15 years one-stop China custom CNC machining parts factory

32 |

Published by VMT at Jan 02 2026 | Reading Time:About 3 minutes

32 |

Published by VMT at Jan 02 2026 | Reading Time:About 3 minutes

Take a moment to look around, there’s a good chance aluminum products is already part of your daily life. From aircraft structures and automotive components to electronic housings, building frames, and food packaging, aluminum is becoming an important metal found everywhere. It is also the preferred material for most of our clients when manufacturing aluminum parts at VMT CNC Machining Factory.

In this article, you’ll gain a clear understanding of what aluminum is, its key properties and characteristics, different aluminum types, commonly used alloy grades, and how it’s applied in manufacturing. This information will help you make more informed engineering and production decisions.

You may have learned about pure aluminum in a high school chemistry class, or simply encountered it in everyday products like beverage cans. It’s easy to recognize—and even easier to find in daily life.

Aluminum is well known for its excellent ductility, natural corrosion resistance, and nonmagnetic properties. These characteristics are what make it so widely used across industries, from medical and automotive applications to electronics and food packaging.

Because aluminum is highly reactive, it isn’t found in its pure metallic form in nature. Instead, it occurs primarily as oxides and silicates, widely distributed throughout the Earth’s crust. In fact, aluminum is the most abundant metal on Earth, accounting for about 8% of the planet’s crust. Today, it ranks just behind steel in total production and is the most commonly used non-ferrous metal worldwide.

From an engineering and manufacturing perspective, aluminum and its alloys offer a rare combination of advantages. An excellent strength-to-weight ratio, good machinability, built-in corrosion resistance, and high recyclability make aluminum an ideal choice for lightweight, high-performance designs. This balance of performance, cost efficiency, and sustainability is why aluminum continues to play a critical role in modern manufacturing.

1.1 The History of Aluminum

Although aluminum is extremely abundant in the Earth’s crust, its high chemical reactivity made it difficult to extract. It wasn’t until the 19th century that humans were able to produce it on a large scale.

Today, aluminum is an essential material in aerospace, automotive manufacturing, and CNC machining, forming the backbone of countless modern engineering applications.

1.2 The Element Aluminum

Aluminum is a typical lightweight metal with a key role both in the periodic table and in engineering materials.

In engineering and manufacturing, the value of aluminum lies in the combined effect of its physical, chemical, and mechanical properties. It’s this synergy that allows aluminum and its alloys to deliver high performance while remaining lightweight, easy to process, and durable.

For instance, aluminum’s lightweight yet high-strength properties make it ideal for aerospace, automotive, and other applications where reducing weight is critical. Its natural corrosion resistance and high recyclability help ensure long service life and sustainability. At the same time, excellent machinability and ductility allow engineers to efficiently produce complex parts through extrusion, CNC machining, or other forming processes.

For details of chemical, physical and mechanical properties, you can check table 1, table 2 , and table 3 in the following ( data credit from: azom).

Aluminum’s chemical properties define its reactivity, corrosion resistance, and alloying potential, making it a versatile material across industries.

Table 1: Chemical Properties of Aluminum

| Property | Value | Notes |

| Atomic Number | 13 | Basic chemical property |

| Atomic Weight (g/mol) | 26.98 | Lightweight advantage |

| Valency | 3 | Ability to form compounds |

| Corrosion Resistance | Excellent | Protective Al₂O₃ layer prevents corrosion |

| Reactivity | High | Does not occur in nature as a pure metal |

The main chemical characteristics of aluminum include:

Good Corrosion Resistance

Aluminum naturally forms a dense oxide layer (Al₂O₃) on its surface, which protects the base metal from corrosion. This makes aluminum well suited for outdoor structures, marine components, and automotive parts exposed to harsh environments.

Alloying Ability

Aluminum readily forms alloys with elements such as copper (Cu), magnesium (Mg), silicon (Si), and zinc (Zn). This flexibility allows engineers to tailor material properties like strength, hardness, and machinability for specific applications.

