15 years one-stop China custom CNC machining parts factory

35 |

Published by VMT at Oct 16 2025 | Reading Time:About 9 minutes

35 |

Published by VMT at Oct 16 2025 | Reading Time:About 9 minutes

Steel is one of the most commonly used materials in CNC machining—but it’s also one of the toughest to handle. The problem? Steel’s hardness and toughness often lead to rapid tool wear, heat buildup, and surface finish issues that can delay production and increase costs.

As the challenges grow, so does the risk of costly mistakes—poor material choice, wrong cutting speed, or insufficient cooling can all compromise your part quality.

The solution lies in understanding steel’s unique behavior during CNC milling. By choosing the right steel grade, cutting parameters, and machining strategy, you can achieve excellent precision, surface finish, and efficiency—making steel a reliable material for everything from automotive parts to aerospace components.

Steel milling is the process of removing material from steel workpieces using CNC milling machines to create precise parts. It offers high strength, durability, and versatility but also presents challenges like tool wear and heat buildup. Choosing the right steel grade, tooling, and cutting parameters ensures accurate, efficient, and cost-effective CNC steel machining.

Now that you understand the basics of steel milling, let’s explore why steel is such a popular choice for CNC machining projects. By learning its properties, challenges, and machining tips, you’ll be able to select the right material and process for your parts—saving time, improving quality, and reducing production costs.

Steel is an alloy made primarily of iron and carbon, often with added elements such as chromium, nickel, manganese, or molybdenum to enhance its strength, corrosion resistance, and machinability. The carbon content—typically between 0.02% and 2.1%—plays a key role in determining the steel’s hardness and ductility.

In CNC machining, steel’s balanced combination of tensile strength, formability, and wear resistance makes it a preferred material for producing durable and high-precision parts. It’s widely used across industries like automotive, aerospace, and construction because it can be milled, turned, or drilled into almost any shape with excellent dimensional accuracy.

Steel remains one of the most trusted materials in CNC machining because it delivers an ideal balance between strength, machinability, and cost. Whether you’re producing custom components or large-scale industrial parts, steel offers properties that make machining faster, more reliable, and more efficient. Let’s look at the main reasons why steel stands out for CNC machining projects.

1. High Tensile Strength

Steel has exceptional tensile strength, meaning it can withstand high stress and heavy loads without deforming. This makes it perfect for demanding applications like automotive frames, shafts, and aerospace components where durability is critical.

2. Low-Temperature Resistance

Steel maintains its structural integrity even in extreme cold, unlike some metals that become brittle. This stability makes it ideal for parts used in cold climates or cryogenic environments.

3. Corrosion Resistance

With the right alloying elements, such as chromium and nickel, steel can resist rust and oxidation effectively. Stainless steels are particularly valuable for CNC machining parts exposed to moisture, chemicals, or harsh environments.

4. Appearance

Steel offers a clean, professional appearance and can be finished in many ways—polished, plated, blackened, or coated—to enhance both aesthetics and performance.

5. Designed for Improved Machinability

Certain steels, such as 1215 free-machining steel, are specifically engineered to reduce tool wear and improve cutting efficiency. These grades help achieve tighter tolerances and smoother finishes during CNC milling or turning.

6. Low Cost

Compared to exotic metals like titanium or Inconel, steel is cost-effective and readily available in multiple grades and sizes. This makes it easier to optimize costs without sacrificing quality.

7. Fast Part Turnaround

Steel’s predictable machining characteristics allow for stable cutting speeds and efficient production cycles, reducing downtime and increasing output.

While steel is one of the most versatile materials for CNC machining, it also presents unique challenges that require precise process control and expertise. Understanding these issues helps you avoid tool damage, poor finishes, and higher production costs when manufacturing custom steel parts.

1. Tool Wear

Steel’s hardness, especially in alloy and tool steels, can rapidly wear down cutting tools. Continuous exposure to heat and friction dulls tool edges, leading to dimensional inaccuracies and surface defects.

2. Heat Generation

Machining steel generates significant heat at the cutting zone, which can affect part tolerance and cause workpiece deformation. Excessive heat can also reduce tool hardness and cause thermal cracking.

3. Work Hardening

Some steels, especially stainless and alloy grades, tend to harden during machining if the cutting conditions are incorrect. This increases cutting resistance, tool load, and the risk of chatter.

