15 years one-stop China custom CNC machining parts factory

25 |

Published by VMT at Nov 24 2025 | Reading Time:About 3 minutes

25 |

Published by VMT at Nov 24 2025 | Reading Time:About 3 minutes

Are you looking for stainless steel with high requirements or special application needs? The answer is 316 stainless steel—a material that offers non-magnetic behavior, food-grade safety, excellent corrosion resistance, high strength, and reliable performance in high-temperature environments.

This article will guide you through the composition, properties, advantages and disadvantages, processing methods, and applications of 316 stainless steel. You will get some useful references when determining whether 316 stainless steel is a good choice for you or not.

316 stainless steel is an austenitic stainless steel with added molybdenum, chromium (Cr), nickel (Ni), and molybdenum (Mo). It meets the high requirements of food-grade, chemical-grade, and marine-grade applications, so basically 316 stainless steel can be used for all kinds of industries.

Common Variants of 316 Stainless Steel

Common variants of 316 stainless steel (316L, 316H, 316Ti) are derivatives of 316, not separate steel grades. Although their microstructure and characteristics are similar to standard 316, there are also some differences for themselves.

Resistant to corrosion during welding. 316L is a low-carbon version of 316 stainless steel, with a maximum carbon content of 0.03%. The low-carbon version of 316L significantly reduces the risk of intergranular corrosion (sensitization) after welding. It is particularly suitable for food, pharmaceutical, and welding equipment applications.

316H (High Carbon Variant)

Maintains strength at high temperatures. 316H stainless steel has a higher carbon content (0.04% to 0.10%), which improves creep strength and tensile strength at high temperatures. Its excellent strength in high-temperature environments makes it suitable for boilers, pressure vessels, high-temperature pipelines, etc.

316Ti (Titanium-Stabilized Variant)

Suitable for long-term high-temperature environments. This stainless steel is stabilized by adding titanium, which combines with carbon to form carbides, preventing carbide precipitation during high-temperature exposure (425–815°C). Its corrosion resistance in high-temperature environments makes it suitable for long-term high-temperature chemical equipment.

Chemical Composition of 316 Stainless Steel

The chemical composition of 316 stainless steel includes molybdenum, chromium (Cr), nickel (Ni), and molybdenum (Mo), etc. Below is the specific composition of 316 stainless steel and its variants.

Table 1: Chemical Composition of 316, 316L, 316H, 316Ti Stainless Steel

| Types( % ) |

316 |

316L |

316H |

316Ti |

| Chromium (Cr) |

16.0–18.0 | 16.0–18.0 | 16.0–18.0 | 16.0–18.0 |

| Nickel (Ni) |

10.0–14.0 | 10.0–14.0 | 10.0–14.0 | 10.0–14.0 |

| Molybdenum (Mo) |

2.0–3.0 | 2.0–3.0 | 2.0–3.0 | 2.0–3.0 |

| Carbon (C) |

≤ 0.08 | ≤ 0.03 | 0.04–0.10 | ≤ 0.08 |

| Manganese (Mn) |

≤ 2.00 | ≤ 2.00 | ≤ 2.00 | ≤ 2.00 |

| Silicon (Si) |

≤ 0.75 | ≤ 0.75 | ≤ 0.75 | ≤ 0.75 |

| Phosphorus (P) |

≤ 0.045 | ≤ 0.045 | ≤ 0.045 | ≤ 0.045 |

| Sulfur (S) |

≤ 0.030 | ≤ 0.030 | ≤ 0.030 | ≤ 0.030 |

| Titanium (Ti) |

none | none | none | ≤ 0.70 |

| Iron (Fe) |

Remainder | Remainder | Remainder | Remainder |

Physical Properties of 316 Stainless Steel

In terms of physical properties, the main parameters include density, melting point, elastic modulus, resistivity, thermal conductivity, and coefficient of thermal expansion. These values reflect the fundamental physical characteristics of 316 stainless steel under conditions of heat, stress, and electrical conductivity. Since the 316 series are all austenitic stainless steels, their physical properties are primarily determined by the austenitic crystal structure.

Therefore, the differences in physical properties between variants such as 316, 316L, and 316Ti are very small, and minute variations in carbon or titanium content have limited impact on these physical parameters.

Based on this, the values of density, thermal expansion, resistivity, and thermal conductivity of 316 stainless steel and its variants are roughly the same. Specific typical physical property data can be found in the table below.

