15 years one-stop China custom CNC machining parts factory

31 |

Published by VMT at Nov 25 2025 | Reading Time:About 2 minutes

31 |

Published by VMT at Nov 25 2025 | Reading Time:About 2 minutes

Perhaps you're preparing to design a lampshade for the outdoor use, an observation window for a biosafety cabinet in the medical, or maybe your next project will design kind of security equipment such as the police face shields. Or you're an automative factory designing headlight lenses and dashboard covers. All of these require a transparent and lightweight material, and depending on your specific application, you'll need this material to possess certain properties such as good optical properties, UV resistance, explosion and impact resistance, chemical corrosion resistance, or scratch resistance, as well as considering factors like cost and processing.

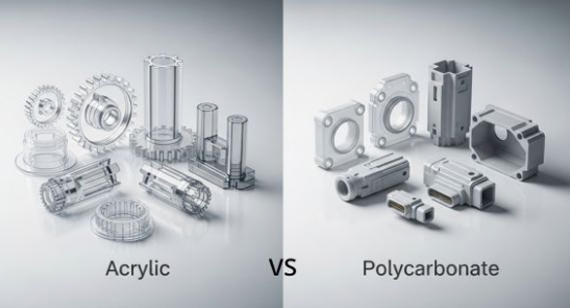

For engineering requirements, acrylic (PMMA) and polycarbonate (PC)—two of the most commonly used and high-performance transparent plastics—may meet your needs. This article will guide you through understanding the core properties and comparisons of acrylic (acrylic) and polycarbonate (PC), helping you understand whether they are suitable for your project.

Acrylic, also known as PMMA, is a transparent plastic with excellent optical transparency and a glossy appearance. Acrylic have a glass-like appearance and, due to their UV resistance, do not easily yellow even after prolonged exposure to sunlight. As a thermoplastic transparent plastic, acrylic can be produced not only in sheet form (acrylic sheets) but also in fibers, casting resins, coatings, or adhesives. Because of its excellent optical transparency and ease of processing, acrylic has long been a popular material in engineering design, advertising production, and product casings.

To learn about acrylic, look at the transparent display stands, illuminated signs, and elegant transparent boxes in shopping malls—most of these are made of acrylic, offering high clarity and a glossy finish.

Acrylic has long been a popular material in engineering design, advertising, and product casings due to its excellent optical transparency and ease of processing.

Polycarbonate, also known as Lexan, or simply PC, is a high-performance transparent plastic with high impact resistance and good optical requirements. Polycarbonate has a high melting point (about 295 ℃) and is an amorphous material without a structured chain-like structure, allowing it to be bent or processed without heating. Polycarbonate can be produced not only in sheet form (PC sheets) but also in films, granules, composites, or coatings. Due to its excellent impact resistance, good heat resistance, and cold-bending ability, polycarbonate has long been a mainstream material for industrial protective components such as protective panels.

To learn about polycarbonate, then look at transparent protective panels on bank counters and sports goggles—products that need to be "transparent yet impact-resistant," which are mostly made of PC.

Polycarbonate has long been a mainstream material for industrial protective components such as protective panels due to its excellent impact resistance, good heat resistance, and cold bending capabilities.

Both acrylic and polycarbonate share common characteristics such as good transparency, lightweight, and ease of processing, and are even interchangeable in many applications. However, they actually show some differences in appearance, durability, cost, and others. Below, you can quickly determine your choice based on the following needs:

Choosing Acrylic:

Choosing Polycarbonate:

While a demand-driven approach may give you a general idea of your choice of acrylic (PMMA) and polycarbonate (PC) materials for your project, here, I provide a more detailed comparison of their properties and corresponding numerical values for your reference. Their physical properties, mechanical properties, and chemical characteristics also will be elaborated to help you compare the pros and cons of acrylic (PMMA) and polycarbonate (PC).

Table 1: Core properties comparison of acrylic (PMMA) and polycarbonate (PC)

| Category |

Property |

Acrylic (PMMA) |

Polycarbonate (PC) |

| Physical |

Transparency | 92% (higher) | 88% |

| Heat Resistance | ~100 °C | ~150 °C (higher) | |

| UV Resistance | Excellent | Needs UV grade | |

| Flammability | Flammable | Self-extinguishing (safer) | |

| Mechanical |

Impact Strength | 10–17× glass | 200–250× glass (much higher) |

| Scratch Resistance | Polishable(Better) | Lower (needs coating) | |

| Tensile Strength | ~80 MPa (higher) | ~60–70 MPa | |

| Flexural Strength | ~115 MPa (higher) | ~90 MPa | |

| Brittleness / Toughness | Hard, brittle | Tough, flexible (better) | |

| Forming | Heat forming | Cold forming | |

| Chemical |

Chemical Resistance | Lower | Higher (better) |

| Solvent Sensitivity | Sensitive | Sensitive | |

| Other |

Polishability | Yes | No |

| Outdoor Suitability | Very good | Good with UV grade | |

| Cost | 1.5–2.0 USD/kg (lower) | 2.5–3.5 USD/kg |

Acrylic vs. Polycarbonate: Physical Properties

Acrylic has higher optical transparency (approximately 92%), a stronger surface gloss, and better UV resistance; while polycarbonate (PC) has advantages in higher heat resistance (up to 150°C) and flame retardancy (self-extinguishing).

