15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 01 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 01 2026 | Reading Time:About 2 minutes

Have you ever faced the problem of choosing an aluminum alloy for pressure vessels, marine decks, or welded structures? In many cases, you have to balance strength, corrosion resistance, and weldability at the same time. 5454 aluminum stands out for its excellent corrosion resistance, stable welding performance, and moderate-to-high strength for the above uses. This guide focuses on 5454 grade aluminium and helps you fully understand the alloy, including its chemical composition, physical and mechanical properties, and typical applications.

In engineering practice, aluminium 5454 is often compared with 5052 aluminum (known for superior formability and corrosion resistance) and 6061 aluminum (known for higher strength and heat-treatable properties). For this reason, this article also includes dedicated sections comparing 5454 vs 5052 and 5454 vs 6061.

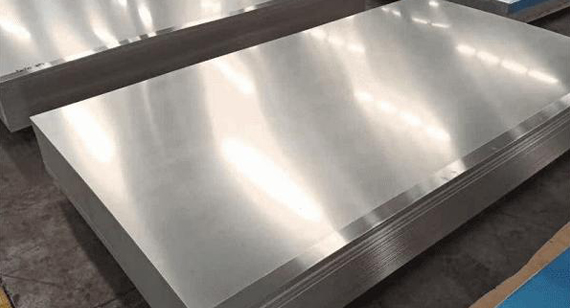

5454 aluminum (aluminium 5454) is a high-strength, corrosion-resistant alloy from the 5000 series. Its main alloying element is magnesium, which gives it excellent durability in harsh environments. Unlike heat-treatable alloys like 6061, 5454 gains strength through cold working, such as rolling or bending, rather than heat treatment.

It also has excellent weldability and good formability, especially in softer tempers like O, H11, H32, and H34. These properties make it ideal for applications that need long-lasting performance under stress.

5454 aluminum is widely used in marine structures, pressure vessels, and industrial equipment. It stands out for resisting saltwater and other corrosive conditions while maintaining strong, stable welds.

Aluminum(95–97%) forms the base of 5454 aluminum alloy, while magnesium and manganese are the main alloying elements that enhance corrosion resistance, strength, and stress-corrosion cracking resistance; minor elements such as chromium, titanium, and zinc further improve corrosion performance and dimensional stability. Below table shows 5454 aluminum’s chemical composition:

Table 1: Chemical Composition of 5454 Aluminum

| Element | Typical Range (%) |

| Aluminum (Al) | Balance ( ≈ 95–97%) |

| Magnesium (Mg) | 2.4 – 3.0 |

| Manganese (Mn) | 0.5 – 1.0 |

| Silicon (Si) | ≤ 0.25 |

| Iron (Fe) | ≤ 0.40 |

| Chromium (Cr) | 0.05 – 0.20 |

| Titanium (Ti) | ≤ 0.20 |

| Zinc (Zn) | ≤ 0.25 |

| Copper (Cu) | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Table 1 Credit: Aircraftmaterials Aluminum 5454

5454 aluminum is a lightweight and thermally stable alloy, offering good conductivity and predictable expansion, making it ideal for structural and industrial applications. The following are 5454 aluminum’s physical properties:

Table 2: Physical Properties of Aluminum 5454

| Property | Typical Value |

| Density | 2.66–2.70 g/cm³ |

| Melting Point | 590–645 °C |

| Thermal Conductivity | 130–150 W/m·K |

| Thermal Expansion | 23.7–24 ×10⁻⁶ /K |

| Electrical Conductivity | 33–35% IACS |

Physical and the Following Mechnaical Data Credit: Makeitfrom Aluminum 5454

5454 aluminum offers moderate-to-high strength, good yield performance, and reasonable elongation, making it suitable for a wide range of structural applications. Since it is a non-heat-treatable alloy, its mechanical properties depend on annealed (O) or work-hardened tempers such as H11, H32, and H34. Below is the mechanical properties of 5454 aluminium under annealed (O) or work-hardened tempers:

Table 3: Mechanical Properties of 5454 Aluminum by Temper

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| O (annealed) | 215–285 | ≥85 | ≥19 | ~50 |

| H11 | 220–290 | ≥90 | 18 | ~55 |

| H32 | 250–305 | ≥180 | ≥12 | ~65 |

| H34 | 275–350 | ≥200 | ≥12 | ~70 |

Key mechanical characteristics of 5454 aluminium include:

5454 Aluminum delivers increasing tensile strength as the temper moves from O through H11, H32, to H34. This allows it to meet the requirements of components that must withstand higher loads.

