15 years one-stop China custom CNC machining parts factory

6 |

Published by VMT at Nov 20 2025 | Reading Time:About 5 minutes

6 |

Published by VMT at Nov 20 2025 | Reading Time:About 5 minutes

When you're planning your metal parts, choosing the right manufacturing method can feel confusing. You might hear terms like forging and fabrication, but not know which one suits your project. Picking the wrong process can lead to higher costs, weak parts, or delays. Fortunately, once you understand the differences and steps between forging and fabrication, you can make smart decisions with confidence. This guide makes it simple and practical for you to choose the right path for your metalworking needs.

Forging shapes metal through pressure and heat, while fabrication combines cutting, welding, and assembling different metal pieces. Forging is best for high-strength parts, and fabrication is ideal for custom fabrication and complex structures. Choosing between them depends on strength requirements, shape complexity, budget, and production volume.

Now that you understand the basic idea, let’s dive deeper into how each process works. You’ll learn each step of forging and fabrication, their common methods, advantages, disadvantages, and how to choose the right one for your CNC machined parts project.

Forging is a metalworking process where metal is shaped using pressure, heat, or both. Instead of removing material like machining does, forging reshapes it to create stronger, more durable parts. This makes it ideal for structural components, high-stress parts, and industries where safety is critical—such as automotive, aerospace, and heavy machinery. You can choose between hot forging and cold forging depending on your material and strength needs.

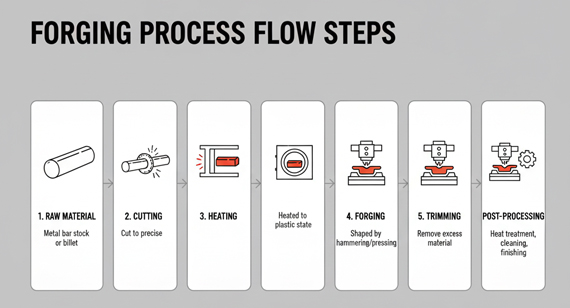

Before forging begins, a clear process flow is essential. Each step—from die design to finishing—affects part quality, strength, cost, and production speed. Understanding the full sequence helps you plan your metal forging project more efficiently and avoid delays. Whether you're developing custom parts or mass production, a structured forging process ensures consistency and reliability.

Die Design and Manufacturing

Die design is the foundation of successful metal forging. The die determines the part’s final shape, dimensions, and tolerances. A well-designed die minimizes defects, reduces machining time, and improves material flow during forging. Once designed, the die is manufactured using high-strength tool steel and precise machining—often done using CNC machining services to ensure accuracy and long tool life.

Bill/Ingot Preparation

In this stage, the raw metal material—usually in the form of billets or ingots—is selected and cut to size. Material selection is critical, as different metals respond differently to heat and pressure during forging. The material must be clean and free from cracks or surface defects, ensuring consistent strength after forging. Proper preparation reduces waste and improves metal flow during shaping.

For hot forging, the billet or ingot is heated to a specific temperature range where it becomes more ductile and easier to form. The heating temperature depends on the metal type: for example, steel may reach 1,100°C while aluminum requires lower temperatures. Controlled heating prevents excessive grain growth and keeps the material ready for forging pressure.

Forging

This is where the metal takes shape. Using high pressure, the heated material is compressed and formed through dies or machinery. Options include hammer forging, press forging, roll forging, and upsetting—each suited for different part shapes and strength levels. The forging step significantly improves grain structure, creating strong, durable forged parts.

After forging, heat treatment improves mechanical properties like hardness, strength, and toughness. Common processes include annealing, quenching, and tempering. This step helps relieve internal stress created during forging and ensures long-term stability of the part before further machining or finishing.

Cooling

Cooling must be controlled to avoid warping or cracks. Depending on the metal and desired properties, cooling may be fast (quenching) or slow (air cooling or furnace cooling). This step locks in the material’s structure and prepares it for final finishing or CNC machining.

