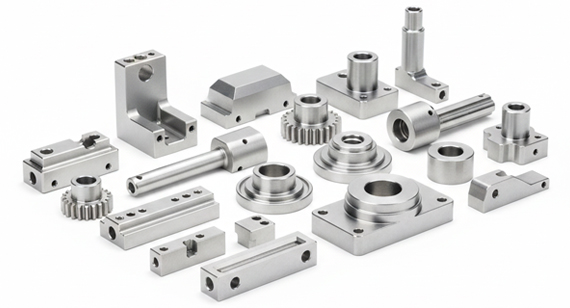

15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Dec 09 2025 | Reading Time:About 3 minutes

0 |

Published by VMT at Dec 09 2025 | Reading Time:About 3 minutes

Nickel often appears shiny and durable, but you may still worry about rust, discoloration, or long-term surface damage. This uncertainty can lead to bad material choices, unexpected failures, and higher project costs. The good news is that nickel behaves very differently from ordinary metals when exposed to moisture and air. Understanding how nickel rusting, nickel corrosion, and nickel oxidation actually work helps you choose the right material and avoid unnecessary issues.

Nickel does not rust like iron, but it can corrode or oxidize under certain conditions. Instead of forming red rust, nickel develops a thin, protective oxide film that slows further damage. Pure nickel and most nickel alloys show strong rust resistance, while nickel-plated steel may corrode if the coating wears off.

Now that you know nickel doesn’t rust in the same way iron does, you can look deeper into how nickel behaves in different environments. Understanding its rust resistance, corrosion patterns, and oxidation helps you make smarter material choices—especially when comparing pure nickel, stainless steel, Inconel, Monel, or nickel-plated steel.

Nickel is a tough, silver-white metal known for its strength, durability, and natural resistance to rust and corrosion. You’ll find it in pure nickel form, nickel alloys, stainless steel (which contains nickel), and nickel-plated steel. Because nickel forms a stable oxide film, it stays shiny and resists deterioration better than many common metals.

Nickel does not rust the way iron does. Instead of forming reddish-brown rust, nickel creates a thin, protective oxide layer. This nickel surface oxidation slows down nickel corrosion and keeps the metal stable. Pure nickel has strong rust resistance, while nickel alloys—like Inconel, Monel, and Hastelloy—offer even better protection. Only nickel-plated steel may rust if the coating gets scratched or worn off.

This section compares how nickel and various nickel-containing metals behave in terms of rusting, corrosion, and oxidation. It highlights which materials are more resistant, which may develop surface deterioration, and under what conditions rust or corrosion can occur. The goal is to give you a clear reference so you can choose the right nickel-based material for your project.

Here’s a table summarizing the rusting behavior:

| Material |

Rusting / Corrosion Behavior |

Notes / Tips |

| Pure Nickel |

Very low rusting; forms protective oxide layer | Ideal for high corrosion resistance; long-lasting in moisture and mild chemicals |

| Nickel Alloys |

Excellent corrosion resistance; depends on alloy composition | Alloys like Inconel, Monel, Hastelloy offer superior rust resistance |

| Nickel-Plated Steel |

Can rust if plating is scratched or worn | Use protective coatings; avoid high-friction or outdoor exposure |

| Stainless Steel (Contains Nickel) |

Low rusting; corrosion-resistant due to chromium content | Regular maintenance recommended in salty or acidic environments |

| Nickel-Chromium Alloys |

Very high rust resistance; stable oxide film forms | Common in industrial applications requiring long-term durability |

| Incol Nickel Alloys |

Excellent rust and corrosion resistance | Suitable for harsh chemical or high-temperature environments |

| Monel |

Extremely high corrosion resistance; does not rust easily | Great for marine and chemical applications |

| Hastelloy |

Exceptional rust resistance, even in acidic environments | Best choice for highly corrosive industrial conditions |

Nickel’s rust resistance isn’t accidental—it comes from several key factors that make it highly durable in harsh environments. Understanding these can help you select the right type of nickel or nickel alloy for your CNC machined parts.

