15 years one-stop China custom CNC machining parts factory

39 |

Published by VMT at Oct 17 2025 | Reading Time:About 3 minutes

39 |

Published by VMT at Oct 17 2025 | Reading Time:About 3 minutes

The notion that material selection is a mere checkbox on a project brief? Utterly preposterous, I say! It is, in my most firm conviction, the very foundation—the absolute bedrock—upon which the triumph or tragic failure of any engineered component rests. Are you truly confident you are specifying the optimal material for your specific application, balancing performance, durability, and cost with undeniable certainty? Or is this profoundly critical decision leaving you with lingering doubts and, dare I suggest, potential future liabilities, like a silent, ticking time bomb?

In the intricate realm of precision engineering, the choice between iron and carbon steel is frequently oversimplified, yet its implications can absolutely determine the very success or failure of your entire project. Our factory, as a trusted source manufacturer with deep technical expertise and transparent pricing, partners with you to cut through this material ambiguity, empowering you to make the precise material selection for your unique application, ensuring superior quality parts, optimized project costs, and accelerated product success—eliminating costly trial-and-error that no one truly desires.

Understanding the elemental disparities between iron and carbon steel is paramount, a truth that cannot be overstated; it is an absolutely irreplaceable truth for anyone engaged in serious fabrication. Fundamentally, both are alloys primarily composed of iron, yet their divergent mechanical virtues stem from distinct variations in carbon content and other alloying elements, profoundly affecting their microstructures and, consequently, their engineering usefulness.

For a component requiring robust strength coupled with good ductility, carbon steel is frequently the superior choice, while for intricate castings demanding excellent dampening and wear attributes, the various cast irons become indispensable considerations. This foundational understanding is not merely academic; it is the genesis of all informed material specification.

The Core of Iron: Cast Iron Variants

When we utter "iron" in manufacturing dialogues, we are, with exceedingly rare exception, referring to cast iron—a family of ferrous alloys renowned for their impressive fluidity in the molten state, which permits the creation of complex shapes with relative ease. A primary defining characteristic? A carbon content typically exceeding 2.14%, often hovering between 2.5% and 4.0%, and frequently with significant silicon content, often 1% to 3%. It truly differentiates it, doesn't it?

Cast irons, a marvel of metallurgy, come in various forms, each presenting distinct properties.

Grey iron, for instance, possesses graphite in flake form, which grants it superb vibration dampening but unfortunately compromises tensile strength and ductility.

Ductile iron, a veritable engineering triumph, sees its graphite formed into spheroids, imbuing it with remarkable toughness and tensile strength, properties akin to some steels, which is quite astonishing.

Malleable iron, another fascinating iteration, starts as white iron, undergoing a prolonged heat treatment to convert brittle cementite into temper carbon, enhancing ductility. White iron, frankly, is too brittle for most structural uses, its cementite lending extreme hardness but no give whatsoever.

But wait a moment, I ought to mention something crucial here: Sometimes clients mistakenly conflate wrought iron with cast iron, believing them similar. Wrought iron, nearly pure iron with fibrous slag inclusions, is essentially an antique material, rarely encountered in contemporary CNC machining. A vastly different beast altogether!

Carbon Steel Fundamentals: Alloying Elements

Carbon steel, in stark contrast, is an alloy of iron and carbon where the carbon content is typically less than 2.14% by weight. It might contain other elements too, of course, but not in quantities sufficient to qualify it as an alloy steel—the defining line can feel a bit arbitrary sometimes, I admit! The absence of massive graphite formations is a key distinguishing feature, rendering its microstructure entirely different from cast iron. This class of material, a veritable workhorse, is globally ubiquitous, its utility simply immense.

We categorize carbon steels generally by their carbon content:

Key Distinctions in Metallurgical Structure

The fundamental divergence in metallurgical structure between cast iron and carbon steel dictates their respective mechanical behaviors, a truth we ignore at our peril! Cast irons, by virtue of their higher carbon content, often precipitate graphite phases directly during solidification. This graphite, be it flakes or spheroids, acts as a stress concentrator in grey iron, reducing tensile strength, or as a crack arrestor in ductile iron, imparting toughness.