The alloy provides reliable yield strength across all common tempers, ensuring structural stability under applied stresses while maintaining good safety margins for welded and fabricated assemblies.

5454 Aluminum maintains reasonable ductility, especially in softer tempers (O and H11), which makes it easy to form and bend, while still providing sufficient flexibility in harder tempers (H32 and H34) for load-bearing applications.

5454 aluminum is highly resistant to corrosion, making it ideal for marine, chemical, and industrial environments.

This superior corrosion resistance comes from its magnesium content, which promotes the formation of a stable aluminum oxide layer on the surface. This oxide layer acts as a natural barrier, protecting the underlying metal from saltwater, chemicals, and industrial pollutants.

Thus, 5454 aluminum components can maintain their structural integrity and appearance over time. This reduces the maintenance costs and extending service life in demanding applications such as ship decks, chemical tanks, and pressure vessels.

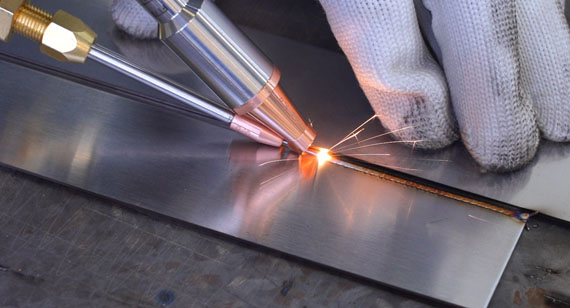

5454 aluminum is highly weldable and compatible with TIG, MIG, and spot welding.

Its alloy composition (primarily magnesium and manganese) allows welded joints to retain both mechanical strength and corrosion resistance, even after fabrication. This makes it possible to construct complex welded structures without compromising performance.

Engineers benefit from easier manufacturing due to good weldability, reduced production costs, and long-lasting reliability in harsh environments, such as marine vessels, trailers, and industrial equipment.

Equivalents of 5454 aluminum are shown in table below:

| Region | Standard | Notes |

| USA | UNS A95454 ASTM B209 ASTM B221 |

Unified Numbering System, identifies 5454 alloy Aluminum and Aluminum-Alloy Sheet and Plate Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes |

| China | GB/T 3190 / GB/T 3880 / GB/T 6892 | GB/T 3190: chemical composition, GB/T 3880: mechanical properties, GB/T 6892: plates and sheets |

| Europe | EN AW-5454 | EN standard for wrought aluminum-magnesium alloys |

| ISO | ISO 6361 | Aluminum and aluminum alloys — Rolled products — Chemical composition and mechanical properties |

| Japan | JIS H4000 / JIS H4100 | JIS standards for aluminum sheets, plates, and chemical composition |

| Germany | DIN 1725 / DIN EN 485 | German standards for aluminum sheets, plates and strips |

| UK | BS EN 485 | British standard aligned with European EN 485 for aluminum sheets and plates |

You will find 5454 aluminum alloy is preferred among many applications including:

5454 aluminum alloy is commonly used for fuel tanks, panels, body reinforcements, and chassis components. This alloy is valued in the automotive industry for its combination of good strength, corrosion resistance, and lightweight nature.

Marine Industry

In the marine industry, 5454 aluminum alloy is commonly used in hulls, decks, and offshore platforms and it is valued for its resistance to seawater corrosion. The alloy’s ability to withstand harsh marine environments and cyclic loads ensures durability of the components and reduces maintenance requirements.

Construction

5454 aluminum alloy is used in structural applications such as facades, window frames, roofing materials, and doors. Its corrosion resistance extends the lifespan of buildings, especially in coastal areas with high humidity. The lightweight nature of the alloy makes transportation and installation easier.

Welded Structures

The alloy is ideal for welded structural frames and assemblies. It allows strong, durable welds with minimal risk of post-weld corrosion. This makes it suitable for construction and engineering applications where welded joints must remain robust over time.

