15 years one-stop China custom CNC machining parts factory

23 |

Published by VMT at Nov 18 2025 | Reading Time:About 5 minutes

23 |

Published by VMT at Nov 18 2025 | Reading Time:About 5 minutes

When you're choosing between CNC machining and additive manufacturing, it’s easy to feel overwhelmed. Both promise precision, speed, and cost-effective production, but picking the wrong method can lead to delays, low-quality parts, or higher project costs. You need a clear, simple comparison that shows which method truly fits your design, budget, and timeline.

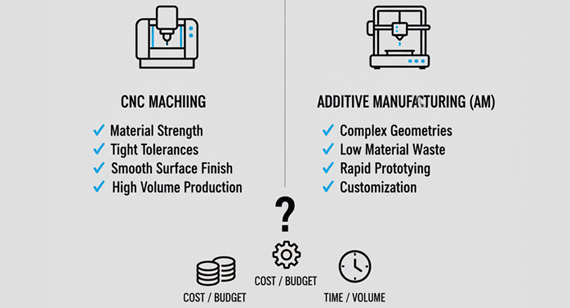

CNC machining removes material to create strong, precise parts, while additive manufacturing (AM) builds parts layer by layer for complex shapes and rapid prototyping. You should choose CNC for tight tolerances, durability, and production volumes, and use AM for fast prototypes, lightweight structures, and designs that traditional subtractive machining cannot achieve.

Now that you understand the core idea behind CNC machining vs additive manufacturing (AM), let’s break down how each process works and why their differences matter. This will help you choose the best option for prototyping, production, and cost control based on your project needs.

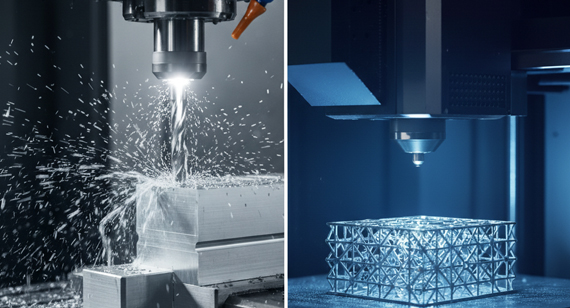

CNC machining is a subtractive manufacturing process that removes material from a solid block using computer-controlled tools. You get accurate, durable parts with tight tolerances, making it a top choice for metal prototypes and production runs. CNC machined parts are widely used because they deliver stable quality and repeatability across different shapes and materials.

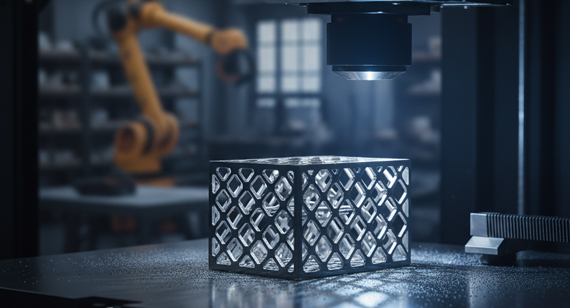

Additive manufacturing (AM), often known as 3D printing, builds parts layer by layer instead of cutting material away. You can create complex shapes, lightweight structures, and rapid prototypes without traditional tooling. AM is ideal when you need fast iterations, internal channels, or designs that subtractive machining cannot easily produce.

No, additive manufacturing and CNC machining are not the same. CNC machining removes material to shape a part, while AM builds the part layer by layer. You get stronger, more precise parts from CNC machining, and greater design freedom and faster prototyping from AM. Each method fits different needs, budgets, and project goals.

CNC machining and additive manufacturing (AM) differ mainly in how parts are created, the materials they support, the level of precision achievable, production speed, and overall cost structure. CNC machining is subtractive and excels in strength, accuracy, and consistency. AM is additive and offers design freedom, faster prototyping, and minimal material waste. Understanding these core differences helps you choose the right method for your part requirements.

