15 years one-stop China custom CNC machining parts factory

2 |

Published by VMT at Dec 31 2025 | Reading Time:About 3 minutes

2 |

Published by VMT at Dec 31 2025 | Reading Time:About 3 minutes

Today, many electronic parts are becoming smaller, lighter, and more powerful. As a result, their internal structures are getting more complex and much harder to manufacture. This is where CNC precision machining stands out. It has become a key technology that supports the electronics industry at every level.

Rising competition in the electronics market has also raised expectations for both performance and appearance. You will need your parts to outperform the competition and finishes that make your products feel premium. CNC machining can help you achieve both, from ultra-precise internal components to high-end surface treatments that shape the look and feel of your electronic assemblies.

In this article, you’ll explore how precision electronics parts are made, the most common CNC-machined electronic components, material options, surface finishes, and the industries that rely on high-accuracy manufacturing. Read on to get better equipped to make informed decisions for your next project.

In the electronics industry, manufacturing high-precision, small, and complex components rely heavily on CNC machining. As component designs become increasingly intricate, traditional methods can no longer meet the requirements. This is where electronics precision machining comes in. It mainly uses CNC machining technology to precisely control cutting tools, transforming raw materials into parts that meet strict dimensional, geometric, and surface finish standards. This ensures functionality, reliability, and overall performance for electronic applications.

How Does CNC Works in Electronics Precision Machining?

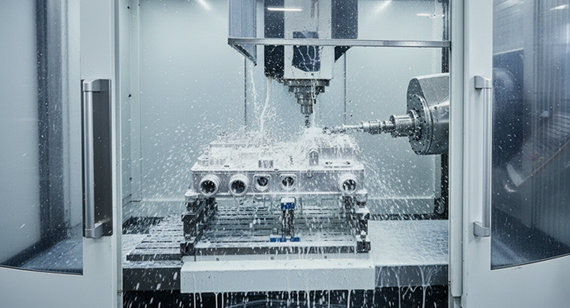

CNC, or Computer Numerical Control, uses computer-generated tool paths to cut a solid block of material into the shape you need. Before machining, the engineering team creates a detailed CAD 3D model acting as a blueprint for the entire process. Then, the engineer generates programs by CAM software and optimizes the tool paths to balance accuracy and efficiency.

Next is the right material being secured to the CNC machine. The machine performs milling, turning, drilling, or threading to create complex shapes that you want. After machining, electronics parts go through deburring and refinement to remove sharp edges and improve surface quality. The final step is to inspect the components using CMMs, projectors, calipers, or other measuring tools to ensure every dimension meets the strict tolerances required in electronics.

Why Electronics Ask for High Precision

Some electronic parts are small, intricate, and have very low tolerance for error. Even a 0.01 mm deviation can cause signal loss, overheating, assembly problems, or misaligned modules. Another internal components like connectors, heat sinks, and support brackets must fit perfectly to maintain stability, performance, and safety.

Modern electronic devices often pack multiple components tightly, like motherboards, batteries, enclosures, and interface modules. If one part is slightly off, it can affect heat dissipation, reduce durability, or create mechanical stress over time. CNC machining consistently achieves micron-level tolerances, making it the most reliable choice for high-precision parts, rapid prototyping, and small-to-medium production runs. With CNC, you can ensure smooth assembly, strong structure, and high-performing electronic products.

The electronics industry demands high precision, multi-material compatibility, and the ability to handle complex geometries, and CNC machining checks all these boxes:

Due to being controlled by computer to run the machine, CNC consistently achieves tight tolerances of ±0.01 mm, keeping intricate components and assembly interfaces highly consistent. This ensures your electronic products remain reliable even after long-term use.

Whether it’s deep cavities for heat dissipation, fine cooling fins, miniature threaded holes, or thin-walled lightweight housings, CNC can machine complex 3D geometries while maintaining structural strength.

CNC doesn’t rely on expensive molds, making it ideal for rapid prototyping, engineering validation (EVT/DVT/PVT), and small-batch custom production. This greatly reduces development costs.

