15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 03 2026 | Reading Time:About 3 minutes

0 |

Published by VMT at Jan 03 2026 | Reading Time:About 3 minutes

When selecting materials for aluminum parts, A356 aluminum alloy is a material that manufacturers can hardly overlook.

As a typical Al–Si–Mg casting alloy, A356 offers an excellent strength-to-weight ratio, outstanding castability, and good corrosion resistance, making it widely used in automotive, aerospace, industrial equipment, and marine applications.

However, whether A356 is truly suitable for your part depends on factors such as heat treatment state (as-cast or T6), cost considerations, and the actual service environment.

To evaluate its suitability, this article examines the chemical composition, mechanical properties, as-cast versus T6 heat-treated performance, and typical applications of A356 aluminum alloy.

By the end, you will be able to determine whether A356 is the right choice for your specific application.

What Is Chemical Composition of A356 Aluminum?

A356 aluminum alloy belongs to the Al–Si–Mg casting alloy family (AA designation A356.0 / UNS A13560). Typical chemical composition ranges (wt.%) are:

Table 1: Chemical Composition of A356 Aluminum Alloy

| Element | Content (wt.%) |

| Aluminum (Al) | 91.1–93.3 |

| Silicon (Si) | 6.5–7.5 |

| Magnesium (Mg) | 0.25–0.45 |

| Iron (Fe) | ≤ 0.20 |

| Copper (Cu) | ≤ 0.20 |

| Manganese (Mn) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.20 |

Notes: Data of Compositions and the Following Properties Credit: MakeItFrom A356.0 (SG70B, A13560) Cast Aluminum

A356 aluminum alloy features stricter chemical composition control than standard 356 alloys, particularly for impurity elements such as iron. The alloy is primarily based on the Al–Si–Mg system, with residual elements limited to ≤ 0.05 wt.% each and ≤ 0.15 wt.% in total.

Silicon enhances castability, magnesium enables heat-treatable strengthening, while controlled levels of iron and manganese help maintain ductility and mechanical reliability. This controlled chemistry contributes to improved microstructural stability and consistent performance in demanding applications.

What Are Physical Properties of Aluminum A356?

A356 aluminum alloy combines low density with good thermal conductivity, moderate electrical conductivity, and stable physical properties, offering strong engineering suitability for both structural and functional parts.Below are physical properties of aluminium A356:

Table 2: Physical Properties of A356 Aluminum

| Property | Value |

| Density | ~2.6–2.68 g/cm³ |

| Melting Range (solidus to liquidus) | ~570–610 °C |

| Thermal Conductivity | ~150 W/m·K |

| Specific Heat Capacity | ~900 J/kg·K |

| Coefficient of Thermal Expansion | ~21 µm/m·K |

| Electrical Conductivity | ~40 % IACS |

| Thermal Diffusivity | ~64 mm²/s |

A356 aluminum alloy features a low density of approximately 2.6–2.68 g/cm³, making it well suited for lightweight structural applications. It exhibits a melting range of roughly 570–610 °C, which supports stable casting behavior and good mold filling characteristics. With a thermal conductivity of about 150 W/m·K, A356 provides effective heat dissipation compared to many other casting alloys, while its electrical conductivity of around 40% IACS places it in the moderate conductivity range. The alloy also shows a coefficient of thermal expansion of approximately 21 µm/m·K, an important consideration for dimensional stability in assemblies. Combined with its inherently good corrosion resistance, particularly in atmospheric and marine environments, these physical properties make A356 a reliable choice for structural and functional aluminum parts.

What Are Mechanical Properties of Aluminum A356?

A356 aluminum exhibits variation in mechanical properties depending on metallurgical condition. Blow are mechanical properties of a356 aluminum under different conditions:

Table 3: Mechanical Properties of A356 Aluminum (Typical Values by Temper)

| Property | As-Cast (A356.0-F) | T6 Heat-Treated (A356.0-T6) | T61 Heat-Treated (A356.0-T61) |

| Ultimate Tensile Strength | 165–230 MPa | 250–310 MPa | 250–310 MPa |

| Yield Strength (0.2% offset) | 75–120 MPa | 200–230 MPa | 200–230 MPa |

| Elongation at Break | 3–10 % | 2–6 % | 2–6 % |

| Brinell Hardness | 60–75 HB | 80–95 HB | 80–95 HB |

| Fatigue Strength (≈10⁷ cycles) | 60–70 MPa | 90–100 MPa | 90–100 MPa |

| Elastic Modulus | ~71 GPa | ~71 GPa | ~71 GPa |

In the as-cast (F) state, the alloy provides moderate strength with higher ductility, suitable for non-critical components.