4. Surface Finish Issues

Improper tool selection or feed rate can result in rough surfaces, burrs, or chatter marks. These imperfections often require secondary finishing, which increases costs.

5. Dimensional Accuracy

Due to steel’s hardness and internal stresses, maintaining tight tolerances can be difficult. Parts may warp or shift during or after machining if not properly managed.

6. Machinability Differences Among Grades

Each steel type behaves differently. For example, 1215 steel machines easily, while 4140 or D2 require more robust setups and slower speeds. Incorrect tool or speed selection can lead to inefficiency and material waste.

Note: Working with an experienced CNC machining factory like VMT ensures proper tool selection, optimized cutting strategies, and high-quality custom steel CNC machined parts—helping you minimize downtime and achieve better cost performance.

Efficient steel machining requires more than just the right tools — it demands careful planning and control over every step of the process. Follow these quick tips to improve accuracy, extend tool life, and reduce machining costs when producing custom steel CNC parts.

1. Choose the Right Steel Grade

Different steels behave differently during machining. Low-carbon steels like 1018 are easier to cut, while high-alloy and tool steels need slower speeds and tougher tools.

2. Use Sharp and Coated Cutting Tools

Dull tools increase friction, heat, and vibration, reducing both precision and tool life. Coated carbide tools (such as TiAlN or TiCN) perform better under high temperatures.

3. Optimize Cutting Speeds and Feeds

Running at improper speeds can cause tool wear or poor surface finish. Adjust feed rates based on material hardness and tool size for optimal chip removal.

4. Use Proper Coolant and Lubrication

Steel machining generates significant heat. Coolants help control temperature, flush chips, and improve tool longevity.

5. Ensure Rigid Workholding

Vibration and movement can ruin accuracy. Always use stable fixturing and rigid setups to keep the workpiece steady during milling or turning.

6. Plan for Toolpath Efficiency

Efficient toolpaths reduce machining time and wear. Use CAM software to minimize unnecessary movements and optimize chip evacuation.

7. Deburr and Inspect After Machining

Steel parts often develop burrs at edges and holes. Finishing processes like grinding or tumbling ensure a clean final product.

Note: Partnering with a professional CNC machining factory like VMT ensures every stage—from tool selection to finishing—is optimized for cost, precision, and speed in steel CNC milling and turning.

Steel comes in many grades, each engineered for specific properties such as hardness, strength, ductility, and machinability. When it comes to CNC machining steel parts, selecting the right alloy determines how efficiently you can cut, shape, and finish the material.

Below, we’ll briefly explain the main steel alloys used in CNC machining, followed by tables summarizing their advantages, disadvantages, properties, and applications. These tables will help you quickly identify the most suitable steel grade for your next project.

Steel 1018

Steel 1018 is a low-carbon, mild steel with excellent machinability and weldability. It’s widely used in CNC machining for parts that require moderate strength and good surface finish without the need for high hardness.

Steel 1018: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Excellent machinability | Limited strength and hardness |

| Good weldability | Poor wear resistance |

| Smooth surface finish | Not suitable for high-temperature applications |

| Affordable and easy to source | Low corrosion resistance |

Steel 1018 Properties

| Property |

Value |

| Carbon Content | 0.18% |

| Tensile Strength | ~440 MPa |

| Yield Strength | ~370 MPa |

| Hardness (Brinell) | ~126 HB |

| Machinability | Excellent |

Steel 1018 Applications

| Industry |

Typical Use |

| Automotive | Shafts, pins, gears |

| Construction | Fasteners, brackets |

| Industrial | Couplings, fittings |

| General Machining | Custom CNC parts, prototypes |

Steel 4130

Steel 4130 is a chromium-molybdenum alloy steel known for its toughness, strength, and fatigue resistance. It’s heat-treatable and often used where high strength-to-weight ratio is needed.

Steel 4130: Advantages and Disadvantages

| Advantages |

Disadvantages |

| High strength-to-weight ratio | Moderate machinability |

| Excellent toughness | Requires heat treatment for best results |

| Good fatigue resistance | Susceptible to corrosion if uncoated |

| Weldable with care | Costlier than mild steels |

Steel 4130 Properties

| Property |

Value |

| Carbon Content | 0.30% |

| Tensile Strength | ~560–670 MPa |

| Yield Strength | ~460 MPa |

| Hardness | ~200 HB |

| Machinability | Moderate |

Steel 4130 Applications

| Industry |

Typical Use |

| Aerospace | Structural tubing, brackets |

| Automotive | Roll cages, crankshafts |

| Oil & Gas | Tool joints |

| Industrial | High-stress components |

Steel 4140

Steel 4140 is a chromium-molybdenum alloy steel similar to 4130 but with higher carbon content, giving it improved hardenability and strength.