Table 2: Physical Properties of 316 Stainless Steel

| Property |

Unit |

Value (Approximately) |

| Density |

g/cm³ | 8.0 |

| Melting Point |

°C | 1370–1400 |

|

Elastic Modulus |

GPa | 193 |

| Electrical Resistivity |

Ω·m | 0.74 x 10⁻⁶ |

| Thermal Conductivity |

W/(m·K) | 16.3–16.6 (20-100°C) |

| Thermal Expansion |

µm/m·°C | 6.5–17.5 (20-100°C) |

Mechanical Properties of 316 Stainless Steel

The mechanical properties of 316 stainless steel are mainly reflected in its tensile strength, yield point, elongation, and Brinell hardness. These parameters collectively reflect the load-bearing capacity, plasticity, and resistance to deformation under stress. The mechanical properties of 316 stainless steel are significantly affected by its carbon content. Higher carbon content increases the material's strength (including tensile strength and yield strength), but decreases its plasticity and elongation. Lower carbon content results in better toughness and plasticity, increased elongation, but slightly reduced strength. The following are the tensile strength, yield point, elongation, and Brinell hardness values for 16, 316L, 316H, and 316Ti stainless steels in the annealed state.

Table 3: Mechanical Property of 316, 316L, 316H, 316Ti Stainless Steel (In Annealed State)

| Property |

316 |

316L |

316H |

316Ti |

| Ultimate Tensile Strength( MPa) |

~520–680 | ~485-585 | ~485-655 | ~515-655 |

| Yield Strength (0.2% Offset) |

≥ 220 | ≥ 170 | ≥ 205 | ≥ 205 |

| Elongation (A50 mm) |

≥ 40% | ≥ 40% | ≥ 30% | ≥ 35% |

| Brinell Hardness (HB) |

~160 (max 217) | ~140 (max 217) | ~180+ | ~160+ |

While 316 stainless steel is excellent in many ways, such as corrosion resistance, high strength, and high temperature resistance, making it suitable for virtually any industry, it also has drawbacks, including difficulty in processing and poor thermal conductivity. You need to understand both its advantages and limitations to make a clear judgment about whether this steel is suitable for your project's application scenario.

Advantages of 316 Stainless Steel

Corrosion Resistance and Durability

316 stainless steel, with the addition of molybdenum, resists pitting and crevice corrosion in chloride environments, exhibiting excellent corrosion resistance in chloride and acidic environments. Therefore, 316 stainless steel has durable properties under high corrosion requirements, such as seawater environments.

Heat Resistance (Thermal Properties)

316 stainless steel has good oxidation resistance and maintains its strength at high temperatures. In particular, 316Ti, stabilized by the addition of titanium, can be used continuously at temperatures up to 925°C (1697°F) while maintaining structural integrity and not cracking.

High Mechanical Strength

316 stainless steel has high tensile and yield strength, making it suitable for shaft, gear and other mechanical parts

Non-magnetic

316 stainless steel is virtually non-magnetic after annealing, making it ideal for magnetically sensitive applications.

Hygiene

316 stainless steel is non-toxic, not easy to breed bacteria, and meets stringent hygiene standards, making it an ideal material for the food and medical industries.

Disadvantages of 316 Stainless Steel

Relatively Hard to Machining

316 stainless steel is more like to harden, requiring more specialized tools and cutting fluids for machining, and the machining speed is slower.

Higher Cost

Compared to other stainless steels (including the widely used 304 stainless steel), 316 stainless steel has a higher alloy content, especially molybdenum and nickel, which makes it more difficult to process and relatively more expensive.

Poor Thermal Conductivity

Like most austenitic stainless steels, 316 has a relatively low thermal conductivity, which is a disadvantage in applications requiring rapid heat exchange (such as certain heat exchanger designs).

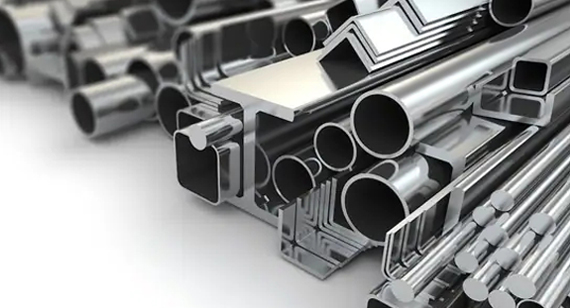

1.Sheet

If you need a versatile and easily machinable material, sheet form is your best choice. Its thickness is typically between 0.5 mm and 6 mm, and you can cut, bend, or weld it into various shapes as needed. Whether it's kitchenware, building facades, or tank sidewalls, you'll find this material in many products.

2.Plate

If your project requires higher structural strength, you can choose the plate form. Its thickness typically exceeds 6 mm, making it ideal for heavy machinery, pressure vessels, or bridge structures.

3.Bar

If you're involved in CNC machining or need to manufacture high-precision parts, a bar is ideal. It boasts excellent mechanical properties, making it perfect for machining bolts, shafts, and structural components that bear heavy loads. We (VMT CNC machining factory) usually use this form to manufacture high-precision parts for the clients.