CNC can machine metals (aluminum, copper, stainless steel), plastics (PC, ABS, POM), high-performance materials (PEEK, PEI), and even ceramics or some composites to create precise electronic components.

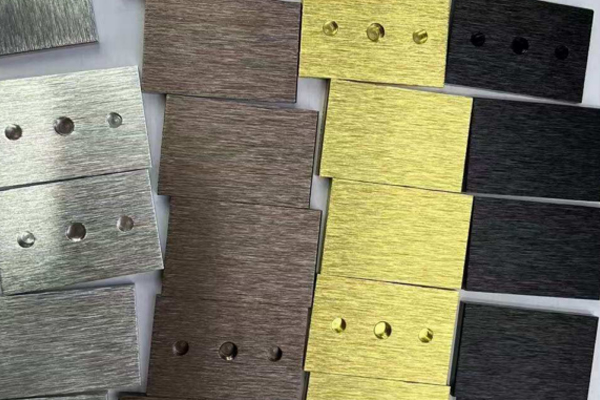

CNC parts can be paired with anodizing, bead blasting, brushing, plating, or coating to meet multiple requirements, from aesthetics and wear resistance to thermal management and protection.

CNC’s flexibility allows rapid prototyping and iterative design, shortening product development cycles, and accelerating time-to-market. This can give you a competitive edge in the fast-paced electronics industry.

Thanks to these advantages, CNC machining is not only the main manufacturing way for consumer electronics, housings, and heat-dissipation modules, etc., but also plays an irreplaceable role in high-end fields like medical devices and aerospace electronics.

During the development of electronics parts, CNC machining is always the top choice for a flexible and highly precise manufacturing method. Popular CNC-machined electronic products vary from aesthetic parts, heat sinks, to functional internal components, or parts for industrial electronic equipment. Below, you can find a showcase of popular CNC-machined electronic components.

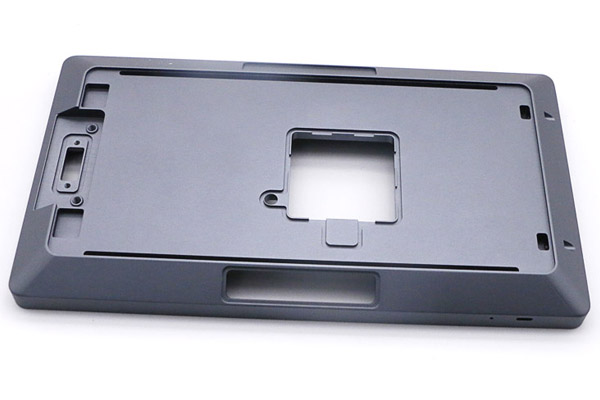

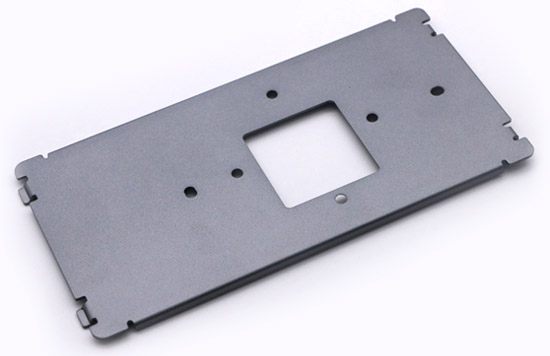

The casings and enclosures of electronic devices provide structural support and shape the electronic product’s look and feel. Examples include smartphone frames, laptop chassis, and small server cases. High-end enclosures and casings of these examples often feature deep cavities, chamfered edges, and refined surface textures. CNC machining excels in these demands, and it’s ideal for small-batch, high-end production of the casings and enclosures.