Comparison Table: CNC Machining vs Additive Manufacturing (AM)

| Category |

CNC Machining (Subtractive) |

Additive Manufacturing (AM) |

| Process Type |

Removes material from a solid block | Builds parts layer by layer |

| Best For |

High precision, durability, tight tolerances | Complex geometries, rapid prototyping |

| Material Options |

Wide range: metals, plastics | Limited in some metals; expanding quickly |

| Surface Finish |

Smooth, high-quality finish | Rougher surfaces; may need post-processing |

| Strength & Reliability |

Strong, consistent, production-ready | Depends on printing method; may be weaker |

| Production Speed |

Slower for complex parts | Faster for one-off prototypes |

| Design Flexibility |

Less flexible; limited internal features | Excellent for internal channels & lightweight structures |

| Cost Structure |

Higher for complex designs; tool wear adds cost | Higher for simple parts; economical for complex shapes |

| Scalability |

Ideal for low to high production volumes | Best for low-volume or prototype runs |

| Waste Generation |

More material waste | Minimal waste |

| Tolerances |

Very tight and consistent | Moderate; may vary by AM technology |

When you compare CNC machining and additive manufacturing (AM), the main difference in cost comes from how each process handles complexity, materials, and production volume. CNC machining is usually the high-end choice because it delivers stronger parts, tighter tolerances, and premium surface finishes. AM becomes the economical option when you need quick prototypes, lightweight structures, or complex shapes without expensive tooling.

CNC Machining vs. Additive Manufacturing (AM) in Metal Prototyping: Advantages and Disadvantages

When you create metal prototypes, choosing between CNC machining and additive manufacturing (AM) affects strength, speed, cost, and design flexibility. CNC machining gives you consistent, production-ready parts, while AM helps you test complex shapes quickly. Understanding their advantages and disadvantages helps you avoid costly mistakes during early development.

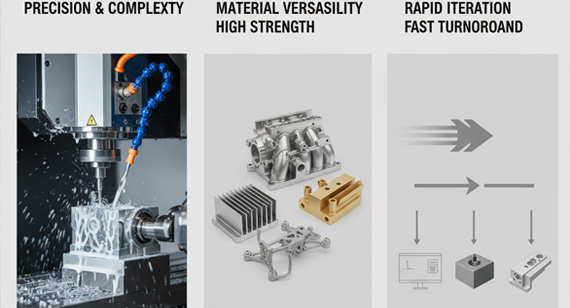

CNC Machining for Metal Prototyping: Advantages

CNC machining is a strong option for metal prototyping because it produces high-quality, stable, and accurate parts from real engineering materials. You get prototypes that closely match final production performance, making CNC ideal for testing strength, fit, and long-term reliability.

Mechanical Properties

CNC machining delivers excellent mechanical properties because parts are made from solid metal stock. You get strong, dense, and reliable prototypes that can handle real mechanical loads. This makes CNC machining superior when your design must pass stress tests or withstand repeated use.

Scalability

CNC machining scales smoothly from one prototype to full production. Once your design is finalized, you can continue manufacturing in the same CNC machining factory without changing processes. This reduces risk and ensures consistent quality from prototype to mass production.

Tight Tolerances

CNC machining offers some of the tightest tolerances in the industry. You get precise dimensions, stable accuracy, and excellent surface finishes. This helps you validate fits, alignments, and assemblies early in the design process.

Other Advantages of CNC Machining for Metal Prototyping

CNC machining offers several additional advantages that make it a reliable choice for metal prototypes:

Tip: Select the right metal early in the design process—material properties affect machining time, project cost, and prototype performance.

