15 years one-stop China custom CNC machining parts factory

1 |

Published by VMT at Dec 30 2025 | Reading Time:About 3 minutes

1 |

Published by VMT at Dec 30 2025 | Reading Time:About 3 minutes

If you’ve ever compared stock parts to CNC motorcycle parts, you already know the difference in feel and performance whether you’re motorcycle enthusiasts or bike parts manufacturers.But why is that?

It’s because, unlike traditional methods such as casting, forging, stamping, or hand-machining, CNC machining delivers far superior precision, repeatability, durability, and design freedom. If you are aftermarket brands, or custom bike builders demanding tight tolerances, smooth fitment, lightweight structures, and premium finishes , that’s only the CNC machining motorcycle parts remains the gold standard.

This guide will help you walk through everything from materials to cost, finishes, and customization of CNC machining motorcycle parts.You’ll finally get some practical insights for your motorcycle manufacturing business.

Many motorcycle riders and enthusiasts are now turning to CNC-machined motorcycle parts. So what makes CNC motorcycle parts so advantageous? For these consumer demands, motorcycle manufacturers need to understand what CNC machining is and what’s it’s advantages.

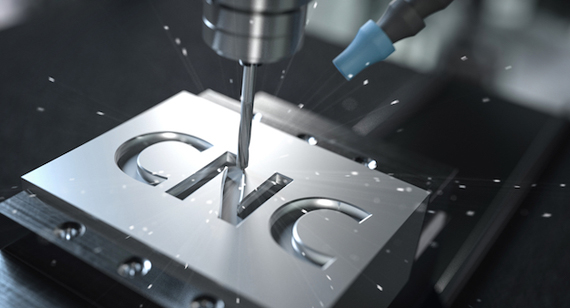

1.1 What Is CNC Machining?

To understand CNC motorcycle parts production, the first is to learn about the CNC machining.

CNC means Computer Numerical Control. It is cutting a whole piece of material into the shape you want where computer-generated toolpaths control cutting tools. This subtractive manufacturing process running exactly by designed programs and won’t be mistaken. And it’s why precision machined motorcycle parts come out consistent, repeatable, and reliable. The CNC workflow includes:

1.2 Core Advantages of CNC Machining Motorcycle Parts

After you’ve learnt about the CNC machining, you will find these following advantages:

High Precision & Repeatability

Even tiny deviations can affect the performance and safety of motorcycle parts. CNC machining cuts each part precisely according to the digital design, ensuring consistent dimensions, perfect fit, and long-term reliable performance.

Complex Geometry

CNC machining uses various sizes and types of cutting tools to follow programmed paths, making it possible to create angled surfaces, or other intricate motorcycle part designs. This allows custom or aftermarket parts to achieve both optimal performance and aesthetic appeal.

Broad Material Compatibility

CNC machining can work with almost any high-performance material, including aluminum, titanium, stainless steel, and brass, depending on the requirements of the part.

Suitable for Customization or Batches

Whether producing a single custom component or a batch of parts, CNC machining can scale efficiently. It meets both one-off and low-volume production needs while maintaining consistent quality.

High Structural Integrity

Because CNC parts are cut directly from solid material blocks, they retain full structural integrity. This way can offer higher strength and durability compared to traditional casting or hand-machined components.

For motorcycle manufacturers, CNC machining enables the creation of high-precision, durable, and performance-optimized parts. From core engine components to drivetrain parts, handlebars, and foot pegs, nearly every motorcycle component can be upgraded and optimized through CNC machining.And if you’re a motorcycle enthusiast, knowing the different parts can also give you useful insights when customizing your bike. Let’s see what they are:

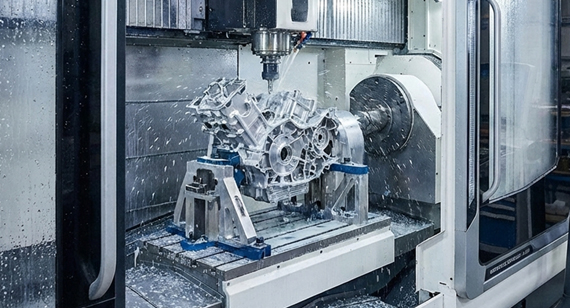

Engine casing can protect the engine’s internal components, such as the crankshaft, camshafts, and pistons. It provides structural support while keeping dust and debris out and ensuring oil and other fluids circulate properly. With CNC machining, you can achieve precise dimensions, smooth surfaces, and complex designs of your engine casings.

Cylinder heads in motorcycles cover the cylinders and control intake, exhaust, and combustion processes. They ensure proper sealing and heat dissipation under high temperatures and pressures. CNC machining can achieve its precise porting, threads, and mounting surfaces, enhancing engine performance and reliability.