Finally, the forged part goes through finishing steps such as deburring, grinding, coating, or polishing. This improves corrosion resistance, appearance, and precision. Surface treatment also prepares the part for CNC machining or assembly. At this stage, dimensions are confirmed to meet final tolerances.

There is no single “best” forging method. Each technique offers different strengths depending on your part shape, metal type, strength requirements, and budget. By understanding the main methods—such as hammer forging, pressure forging, and precision forging—you can choose the most efficient process for your metalworking project.

Hammer Forging

Hammer forging uses repeated blows from a hammer to shape the heated metal. It’s simple, flexible, and ideal for small batches or custom shapes. However, accuracy depends heavily on operator skill, and surface defects may appear if not controlled properly.

Pressure Forging

In pressure forging, the force is applied steadily through a press rather than repeated hammer strikes. This ensures better material flow and more accurate dimensions. It is suitable for medium to large production volumes and high-strength parts.

Roll Forging

Roll forging continuously shapes metal by passing it through rotating rolls. This process is efficient for long parts like shafts, bars, or tapered components. It improves grain structure and reduces material waste.

Upsetting

Upsetting increases the cross-sectional area of the metal by compressing one end. It’s commonly used to create bolt heads, valves, and fasteners. The process is quick and helps maintain strength without removing any material.

Automatic Hot Forging

Automatic hot forging is a high-speed, automated process used for mass production of forged parts. Metal is heated and shaped in a continuous line, reducing labor and increasing consistency. It’s widely used in automotive components and hardware manufacturing.

Rolled Ring Forging

This method forms strong rings by piercing a hole in a metal billet and then rolling it into shape. It produces excellent strength-to-weight ratio, making it ideal for aerospace, bearings, and turbines.

Precision Forging (Cold Forging)

Precision forging—often done at room temperature—produces near-net-shape parts with excellent accuracy. Since it doesn’t use heat, it requires high pressure but reduces finishing steps and material waste.

Isothermal Forging

In isothermal forging, the die is kept at the same temperature as the metal. This prevents thermal shock and improves metal flow. It’s ideal for hard-to-forge materials such as titanium or superalloys.

Induction Forging

Induction forging uses electromagnetic induction to heat metal rapidly and uniformly before forging. It is energy-efficient and precise, making it suitable for selective heating and continuous production lines.

Spinning

Spinning shapes metal using rotational force and a pressing tool. It creates hollow, symmetrical parts like cones, cylinders, or cookware. Spinning is often used with sheet metal and can be combined with CNC machining for accuracy.

Fabrication is the process of creating metal structures by cutting, welding, bending, and assembling different metal parts together. Unlike forging—where metal is reshaped under pressure—fabrication focuses on building components from separate pieces. It’s ideal for custom fabrication, complex structures, and large assemblies such as frames, enclosures, and industrial equipment.

Fabrication combines different metalworking technologies to build parts from separate components. Each technology—casting, welding, or cutting—serves a specific purpose depending on your design, strength needs, and budget. Understanding these methods helps you choose the most cost-effective fabrication process for your manufactured parts.

Casting involves pouring molten metal into a mold to create a shaped part. It’s ideal for complex shapes and large components, especially when cost efficiency matters. However, casting usually requires additional finishing or CNC machining to achieve precise tolerances.

Welding joins metal pieces together using high heat. It’s widely used in metal fabrication to assemble frames, supports, and structural components. Different welding methods (MIG, TIG, laser welding) can be selected based on metal type and strength requirements.

Cutting

Cutting prepares raw material for fabrication by separating metal into workable shapes. Modern fabrication uses advanced cutting technologies like laser cutting or waterjet cutting to improve precision and reduce waste. Proper cutting helps lower material cost and speeds up assembly.

Cutting Types

Different cutting methods offer different levels of precision, speed, and cost. Choosing the right cutting method depends on material type, part thickness, and accuracy needs. Using the wrong cutting method can increase scrap rate or require extra machining afterward.

Waterjet Cutting

Waterjet cutting uses high-pressure water—sometimes with abrasive particles—to cut metal without heat. It avoids heat distortion and works well on thick, hard materials.