High Reactivity

Due to its high chemical reactivity, aluminum does not occur in a pure metallic state in nature and is typically extracted from oxides such as bauxite. This reactivity also makes aluminum compounds useful in industrial chemistry, water treatment, and pharmaceutical applications.

Physical Properties of Aluminum

Aluminum’s physical properties contribute to its lightweight nature, thermal and electrical conductivity.

Table 2: Physical Properties of Aluminum

| Property | Value | Notes |

| Density (g/cm³) | 2.6898 | Low weight, high strength-to-weight ratio |

| Melting Point (°C) | 660.2 | Suitable for high-temperature applications |

| Boiling Point (°C) | 2480 | High-temperature stability |

| Crystal Structure | FCC | Excellent ductility and formability |

| Coefficient of Linear Expansion (0-100°C) (×10⁻⁶/°C) | 23.5 | Thermal expansion |

| Thermal Conductivity (cal/cm·s·°C) | 0.57 | Efficient heat conduction |

| Specific Heat (0-100°C) (cal/g·°C) | 0.219 | Heat capacity |

| Electrical Conductivity | High | Widely used in electrical wiring |

| Thermal Reflectivity | High | Reflects light and heat efficiently |

| Nonmagnetic | Yes | Critical for electronic applications |

The physical properties lead to key characteristics of aluminum, include:

Lightweight Advantage

Aluminum has a low density of approximately 2.7 g/cm³—about one-third that of steel—which makes it a material for weight-sensitive applications. This lightweight advantage helps reduce overall system mass, improve fuel efficiency, and simplify handling and installation in aerospace structures, automotive body panels, and lightweight machinery components.

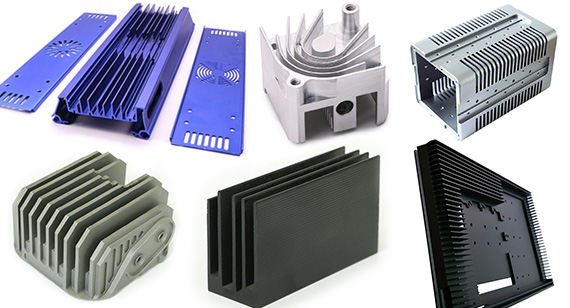

Good Thermal and Electrical Conductivity

Aluminum exhibits excellent thermal and electrical conductivity, second only to copper among commonly used metals. While it is lighter and more cost-effective than copper, aluminum still delivers efficient heat dissipation and electrical performance. As a result, it is widely used in heat exchangers, radiators, power transmission lines, electrical wiring, and electronic housings.

Good Formability

Thanks to its face-centered cubic (FCC) crystal structure, aluminum offers high ductility and formability. It can be easily shaped through extrusion, CNC machining, stamping, bending, and sheet metal forming. This versatility allows manufacturers to produce complex geometries with tight tolerances, making aluminum especially suitable for precision components and custom-designed parts.

Mechanical Properties of Aluminum

Aluminum’s mechanical properties determine its strength, ductility, hardness, and fatigue resistance, which are critical for structural and load-bearing applications.

Table 3: Mechanical Properties of Aluminum

| Property | Value | Notes |

| Tensile Strength (Pure Al) | ~90 MPa | Can be increased >690 MPa via alloys |

| Shear Strength | Varies by alloy | Depends on alloy and heat treatment |

| Modulus of Elasticity (GPa) | 68.3 | Relatively low stiffness but lightweight |

| Poisson’s Ratio | 0.34 | Elastic property |

| Ductility | High | Easy to form and stretch |

| Hardness (Brinell / Vickers) | Varies by alloy | Adjustable via alloying and heat treatment |

| Fatigue Endurance Limit (MPa) | Varies | High-strength alloys resist repeated loading |

The main mechanical properties and characteristics of aluminum include:

High Strength-to-Weight Ratio

Aluminum alloys offer an excellent balance between strength and low weight, making them well suited for aerospace structures, automotive components, and other applications where weight reduction is critical.

Ductility and Formability

Aluminum exhibits high ductility and formability, allowing it to be easily processed through extrusion, stamping, and CNC machining. This makes it ideal for producing complex geometries used in consumer electronics, furniture, and structural components.