Valve covers protect your valve train while preventing dirt from entering the engine and keeping lubricants sealed inside. With CNC machining, you can produce valve covers with precise fitment and even add custom engraving or branding, combining functionality and aesthetics.

Triple trees connect the front forks to the frame and secure the steering stem, playing a critical role in handling and stability. CNC machining allows you to achieve precise angles and strict tolerances of triple trees, ensuring perfect fitment and stronger structural integrity.

Foot pegs are essential for rider comfort and control, providing stable support and grip. CNC machining also creates pegs with precise dimensions, surface texture, and lightweight designs, improving safety and the riding experience of riders.

Handlebars give bikers control and comfort. Control diameter, shape, and thickness can be customized through CNC machining.

Sprockets and gears are core drivetrain components, transmitting power smoothly while handling high loads. CNC machining ensures the precise tooth profiles and dimensions.

Brake calipers are safety-critical components that ensure reliable braking performance. CNC machining allows you to produce calipers with strict tolerances and high-strength structures, assuring the durability and braking reliability.

Wheels hubs bear the weight of the motorcycle and influence handling and comfort. CNC machining allows you to produce precise dimensions and complex designs, manufacturing stronger, lighter, and more customizable wheels.

Besides the main parts you've learnt about above, there are plenty of other components such as brackets, mounts, engine guards, decorative covers, and other custom or performance pieces. All of them can take advantage of CNC machining actually, to achieve high precision, durability, and design flexibility.

With parts of a motorcycle, it is understandable to consider what materials will be included in the CNC motorcycle components. Aluminum alloys,titanium, stainless steel, steels, titanium, and some other engineering plastics are the popular CNC material options to machine motorcycle components. To break down these materials into more detail, you may check the Table 1 below:

Table 1: Common Materials Used in CNC Motorcycle Parts

| Common Material | Key Properties | Used For |

| Aluminum Alloys (6061-T6, 7075-T6) | Lightweight, strong, corrosion-resistant, excellent machinability | Engine covers, triple trees, rearsets, brake calipers, frame components |

| Titanium | Extremely strong, lightweight, high heat resistance, premium performance | Valves, connecting rods, exhaust brackets, high-stress structural parts |

| Stainless Steel (304, 316) | Very durable, corrosion-resistant, ideal for heavy-load components | Bolts, fasteners, axle pins, brake parts, hardware |

| Steel Alloys (e.g., 4130 Chromoly) | High strength, high rigidity, excellent for load-bearing structures | Chassis parts, steering shafts, drivetrain components |

| Carbon Fiber & Composites | Ultra-lightweight, strong, high stiffness, modern aesthetics | Fairings, dashboards, lightweight structural shells |

| Brass & Bronze | Easy to machine, corrosion-resistant, visually appealing | Bushings, gaskets, decorative covers, electrical connectors |

| Engineering Plastics (PVC, Delrin/POM, Nylon, etc.) | Lightweight, highly machinable, impact-resistant | Light housings, covers, spacers, non-structural custom parts |

A proper finish not only enhances the appearance of a CNC motorcycle part but also protects it from corrosion or wearing. So, achieving the right surface finish is just as important as machining itself.Let’s see the different surface finishes in the rundown below.

A raw machined finish is the natural surface left after CNC cutting. Tool marks are visible, giving the part a clean, industrial look. This finish is common for precision components or parts where appearance is not the priority. Surface roughness can range from Ra 3.2 μm to 0.4 μm of motorcycle cnc parts depending on tooling and cutting parameters. It applies to all CNC-machinable materials.

Anodizing is an electrochemical process used mainly on aluminum alloys. It creates a hard, wear-resistant, corrosion-resistant, and colorable oxide layer on the surface. This makes it ideal for both durability and custom appearance upgrades of bike parts. Anodizing is commonly used on aluminum such as 6061 and 7075. Titanium can also be anodized, but only for decorative color effects rather than protection.

Powder coating applies dry powder to the motorbike part using electrostatic charge, then cures it at high temperature to form a thick, durable finish. It’s a great option for CNC motorcycle parts that need toughness and bold visual style, such as brackets, frames, and exposed structural components. This surface finishing process works well on aluminum, steel, and stainless-steel parts.

Electroplating deposits a thin metal layer( such as chrome, nickel, or zinc) onto the part’s surface. This improves hardness, corrosion resistance, and adds a bright metallic look for the bike components. Chrome plating is popular for both style and wear resistance on items like foot pegs, guards, and cover plates. Nickel plating boosts wear resistance and corrosion protection, while zinc plating is common for fasteners. This surface finishing process can be used on steel, stainless steel, brass, copper, and aluminum with proper pre-treatment.

