hardening.

The second digit after H (e.g., 6 in H16) measures the strength level:

Now, you can find what’s the number means of 5052 aluminum’s H12、H18、H24、H32、H34.The following sections are more detailed introduction for 5052 aluminum’s O, H12、H18、H24、H32、H34.

Among all the temper conditions, the 5052 aluminum alloy exhibits significant performance differences, and the O-temper (annealed) is widely used in many fields due to its excellent ductility and formability.

What is 5052 Aluminum Alloy O Temper?

5052 aluminum alloy in the O-temper is achieved by heating cold-worked aluminum material to an annealing temperature (approximately 345°C) and controlling the cooling rate to allow the metal grains to soften, thereby completely eliminating the processing stresses. At this stage, 5052-O is the softest and most ductile state with the lowest hardness (HB 45-50) of all temper conditions. It has a typical tensile strength of about 70-120 MPa (depending on thickness and alloy batch) and can have an elongation rate as high as 25-30% or even higher.For more specific property data,you may refer to “Aluminum 5052-O”

What are the best processing methods for 5052-O?

The best processing methods for 5052-O aluminum alloy are sheet metal machining—the cold working. If your parts primarily require sheet metal forming, such as bending, stamping, or spinning, as well as deep drawing or complex forming, 5052-O is the preferred choice. If higher strength is needed after forming, cold working can be used to achieve the required mechanical properties in an H-temper. CNC machining is generally not recommended for , unless only light cutting is needed with special processing measures. However, 5052-O 5052-O aluminum is excellent for applications where appearance is important, such as complex instrument housings, and is ideal for anodizing and painting to achieve a uniform, attractive surface finish.

What are the advantages of 5052-O?

What are the disadvantages of 5052-O?

Where is 5052-O used?

5052-O is typically used in applications that require excellent formability but moderate strength, such as:

5052-H12 aluminum alloy is in the "quarter hard" (1/4 hard) state, achieved through approximately 10%-15% cold working of annealed aluminum material, resulting in pure strain hardening. This temper provides an excellent balance between "high formability" and "structural rigidity," making it suitable for applications that require both strength and good formability. Compared to the O-temper, 5052-H12 has a yield strength of approximately 100-120 MPa, more than twice that of the annealed (O) state, while still maintaining good elongation (about 10%-15%).

This alloy is especially advantageous in CNC machining, where it provides smooth chip removal and resists tool adhesion, making it ideal for parts requiring precision and high strength. Additionally, it resists cracking during sheet metal bending operations, providing an excellent combination of corrosion resistance, especially in marine environments, and moderate hardness. It is commonly used in applications requiring complex bending and forming, as well as some structural elements that demand certain load-bearing capabilities, such as marine equipment, automotive body panels, and precision sheet metal components. For more specific property data,you may refer to “Aluminum 5052-H12”.

What metalworking methods are suitable for 5052-H12 aluminum alloy?

Sheet Metal Forming: 5052-H12 is particularly well-suited for sheet metal processes like bending and punching. It can undergo conventional forming operations, but it is important to note that the springback during bending may be slightly higher compared to the O-temper.

CNC Machining: It is suitable for certain CNC machining operations, especially for thin-sheet components. Due to its higher strength compared to the O-temper, it is well-suited for parts that require higher strength without sacrificing formability.

Does 5052-H12 share any advantages with O-temper?

Like 5052-O, 5052-H12 aluminum alloy is highly compatible with various surface treatments. The most recommended treatment is hard anodizing, which enhances wear resistance and gives the material a matte gray surface. Its excellent corrosion resistance, particularly to seawater, means that it requires minimal additional processing before anodizing or coating, making it ideal for the manufacture of marine equipment, electrical devices, general sheet metal components, and parts requiring good appearance. Similar to O-temper, 5052-H12 also offers good weldability, supporting both MIG and TIG welding processes with minimal strength degradation after welding.

Actually, because of the chemical composition of the 5052 alloy remains unchanged in all H-temper states, they all inherit excellent corrosion resistance and good weldability,which will not be repeatly discussed in subsequent chapters.