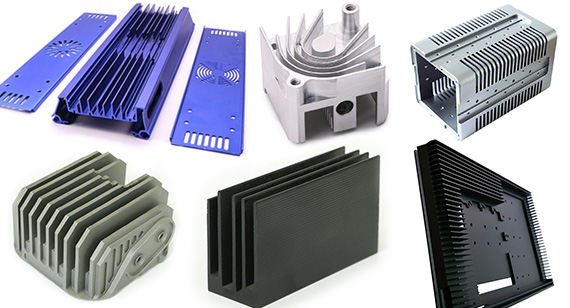

Electronic devices generate significant heat during operation, requiring efficient heat dissipation. Heat sinks typically consist of aluminum or copper bases with finely spaced fins to quickly transfer and disperse heat. CNC machining allows for precise fin structures, maximizing thermal performance while maintaining material conductivity.

Connectors and metal terminals are critical for establishing reliable electrical connections within electronic devices. They demand high-dimensional consistency and excellent conductivity. CNC machining ensures accurate features and tight tolerances, providing reliable electrical contact.

Printed circuit boards (PCBs) are the backbone of electronic devices, connecting and supporting components. Traditional PCBs are usually made using chemical etching. For small-batch projects, CNC machining can mill copper directly to produce PCB prototypes quickly, reducing environmental and safety risks associated with etching chemicals.

Components used in semiconductor equipment include wafer chucks, vacuum chamber parts, and gas distribution plates. These parts directly impact wafer processing precision and equipment stability. The semiconductor equipment components are typically made from aluminum, PEEK, or stainless steel, and they require tight control over flatness, and stable dimensions. CNC machining can ensure these complex parts meet design specifications of semiconductor equipment parts.

Internal brackets and frames secure battery modules, motherboards, displays, and other key components. They must meet the asks such as withstand mechanical stress, remain lightweight, and maintain assembly accuracy for long-term durability. CNC machining can precisely form complex geometries, including thin-wall brackets, reinforcement ribs, screw holes, and mounting slots, ensuring these components fit securely with optimal spacing.

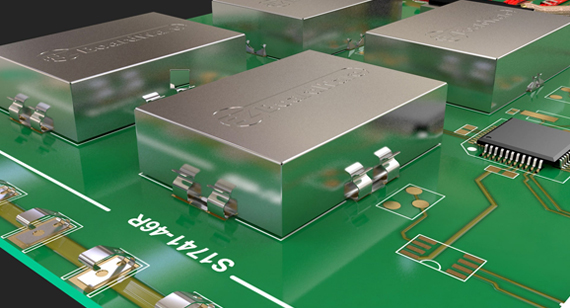

Shielding components prevent electromagnetic interference (EMI/RFI), keeping internal signals stable and protecting electronic components or external devices. They are commonly used in motherboards, server chassis, high-frequency communication equipment, and medical devices where electromagnetic compatibility (EMC) is critical. CNC machining can accurately produce shielding components with precise shapes and mounting holes, ensuring both effective shielding and mechanical stability.

CNC-machined electronic parts include structural parts, thermal components, insulating parts, and various functional elements and others, so the range of materials used is very broad. One of the biggest advantages of CNC machining is its compatibility with metals, engineering plastics, and some others. When selecting materials, you may need to balance appearance, cost, properties like heat resistance, conductivity, and strength.

Many consumer electronics place a strong emphasis on looks and feel, such as metal phone housings and wearable devices. They require not only solid mechanical strength but also high-quality surface finishes. On the other hand, components related to heat dissipation, electrical insulation, or high-temperature environments must be made from specialized metals or high-performance plastics.