T6 heat treatment significantly increases tensile strength, yield strength, hardness, and fatigue resistance, making it appropriate for structural and load-bearing parts. T61 achieves virtually the same strength as T6 but incorporates stress relief and dimensional stability measures, which are valuable for precision or thin-walled components.

In practice, A356.0-T6 and A356.0-T61 exhibit very similar mechanical properties and are often grouped together in engineering applications. The primary distinction lies in stress control and dimensional stability rather than strength levels. Elastic modulus of a356 aluminum remains essentially unchanged across all states.

Heat Treatment State(A356.0-T6/T61)vs. As-Cast State(A356.0-F)

A356 aluminum alloy can be used either in the as-cast state (A356.0-F) or after heat treatment (T6/T61), with each condition offering distinct advantages. (For detailed mechanical properties under A356.0-F, T6/T61 states, see the previous section.)

You can view the impact on parts under different conditions below:

Under As-Cast (A356.0-F) Condition

As-Cast (A356.0-F) aluminum components are produced without any strengthening heat treatment.

Under T6/T61 Heat-Treated Condition

T6/T61 Heat-Treated aluminum components undergo a controlled process of solution treatment, quenching, and artificial aging.

Enhancing tensile strength, yield strength, and hardness

During solution treatment, the alloy is heated to approximately 538 °C (1000 °F) to dissolve strengthening elements, followed by rapid quenching, typically in hot water, which may cause slight distortion. Subsequent artificial aging at 155–205 °C (310–400 °F) for several hours precipitates fine strengthening phases, significantly enhancing tensile strength, yield strength, and hardness while maintaining reasonable ductility.

Common examples of T6/T61 heat-treated aluminum components

Typical examples include structural and load-bearing parts, thin-walled housings, suspension components, aerospace brackets and supports, precision components requiring dimensional stability, etc.

Slightly different uses between T61 and T6

A356 T61 aluminum is essentially the same as A356 T6 aluminum but includes additional stress-relief steps to improve dimensional stability. This makes T61 particularly suitable for parts where precision, minimal distortion, or dimensional stability are critical, such as thin-walled or complex-shaped structural components.

In practice, the choice between as cast and heat-treated A356 depends on mechanical requirements, dimensional stability needs, and cost considerations. For parts subjected to significant structural loads, repeated fatigue, or precision tolerances, T6/T61 is generally preferred, whereas the as-cast state remains advantageous for cost-sensitive, low-load, or less critical applications.

Why Aluminum A356 Benefits Industrial Uses?

A356 aluminum alloy is a popular choice in industrial applications, largely due to the following key characteristics:

Excellent strength combined with lightweight characteristics

A356 is a widely used cast aluminum alloy that offers an excellent balance of light weight and mechanical performance, making it highly attractive for modern engineering applications. With a density of approximately 2.68 g/cm³—about one-third that of steel—A356 enables significant weight reduction while maintaining sufficient structural strength. When subjected to T6 heat treatment, its mechanical properties can be further enhanced, allowing it to meet the performance requirements of weight-sensitive industries such as automotive and aerospace. In aerospace applications, A356 is commonly used for secondary load-bearing components, including brackets, housings, and seat frames, where weight reduction is critical but ultimate strength demands are moderate. Primary load-bearing structures, by contrast, typically rely on higher-strength wrought aluminum alloys such as the 7xxx series.

Good ductility and impact resistance

In addition to its favorable strength-to-weight ratio, A356 exhibits good ductility and impact resistance. Its low iron content and silicon-based eutectic microstructure allow the material to absorb energy and undergo controlled plastic deformation when subjected to dynamic loads or impact conditions. This behavior improves component safety and reliability by reducing the risk of sudden brittle failure. As a result, A356 is well suited for automotive crash-related components, motorcycle parts, and protective housings for industrial machinery. Its stable microstructure also contributes to consistent performance under long-term vibration or cyclic loading, helping extend component service life.

Good corrosion resistance

A356 also offers strong corrosion resistance. A naturally forming aluminum oxide passivation layer protects the surface in many environments, and corrosion performance can be further improved through surface treatments such as anodizing or protective coatings. In applications where corrosion conditions are not extremely aggressive, A356 can replace certain stainless-steel components—such as 316 stainless steel—in marine equipment fittings, ship components, and chemical pump housings. This substitution can achieve comparable functional performance while significantly reducing weight and material cost. Compared with conventional carbon steels, such as A36 structural steel, A356 typically requires less maintenance and provides a longer service life in corrosive environments.

