15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

300 |

Published by VMT at Oct 27 2021

300 |

Published by VMT at Oct 27 2021

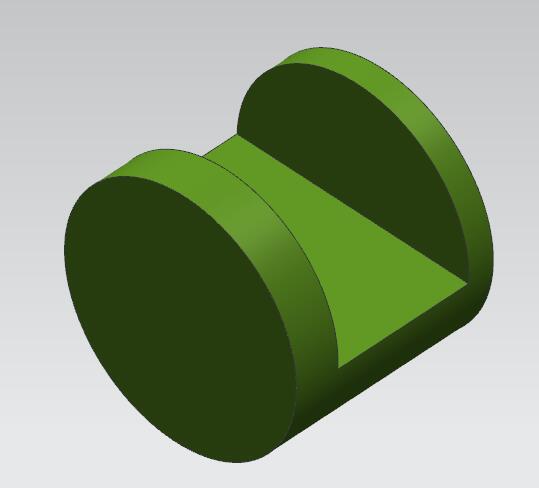

In this era when user experience is highly valued, more and more herd weed grinder with novel structures and appearances are designed and manufactured. Let me tell you how this cigarette holder was designed and machined by VMT. This cigarette holder has a 4-layer structure. After assembly, the middle cigarette holder rotates inside and out, which is very convenient to use. Today we will focus on the most difficult parts of herd weed grinder.

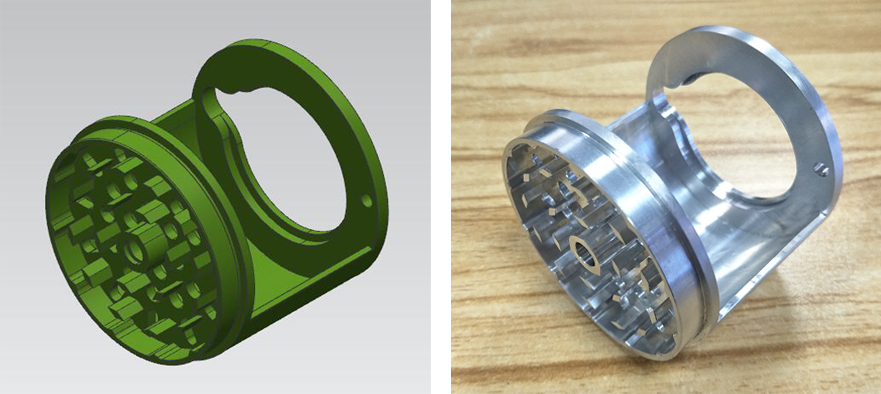

1. CNC Rough Milling Chip Flutes.

The reason why this process is added is to allow the aluminum chips to be discharged normally during lathe processing, otherwise the aluminum slag will not be discharged in the product cavity, which will cause the tool to let the knife, and the product cavity will have severe vibration marks and the size Unstable.

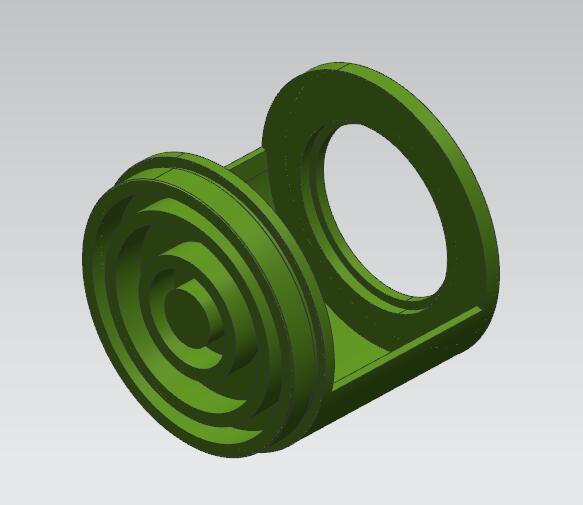

2. Lnside and Outside Circle of CNC Car

Numerical control lathes finely turn the inner and outer circles, and the key assembly must be strictly controlled according to the drawings, otherwise it will cause jams or jams after assembly.

3. CNC Precision Milling and Grinding of Tobacco Teeth and Positioning Holes

The difficulty of this process is that there will be overlapping processing areas between the CNC and CNC lathes, which leads to the appearance of the tool connection step, and the tool connection step should be controlled within 0.05MM, which is a great impact on the on-site manufacturing process. The management and control ability and the layout of the processing technology have a greater test.

4. Anodizing

The difficulty in this process lies in the consistency of the oxidation color control, the color difference must be guaranteed not to exceed the color limit, and the method of hanging up and down during the oxidation process must be controlled to reduce defects caused by scratches.

5. Assemble

This process needs to assemble all the parts of the cigarette grinding box. The parts include 4 N52 powerful magnets, 1 80 mesh stainless steel filter screen, a stainless steel rotating shaft, a white Teflon washer, and a white steel plug for fastening. Ring and other 4 main parts. This process is prone to defects that the glue overflows when the magnet is installed, and the riveted stainless steel filter is not in place, which causes the filter to slack. So pay attention to controlling the amount of glue and the method of riveting the filter.

6. Demonstration of the Operation of the Finished Herb Weed Grinder

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!