What are the unique advantages and disadvantages of 5052-H12?

Advantages: Compared to the O-temper, H12 offers higher rigidity and better machining stability, making it ideal for applications requiring strength while maintaining good formability. It can handle medium complexity forming and machining tasks.

Disadvantages: While H12 is stronger than the O-temper, it has slightly reduced formability, particularly for deep drawing and large deformation forming, making the manufacturing of certain complex shapes more difficult.

Where is 5052-H12 used?

5052-H12 aluminum alloy is typically used in applications that require high strength and some formability, and it is widely found in:

5052-H18 is in a full hard condition, which represents the highest strength category of the 5052 alloy. It is obtained through a high degree of cold working (pure strain hardening) of over 75%. In this state, the dislocation density of the material reaches a very high level, significantly increasing its yield strength (up to over 260 MPa). However, this comes at the cost of a significant reduction in ductility, with elongation typically falling to around 3%-5%. Due to its dense material structure and high hardness, H18 has excellent cutting performance in CNC machining, offering a high surface finish and resistance to burr formation. It is commonly used in applications where both strength and hardness are critical, and there is minimal requirement for subsequent forming processes, such as high-end signs, rigid panels, and specific precision electronic product supportsFor more specific property data,you may refer to “Aluminum 5052-H18”.

What metalworking methods are suitable for 5052-H18 aluminum alloy?

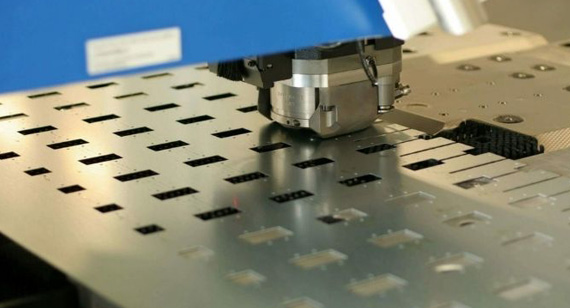

CNC Machining:Given its high hardness, 5052-H18 is suitable for precise CNC machining to produce intricate parts. It provides good processing stability and dimensional accuracy. However, when machining, considerable cutting force and strong clamping force are needed to prevent workpiece vibration and deformation. Additionally, the material's high hardness causes tools to wear more quickly, so regular tool replacement or using more wear-resistant cutting tools is necessary.

Sheet Metal Machining:5052-H18 can be used in sheet metal applications requiring high strength and low formability, such as bending and punching. However, significant mechanical pressure is needed for bending operations to avoid excessive springback during the process.

What are the advantages and disadvantages of 5052-H18 aluminum alloy?

Advantages:

5052-H18 aluminum alloy has very high strength and rigidity, making it suitable for applications that must bear significant mechanical loads. It performs exceptionally well in structural components.

Disadvantages:

The main disadvantage of H18 is poor formability, especially in processes requiring complex bending, deep drawing, or large deformations, compared to O-temper and H12 states. Ductility is significantly reduced, and products may become brittle after cold working, making them prone to cracking.

Where is 5052-H18 aluminum alloy used?

5052-H18 aluminum alloy is commonly used in applications that require extremely high strength but moderate forming requirements. Typical uses include:

5052-H24 aluminum alloy represents a "half hard" state, with properties that fall between the very soft O-temper and the very hard H18-temper. Unlike the pure cold-working process of the H1x series, the H24 temper is achieved by first undergoing a cold working process equivalent to the H14 temper (half-hard), followed by a low-temperature partial annealing (stabilizing treatment).

The purpose of this stabilizing treatment is to:

The yield strength of H24 typically ranges from 210-230 MPa, with an elongation rate of approximately 8%-12%. It is one of the most widely used temper states for 5052 alloys, as it offers an ideal balance between strength, rigidity, and good formability. It can meet the load-bearing requirements of most sheet metal parts and can easily handle moderate bending, stamping, and welding operations. Common applications include aircraft fuel tanks, ship structures, pressure vessels, and enclosures for electronic products.For more specific property data,you may refer to “Aluminum 5052-H24”.