The table below summarizes the most commonly used materials in CNC-machined electronic components:

Table 1: Common CNC Materials Used in the Electronics Industry

| Material Category | Typical Grades | Key Properties | Cost | Typical Applications |

| Aluminum Alloys | 6061, 7075, 5052 | Lightweight, good thermal conductivity, excellent machinability, great surface finish options | Medium (6061) / Higher (7075) | Housings, frames, heat sinks, internal brackets |

| Copper / Brass | C110, C101, H59, H62 | Excellent thermal & electrical conductivity, polishable, good for EMC shielding | Higher | Terminals, connectors, shielding covers, thermal bases |

| Stainless Steel | 304, 316, 303, 17-4PH | High strength, corrosion-resistant, durable, premium appearance | Higher | Fasteners, precision structures, medical electronics |

| Titanium Alloy | Ti-6Al-4V | High strength-to-weight ratio, corrosion-resistant, biocompatible | High | Medical electronics, aerospace electronics |

| General Engineering Plastics | ABS, PC, PC-ABS, PMMA | Easy to machine, lightweight, cost-effective | Cost-effective | Enclosures, light covers, basic structural parts |

| Mechanical Performance Plastics | POM, PA6, PET | Wear-resistant, tough, low friction, dimensionally stable | Cost-effective / Medium | Gears, sliding components, small mechanisms |

| High-Performance Plastics | PEEK, PEI, PPS, PTFE, LCP | High-temperature resistance, excellent insulation, stable under load | High | High-end connectors, thermal/electrical isolation parts, RF carriers |

| Magnesium Alloy | AZ91D | Extremely lightweight, strong, ideal for portable devices | Medium | Lightweight housings, drone components |

| Zinc Alloy | Zamak series | Strong, wear-resistant, good for small precision components | Cost-effective | Buttons, connectors, mechanical linkages |

Once you understand the common CNC materials used in electronic products, you can quickly select the right material by considering the following factors:

Electrical Requirements: Conductive or Insulating?

If your electrical parts need to conduct electricity or provide EMI/RFI shielding, metals such as copper, aluminum, or stainless steel are ideal. For components that must isolate or insulate, choose ABS, PEEK, PTFE, FR-4, or other high-insulation materials.

Thermal Management Needs?

For parts that require strong heat dissipation, aluminum and copper are the top choices. For high-temperature environments, such as power modules or aerospace electronics, materials like PEEK, PEI, or ceramics offer superior stability.

Strength and Durability?

Parts that experience mechanical loads or vibration benefit from stainless steel, 7075 aluminum, or high-strength engineering plastics. Consumer electronics often favor aluminum alloys because they balance lightweight design with good structural strength.

Weight Considerations?

Wearables, drones, and other portable devices prioritize low weight. Materials such as aluminum, magnesium, or engineering plastics are usually preferred in these applications.

Cost and Machinability?

Aluminum and ABS are the most economical and efficient options for CNC machining. PEEK and titanium deliver exceptional performance but come with a significantly higher cost, making them better suited for high-end or specialized products.

Below is a quick comparison that highlights the fundamental differences between materials used inside electronic systems (for electrical performance and safety) and materials used for CNC-machined structural parts.

Table 2: Comparison of Electronics Materials vs. CNC Machining Materials

| Category | Electronics-Specific Materials | CNC Machining Materials |

| Primary Purpose | Electrical functionality, insulation, conductivity, dielectric performance, safety | Structural support, housings, heat dissipation, mechanical components |

| Typical Materials | Silicon wafers, FR-4, conductive adhesives, solder, conductive films, flame-retardant polymers | Aluminum, stainless steel, copper, titanium, engineering plastics (ABS, PC, POM, PEEK) |

| Key Focus | Insulation/conductivity, thermal stability, flame retardancy, signal integrity | Strength, dimensional accuracy, surface quality, machinability |

| Suitable for CNC Cutting? | Mostly not machinable or not suitable | Specifically optimized for milling, turning, drilling, tapping |

| Common Manufacturing Processes | PCB fabrication, lamination, molding, thin-film deposition | CNC milling, turning, drilling, 5-axis machining |

| Typical Industries | Semiconductors, PCB manufacturing, battery systems, power electronics | Consumer electronics, medical devices, aerospace, precision industrial equipment |

| Structural Use? | Limited (PEEK/PEI can be structural; most others cannot) | Fully suitable—often the primary structural materials |

| Flame Retardancy | Many meet UL94 V-0 / V-1 | Metals: inherently non-flammable; plastics require specific FR grades |

Electronics specific materials are primarily designed around electrical performance and safety requirements, such as insulation, conductivity, dielectric strength, semiconductor properties, and flame-retardant ratings like UL94 V-0. These materials are commonly used in circuit substrates, chip packaging, thermal pathways, power modules, and electrical protection, rather than for load-bearing structural parts.