Laser Cutting

Laser cutting provides high precision and smooth edges, making it ideal for detailed or intricate designs. It works best with thin metal sheets and is often used in custom fabrication or prototype manufacturing.

Plasma Cutting

Plasma cutting uses high-temperature plasma to cut through thick metals quickly. It is faster than laser cutting but offers slightly lower precision. It is commonly used in structural fabrication or large-scale manufacturing.

Torches

Torch cutting is a traditional method using oxy-fuel to melt and cut metal. It’s affordable and suitable for on-site work but lacks precision and may leave rough edges.

Mechanical Cutters

Mechanical cutters include shears, saws, and milling machines. They physically remove material and require manual or semi-automatic control. They are useful for simple shapes and small batches.

Drilling creates holes for bolts, assembly, or alignment. It is commonly used during fabrication to prepare parts for later joining or CNC machining. Drilling machines and CNC drilling stations improve speed and consistency.

Punching uses force to push metal through a die, creating holes or shapes. It’s fast and efficient for sheet metal fabrication and mass production.

Bending/Folding

Bending shapes metal without cutting it. Press brakes or rollers are used to form angles, curves, or channels. This is essential in frame building, enclosures, and chassis fabrication.

Stamping forms metal into complex shapes using a die and high pressure. It’s suitable for high-volume production of parts like brackets, housings, and automotive components.

Drawing

Drawing stretches metal to create deeper shapes such as cups, cans, or containers. It is similar to stamping but focuses on depth rather than flat shape formation.

Both forging and fabrication are essential metalworking processes, but they serve different goals. Forging reshapes a single piece of metal using pressure and heat, which improves strength and structural integrity. Fabrication combines multiple metal parts through cutting, welding, and assembly, offering more flexibility and design freedom. Your choice depends on strength requirements, part complexity, cost, and production volume.

Table:Key Differences Between Forging and Fabrication

| Comparison Factor |

Forging |

Fabrication |

| Basic Process |

Reshapes one metal piece using pressure and heat | Builds parts by assembling multiple pieces |

| Strength |

Very high — ideal for stressed parts | Depends on welds and joints |

| Material Use |

Minimal waste | Can generate more scrap |

| Design Flexibility |

Lower — limited shape complexity | High — supports complex structures |

| Common Applications |

Shafts, gears, valves, aerospace parts | Frames, enclosures, machinery, custom fabrication |

| Production Volume |

Suitable for medium to large batches | Suitable for custom or low-volume projects |

| Cost Efficiency |

Higher tooling cost but strong durability | Lower tooling cost but more assembly labor |

| CNC Machining Needs |

Often requires finishing machining | Machining may be needed after welding/cutting |

| Ideal Choice When |

High strength and durability are required | Design flexibility and customization are needed |

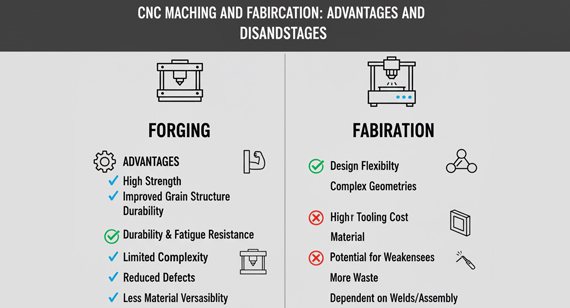

Both forging and fabrication have clear strengths and limitations. The right choice depends on part performance, complexity, and production volume. Understanding their pros and cons helps you select the most cost-effective process for your metalworking project and avoid expensive redesigns later.

Forging: Advantages and Disadvantages

Forging is chosen when maximum strength and reliability are required. However, it also has limitations in design flexibility and tooling cost. Reviewing both sides helps you decide whether forged parts are the best fit for your product.

Advantages of Forging

Tip: When working with a CNC machining factory, provide clear forging drawings to limit machining revisions.

Disadvantages of Forging

Tip: If the part shape changes often, fabrication might be more economical than forging.

Fabrication: Advantages and Disadvantages

Fabrication is more flexible and suitable for custom designs, but each joint or weld affects strength and appearance. Knowing both sides helps you balance performance with cost.