Durability and Fatigue Resistance

Many aluminum alloys demonstrate good fatigue performance and can withstand repeated loading in applications such as automotive suspension systems, aircraft components, and industrial machinery, contributing to long service life.

Depending on chemical composition and forming methods, aluminum materials are available in various types to suit different engineering designs and manufacturing processes. In manufacturing, choosing the right type of aluminum plays a key role in part performance and production efficiency.

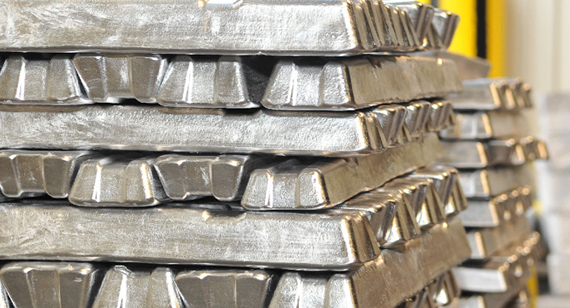

Pure Aluminum

Pure aluminum typically refers to the 1XXX series, with an aluminum content of 99% or higher. With virtually no alloying elements, it offers excellent electrical and thermal conductivity along with outstanding corrosion resistance. However, its relatively low strength limits its use in load-bearing applications. As a result, pure aluminum is most commonly used in products such as electrical wires and cables, chemical processing equipment, food and pharmaceutical packaging, and other components where conductivity and corrosion resistance are more important than structural strength.

Aluminum Alloys

Aluminum alloys are produced by adding elements such as copper (Cu), magnesium (Mg), silicon (Si), manganese (Mn), or zinc (Zn) to pure aluminum. These alloying elements significantly enhance strength, hardness, wear resistance, and machinability, making aluminum alloys the most widely used form of aluminum in engineering and manufacturing. Different alloy series are designed for different performance requirements, ranging from high-strength aerospace structures to general-purpose CNC machining parts and corrosion-resistant marine components.The most common aluminum alloy series and their typical characteristics are summarized in Table 4 below.

Table 4: Common Aluminum Alloy Series and Applications

| Alloy Series | Main Alloying Elements | Key Characteristics | Typical Applications |

| 1XXX | Pure aluminum | Excellent conductivity, low strength | Electrical conductors, foil |

| 2XXX | Aluminum–Copper (Al-Cu) | High strength, good fatigue resistance | Aerospace structural parts |

| 3XXX | Aluminum–Manganese (Al-Mn) | Good formability, moderate strength | Cookware, cans, heat exchangers |

| 4XXX | Aluminum–Silicon (Al-Si) | Low melting point, good fluidity | Welding filler materials |

| 5XXX | Aluminum–Magnesium (Al-Mg) | Excellent corrosion resistance | Marine and shipbuilding components |

| 6XXX | Aluminum–Magnesium–Silicon (Al-Mg-Si) | Balanced strength and machinability | CNC machining, structural profiles |

| 7XXX | Aluminum–Zinc (Al-Zn) | Ultra-high strength | Aerospace and high-stress parts |

| 8XXX | Other alloy systems | Specialized properties | Aluminum foil, niche applications |

Cast Aluminum

Cast aluminum is formed by pouring molten aluminum into molds, allowing it to take on complex shapes that are difficult or costly to produce using other methods. This makes cast aluminum well suited for parts with intricate geometries or varying wall thicknesses. While it offers high design flexibility and relatively low production costs, its mechanical properties and material density are generally lower than those of wrought aluminum. Common applications include engine housings, pump and valve bodies, and other complex structural components.

Wrought Aluminum

Wrought aluminum refers to aluminum and aluminum alloys that are shaped through plastic deformation processes such as rolling, extrusion, drawing, or forging. Compared with cast aluminum, wrought aluminum has a more uniform and dense internal structure, resulting in superior mechanical properties and greater reliability. Because of its consistent performance and excellent machinability, wrought aluminum is the most commonly used material for CNC machining and precision structural components.