Polishing uses mechanical methods to remove small tool marks and create a smooth or mirror-like shine. It’s ideal for showing bikes, vintage-style components, or any part that needs a clean, high-gloss metal look. This way can improve aesthetics and feel of the parts. It works well on aluminum, stainless steel, brass, copper, and some titanium parts.

Blasting uses abrasive media such as glass beads or aluminum oxide to create an even matte texture on the surface. It can remove small imperfections, prep the surface for coatings, or serve as a final finish. It’s frequently used on triple trees, foot pegs, and housings to achieve the industrial look. Suitable materials include aluminum, stainless steel, steel, and titanium.

Passivation is a chemical treatment designed for stainless steel. It removes free iron on the surface and strengthens the metal’s natural corrosion resistance. The appearance does not change, and no extra thickness is added. This makes it ideal for brake components, bolts, shafts, and parts exposed to harsh environments. Commonly used on 304 stainless steel and 316 stainless steel.

Electropolishing uses an electrochemical process to remove a thin, controlled layer of metal from the surface. It creates a very smooth, bright finish and improves corrosion resistance. It is especially useful for stainless steel parts that need high cleanliness, shine, or enhanced durability, such as exhaust components, fasteners, and decorative parts. This way is only suitable for stainless steel.

Chemical conversion coatings are used on aluminum to improve corrosion resistance and enhance paint or powder coat adhesion. This finish is common for aluminum parts that will receive another coating afterward, such as body panels, electronic housings, and mounting brackets. Popular types include chromate conversion coating and Alodine.

Laser marking uses a focused laser beam to create permanent text, graphics, serial numbers, or branding on a part. It is ideal for custom motorcycle parts or OEM/ODM identification. This process works on aluminum, stainless steel, steel, titanium, copper, brass, and many engineering plastics like POM and nylon.

When planning to manufacture CNC motorcycle parts, several factors affect the overall cost.

To optimize costs, you may consider :

By clearly specifying the tolerances and features that are essential for performance, you can avoid unnecessary machining complexity and keep CNC motorcycle part production both efficient and affordable.

Producing precision CNC motorcycle parts demands strict quality control to ensure each component meets performance and safety standards.

All these quality control measures guarantee long-term reliability, rider safety, and OEM-level performance for CNC-machined motorcycle parts.

While CNC machining is a powerful tool for producing high-precision motorcycle parts, it also comes with some limitations. That may include:

Programming, tooling, and machine setup make single-piece production relatively expensive compared to traditional methods.

CNC is a subtractive process, and the excess material is removed to create the part. Depending on the geometry and material, this can generate scrap and increase overall material cost.

Large parts may require multiple setups, specialized fixtures, or even alternative fabrication methods.

This article has showed full aspects of cnc machined motorcycle parts, from part types, material selection, surface treatment,to cost and risks, etc. With unmatched precision, flexible design, and compatibility with high-performance materials, CNC machining empowers riders and manufacturers to create durable, beautiful, and fully custom components.

If you’re looking for a reliable manufacturer to bring your CNC motorcycle parts to life, VMT CNC Machining Factory has extensive experience producing a wide range of motorcycle components, from foot pegs, gears, to sprockets and other critical parts. With over 1,000 motorcycle parts clients worldwide, VMT offers professional services covering high-precision metal machining and a full spectrum of surface finishes. We can provide a one-stop solution that ensures your custom or OEM motorcycle parts meet the highest standards of quality, precision, and durability.

What are the maintenance tips for CNC motorcycle parts?

Regularly clean your parts to remove dirt and debris, inspect any signs of damage, keep moving parts properly lubricated, and prevent surface corrosion by using protective coatings or storage methods.

Can CNC motorcycle parts be customized?

Yes! CNC machining excels in custom designs. You can adjust size, shape, surface texture, and even add engraving or laser markings for branding or personalization.

Are CNC motorcycle accessories safe for high-performance use?

Yes. When manufactured with proper quality control and testing, CNC motorcycle parts meet or exceed OEM standards for durability, fitment, and performance, making them suitable for both daily riding and high-performance applications.

Is CNC machining better than forging?

It depends on the application. CNC machining offers higher precision, more design flexibility, and excellent surface finish options. Forging provides higher material strength and toughness but is less flexible for complex geometries.

Are forged parts stronger than machined parts?

Forged parts typically have better grain structure and higher impact strength, making them ideal for high-load applications. CNC machined parts can match strength if the raw material is solid billet and the design is optimized, while also offering tighter tolerances.

How often should a CNC machine be serviced?

CNC machines should have routine maintenance at least once every 3–6 months, depending on usage, including cleaning, lubrication, checking tool calibration, and inspecting critical components for wear.