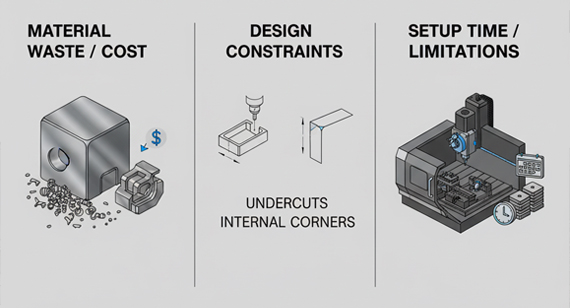

CNC Machining for Metal Prototyping: Disadvantages

While CNC machining has many strengths, it also comes with several limitations you should consider:

CNC machining can be more expensive for complex shapes because removing large amounts of material increases machining time. Some internal geometries and deep cavities require special tooling or may be impossible to machine. You also generate more material waste compared to AM.

Tip: If your design requires deep internal channels or hollow structures, consider redesigning for AM to reduce machining challenges and cost.

Tip: Review your CAD design for features that increase toolpath complexity—small design adjustments can significantly reduce machining time and cost.

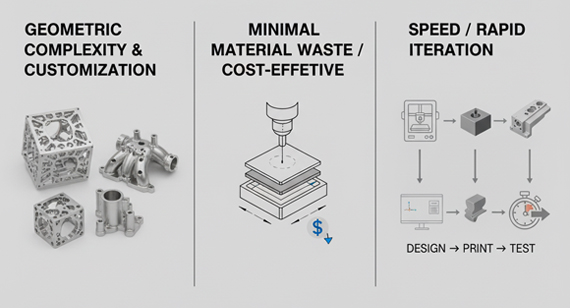

Additive Manufacturing in Metal Prototyping: Advantages

Additive manufacturing (AM) gives you the ability to create metal prototypes quickly and with complex shapes that CNC machining cannot easily achieve. It is ideal for early design validation, lightweight structures, and projects that benefit from rapid changes without needing expensive tooling.

Speed and Price of One-Off Products

AM is highly efficient for single prototypes because you avoid tooling costs and long machine setups. You only pay for the material used and the print time, making it cost-friendly for unique parts, design tests, or small trial batches.

Internal Geometry

With AM, you can create hollow structures, internal channels, lightweight lattice cores, and curved shapes that are impossible or extremely expensive to machine. This opens new design possibilities for cooling systems, aerospace parts, and fluid flow components.

Design Flexibility

AM supports freeform shapes, organic curves, and highly customized designs. You can modify your CAD files quickly and print a new version without rebuilding tools or fixtures. This helps you speed up your development cycle.

Low Cost

For small quantities or highly complex designs, AM is often cheaper because you avoid material waste and machining hours. The cost remains predictable, even with challenging geometries.

Short Lead Time

AM offers quick production because printing begins as soon as you upload your design. No tooling, no setup delays, and minimal manual intervention allow prototypes to be completed in hours or days.

Other Advantages of Additive Manufacturing for Metal Prototyping

Here are additional benefits AM offers beyond speed and flexibility:

Tip: Use AM for weight-critical parts that require optimization—you can remove unnecessary mass without harming performance.

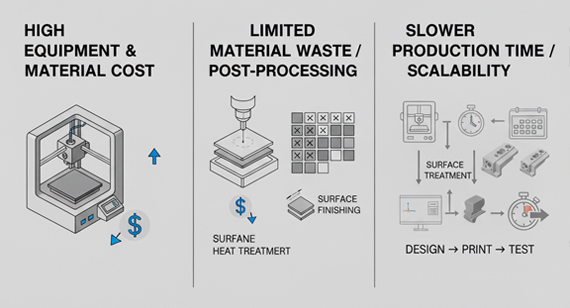

Additive Manufacturing in Metal Prototyping: Disadvantages

Even though AM offers strong benefits, it also comes with limitations in material options, accuracy, and production scale. These factors can affect part performance, especially when the prototype must match final production quality.

Limitations in Material Selection

Metal AM materials are more limited compared to CNC machining. While you can print aluminum, stainless steel, titanium, and Inconel, the material choices are still fewer and often more expensive.