1. Alloy Composition

Nickel’s resistance to rust improves when combined with elements like chromium, molybdenum, and iron. These alloys, such as Inconel, Monel, and Hastelloy, form stable oxide layers that prevent corrosion.

2. Surface Finish

Smooth, polished, or coated surfaces reduce the chances of corrosion because they limit areas where moisture or chemicals can settle. Satin or brushed finishes may slightly reduce protection compared to polished finishes.

3. Passivation

Passivation is a chemical treatment that enhances the protective oxide layer on nickel or nickel alloys. This process greatly reduces the risk of rusting or tarnishing, especially for CNC machined parts.

4. Low Reactivity

Nickel naturally reacts very slowly with oxygen and water, which limits rust formation. Its low reactivity compared to iron or steel makes it ideal for long-term applications.

5. Chemical Stability

Nickel’s stable chemical structure prevents nickel deterioration in most environments. This stability is why nickel alloys and stainless steel containing nickel are preferred for industrial and marine use.

Nickel doesn’t rust like iron, but it can still experience nickel corrosion under certain conditions. Rusting usually refers to the reddish-brown oxide forming on iron, while nickel primarily undergoes nickel oxidation, creating a thin, protective layer that slows further damage. Understanding this difference helps you choose materials for CNC machined parts that last longer.

| Type |

Definition / Behavior |

Impact on Nickel |

| Nickel Rusting |

Similar to iron rust but extremely rare; forms reddish-brown deposits only under extreme conditions | Minimal effect; mostly a surface phenomenon, often preventable with coatings |

| Nickel Corrosion |

Chemical or electrochemical reaction leading to nickel surface deterioration or oxidation | More common; can dull surfaces or slightly weaken nickel over time |

| Nickel Oxidation |

Formation of a thin, protective oxide layer that naturally resists further corrosion | Beneficial; enhances nickel rust resistance and prolongs part life |

Even though nickel has excellent rust resistance, taking extra precautions ensures your parts last longer and maintain their appearance. Proper care and material handling can prevent surface deterioration, tarnishing, or corrosion in CNC machined parts.

1. Keep Clean

Regular cleaning removes dirt, dust, and contaminants that can trap moisture and promote nickel oxidation. Use mild soap and water, then dry thoroughly.

2. Coatings and Surface Treatments

Applying protective coatings, polishing, or passivation enhances nickel’s natural resistance. Nickel-plated steel, for example, benefits greatly from additional surface treatments to prevent corrosion if the plating wears off.

3. Avoid Contact with Strong Acids and Alkalis

Harsh chemicals can break down the protective oxide layer on nickel, leading to corrosion or surface discoloration. Always minimize exposure to acidic or alkaline substances, especially for nickel-plated steel or sensitive alloys.

Nickel is known for its strong rust resistance, but how does it stack up against other metals and alloys? Comparing nickel to common metals helps you decide which material is best for your CNC machined parts in terms of durability, chemical stability, and long-term maintenance.

| Comparison |

Corrosion Resistance |

Notes / Tips |

| Nickel vs. Aluminum |

Aluminum is lightweight but forms a softer oxide layer; nickel generally resists corrosion longer | Use aluminum for lightweight parts; nickel for high-durability applications |

| Nickel vs. Stainless Steel (Contains Nickel) |

Stainless steel resists rust well due to chromium; nickel adds extra corrosion resistance | Ideal for kitchen, medical, and outdoor applications |

| Nickel vs. Titanium |

Titanium is extremely corrosion-resistant, even in seawater; nickel is slightly less resistant but more cost-effective | Choose titanium for extreme environments; nickel for moderate chemical exposure |

| Nickel vs. Inconel |

Inconel outperforms pure nickel in harsh chemicals and high temperatures | Best for industrial CNC machined parts exposed to acids or heat |

| Nickel vs. Nickel-Chromium Alloy |

Alloying improves corrosion resistance over pure nickel | Consider for marine, chemical, or high-wear environments |

| Nickel vs. Monel |

Monel has superior corrosion resistance, especially in saltwater and acidic environments | Excellent for marine, chemical, and CNC machined components |

| Nickel vs. Hastelloy |

Hastelloy is one of the most corrosion-resistant alloys; nickel alone is less robust in extreme conditions | Use Hastelloy for highly acidic or industrial chemical applications |

Summary of Nickel Compared to Other Metals

Tip: Use this summary as a quick reference when planning CNC machining projects involving nickel or nickel-based alloys.