Forged Aluminum

Forged aluminum is a specific type of wrought aluminum produced by applying compressive forces to the material, either at elevated or room temperatures. This forging process refines the grain structure and increases material density, leading to improved strength and fatigue resistance. Forged aluminum is therefore well suited for high-load and high-stress applications, such as aerospace structural parts, automotive suspension and steering components, and critical load-bearing elements in industrial machinery.

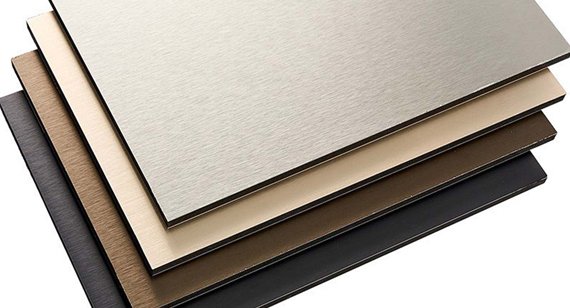

Anodized aluminum is aluminum that has undergone an electrochemical surface treatment to form a hard, protective oxide layer. This anodized layer significantly improves corrosion resistance, wear resistance, and surface appearance without compromising the material’s lightweight nature. As a result, anodized aluminum is widely used in electronic enclosures, architectural profiles, and decorative or wear-resistant components.

Clad aluminum consists of an aluminum alloy core bonded with a thin layer of high-purity aluminum on the surface. This structure combines the strength of the alloy with the superior corrosion resistance of pure aluminum, making it especially suitable for harsh or corrosive environments. Clad aluminum is commonly used in aerospace structures, chemical processing equipment, and high-corrosion-resistance sheet materials.

In CNC machining and industrial manufacturing, some popular aluminum alloys are widely used because they offer excellent strength, machinability, corrosion resistance, or other advantages. The table below highlights some of the most popular aluminum alloy grades used across manufacturing industries.

Table 5: Common Aluminum Alloy Grades

| Alloy Grade | Alloy Series | Key Characteristics | Typical Applications |

| 3003 | 3XXX (Al-Mn) | Good formability, excellent corrosion resistance, moderate strength | Cookware, architectural sheet metal, storage tanks, heat exchangers |

| 5052 | 5XXX (Al-Mg) | Outstanding corrosion resistance, good fatigue strength, easy to form | Marine components, sheet metal parts, pressure vessels |

| 6061 | 6XXX (Al-Mg-Si) | Excellent balance of strength and machinability, heat-treatable, good weldability | CNC machined parts, structural components, automotive and industrial parts |

| 6063 | 6XXX (Al-Mg-Si) | Superior extrudability, smooth surface finish | Architectural profiles, window and door frames, decorative extrusions |

| 7075 | 7XXX (Al-Zn) | Very high strength, excellent fatigue resistance | Aerospace structures, high-stress mechanical components |

Thanks to its low density, high strength, excellent corrosion resistance, and good formability, aluminum is widely used across many key industries. Below are some of the most common and representative application areas for aluminum materials.

Aluminum is extensively used in automotive structural components and lightweight parts due to its high strength-to-weight ratio and excellent formability. Replacing steel with aluminum helps significantly reduce vehicle weight, improving fuel efficiency and lowering emissions. With the rapid growth of electric vehicles, aluminum is increasingly used in body frames, battery enclosures, and suspension systems.

Aerospace Industry

In aerospace applications, aluminum and aluminum alloys are essential materials thanks to their outstanding strength-to-weight ratio and good fatigue performance. They are widely used in aircraft structures, fuselage skins, and aerospace components. Aluminum alloys help reduce overall aircraft weight while maintaining structural integrity, improving flight efficiency and payload capacity.

Medical Equipment

Aluminum is commonly used in medical equipment housings and precision components. Its excellent machinability allows high-precision parts to be produced through CNC machining, while its corrosion resistance and surface treatment compatibility meet strict hygiene and safety requirements. The lightweight nature of aluminum also enhances portability and ease of use in medical devices.

Marine Industries

In marine environments, aluminum and aluminum-magnesium alloys are widely adopted due to their exceptional resistance to seawater corrosion. Aluminum is commonly used in ship structures, decks, and corrosion-resistant components. Its lightweight properties improve fuel efficiency, reduce maintenance requirements, and enhance overall vessel performance.