Excellent castability

Another key characteristic of A356 is its excellent castability. High molten-metal fluidity combined with relatively low solidification shrinkage allows complex geometries and thin-walled components to be formed accurately in a single casting operation. High-precision parts such as automotive engine blocks and robotic housings can be produced efficiently with minimal secondary machining. The reduced tendency for shrinkage porosity and hot cracking also improves yield rates and overall production efficiency, contributing to lower manufacturing costs.

Suitable for anodizing treatment

For applications where surface appearance and durability are important, A356 can also be anodized. Through an electrochemical process, a relatively dense oxide layer is formed on the surface, enhancing wear resistance, corrosion protection, and aesthetic quality. Anodized A356 components are commonly used in electronic enclosures, bicycle parts, and architectural elements. The anodized surface also provides good electrical insulation and increased surface hardness, making it suitable for components that require both wear resistance and insulating properties.

The price of A356 aluminum alloy is influenced by several key factors, including the global aluminum ingot market, the cost of alloying elements such as magnesium and silicon, heat treatment requirements, and the selected manufacturing process. Regional supply chain conditions, tariffs, and logistics costs also play an important role in determining the final material price.

Compared with common wrought aluminum alloys such as 6061 and 7075, A356 typically offers a favorable balance between material cost and manufacturing efficiency for complex geometries. While its raw material cost may be higher than basic die-casting alloys, the ability to produce near-net-shape castings often reduces overall machining time and total project cost. You can find out the following cost comparison table of A356 aluminum and other common aluminum alloys:

Table 4: Cost Comparison of A356 and Other Common Aluminum Alloys (Relative)

| Aluminum Alloy | Typical Form | Relative Material Cost | Machining Cost | Overall Cost Level | Typical Applications |

| A356 | Casting | Medium | Medium | Medium | Structural housings, pump bodies,automotive castings |

| 6061 | Wrought (Plate / Bar) | Low–Medium | Low | Low–Medium | Machined brackets, frames, general-purpose components |

| 7075 | Wrought (Plate / Bar) | High | Medium–High | High | High-strength structuralcomponents |

| ADC12 | Casting | Low | Medium | Low–Medium | Thin-wall die-cast housings andcovers |

| 5052 | Wrought (Sheet) | Low | Low | Low | Sheet metal panels, enclosuresformed components |

In general, A356 cast components are more expensive than basic aluminum alloys but remain more cost-effective than high-performance aerospace-grade aluminum materials. For accurate and up-to-date pricing, it is recommended to consult metal trading platforms or contact qualified suppliers directly.

What Are A356 Aluminum Equivalents?

The following is recognized as functionally equivalent to A356 for casting applications, with comparable chemical composition and mechanical performance. Minor variations in composition limits or heat treatment specifications may exist according to each standard, so you may confirm requirements for critical applications.

Table 5: Equivalents of A356 Aluminum

| Standard | Equivalent Designation |

| ASTM / SAE | A356.0 |

| Aluminum Association (AA) | A356 |

| UNS | A13560 |

| ISO | AlSi7Mg0.3 |

| EN / DIN | EN AC-42100 |

| JIS | AC4CH |

| British Standard | LM25 |

What Are A356 Aluminum Applications?

A356 aluminum alloy is widely used across multiple industries due to its lightweight, high strength, corrosion resistance, excellent castability, and machinability. Here listed some common applications of a356 aluminum:

A356 aluminum is known for its lightweight and high-strength properties, making it ideal for engine blocks, cylinder heads, wheels, suspension components, brake calipers, and transmission housings. This material reduces component weight to improve fuel efficiency and vehicle handling while maintaining excellent durability and impact resistance, capable of withstanding both everyday driving and high-performance conditions.

Aerospace Components

In aerospace applications, A356 is commonly used for structural housings, support brackets, seat frames, instrument mounts, and secondary cabin components. Its high strength-to-weight ratio and precision casting capabilities allow for complex, lightweight structures while ensuring strict safety and reliability standards, enhancing payload efficiency and overall flight performance.

Industrial Machinery

A356 is widely used for pump bodies, valve bodies, machinery housings, gearbox casings, and robot chassis. Its excellent corrosion and wear resistance ensures long-term stability in diverse industrial environments, reducing maintenance frequency and improving overall equipment reliability.