Among electronics specific materials, flame-retardant materials are especially critical in electronic product design. UL94 V-0, one of the strictest and most widely adopted ratings, requires materials to self-extinguish almost immediately during a vertical burn test and to produce no flaming drips. Such materials are foundational in high-safety applications including battery modules, power systems, telecom servers, automotive electronics, and industrial control equipment. Common UL94 V-0 rated materials include:

Unlike electronics-specific materials, CNC machining materials prioritize mechanical performance, structural stability, dimensional accuracy, and machinability. They are used to make enclosures, brackets, heat-dissipation parts, mechanical linkages, and other components that rely on structural integrity. (For the details, you can refer to the previous section:”What Are CNC Machining Materials for Electronics”)

In short, electronics special materials and CNC machining materials each serve critical but different functions—and together they make modern electronic components possible.

Surface finishing plays a crucial role in improving tactile quality, corrosion resistance, thermal performance, and overall aesthetics of CNC-machined electronic parts. Depending on the product positioning, different finishing processes can deliver entirely different functional and visual results.

As-Machined

The as-machined finish refers to parts that undergo no additional surface treatment after CNC cutting. They retain visible tool paths and slight machining marks (typically removed through light deburring). Because no extra processing is required, as-machined surfaces are ideal for internal brackets, fixtures, test jigs, mechanical joints, or any component where appearance is not a priority. It’s also a common choice for EVT (Engineering Verification Test) parts due to its speed and cost-effectiveness.

Bead blasting uses fine glass beads or ceramic media to smooth out minor tool marks and create a uniform, satin-like matte finish. Compared with an as-machined surface, bead-blasted parts feel smoother and look more refined.

This finish is widely used in consumer electronics such as smartphone housings and laptop covers, to achieve a soft-touch appearance, reduce glare, and minimize fingerprint visibility. Bead blasting is also commonly used as a pretreatment step before anodizing to ensure more consistent color results.

Anodizing

Anodizing is an electrochemical process that creates a dense, protective oxide layer on aluminum surfaces. This coating provides excellent corrosion resistance, wear resistance, and electrical insulation, and can be colored in a wide range of premium finishes. In consumer electronics, anodizing is almost standard for aluminum electronic housings. It is one of the most reliable and cost-efficient finishes for lightweight, high-precision electronic products.

Brushing produces a controlled, directional grain on metal surfaces using abrasive belts, pads, or wheels. This creates a linear metallic sheen that enhances the visual texture while subtly masking minor machining marks. It is often combined with anodizing, which helps highlight the grain pattern and achieve a cleaner, more high-end finish.

Plating ( also Electroplating )

Plating deposits a uniform metallic layer, such as nickel, chrome, gold, or tin, onto the surface of a part using chemical or electrochemical processes. The plated layer enhances corrosion resistance, surface hardness, conductivity, and reflectivity, while also offering a polished, high-end appearance. In electronics, plating serves both functional and decorative purposes.

For example:

Its combination of durability and aesthetics makes plating a staple in high-end electronic manufacturing.

Painting and Powder Coating

Painting and powder coating create a protective, fully covered surface layer with customizable colors and textures. Liquid paints allow precise color matching, while powder coating forms a thicker, more durable finish—ideal for parts that require higher impact or abrasion resistance.

These coatings offer excellent color range, improved corrosion protection, and the ability to hide minor surface imperfections. They are commonly used for large electronic enclosures, appliance housings, audio equipment bodies, and various consumer electronics. Powder coating is particularly favored for rugged or industrial devices that must withstand long-term wear.