Advantages of Fabrication

Tip: Fabrication is ideal when design changes are likely—especially during prototyping.

Disadvantages of Fabrication

Tip: For large fabricated parts, check distortion risk—CNC machining may be required for final alignment.

Different industries rely on forging and fabrication for very different reasons. Forging is preferred when strength and durability are critical, while fabrication is ideal for larger structures or assemblies with multiple components. Knowing where each process is used will help you choose the right manufacturing method for your CNC machined parts or custom fabrication projects.

Forging: Industry Applications and Parts

Forging is commonly used in industries where safety, durability, and performance are essential. Below are typical applications and forged parts:

Industries using forging:

Common forged parts:

Tip: Forged parts often require CNC machining services for final precision—request tolerance data from the start to avoid rework.

Fabrication: Industry Applications and Parts

Fabrication is ideal for structures and assemblies that need flexibility, customization, or modular design. It is widely used in construction, machinery manufacturing, and metalworking projects.

Industries using fabrication:

Common fabricated parts:

Tip: For large fabricated assemblies, consider combining fabrication with CNC machined parts to improve accuracy and alignment.

Why Forging and Fabrication Can Be Applied to These Industry Parts

Forging and fabrication are widely used in industrial manufacturing because they offer different structural, mechanical, and design advantages. Their suitability depends on the performance requirements of each part, such as strength, precision, fatigue resistance, corrosion resistance, and weight-to-strength ratio.

Why Forging Works

Forged parts are hot- or cold-shaped under pressure, which refines the metal grain structure and eliminates internal voids. This process results in:

Therefore, industries that require structural integrity, durability, and reliability—such as automotive, aerospace, energy, and heavy machinery—often use forged parts.

Why Fabrication Works

Fabrication involves cutting, bending, welding, machining, and assembling metal components. It provides:

Thus, fabrication is ideal for custom structures, housings, frames, enclosures, piping systems, and specialized equipment across multiple industries.

Applications of Forging & Fabrication by Industry

| Industry |

Why Forging is Used |

Why Fabrication is Used |

Typical Forged Parts |

Typical Fabricated Parts |

| Automotive |

High-strength components that withstand dynamic loads | Complex vehicle structures and custom assemblies | Crankshafts, gears, axles, steering knuckles | Exhaust systems, chassis frames, brackets |

| Aerospace |

Requires extreme reliability and fatigue resistance | Lightweight structural assemblies and enclosures | Turbine blades, landing gear, engine parts | Aircraft frames, fuel tanks, control panels |

| Oil & Gas |

Must tolerate high pressure and corrosion | Large-scale structural support and piping | Valve bodies, flanges, drill bits | Pipelines, storage tanks, platforms |

| Construction & Infrastructure |

Load-bearing components and safety-critical parts | Structural frameworks and support systems | Structural bolts, anchors, lifting hooks | Beams, railings, columns, steel structures |

| Heavy Machinery |

Needs high wear resistance and impact strength | Housing, body frames, and machine enclosures | Shafts, gear blanks, bearings | Machine housings, guards, welded assemblies |

| Defense & Military |

High-stress conditions and extreme durability | Rapid customization and specialty equipment | Missile components, weapon mounts | Armor panels, vehicle frames, shelters |

| Rail & Marine |

Fatigue and corrosion resistance required | Complex cabin structures and vessel interiors | Couplers, axles, engine parts | Ship hulls, containers, hydraulic lines |

| Renewable Energy |

High-load-bearing and rotating parts | Structural support and precision assemblies | Turbine shafts, rotor hubs | Mounting frames, brackets, enclosures |

Why These Manufacturing Methods Match Industry Needs

Industry demands can be summarized into four core criteria:

| Requirement |

Forging Advantage |

Fabrication Advantage |

| High Mechanical Strength |

Excellent grain structure and strength |

Can combine forged parts into assemblies |

| Complex Shapes |

Near-net forging capabilities | Full design flexibility through welding and bending |

| Corrosion / Fatigue Resistance |

Controlled grain flow improves performance | Can integrate coatings and sealing systems |

| Cost & Production Volume |

Efficient for high-volume production | Ideal for low-volume or customized parts |

Why They Suit Industry Parts

Conclusion

Both forging and fabrication are fundamental to modern manufacturing, and each plays a specific role in part design and industry application. Forging ensures strength, reliability, and safety, while fabrication delivers design flexibility, scalability, and cost efficiency. Many industries use both processes together — forged parts for mechanical performance and fabricated structures for support and assembly — creating optimized solutions for demanding environments.