Carbon steels, conversely, primarily solidify into a microstructure of ferrite and pearlite, or martensite and bainite after heat treatment. These microstructures, utterly devoid of free graphite, grant carbon steels their characteristic combination of strength, ductility, and malleability. The presence of these different phases—like microscopic architectural blueprints—determines everything.

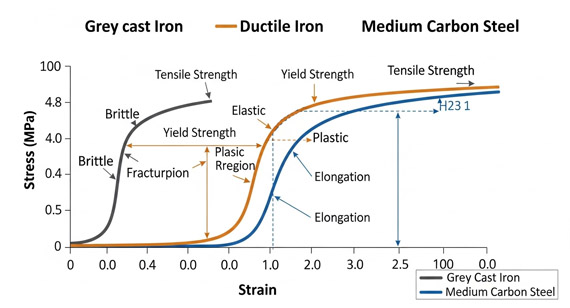

Choosing the right material necessitates a painstaking examination of mechanical properties, a task demanding utmost precision. This is where the rubber truly meets the road, where theoretical metallurgy transforms into tangible performance. We consistently advise our clients that relying solely on intuition is an unbelievably foolish assumption; data, always data, must be your guiding star.

Tensile Strength, Yield Strength, and Hardness

The disparity in tensile strength between cast iron and carbon steel is often pronounced. Carbon steels generally exhibit higher tensile and yield strengths, permitting them to withstand greater pulling forces before fracture or permanent deformation. Ductile irons, however, stand out among cast irons, presenting strengths comparable to, or even exceeding, some lower-grade carbon steels, which is quite the feat! Hardness, a critical property for wear resistance, can also vary considerably.

Consider these approximate ranges, for instance:

Table: Comparative Strength and Hardness

| Property | Grey Cast Iron (Typical) | Ductile Iron (Typical) | Low Carbon Steel (Typical) | Medium Carbon Steel (Typical) |

| Tensile Strength (MPa) | 120-300 | 400-800 | 300-550 | 500-900 |

| Yield Strength (MPa) | N/A (Brittle) | 250-550 | 200-400 | 350-700 |

| Brinell Hardness (BHN) | 150-250 | 160-270 | 90-160 | 150-250 |

Ductility, Brittleness, and Impact Resistance

Ductility, a material's capacity to deform plastically without fracturing, is a critical differentiating factor. Carbon steels, particularly low and medium grades, are generally highly ductile, allowing for forming operations and absorbing impact energy effectively. Cast irons, especially grey iron, are inherently brittle due to their graphite microstructure. They possess minimal ductility, often fracturing suddenly without significant prior deformation, a characteristic that demands careful design consideration to avoid a downright catastrophic failure!

Ductile iron, with its spheroidal graphite, represents an anomaly among irons, possessing commendable ductility and impact resistance. For applications involving shock loading or potential unexpected impacts, the superior toughness of most carbon steels or ductile iron is a decisive advantage.

Table: Ductility and Impact Resistance Overview

| Characteristic | Grey Cast Iron | Ductile Iron | Low Carbon Steel | High Carbon Steel |

| Ductility | Very Low (Brittle) | Moderate to High | High | Low to Moderate |

| Impact Resistance | Poor | Good | Excellent | Moderate |

| Elongation at Break (%) | <1 | 5-25 | 20-35 | 5-15 |

Fatigue Resistance and Wear Characteristics

Fatigue, the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, is an insidious threat in many mechanical systems. Carbon steels often exhibit superior fatigue limits compared to many cast irons, particularly under conditions of high stress concentration. The absence of graphite flakes, which can act as internal notches, contributes significantly to this improved performance.

However, when it comes to wear characteristics, the narrative can shift. Some cast irons, notably white iron and certain alloyed grey irons, offer exceptional wear resistance due to their hard carbide phases or the lubricating effect of graphite in grey iron. For sliding wear applications, a proper grade of cast iron can sometimes outperform carbon steel, which is an interesting paradox given steel's overall strength! The selection, truly, must be contextual.