4.Strip

If you require high precision of small, lightweight parts , you can choose a stainless steel strip. It's a narrow sheet coil suitable for stamping, bending, and stretching processes. Spring sheets, washers, and metal clips are commonly made from this material.

5.Tubes(Thin-Walled )

If your application involves light structures, furniture, medical devices, or decorative uses, thin-walled stainless steel tubes are ideal. They offer high dimensional accuracy and a superior appearance, making them suitable for manufacturing support frames, handrails, display structures, or for low-pressure fluid transport.

6.Pipes(Thick-Walled)

Thick-walled stainless steel tubes are better suited for transporting industrial fluids such as water, oil, gas, or chemicals. They offer a wider range of wall thicknesses to match pressure ratings, ensuring your system has excellent pressure and corrosion resistance, making them an indispensable material in industrial environments.

7.Fittings & Flanges

If your piping system requires connections, reversals, seals, or terminations, you'll need various fittings and flanges. Examples include elbows, tees, reducers, and flanges. These help you build a safe, stable, and leak-free piping system, an essential component of any fluid transport project.

Regarding the manufacturing and processing methods for 316 stainless steel, you should know the following:

The high strength, high toughness, and excellent corrosion resistance of 316 stainless steel make it a high-performance material in CNC machining.

We (the VMT professional team) typically process 316 stainless steel bars and plates into precision parts through turning, milling, drilling, and tapping.

However, the machining process for 316 stainless steel is relatively more difficult compared to other materials (such as 304 stainless steel). It is prone to work hardening, tool sticking, and accelerated tool wear during cutting, which also results in relatively higher costs.

However, if you have stringent requirements for application scenarios and precision (such as food equipment or high-precision medical parts), it is best to choose 316 stainless steel for CNC machining.

Metal Laser Sintering

If you require complex, lightweight structural parts, you can choose the metal laser sintering for manufacturing. 316L powder (low-carbon version) is particularly suitable for this type of additive manufacturing because it better avoids cracking and intergranular corrosion.

It may retain heat during laser processing, leading to residual stress, which we (the VMT professional team) usually eliminate through subsequent annealing.

The metal laser sintering process for 316L (low-carbon version) stainless steel is suitable for producing small-batch custom parts for medical, aerospace, and chemical applications.

If you require large-volume production of parts, in 3D printing processes, such as binder jetting, is another way to manufacture 316 stainless steel parts.

However, the strength produced by this process is lower, and the surface accuracy of the adhesive injection is slightly lower.

If you are not particularly strict with strength and surface accuracy, you can choose this manufacturing way.

If your 316 stainless steel parts require welding, then 316L (low-carbon version) should be the preferred choice for welding to avoid the risk of intergranular corrosion and maintain corrosion resistance.

Welded 316L (low-carbon version) remains non-magnetic (annealed state), making it ideal for magnetically sensitive applications.

About Annealing: Hot-Rolled vs. Cold-Drawn

316 stainless steel undergoes hot rolling or cold rolling during manufacturing, and annealing is a crucial step in ensuring its performance.

After annealing, hot-rolled 316 stainless steel achieves a more balanced strength and toughness, and stronger resistance to intergranular corrosion.

After annealing, cold-drawn 316 stainless steel eliminates the hardening caused by cold drawing, maintaining its good machinability.

Why 316 Stainless Steel Fits These Industries and Components?

316 stainless steel is chosen across demanding industries because of its exceptional corrosion resistance, especially against chlorides, chemicals, and acidic environments. The addition of 2–3% molybdenum significantly enhances its durability in saltwater, high-humidity, and chemically aggressive conditions. Its excellent weldability, formability, and high-temperature stability also make it suitable for precision CNC machining of complex geometries. Moreover, 316 stainless steel offers superior hygiene performance, making it a preferred material for industries requiring sterile or contamination-free environments. These combined characteristics allow 316 stainless steel CNC machined parts to deliver long-term reliability, safety, and performance across multiple sectors.