Therefore, acrylic is often used for aesthetic purposes (fish tanks, retail displays, etc.) or in scenarios exposed to sunlight (outdoor signage, skylights, etc.). Polycarbonate (PC) is suitable for environments that withstand temperature differences, heat, or have high safety requirements (vehicle windshields, computer equipment casings, etc.).

Acrylic vs. Polycarbonate: Mechanical Properties

Acrylic has a higher surface hardness and better scratch resistance, but its disadvantage is that the material is relatively brittle and easily breaks or shatters when subjected to sharp or heavy impacts. Therefore, it is more suitable for applications that emphasize aesthetic quality rather than extreme impact resistance, such as ordinary display cases and fish tanks.

The mechanical advantages of polycarbonate lie in its extremely high impact resistance. The material is flexible yet not easily broken, and can be cold-bent at room temperature. Therefore, it is widely used in applications requiring high safety, high durability, or strong impact protection, such as sports goggles and racing car windows.

Acrylic vs. Polycarbonate: Chemical Properties

Acrylic has relatively limited chemical resistance, while polycarbonate has a greater advantage in this area, withstanding acids, alkalis, and ammonia-based cleaning agents. Therefore, polycarbonate is more suitable for applications such as viewing windows in chemical environments.

It is worth noting that the chemical properties of polycarbonate: traditional polycarbonate (PC) may contain BPA (BPA is considered an endocrine disruptor that can migrate from plastics in trace amounts, be absorbed by the human body, and potentially affect the hormone system). If it is used in food contact or consumer products, a BPA-free rating compliant with regulations must be selected.

What Is Acrylic Used For ?

Acrylic is most valued for its cost, shininess, and scratch resistance, making it widely used in scenarios requiring long-term clarity and aesthetic appeal, including:

What Is Polycarbonate Used For?

Polycarbonate is most valued for its far greater impact resistance, flexibility, and chemical resistance, making it the preferred material for applications requiring safety, durability, and impact resistance, including:

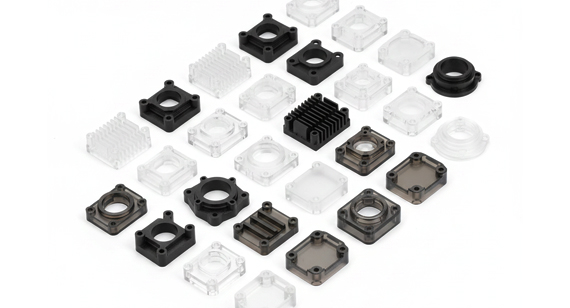

Choosing the right plastic material doesn't have to be complicated. Whether you're hesitating between acrylic (PMMA) and polycarbonate (PC), or considering other plastic materials, VMT professional team can provide you with reliable materials, professional processing capabilities(CNC acrylic , CNC polycarbonate), and precise, consistent quality.

VMT CNC machining factory are using industry-leading CNC machining equipment and rigorous quality control to ensure that every plastic part meets the needs in terms of dimensional accuracy, surface finishes, and more. From plastic prototyping to mass production, we can provide fast and reliable manufacturing support for your project.

Unsure which material to choose?

VMT engineers will offer you advice on material selection, processing techniques, and customized solutions—ensuring your project is on the right track from the start. Contact VMT experts for a free consultation or quote.

For basketball backboard materials , choose acrylic or polycarbonate (PC)?

If you prioritize durability, safety, and high impact resistance, choose polycarbonate (PC). If you prioritize a clean look, cost-effectiveness, and light home use, choose acrylic.

For greenhouse materials , choose acrylic or polycarbonate (PC)?

If you prioritize high light transmittance, choose acrylic. If you prioritize durability, storm resistance, hail resistance, and insulation, choose polycarbonate (PC).

Which scratches more easily, polycarbonate or acrylic?

Polycarbonate is generally more prone to scratching than acrylic. While both materials are highly durable, acrylic tends to be more resistant to surface scratches. However, polycarbonate is much tougher overall, offering superior impact resistance. To prevent scratches, both materials should be handled with care, and protective coatings can be applied.

What materials are better than acrylic?

If you're looking for materials with superior properties over acrylic, polycarbonate is a good choice due to its enhanced impact resistance and strength. PETG is another alternative that offers excellent clarity and is more resistant to chemical damage. For extreme durability and resistance to high temperatures, polycarbonate with a UV coating or even metalized plastics might be better options, depending on your specific needs.

Which is more expensive, acrylic or polycarbonate?

Polycarbonate is typically more expensive than acrylic. The increased cost is due to polycarbonate’s superior impact resistance and added strength, making it a premium material. Acrylic, while less expensive, offers excellent optical clarity and a more cost-effective solution for applications where impact resistance is not the top priority.

Will polycarbonate yellow in sunlight?

Yes, polycarbonate can yellow over time when exposed to sunlight. However, modern UV-resistant coatings can significantly slow down this process and improve the material’s durability in outdoor applications. Acrylic, on the other hand, is more resistant to yellowing but does not offer the same level of impact resistance as polycarbonate.