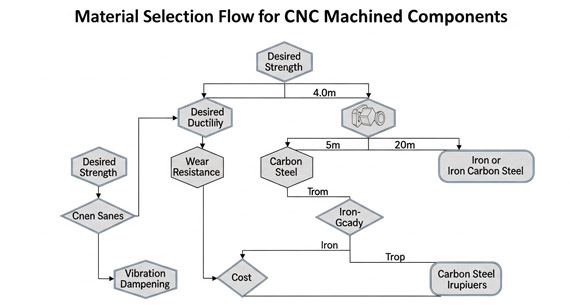

The question isn't whether iron or carbon steel is intrinsically "better"; it's about which material is optimally suited for your specific application, considering the myriad operational conditions it will face. This demands a holistic understanding, something we at VMT CNC Machining Parts Services Factory frequently help clients navigate.

Corrosion Resistance: Environmental Durability

Neither plain carbon steel nor standard cast iron is inherently corrosion resistant; they will both rust in moist, oxygenated environments. However, their rates and forms of corrosion can differ. Cast irons, particularly grey iron, sometimes form a tight, adherent rust layer that can offer a degree of protection against further atmospheric corrosion, which is a minor reprieve. Carbon steels, though, often exhibit more uniform corrosion, potentially leading to section loss more rapidly in aggressive conditions.

For truly demanding corrosive environments, both materials typically necessitate protective coatings, galvanizing, or are substituted entirely by stainless steels or other corrosion-resistant alloys. It seems to me, ignoring this aspect, purely focusing on mechanical strength, is a truly mind-blowing error in judgment for any outdoor or humid application.

Heat Treatment Responses and Enhancements

The response to heat treatment is another crucial differentiator. Carbon steels are highly amenable to various heat treatment processes—annealing, normalizing, hardening, tempering—each designed to precisely modify their microstructure and, consequently, their mechanical properties. This allows engineers to tailor a specific steel grade for an astonishing array of performance requirements. Hardening, for instance, transforms steel into a much more wear-resistant material, while tempering can restore some ductility, managing brittleness.

Cast irons' response to heat treatment is more constrained. While ductile iron can be heat treated (e.g., austempering to produce ADI for exceptional strength and toughness), and malleable iron undergoes a specific annealing process, grey iron typically does not respond to hardening treatments in the same transformative way as steel due to the presence of free graphite. Its utility lies more in its inherent as-cast properties, which are quite distinct.

Weight, Density, and Structural Considerations

When considering structural components, weight and density play pivotal roles. The density of cast iron and carbon steel is quite similar, generally around 7.2 to 7.8 g/cm³. However, due to carbon steel's superior strength-to-weight ratio, particularly for applications requiring high tensile loads, a carbon steel part can often be designed with a thinner cross-section than its cast iron counterpart, achieving equivalent strength with less material and less mass.

This becomes especially pertinent in industries where weight reduction is a paramount concern, such as automotive or aerospace, though frankly, neither material is generally considered "lightweight." For large, complex castings where rigidity and vibration dampening are key, cast iron might indeed be the more judicious choice, often simplifying the manufacturing process immensely.

Machinability and cost are two inextricably linked factors that profoundly influence material selection from a manufacturing perspective. One simply cannot disregard either, lest project budgets spiral out of control!

Manufacturing Considerations for Machining Iron

Cast irons are generally regarded as having good to excellent machinability. Grey cast iron, in particular, with its lubricating graphite flakes, produces short, brittle chips that are easily cleared from the cutting zone, extending tool life—a truly fantastic characteristic for volume production! However, its inherent brittleness demands careful tool selection and machining parameters to prevent chipping or cracking. Machining ductile iron is somewhat more challenging than grey iron but still quite manageable. Its toughness means chips aren't as brittle, requiring slightly different cutting speeds and feeds.

Table: Machinability Index Comparison (Relative)

| Material | Machinability Index (B1112 Steel = 100%) | Typical Chip Formation | Surface Finish Potential |

| Grey Cast Iron (Class 30) | 90-120 | Short, Brittle | Good |

| Ductile Iron (65-45-12) | 60-80 | Segmented | Good |

| Low Carbon Steel (1018) | 70-80 | Continuous | Excellent |

| Medium Carbon Steel (1045) | 50-65 | Continuous | Very Good |

Carbon Steel Machining: Efficiency and Finish

Carbon steels present a wider range of machinability, largely dependent on their carbon content and heat treatment state. Low-carbon steels, while ductile, can sometimes form long, stringy chips that entangle tools, demanding higher cutting forces and specialized chip-breaking techniques. Medium and high-carbon steels, especially in a hardened state, become progressively more difficult to machine, significantly increasing tool wear and necessitating carbide tooling or more aggressive machining strategies. However, the surface finish achievable on carbon steels, when properly machined, can be exquisitely smooth, often superior to cast irons.