Industries That Commonly Use 316 Stainless Steel

Marine Industry

Medical & Healthcare

Food & Beverage Processing

Chemical Processing & Petrochemical

Pharmaceutical Manufacturing

Oil & Gas

Water Treatment & Environmental Equipment

Automotive & New Energy Vehicles

Table: Industries, Part Types, and the 316 Stainless Steel Properties That Make Them Suitable

| Industry |

Typical CNC-Machined Parts |

Why 316 Stainless Steel Is Ideal |

| Marine Industry |

Brackets, fasteners, pump housings, marine fittings | Outstanding chloride & saltwater corrosion resistance; prevents pitting and crevice corrosion in seawater environments |

| Medical & Healthcare |

Surgical handles, orthopedic components, sterilization equipment parts | High hygiene standards, excellent sterilization resistance, biocompatibility, and durability under repeated cleaning cycles |

| Food & Beverage Processing |

Sanitary valves, mixing blades, equipment fittings | Smooth finish, high corrosion resistance, and easy sanitization for contamination-free food processing environments |

| Chemical & Petrochemical |

Chemical pump components, reactor fittings, corrosion-resistant valves | Exceptional chemical resistance, especially against acids and chlorides; stable performance in harsh chemical exposure |

| Pharmaceutical Manufacturing |

High-purity manifolds, metering parts, cleanroom components | High cleanliness, non-reactive surface, and long-term stability in sterilized or controlled environments |

| Oil & Gas |

Connectors, sealing components, high-pressure fittings | Strength and corrosion resistance under high heat, pressure, and chemical exposure |

| Water Treatment & Desalination |

Filter housings, desalination parts, pump components | Proven performance against chlorides and moisture; resistant to pitting and corrosion in water filtration systems |

| Automotive & New Energy Vehicles |

Sensor housings, fuel system parts, battery hardware | Heat resistance, corrosion resistance, and stable performance in fuel, chemical, and high-temperature environments |

To help you find equivalent names for 316 stainless steel (and its variants) in other regions, I have compiled a table below for your convenience.

Table 4: Equivalent Grades of 316 (and its variants) Stainless Steel in Different Regions

| Country |

316 |

316L |

316H |

316Ti |

|

United States |

ASTM/UNS S31600 | ASTM/UNS S31603 | ASTM/UNS S31609 | ASTM/UNS S31635 |

| European Union (EN/DIN) |

EN 1.4401, X5CrNiMo17-12-2 | EN 1.4404, X2CrNiMo17-12-2 | EN 1.4919, X6CrNiMoTi17-12-2 | EN 1.4571, X6CrNiMoTi17-12-2 |

| Germany (DIN) |

X5CrNiMo17-12-2 | X2CrNiMo17-12-2 | X12CrNiMo17-12-2 / 1.4919 | X6CrNiMoTi17-12-2 |

| United Kingdom (BS) |

BS 316S31, 316S11 | BS 316S11, 316S13 | 316S51, 316S52 | 320S31 |

| France (AFNOR) |

Z6CND17-11 | Z2CND17-12 | Z10CND17-12 | Z6CNDT17-12 |

| Japan (JIS) |

SUS 316 | SUS 316L | SUS 316H | SUS 316Ti (also known as SUS 316T) |

| China (GB) |

0Cr17Ni12Mo2 | 00Cr17Ni14Mo2 | 0Cr17Ni12Mo2H( 12Cr17Ni7) | 0Cr18Ni12Mo2Ti |

| Russia (GOST) |

08X17H13M2T | 03X17H14M3 | 08X17H13M2T-H | 10X17H13M2T |

Machining 316 stainless steel parts is one of the many stainless steel machining services offered by VMT CNC Machining Factory. We (VMT professional team)have extensive experience and numerous cases in stainless steel CNC machining and complex surface finishes. We can provide you with complete solutions from material selection and structural optimization to mass production.

If your project is seeking feasible advice, processing solutions, and rapid prototyping services for stainless steel parts, please contact VMT experts for a free consultation and quote.

316 vs. 304 Stainless Steel: Which to Choose?

316 has better corrosion resistance and hardness than 304, and is biocompatible and non-magnetic, but it is more expensive. For general applications, 304 offers better value for money. For more demanding requirements or special applications, 316 is recommended.

316 vs. 308 Stainless Steel: Which to Choose?

316 is a structural material used for manufacturing parts; 308 is mainly used for welding and is a common material for welding wires and electrodes.

316 vs. 416 Stainless Steel: Which to Choose?

316 is significantly superior to 416 in corrosion resistance and durability, while 416 has the advantage of excellent machinability. If you need to use your stainless steel in corrosive environments for extended periods, choose 316; if you prioritize machining efficiency for components such as shafts and gears, then choose 416.

316 vs. 3Cr13 Stainless Steel: Which to Choose?

316 has stronger corrosion resistance, while 3Cr13 can achieve higher hardness through quenching. If you need to make corrosion-resistant parts or hygienic products, choose 316. If you need to make high-hardness tools such as knives and scissors, 3Cr13 is more suitable.

316 vs. 420 Stainless Steel: Which to Choose?

316 performs better in terms of corrosion resistance, hygiene, and stability, while 420 stainless steel can be hardened and has higher hardness (harder and more expensive than 3Cr13). If you need to use it in chemical, food, or marine environments, choose 316; if you need to make knives, scalpels, or wear-resistant parts, 420 is more suitable.