Laser Marking

Laser marking uses a focused laser beam to etch, ablate, or discolor the surface of a component, creating permanent markings such as logos, serial numbers, QR codes, product specs, or button icons. Because laser marking does not alter the structure of the part or require additional coatings, it is universally compatible. Laser marking is widely used in smart devices, medical electronics, precision sensors, and automation components to ensure traceability and long-term identification.

CNC machining has become one of the most critical manufacturing technologies in the electronics industry. Thanks to its high precision, excellent repeatability, broad material compatibility, and rapid prototyping capability, CNC machining supports everything from consumer electronics to medical devices and aerospace electronic systems. These sectors rely heavily on CNC to produce high-quality structural parts, thermal components, housings, and functional modules. Below are the three industries that depend the most on CNC machining for electronic components and continue to drive demand for advanced precision manufacturing.

Consumer Electronics: The Largest CNC Machining Market

The consumer electronics industry is the biggest user of CNC-machined parts. Products such as smartphones, tablets, laptops, smartwatches, and AR/VR devices all require thin-wall designs, lightweight structures, and highly accurate assemblies. CNC machining delivers exceptional precision on materials like aluminum, magnesium, stainless steel, ceramics, and titanium, making it essential for producing premium enclosures and internal structural components.

Common CNC-machined electronics parts include:

Because consumer electronics evolve quickly, manufacturers must complete prototypes, EVT/DVT builds, and low-volume pilot runs in short timeframes. CNC machining’s tool-free workflow allows companies to accelerate development cycles, improve product performance, and achieve consistent high-quality surface finishes.

Aerospace Electronics: High-Reliability CNC Components

Aerospace electronics require some of the highest standards in modern engineering. Devices must withstand extreme temperatures, vibration, pressure changes, and radiation. CNC machining is ideal for aerospace because it can meet strict tolerance control and process high-performance materials such as 7075-T6 aluminum, titanium alloys, PEEK, and PEI.

Typical CNC-machined aerospace components include:

These components must deliver long-term stability and mechanical strength, while maintaining precise dimensions. Multi-axis CNC machining enables complex lightweight geometries that meet aerospace standards for durability and reliability.

Medical Electronic Devices: Precision and Safety Requirements

Medical electronic devices, such as MRI systems, surgical robots, patient monitors, and implantable technologies, demand exceptional accuracy, safety, and consistency. CNC machining supports this industry by producing small, precise, and highly reliable mechanical parts and housings.

Common CNC-machined medical electronic components include:

Medical devices often work in sterile environments or come into direct contact with patients, requiring materials like titanium, 316L stainless steel, ULTEM (PEI), and PEEK, many of which meet UL94 V-0 flame-retardant standards. CNC machining ensures that these advanced materials maintain structural integrity in complex designs while complying with regulatory requirements such as FDA and ISO 13485.

VMT provides high-precision CNC machining services for all types of electronic products, including housings, connectors, brackets, heat-management components, and internal structures. We have supported 1,000+ electronics companies worldwide, helping them solve engineering challenges and bring high-quality custom parts into production. Below is a case of an electronics company's success cooperatong with VMT CNC machining factory:

A European electronics company approached VMT to develop a high-precision aluminum enclosure for its next-generation communication module. The design required an ultra-thin 0.8 mm wall, multiple internal cooling chambers, and a flawless surface finish suitable for premium consumer products. Previous suppliers failed to maintain dimensional stability during mass production, causing assembly issues and high rejection rates. To overcome these challenges, VMT’s engineering team optimized machining paths with 5-axis milling, designed custom fixtures to prevent deformation, refined tool strategies to minimize stress, implemented multi-stage CMM inspections, and developed a customized anodizing formulation for consistent color and edge protection.

As a result, VMT delivered a structurally stable and visually perfect enclosure that exceeded customer expectations. The project achieved a 99.6% yield rate, flawless compatibility with internal PCB and connectors, over 3,000 units per batch with consistent anodizing, and a 30% reduction in production time—allowing the client to launch ahead of schedule. This success led to a long-term partnership and reinforced VMT’s position as one of the most trusted CNC manufacturers in the global electronics industry.