15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 08 22

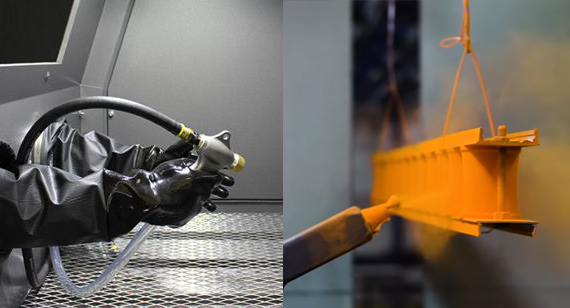

2023 08 22 Sandblasting, also known as abrasive blasting, is a surface preparation technique that involves propelling abrasive particles at high speeds to clean, smooth, or reshape a surface. This process is commonly used in various industries for cleaning, finishing, and restoring surfaces. Here, we explore the advantages and disadvantages of sandblasting.

66

66

Read more

Read more

VMT

VMT  2023 08 21

2023 08 21 Copper and aluminum are two distinct metal materials with varying characteristics and applications. This article outlines the key differences between copper and aluminum in terms of properties, uses, and advantages in different industries.

66

66

Read more

Read more

VMT

VMT  2023 08 19

2023 08 19 Sandblasting, also known as abrasive blasting, is a manufacturing process that involves propelling fine particles or abrasive materials at high speeds onto a surface. This process is used for various purposes, such as cleaning, shaping, smoothing, or roughening surfaces. It's a versatile technique that finds applications in industries ranging from construction to art.

66

66

Read more

Read more

VMT

VMT  2023 08 18

2023 08 18 1018 steel is a versatile and widely used carbon steel alloy known for its good weldability, machinability, and cost-effectiveness. Its balanced properties make it suitable for a variety of applications across industries, making it a go-to choice for components that require moderate strength and easy fabrication.

66

66

Read more

Read more

VMT

VMT  2023 08 17

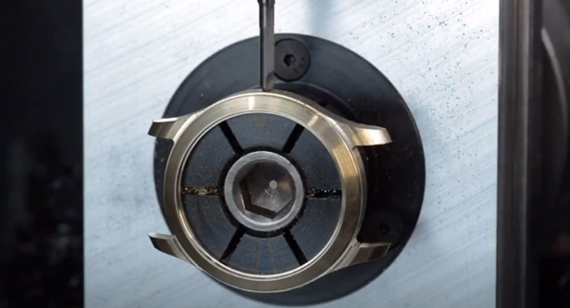

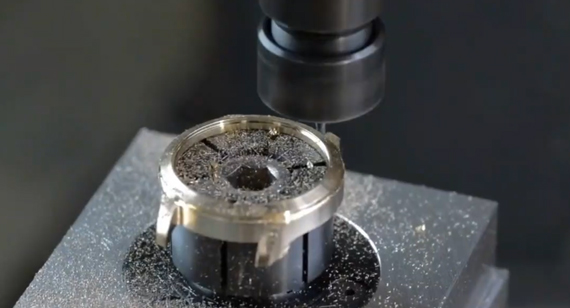

2023 08 17 In the realm of precision engineering, the process of CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape. This article delves into the intricate world of custom CNC watch case manufacturing and explores how it can bring substantial benefits to your customers.

66

66

Read more

Read more

VMT

VMT  2023 08 16

2023 08 16 In the fast-paced world of smartwatches, a case is more than just a case, it's an expression of style and innovation. From gleaming metal finishes to sleek ceramic designs, each smartwatch case is the result of meticulous manufacturing techniques. In this article, we take you on a journey into the fascinating world of smartwatch casing production, exploring the methods, benefits and factors that influence the choices of manufacturers and consumers.

66

66

Read more

Read more

VMT

VMT  2023 08 15

2023 08 15 Polyimide and nylon are two distinct types of polymers that have various industrial and commercial applications. While they might share some similarities in terms of being polymers, they have unique properties, characteristics, and uses. In this article, we will delve into the key differences and applications of polyimide and nylon, shedding light on their respective roles in various industries.

66

66

Read more

Read more

VMT

VMT  2023 08 14

2023 08 14 Copper, a metal widely used for its conductivity and versatility, often undergoes intriguing color changes, from green to black. These transformations can be perplexing, prompting questions about the underlying causes and potential remedies. In this article, we delve into the fascinating world of copper's color changes, exploring the factors responsible for the shift, and providing insights into how to address this phenomenon.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!