Lifecycle Cost and Material Sourcing Implications

The initial material cost is only one piece of the economic puzzle; lifecycle cost analysis, in my view, presents a far more accurate financial picture. Factors such as machining time, tool wear, scrap rates, heat treatment expenses, and projected part lifespan all contribute significantly. While cast iron might have a lower per-pound raw material cost in some instances, the overall manufacturing efficiency, post-processing requirements, and expected operational longevity often dictate the true cost-effectiveness.

Our factory, as a direct source manufacturer, maintains transparent pricing models, ensuring you comprehend the full cost implication of your material choice from procurement through machining and finishing. We work tirelessly to identify the most cost-efficient and performant material for your specific requirements, eliminating costly surprises.

The choice between iron and carbon steel is, in essence, a strategic engineering decision, a dance between competing performance requirements, manufacturability, and cost. It is a decision that, when executed with our deep technical expertise, can accelerate your product's market success.

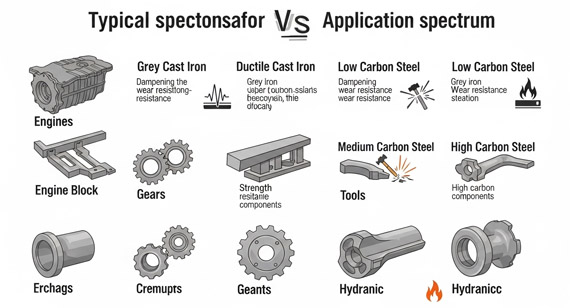

Application-Specific Decision Matrix

No single material triumphs universally; each possesses its unique domain of optimal application. For components demanding exceptional vibration dampening, high compressive strength, and good wear resistance, such as machine bases, engine blocks, or intricate pump housings, grey cast iron frequently proves invaluable. If high tensile strength, ductility, and impact resistance are paramount—think gears, shafts, fasteners, or structural brackets—then carbon steel, or perhaps even ductile iron, steps into the limelight.

We recently had a client, a pioneer in industrial automation, developing a novel high-speed actuator. Initially, their design called for a specific grade of medium-carbon steel for the housing, believing its inherent strength was irreplaceable. Our engineering team, through an in-depth finite element analysis and understanding of the actuator's dynamic loading, identified that the primary failure mode was actually vibration-induced fatigue. We recommended transitioning to a particular grade of vibration-dampening grey cast iron, demonstrating how its superior acoustical properties and inherent rigidity would not only enhance the actuator's operational lifespan but also reduce manufacturing complexity due to its excellent machinability. This proactive material optimization, backed by our transparent cost analysis, not only prevented future failures but also demonstrated a superior value proposition, solidifying a truly long-term partnership with VMT CNC.

Common Misconceptions in Material Choice

One prevalent misconception, oh how it persists!, is that steel is always stronger than iron. While true for many comparisons, it's not universally so. Certain grades of ductile iron, especially Austempered Ductile Iron (ADI), can rival or even surpass the strength and toughness of many carbon steels. Another persistent error is underestimating the specific applications where cast iron's unique properties—its outstanding dampening capacity or its excellent galling resistance—make it unequivocally superior. One should never assume; always verify.

Expert Consultation for Precision Parts

Navigating the complexities of material science and optimal selection is precisely where our factory excels. We offer not merely CNC machining services but a partnership built on deep technical expertise and a steadfast commitment to high-quality parts. Our team understands the nuances of iron and carbon steel, knowing precisely how each material behaves under specific machining conditions and operational stresses.

Wait, I need to clarify that point—our role isn't just about cutting metal. It's about providing an engineering solution from the very inception of your project, ensuring the foundational material choice aligns perfectly with your part's intended function, budget, and longevity. We believe in transparent pricing and clear communication every step of the way, because truly, that's what builds enduring trust.