What metalworking methods are suitable for 5052-H24 aluminum alloy?

What are the advantages and disadvantages of 5052-H24 aluminum alloy?

Advantages:

Balanced Overall Performance: H24 offers a good combination of strength and ductility, making it suitable for multi-step processing.

Disadvantages:

Lower Strength in Specific Applications: In applications where high strength is required with no need for further forming, H24 may not perform as well as H18.

Where is 5052-H24 aluminum alloy used?

5052-H24 aluminum alloy is ideal for applications that require good mechanical performance and the ability for further forming. Common uses include:

5052-H32 aluminum alloy is in a "quarter hard" (1/4 hard) and stabilized temper, making it the most commonly used and versatile condition in sheet metal processing for the 5052 alloy series. This temper is achieved through cold working to harden the material, followed by low-temperature stabilization heat treatment.

Since 5052 is a high-magnesium alloy, its mechanical properties can undergo slight fluctuations (natural aging) over time after cold working. However, the H32 temper is artificially stabilized to eliminate this instability, ensuring consistent dimensional accuracy and mechanical properties throughout the material's service life.

In terms of performance, H32 has a yield strength of approximately 190-210 MPa. Its hardness is similar to H12, but it has better ductility and crack resistance, with an elongation rate typically above 12%. It exhibits excellent formability, capable of withstanding medium-radius bending without cracking. Due to its moderate hardness, its CNC cutting and drilling performance are significantly better than in the O-temper. Combined with its excellent resistance to marine corrosion and outstanding weldability, 5052-H32 is widely used in automotive panels, inner ship structures, enclosures, fuel tanks, and various precision sheet metal parts that require balanced resistance to corrosion and formability.For more specific property data,you may refer to “Aluminum 5052-H32”.

What metalworking methods are suitable for 5052-H32 aluminum alloy?

CNC Precision Machining: 5052-H32 aluminum alloy is suitable for CNC machining, especially in applications where high precision and surface finish are required. Due to its relatively lower hardness compared to H18, tool wear is slower, and it can be reliably used for machining complex-shaped parts. Additionally, because the H32 temper has been stabilized, internal stresses are lower, making it easier to control deformation during machining. However, compared to O-temper aluminum, 5052-H32 still has a higher hardness, so careful selection of tools and cutting parameters is necessary.

Sheet Metal Processing: 5052-H32 aluminum alloy is highly suitable for forming at room temperature through sheet metal processes like stamping and bending. Due to its special H32 temper, it maintains stable dimensions after processing and is less prone to deformation.

What are the advantages and disadvantages of 5052-H32 aluminum alloy?

Advantages:

Disadvantages:

Where is 5052-H32 aluminum alloy used?

5052-H32 aluminum alloy is ideal for applications that demand both high strength and stability. Common uses include:

5052-H34 aluminum alloy represents a "half hard" and stabilized temper, which is a typical balance of high strength and stable formability within the 5052 alloy series. This temper is achieved through medium-level cold working (strain hardening) followed by a low-temperature stabilization heat treatment. In terms of mechanical properties, H34 has a yield strength typically between 230-250 MPa (higher than H32, slightly lower than H18), with an elongation rate maintained around 8%-10%. Its core feature lies in the "stabilization" process, which addresses the natural softening problem that high-magnesium alloys often experience after cold working, ensuring that the material maintains consistent mechanical properties throughout its service life. For more specific property data,you may refer to “Aluminum 5052-H34”.

What metalworking methods are suitable for 5052-H34 aluminum alloy?

What are the advantages and disadvantages of 5052-H34 aluminum alloy?

Advantages:

High Strength and Rigidity: H34 aluminum alloy provides high strength and rigidity, making it ideal for applications that require load-bearing capacity, especially for thin-walled structural components and high-rigidity panels.

Disadvantages:

Where is 5052-H34 aluminum alloy used?