Precision and Surface Finish

AM typically cannot match CNC machining’s tight tolerances or smooth surfaces. You may need post-processing, such as polishing or machining, to achieve final dimensions or finishes.

Part Size Limitations

AM build chambers limit the maximum size of metal prototypes. Large components may need to be printed in sections and later welded or assembled, which increases cost and risk.

Other Disadvantages of Additive Manufacturing for Metal Prototyping

Here are additional drawbacks you should be aware of:

Tip: Use simulation or orientation tools to reduce print defects—poor orientation increases surface defects and reduces part strength.

Choosing between CNC machining and additive manufacturing (AM) depends on what your project needs—precision, complexity, speed, or cost. CNC machining is ideal for strong, accurate, and production-ready metal prototypes, while AM helps you create complex shapes, rapid iterations, and lightweight structures without expensive tooling.

When to Choose CNC Machining?

You should choose CNC machining when your prototype must match final production quality. CNC delivers tight tolerances, smooth surfaces, and strong metal parts that can withstand real testing. It is the better option when you need stable performance, repeatability, and material flexibility.

Other Reasons to Choose CNC Machining

Beyond precision, strength, and production consistency, there are several additional situations where CNC machining becomes your best option:

When You Need Superior Surface Quality

CNC machining provides smoother surfaces and tighter dimensional control than AM. This is important for sealing surfaces, sliding components, optical housings, and aesthetic metal parts. You can achieve near-finished surfaces without heavy polishing or secondary operations.

When You Need Large Metal Parts

CNC machines are not limited by a build chamber like AM printers. You can machine long, wide, or thick metal components easily, making CNC ideal for oversized prototypes, structural frames, and large housings.

When You Need Excellent Heat Resistance and Material Stability

CNC machining works directly with solid engineering metals that maintain performance under high temperatures. If your prototype must withstand heat cycles, friction, or constant load, CNC machining gives you stable results.

When You Need Repeatable Accuracy Across Multiple Prototypes

CNC machining delivers consistent results across repeated runs. If you need several prototypes with identical geometry, CNC ensures they all meet the same tolerances and fit perfectly together.

When Your Design Requires Press-Fit, Threading, or Tight Assembly Features

CNC machining produces highly accurate bores, threads, and precision mating surfaces. These features are difficult to achieve reliably with AM and often require post-machining anyway.

When Your Metal Material Has Strict Certification Requirements

Some industries require certified metals (aerospace-grade aluminum, medical-grade titanium, etc.). These metals are more reliably available in billet form for CNC machining than as AM powders.

When You Want Lower Production Costs for Simple Geometries

Simple brackets, plates, blocks, or housings are much cheaper to machine than to print. CNC machining wins in cost efficiency when the part does not require complex internal features.

Tip: If your part is simple, don’t waste money on AM—CNC machining is faster and cheaper.

When You Need Strong, Fully Dense Parts Without Post-Processing

CNC machining gives you fully dense metal parts right out of the machine. AM parts often require heat treatment, stress relief, or machining to reach the same performance level.

These additional reasons help you decide confidently when CNC machining is the right fit for your metal prototyping needs.

When to Choose Additive Manufacturing (AM)?

AM is the better choice when you need faster prototypes, complex geometries, or lightweight structures that subtractive machining cannot create. It allows quick design changes and supports early-stage testing without heavy investment.

When Specifications and Designs Require Custom Parts and Molds

AM is ideal for custom molds, jigs, fixtures, or low-volume specialized components. You can print unique shapes without the cost of machining blocks, creating molds faster and at a fraction of the price.

When the Design and Specifications of Manufactured Parts Are Complex

If your part has internal channels, hollow sections, lattice structures, or organic curves, AM is often the only practical manufacturing method. The design freedom lets you test versions that would be expensive or impossible to machine.

When Part Labeling Is Required

AM allows you to integrate serial numbers, logos, barcodes, or labels directly into the printed geometry. You don't need additional engraving or machining steps, reducing time and cost.