Marine Engineering

In marine applications, A356 is used for boat components, offshore platform supports, propeller housings, and hull frames. The naturally formed oxide layer and anodized surface provide superior seawater corrosion resistance, extending component lifespan and reducing maintenance costs.

Electronic and Electrical Enclosures

A356 is suitable for distribution boxes, control panels, switch housings, electronic instrument casings, and busbar supports. It combines sufficient mechanical strength with excellent insulation properties, effectively protecting sensitive electrical components and ensuring long-term reliability.

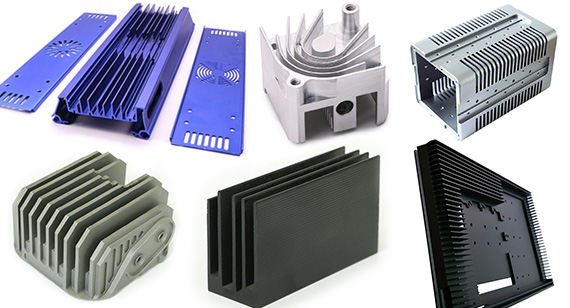

Consumer Electronics

In consumer electronics, A356 is commonly used for laptop and tablet housings, smart home devices, speaker casings, brackets, and heat sinks.Its lightweight design reduces overall device weight, while good thermal conductivity ensures efficient heat management and reliable performance under high loads.

Firearms Components

A356 is applied to receiver housings, support structures, handguards, trigger components, and sight mounts.Its high strength and precision casting capabilities ensure structural reliability while reducing weight, improving handling and operational ease.

A356 aluminum alloy has proven to be an ideal material for manufacturing complex, thin-walled, and high-performance cast components due to its excellent castability, heat-treatable strengthening capability, and good corrosion resistance. For applications that require a balance between lightweight design, mechanical strength, and cost efficiency, A356 remains a reliable and well-established solution across a wide range of industries.

While A356 is primarily designed as a casting alloy rather than a wrought aluminum alloy for direct CNC machining, it is very commonly subjected to post-machining operations. In practical applications, A356 components are typically cast to near-net shape and then CNC machined to achieve tight tolerances, precision mounting features, sealing surfaces, and other critical functional interfaces. This combination of casting and CNC machining allows manufacturers to fully leverage the material’s castability while meeting demanding dimensional and performance requirements.

At VMT CNC machining factory, we specialize in high-precision CNC machining of A356 cast components, delivering tight tolerances, excellent surface quality, and consistent dimensional accuracy. Whether your project requires post-machining of complex castings, prototype development, or high-volume production, our experienced engineering team and advanced CNC equipment ensure reliable results from concept to final part.

If you are looking for a trusted manufacturing partner for high-precision metal part prototyping and surface finishing, VMT CNC Machining is your reliable choice. With over 15 years of experience, we specialize in aluminum CNC machining and the production of high-precision metal components, including custom aluminum enclosures, housings, and complex structural parts. Serving industries such as medical, electronics, and automotive, we deliver parts with tolerances as tight as ±0.01 mm, helping you transform your designs into reliable, high-performance components. Contact VMT today to discuss your aluminum machining project.

1. What are the limitations of A356 aluminum alloy?

A356 is sensitive to casting defects such as porosity and shrinkage. It is not suitable for die-casting processes and generally has lower strength compared to some forged aluminum alloys. Careful casting and heat treatment are required to achieve optimal performance.

2. Is A356 aluminum suitable for welding?

A356 can be welded using appropriate filler materials, such as Al-Si alloys. Post-weld heat treatment is recommended to restore mechanical properties and ensure structural integrity. Proper preparation is essential to minimize cracking.

3. A356 Aluminum vs 6061 Aluminum: what’s the difference?

A356 is a casting alloy ideal for complex shapes, while 6061 is a wrought (forged) alloy with more stable mechanical properties. A356 can sometimes replace 6061 in cast applications, but the manufacturing processes are different.

4. What is the difference between Aluminum 356 and A356?

356 is the standard version of this alloy, whereas A356 is a refined version with lower iron content and improved mechanical properties. A356 offers better strength, corrosion resistance, and casting performance.

5. How does 319 aluminum compare with A356?

319 aluminum contains higher copper, which improves heat resistance. In contrast, A356 provides superior ductility and corrosion resistance, making it better for structural applications exposed to harsh environments.

6. What is A356.2 aluminum?

A356.2 is a high-end version of A356 with further reduced impurities. It is designed for applications that require stricter mechanical performance and higher reliability, such as critical structural components.