H34 aluminum alloy is widely used in applications that require high strength and high rigidity, particularly in thin-walled structural components and parts subject to significant loads. Common applications include:

From this article, you’ve learnt that 5052 aluminum alloy is a non-heat treatable, magnesium-based alloy with excellent corrosion resistance, good formability, and weldability; Its strength is enhanced through cold working (strain hardening);Different temper states (O, H12, H18, H24, H32, H34) show distinct differences in strength, ductility, and processing adaptability. Therefore, choosing the appropriate states is critical for forming, bending, CNC machining, and surface treatment processes for their differences. And whether performing CNC machining or sheet metal machining on 5052 aluminum alloy, the right temper state and process should be selected based on the part's function (load-bearing, corrosion resistance, appearance, or forming complexity).

A customer company of VMT planned to produce protective covers for marine equipment, requiring 5052-H32 aluminum alloy sheet with a thickness of 3.0 mm, and dimensions of 400 x 600 mm. The components required CNC bending, CNC precision cutting, threading, flanging, and sheet metal welding assembly, with a total of 200 pieces.

For this, the VMT CNC machining factory adopted the following process flow:

During the machining process, issues such as springback during thin sheet bending, extrusion during tapping, and welding distortion were encountered. VMT experts took targeted measures: CNC springback compensation, uniform fixture distribution, use of self-tapping inserts or thread-locking combinations, and optimized welding sequence and fixture fixation.

In the end, the 200 finished parts were delivered on time, with a dimensional pass rate of 98%, appearance meeting marine protection standards, and the salt spray test showing a pass rate of 500 hours in samples. The customer was very satisfied and indicated that they would continue the collaboration.

1) What is the difference between 5052 and 6061 aluminum alloys?

5052 is a non-heat treatable alloy that offers excellent corrosion resistance, good formability, and weldability, making it ideal for sheet metal work and environments exposed to chemicals or marine conditions. It has medium strength. On the other hand, 6061 is a heat-treatable alloy that provides high strength and excellent machinability, especially for turning and milling. However, its corrosion resistance is lower than 5052, and its mechanical properties may decrease after welding.

2) How do 5052 and 3003 aluminum alloys compare, and which one should be chosen for different needs?

3003 is an aluminum-manganese alloy known for its excellent formability but has lower strength than 5052. While its corrosion resistance is good, it is slightly lower than 5052, especially in marine environments. Thus, 5052 is preferred for applications requiring higher strength and superior corrosion resistance while 3003 aluminum is suitable for a higher formability uses.

3) How does 5052 compare to 5083 aluminum, and what factors should be considered when choosing between them?

5083 aluminum excels in both strength and corrosion resistance, particularly in harsh marine environments, which is why it is often used in shipbuilding. However, it is more expensive and has slightly worse formability compared to 5052. When to choose: 5083 is the better option for load-bearing structures or extreme marine conditions, while 5052 is more suitable for general marine applications, chemical environments, or sheet metal fabrication.

4) Can 5052 aluminum be anodized, painted, or electroplated?

Yes, 5052 aluminum can be anodized. However, due to its magnesium content, it requires strict pre-treatment to ensure uniform color and pore consistency. It also works well with spray painting and powder coating. For electroplating, proper pre-treatment is necessary to ensure strong adhesion of the coating.

5) What are the common defects when machining 5052 aluminum, and how can these be avoided?

Common defects during CNC machining of 5052 include tool chip adhesion, burr formation, thin-wall deformation, and cracking during bending. To avoid these issues, it is important to select appropriate tools with coatings, optimize cutting parameters, ensure uniform clamping and support, use step forming when necessary, and design reasonable chamfers and molds to minimize stress concentration.

6) Does welding affect the corrosion resistance of 5052 aluminum?

Welding can change the local microstructure of 5052 aluminum, potentially reducing its corrosion resistance and mechanical properties in the welded area. However, this effect can be minimized by choosing the right welding wire and applying post-weld surface treatments such as passivation, anodizing, or coating to restore the material’s protective layer.