Industrial Equipment

5454 aluminum alloy is commonly used in pressure vessels, boilers, pipelines, and cryogenic storage. Its high corrosion resistance ensures reliable operation even under harsh chemical or low-temperature conditions. The alloy’s strength also allows it to handle mechanical stresses in demanding industrial applications.

Both 5454 and 5052 aluminum alloys offer excellent corrosion resistance and weldability, making them popular choices in marine, automotive, and industrial applications.

However, 5454 aluminum has a higher tensile strength (240–300 MPa) compared to 5052 aluminum (215–265 MPa), which makes it better suited for applications requiring greater load-bearing capacity.

On the other hand, 5052 aluminum is known for its superior formability, making it easier to shape into complex components. Neither alloy is heat-treatable, so mechanical properties are achieved through work hardening rather than thermal processing. Below table shows their similarity and the difference.

Table 4:Comparison of 5454 Aluminum vs 5052 Aluminum

| Alloy | Tensile Strength (MPa) | Corrosion Resistance | Weldability | Heat Treatable | Formability |

| 5052 | 215–265 | Excellent | Excellent | No | Superior |

| 5454 | 240–300 | Excellent | Excellent | No | Good |

5454 and 6061 aluminum alloys serve different engineering needs. While 6061 is chosen for high-strength structural parts, 5454 is favored when corrosion resistance, weldability, and ease of forming are more important.

5454 aluminum is not heat-treatable but provides excellent corrosion resistance and weldability, making it a preferred choice for marine environments, pressure vessels, and sheet or plate applications that require forming.

In contrast, 6061 aluminum is heat-treatable and delivers superior load-bearing performance in structural applications. This makes it ideal for aerospace components and other parts where strength and stiffness are critical. Below table shows their differences.

Table 5: Comparison of 5454 Aluminum vs 6061 Aluminum

| Alloy | Heat Treatable | Tensile Strength (MPa) | Corrosion Resistance | Weldability |

| 5454 | No | 240–300 | Excellent | Excellent |

| 6061 | Yes | 240–310 | Good | Good |

This article provides a comprehensive overview of 5454 aluminum, covering its chemical composition, mechanical and physical properties, corrosion resistance, weldability, applications, and comparisons with common aluminum alloys 5052 and 6061.

If you are looking forward to high precision aluminum parts, you find us VMT CNC Machining Factory. We offer professional CNC machining services for 5454, 5052, 6061, and other alloys, turning your designs into high-quality finished components with tight tolerances, excellent surface finishes, and fast turnaround—ideal for prototypes or mass production.

What are the key design considerations and limitations of 5454 aluminum?

A: 5454 aluminum’s strength decreases at elevated temperatures compared to heat-treatable alloys, and excessive cold working can reduce its ductility. Applying proper surface treatments improves long-term corrosion resistance, and its sheet and plate forms are cost-effective alternatives to 5083 for marine and industrial applications.

What are the common tempers available for 5454 sheet and plate?

The most common tempers for 5454 grade aluminium sheet/plate include O (soft), H11, H32, and H34. O provides maximum ductility, H11 is semi-hard, H32 is moderately hardened, and H34 offers higher strength for welded and load-bearing structures.

Is 5454 aluminum suitable for welding and fabrication?

Yes, 5454 aluminum/aluminium sheet and plate are highly weldable using TIG, MIG, and spot welding. Its welds retain corrosion resistance and strength, making it ideal for industrial, marine, and automotive applications.

Can 5454 grade aluminium be heat treated to increase strength?

No. 5454 is a non-heat-treatable alloy. Its strength is increased only through cold working (rolling, bending, stamping). Heat treatment does not significantly enhance mechanical properties.

What applications are best suited for 5454 aluminum sheet and plate?

5454 aluminium sheet and plate are ideal for marine structures (ship hulls, decks), pressure vessels, chemical tanks, automotive bodies, and welded structural components, where corrosion resistance, moderate-to-high strength, and good formability are required.

How can corrosion resistance be improved for 5454 aluminum?

Applying appropriate surface treatments, such as anodizing or coatings, enhances long-term corrosion resistance, especially in marine or industrial environments.