Nickel behaves differently from iron when exposed to oxygen and moisture. Instead of forming reddish-brown rust, nickel develops a thin nickel oxide layer on its surface. This oxide acts as a protective barrier, preventing further nickel corrosion or deterioration. True nickel rusting is extremely rare and usually only occurs under harsh conditions, unlike the common rust seen on iron or steel.

| Term |

Definition / Behavior |

Impact on Nickel |

| Nickel Oxide |

A thin, stable oxide layer that forms naturally on nickel surfaces | Beneficial; protects the metal from further corrosion and maintains surface integrity |

| Nickel Rusting |

Rare occurrence of surface corrosion under extreme conditions | Minimal; can cause slight discoloration but is largely preventable |

Summary of Nickel Oxide vs. Nickel Rusting

Tip: Understanding this difference helps you avoid unnecessary concerns about rust when using pure nickel or nickel alloys in CNC machined parts.

Even though nickel rarely rusts, scratches or damaged coatings on nickel-plated steel or nickel alloys can lead to surface corrosion. Removing rust properly restores appearance and prevents further deterioration. Here are the most effective methods:

1. Metal Polishing Agents

Specialized metal polish removes minor nickel oxidation and restores shine without damaging the surface. Use a soft cloth and follow the product instructions carefully.

2. Baking Soda and Vinegar

A gentle homemade solution of baking soda and vinegar can help remove light rust or tarnish. Apply a paste, rub lightly, then rinse and dry.

3. Soap and Water

For mild surface oxidation, warm soapy water and a soft cloth may be enough. Regular cleaning prevents buildup and preserves the protective nickel oxide layer.

4. Commercial Rust Removers

Products designed for metal corrosion can safely remove rust from nickel-plated surfaces. Follow instructions and wear protective gloves.

5. Lemon Juice and Salt

A natural method using lemon juice and salt can help lift light rust. Apply, let sit briefly, scrub gently, then rinse and dry.

Nickel and nickel alloys are used in industries where corrosion resistance, strength, and durability are essential. Here’s a detailed breakdown:

Aerospace Industry

Marine Industry

Chemical and Petrochemical Industry

Medical and Pharmaceutical Industry

Energy and Power Industry

Tip: Using the right nickel or nickel alloy for each industry ensures long-term performance and reduces maintenance costs for CNC machined parts.

Client Background and Challenges

A U.S.–based aerospace technology company approached VMT to manufacture a series of nickel alloy CNC machined parts used in their high-temperature propulsion and thermal management systems. Nickel alloys—such as Inconel 625 and 718—were chosen for their exceptional heat resistance, corrosion resistance, and strength at elevated temperatures.

However, these same advantages created significant machining challenges for the customer’s previous suppliers. They experienced:

The customer urgently needed a machining partner capable of controlling heat, maintaining accuracy, and delivering stable production for nickel alloy components used in mission-critical applications.

Our Solutions and Breakthroughs

VMT assigned a senior engineering team with extensive experience in superalloy machining and optimized the entire production workflow. Key breakthroughs included:

1. Specialized Cutting Strategies for Nickel Alloys

We applied low-speed, high-torque cutting parameters to reduce work-hardening and maintain structural stability. Multi-step roughing and finishing ensured dimensional accuracy throughout the machining cycle.

2. High-Pressure Coolant Delivery System

To combat excessive heat buildup, VMT used 70-bar high-pressure coolant to flush chips instantly and maintain a cool cutting environment—critical for preventing surface cracking and thermal distortion.

3. Premium Heat-Resistant Tooling

We selected carbide tools with advanced coatings designed for superalloys, significantly increasing tool life and enhancing cutting consistency.