The choice between iron and carbon steel for CNC machined parts is a critical engineering decision driven by specific application requirements. While cast irons excel in vibration dampening, compressive strength, and intricate casting, offering good machinability, carbon steels provide superior tensile strength, ductility, and fatigue resistance, with broad heat treatment versatility. Understanding their distinct metallurgical structures, mechanical properties, machinability, and lifecycle costs is paramount. VMT CNC Machining Parts Services Factory provides expert guidance to navigate these complexities, ensuring optimal material selection for superior parts, cost efficiency, and project success.

What are the primary differences between cast iron and carbon steel?

The principal distinction lies in carbon content and microstructure. Cast iron typically contains over 2.14% carbon (often 2.5-4%), forming graphite flakes or spheroids, which impart excellent casting fluidity, vibration dampening, and compressive strength, but generally lower ductility. Carbon steel has less than 2.14% carbon, forming ferrite, pearlite, or martensite, offering higher tensile strength, ductility, and impact resistance. Their differing microstructures fundamentally dictate their mechanical properties and applications, making this an utterly critical divergence.

When should I choose cast iron for my CNC machining project?

You should opt for cast iron when your part requires superior vibration dampening, high compressive strength, excellent wear resistance, or the ability to produce complex, near-net shapes through casting. Common applications include machine bases, engine blocks, pump housings, and large industrial castings. Grey cast iron is ideal for dampening, while ductile iron is chosen for increased toughness and strength, sometimes rivaling steel.

What are the advantages of carbon steel in CNC machining?

Carbon steel offers distinct advantages where high tensile strength, yield strength, ductility, and impact resistance are paramount. It is also highly responsive to various heat treatments, allowing for a wide range of tailored mechanical properties, from improved hardness and wear resistance to enhanced toughness. Carbon steels are typically chosen for shafts, gears, structural components, and fasteners, where dynamic loading or demanding mechanical stresses are encountered.

How does machinability compare between iron and carbon steel?

Grey cast iron is generally considered highly machinable due to its lubricating graphite and brittle chip formation, which extends tool life. Ductile iron is also quite machinable, albeit slightly tougher. Carbon steels offer varied machinability; low-carbon steels can produce stringy chips, while higher carbon or hardened grades require more robust tooling and precise machining parameters. The specific grade and heat treatment profoundly influence machining ease, making a direct comparison tricky, but one must acknowledge their intrinsic differences.

Can VMT CNC Machining Parts Services Factory help with material selection?

Absolutely, yes! As a source manufacturer with deep technical expertise, we provide comprehensive material selection consultation. Our engineering team meticulously analyzes your application's requirements—including mechanical properties, environmental conditions, budget, and projected lifespan—to recommend the optimal grade of iron or carbon steel, or indeed any other suitable material, ensuring peak performance and cost-efficiency for your CNC machined parts.

Is carbon steel always stronger than cast iron?

Not always, and frankly, this is a pervasive misconception! While many carbon steels exhibit higher tensile and yield strengths than common grey cast irons, certain advanced grades of ductile iron, like Austempered Ductile Iron (ADI), can possess strength and toughness properties that rival or even surpass those of many medium-carbon steels. The specific grade and engineering context are vital for an accurate comparison, which cannot be understated.

What are the cost implications of choosing iron versus carbon steel?

The cost comparison extends beyond raw material price. While cast iron can sometimes be cheaper per pound, factors like machining difficulty, tool wear, heat treatment requirements, and the expected lifespan of the finished part all contribute to the overall lifecycle cost. Our transparent pricing ensures you receive a clear, detailed quote that accounts for all these aspects, guiding you toward the most economical and effective solution.

What quality control measures are in place for material sourcing and part production at VMT CNC?

We implement stringent quality control measures from the very outset, ensuring material traceability and compliance with industry standards. This encompasses meticulous supplier qualification, comprehensive material certifications (e.g., chemical composition analysis, mechanical testing), and rigorous in-process inspections throughout the CNC machining and finishing stages. Our commitment to high-quality parts means every component undergoes thorough dimensional checks and adherence to specified tolerances, truly guaranteeing your peace of mind.

Stop second-guessing your material choices. Leverage our deep technical expertise and commitment to high-quality parts and transparent pricing to ensure your next project is built on the optimal foundation. Contact our engineering team today for a personalized material selection consultation and a detailed, transparent quote!