Other Reasons to Choose Additive Manufacturing (AM)

Here are additional situations where AM gives you clear advantages:

Tip: Use AM for concept validation and CNC for final validation—this workflow saves cost and improves product accuracy before production.

Choosing between CNC machining and additive manufacturing (AM) depends on your project’s goals, complexity, and budget. CNC machining excels in precision, strength, surface finish, and repeatability, making it ideal for production-ready metal prototypes and functional parts. AM shines for rapid prototyping, complex geometries, lightweight structures, and quick design iterations. By understanding the advantages and limitations of each method, you can select the right process for your parts, optimize costs, and ensure your prototypes or production components meet performance and design requirements.

Choosing the right manufacturing process can be confusing. You may worry about high costs, long lead times, or parts that don’t meet your design specifications. VMT helps you navigate these challenges by offering expert guidance to select between CNC machining and additive manufacturing (AM) based on your project needs, complexity, and budget.

How VMT Helps You Choose

At VMT, we evaluate your design requirements and production goals to recommend the most suitable method. Whether your project demands high precision, strong metal parts, or rapid prototyping, VMT matches you with the right technology. Our experts compare CNC vs AM, subtractive vs additive machining, and even hybrid solutions to optimize your manufacturing plan.

VMT CNC Machining and Additive Manufacturing Services

VMT’s CNC machining factory offers a wide range of CNC machining services, including 3-axis, 4-axis, and 5-axis milling, turning, and custom prototyping. Our subtractive machining capabilities ensure precise, durable, and production-ready parts.

For designs requiring complex geometries, lightweight structures, or rapid iterations, VMT also provides additive manufacturing (AM) services. You can create metal or plastic prototypes layer by layer, minimizing waste and speeding up the product development cycle.

Why Choose VMT

With VMT, you get a full-service CNC machining and AM partner that understands both processes. Our integrated approach ensures cost-effective solutions, quick lead times, and high-quality CNC machined parts or 3D-printed components. Whether you need rapid prototyping or production-ready parts, VMT delivers expertise, precision, and reliability.

1. What is the Difference Between CNC Machining and 3D Printing?

CNC machining is subtractive—you remove material from a solid block to create a part. 3D printing is additive—you build parts layer by layer. CNC produces stronger, more precise parts with tight tolerances, while 3D printing allows complex geometries, lightweight structures, and faster prototypes.

2. Is CNC Machining Faster Than 3D Printing? Is 3D Printing Faster or Building from Scratch?

CNC machining is faster for simple or large-volume parts because material removal is predictable and automated. 3D printing is faster for complex, one-off parts since no tooling is needed. “Building from scratch” in CNC usually involves setup time, which can make AM faster for a single prototype.

3. Is 3D Printing Faster Than Manufacturing?

3D printing is faster for prototypes, low-volume parts, or complex geometries without tooling. Traditional manufacturing, including CNC machining or casting, is faster for large-volume production of standard parts.

4. What Are the 7 Types of Additive Manufacturing Technology?

The seven main AM technologies are:

Tip: Choose AM technology based on material, accuracy, and part size requirements.

5. What is the Difference Between 3D Printing and Additive Manufacturing?

3D printing is a type of additive manufacturing, typically used for rapid prototyping or consumer applications. Additive manufacturing is a broader term that includes industrial-scale production with metals, high-performance plastics, and engineering materials.

6. What Are the Three Types of 3D Printing?

The three main categories of 3D printing are:

Tip: Match the 3D printing type with your material and precision needs.

7. What is the Difference Between CNC Manufacturing and Additive Manufacturing?

CNC manufacturing removes material from solid stock (subtractive), producing strong, accurate parts. Additive manufacturing builds parts layer by layer, allowing complex geometries, minimal material waste, and rapid prototyping. CNC excels in durability and tolerances, while AM excels in design flexibility and speed for low-volume or complex parts.