4. Adaptive Toolpath Programming

Our 5-axis machining team optimized toolpaths to reduce tool engagement, minimize dwell marks, and maintain precise geometries even on thin sections or complex contours.

5. Rigorous In-Process Quality Control

CMM inspections, real-time tool wear monitoring, and thermal influence evaluation were incorporated into the workflow to maintain repeatability across every batch.

These process innovations allowed VMT to achieve stable, predictable machining performance even under the demanding conditions associated with nickel alloys.

Results and Customer Value

The customer achieved substantial and measurable improvements after transitioning production to VMT:

With VMT’s support, the customer successfully launched their new propulsion system components on schedule and expanded their cooperation to include additional nickel alloy parts for aerospace and energy applications.

This case demonstrates VMT’s expertise in handling superalloys like nickel, where precision, heat control, and advanced machining strategy are essential for achieving long-term performance and manufacturing consistency.

Nickel stands out as a highly corrosion-resistant metal, making it ideal for CNC machined parts across aerospace, marine, chemical, medical, and industrial applications. While it rarely rusts like iron, understanding nickel corrosion, nickel oxidation, and nickel rusting behavior is key to maximizing durability. Selecting the right material—whether pure nickel, nickel alloys like Inconel, Monel, Hastelloy, or nickel-plated steel—combined with proper surface treatments, cleaning, and maintenance, ensures long-lasting performance, reduces maintenance costs, and maintains aesthetic appeal.

1. Does nickel rust in water?

No, pure nickel forms a protective oxide layer that prevents rust. It may experience slight oxidation over time, but true rusting is extremely rare.

2. Does nickel rust in salt water?

Pure nickel resists corrosion in salt water better than many metals, but nickel-plated steel may corrode if the coating is damaged. Alloys like Monel or Hastelloy perform best in marine environments.

3. Do nickel-plated surfaces rust?

Yes, but only if the plating is scratched, worn, or damaged. The underlying steel can then corrode. Maintaining coatings and applying passivation helps prevent this.

4. Does nickel lose its shine?

Nickel may tarnish or dull slightly over time due to surface oxidation, but this does not mean it is rusting. Regular cleaning preserves its appearance.

5. Does satin-finish nickel rust?

Satin finishes have slightly lower corrosion resistance than polished surfaces but are still highly resistant to rust. Proper cleaning and maintenance prevent oxidation buildup.

6. How quickly does nickel rust?

Pure nickel rarely rusts. Any surface corrosion develops very slowly, especially compared to iron or ordinary steel.

7. Does brushed nickel rust?

Brushed nickel is resistant to rust. Occasional cleaning is recommended to remove contaminants that could affect surface oxidation.

8. Does polished nickel rust?

Polished nickel is highly resistant due to its smooth surface and protective oxide layer. It is one of the best finishes for rust prevention.

9. Does black nickel rust?

Black nickel coatings are corrosion-resistant, but like all plating, they can rust if scratched or exposed to harsh chemicals.

10. Does copper-nickel alloy rust?

Copper-nickel alloys resist rust well. They form a stable oxide layer that protects the metal in marine or industrial environments.

11. Does leaded nickel rust?

Leaded nickel alloys are corrosion-resistant and rarely rust, but extreme chemical exposure may cause minor surface oxidation.

12. Does nickel rust outdoors?

Pure nickel and most alloys resist outdoor corrosion. Environmental factors like acid rain or salt exposure may require high-grade alloys or protective coatings.

13. How to remove rust from nickel surfaces?

Use gentle methods like metal polishing agents, baking soda and vinegar, lemon juice and salt, or commercial rust removers. Avoid abrasive cleaners that can scratch the surface.

14. Does stainless steel rust due to nickel?

No, stainless steel contains nickel to enhance corrosion resistance. Rust on stainless steel is usually due to low chromium content, surface damage, or environmental conditions—not the nickel itself.

Tip: Regular cleaning, proper surface finish, and choosing the right nickel alloy are the best ways to maintain rust resistance and prolong the life of your CNC machined parts.