Choosing the right process for your metal parts can make or break your project. Forging and fabrication each have strengths and limitations, and selecting the wrong method can increase costs, reduce part strength, or slow production. By understanding when to use each process, you can ensure your parts meet performance, design, and budget requirements.

When to Choose Forging?

You should choose forging when your project demands maximum strength, reliability, and fatigue resistance. Forging is ideal for parts that will experience high stress, impact, or extreme conditions. It’s especially suited for applications like automotive shafts, aerospace components, industrial gears, and heavy machinery parts. Forging ensures a refined grain structure, reducing defects and improving durability, which makes it the go-to method for high-performance components.

When to Choose Fabrication?

Fabrication is the better choice when your design requires complex geometries, custom assemblies, or modular structures. It’s ideal for low-volume projects, prototypes, or parts that cannot be formed as a single piece. Fabrication excels in producing frames, enclosures, tanks, piping systems, and industrial equipment where welding, cutting, and bending create the desired structure. It’s also cost-effective for designs that frequently change, as tooling costs are lower than forging.

Starting a forging or fabrication project with VMT ensures your metal parts are produced efficiently, accurately, and to your specifications. First, define your project goals, including strength, design complexity, and production volume. Share detailed drawings and material requirements with the CNC machining factory. VMT can guide you in selecting the optimal process—whether forging for durability or fabrication for complex assemblies—and provide professional CNC machining services to finish your parts.

Forging and fabrication are two cornerstone processes in modern metalworking, each with distinct advantages and applications. Forging is ideal for high-strength, fatigue-resistant parts like shafts, gears, and turbine components, while fabrication offers flexibility for complex assemblies, custom structures, and large-scale projects. Choosing the right method depends on your part’s strength requirements, complexity, production volume, and budget.

By understanding the differences, processes, and industry applications, you can make informed decisions, optimize material use, reduce costs, and ensure your parts perform reliably. Combining forging, fabrication, and CNC machining services allows you to achieve both durability and precision, delivering high-quality metal parts tailored to your project’s needs.

1. What are the four types of forging?

The four main types of forging are:

Tip: Choose the type based on part size, shape, and required mechanical strength.

2. Which metals cannot be forged?

Metals that are very brittle or have low ductility are difficult or impossible to forge. Examples include:

Tip: For these metals, consider casting or specialized machining methods instead.

3. Which is better, hot forging or cold forging?

Tip: Choose hot forging for strength and large parts; cold forging for precision and low scrap.

4. What are the three types of metal fabrication?

The three common types of metal fabrication are:

Tip: Complex parts often combine all three techniques.

5. Which is stronger, casting or forging?

Forging produces stronger parts than casting because it refines the metal grain structure and reduces internal voids. Cast parts may be suitable for complex shapes but usually have lower fatigue and impact resistance.

6. Is forging stronger than welding?

Yes, forging generally produces stronger components. Welds can introduce weak points, heat-affected zones, or residual stresses, whereas forged parts are a single, continuous piece with enhanced grain flow.

7. Welding vs. Metal Fabrication: What’s the Difference?

Tip: Think of welding as one step within the larger fabrication process.

8. What type of steel is used for forging?

Common steels for forging include:

Tip: Select the steel grade based on strength, heat treatment, and application requirements.

9. Which metal is the most difficult to forge?

Metals that are extremely hard, brittle, or have high melting points are difficult to forge. Examples include:

Tip: For these metals, specialized processes like powder metallurgy, casting, or CNC machining are usually more practical.