Machinery and Equipment Manufacturing

Aluminum and aluminum alloys are widely used in machinery and automation equipment for both structural and functional components. Their excellent machinability makes them ideal for CNC machining, enabling high precision and complex geometries. Using aluminum helps reduce equipment weight, improve operational efficiency, and lower long-term maintenance costs.

Construction Industry

Aluminum is widely used in construction thanks to its strength, ductility, and corrosion resistance. Common applications include doors, windows, curtain walls, and architectural profiles. Its lightweight nature helps reduce structural loads, lower foundation costs, and improve installation efficiency in both residential and commercial buildings.

Packaging Industry

Aluminum is non-toxic, corrosion resistant, and offers excellent barrier properties, making it ideal for food, beverage, and pharmaceutical packaging. Beverage cans, aluminum foil, and medical packaging rely heavily on aluminum to protect contents and maintain freshness. Its high recyclability also makes aluminum one of the most sustainable packaging materials available.

Electrical Appliances

With excellent thermal and electrical conductivity, aluminum plays a key role in electrical and household appliances. It is commonly used in heat sinks, enclosures, and electronic structural components, improving heat dissipation and extending product lifespan. Lightweight aluminum designs also contribute to more compact and energy-efficient appliances.

Consumer Goods

In consumer products, aluminum is valued for its attractive appearance, durability, and ease of processing. It is widely used in electronics housings, home furnishings, and everyday products. Anodized aluminum surfaces further enhance aesthetics while improving wear and corrosion resistance.

This article provides a comprehensive overview of aluminum, covering its fundamental concepts, elemental properties, key characteristics, material types, commonly used alloy grades, and applications in modern manufacturing. Thanks to its lightweight nature, excellent machinability, natural corrosion resistance, and high recyclability, aluminum and its alloys have become indispensable materials in CNC machining and advanced manufacturing.

If you’re looking for high-precision aluminum CNC machining solutions, VMT CNC Machining Factory is your trusted partner. With 15 years of experience, we specialize in producing aluminum or other high-precision metal parts, including aluminum housings, enclosures, and complex structural components. From prototyping and precision machining to a variety of surface finishes, we provide complete solutions tailored to your specifications. Serving industries such as medical, electronics, and automotive, we deliver components with tolerances as tight as ±0.01 mm, ensuring your designs are transformed into reliable, high-performance parts. Get in touch with VMT today and let our expert team support your aluminum projects with professional, fast, and round-the-clock service.

Is aluminum durable?

Yes, aluminum is durable, especially when alloyed or treated. It naturally forms a protective oxide layer that resists corrosion, making it suitable for outdoor structures, marine environments, and long-lasting industrial components.

Aluminum vs. Steel: which is better?

Aluminum is much lighter than steel, making it ideal for weight reduction and corrosion resistance. Steel, however, is stronger in absolute terms and often more cost-effective for heavy-load structural applications. The choice depends on your design priorities.

Aluminum vs. Copper: which should I use?

Copper has higher electrical and thermal conductivity, but it is much heavier and more expensive. Aluminum offers a good balance of conductivity, lightness, and cost, which is why it’s widely used in electrical wiring, heat exchangers, and structural applications.

What are the limitations of aluminum?

While strong, aluminum is not as hard as steel. High-grade aerospace alloys can be costly. Additionally, its high thermal conductivity makes welding challenging, as welds can solidify very quickly.

What are the common supply forms of aluminum?

Aluminum is supplied in various forms to meet different manufacturing needs. Common forms include sheets and plates for bending and stamping, extrusions for custom profiles, bars and rods for machining, tubes and pipes for structural or fluid applications, wires for electrical use, castings for complex parts, and foils for packaging.

Is aluminum recyclable and environmentally friendly?

Absolutely. Aluminum is 100% recyclable, and recycling it requires only about 5% of the energy needed to extract primary aluminum from bauxite. This makes aluminum a highly sustainable choice for green manufacturing and eco-friendly industries.