Steel 4140: Advantages and Disadvantages

| Advantages |

Disadvantages |

| High tensile and yield strength | Harder to machine than mild steels |

| Excellent wear resistance | Requires proper heat treatment |

| Good toughness | Prone to surface cracking if overheated |

| Maintains strength at high temperature | More expensive than low-carbon steels |

Steel 4140 Properties

| Property |

Value |

| Carbon Content | 0.40% |

| Tensile Strength | ~950 MPa (quenched and tempered) |

| Yield Strength | ~655 MPa |

| Hardness | 197–302 HB |

| Machinability | Fair to good |

Steel 4140 Applications

| Industry |

Typical Use |

| Automotive | Axles, gears, crankshafts |

| Aerospace | Landing gear components |

| Industrial | Shafts, couplings, dies |

| Tooling | Molds and fixtures |

Steel 4140 PH

Steel 4140 PH (pre-hardened) is a heat-treated version of 4140 that’s supplied in a pre-hardened condition, eliminating the need for post-machining heat treatment.

Steel 4140 PH: Advantages and Disadvantages

| Advantages |

Disadvantages |

| No heat treatment required | Slightly reduced machinability |

| Consistent hardness and strength | Less flexible for custom hardness adjustments |

| Good wear and fatigue resistance | Higher initial cost |

| Stable dimensional performance | Difficult to weld |

Steel 4140 PH Performance

| Property |

Value |

| Hardness | 28–32 HRC |

| Tensile Strength | ~950–1100 MPa |

| Yield Strength | ~850 MPa |

| Machinability | Moderate |

| Thermal Stability | High |

Steel 4140 PH Applications

| Industry |

Typical Use |

| Tooling | Molds, fixtures |

| Industrial | Shafts, spindles |

| Automotive | Drive components |

| Oil & Gas | Valve bodies, couplings |

Steel A36

Steel A36 is a low-carbon structural steel known for its excellent weldability, machinability, and affordability. It is one of the most widely used steels in fabrication and CNC machining applications, offering a balanced combination of strength and ductility. A36 steel is commonly supplied in hot-rolled form and used in a wide range of construction, industrial, and machinery components.

Steel A36: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Excellent weldability and machinability | Lower tensile strength compared to alloy steels |

| Cost-effective and widely available | Limited corrosion resistance |

| Good ductility and formability | Not suitable for high-temperature or high-stress applications |

| Easy to cut, drill, and machine | Susceptible to rust without coating |

Steel A36 Performance

| Property |

Typical Value |

| Tensile Strength | 400–550 MPa |

| Yield Strength | 250 MPa |

| Elongation | 20% (in 200 mm) |

| Hardness (Brinell) | 120–180 HB |

| Machinability Rating | 72% (compared to AISI 1212) |

| Weldability | Excellent |

| Corrosion Resistance | Low |

Steel A36 Applications

| Industry |

Typical Uses |

| Construction | Beams, channels, plates, structural frames |

| Machinery | Base plates, brackets, supports |

| CNC Machining | Prototypes, fixtures, and general-purpose components |

| Transportation | Truck frames, rails, and equipment housings |

Steel 1215

Steel 1215 is a free-machining low-carbon steel specifically designed for high-speed machining and mass production. It contains higher levels of sulfur and phosphorus, which create small, well-distributed inclusions that act as natural lubricants during cutting. This gives 1215 steel exceptional machinability, making it one of the easiest steels to machine. However, it has lower strength and poor weldability, limiting its use in structural or load-bearing applications.

It’s often used in CNC turning, screw machining, and precision components where high production efficiency and smooth surface finishes are essential.

Steel 1215: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Outstanding machinability (up to 136% of AISI 1212) | Poor weldability due to high sulfur content |

| Excellent for high-speed CNC machining | Not suitable for heat treatment |

| Produces fine surface finishes | Low strength and toughness |

| Cost-effective for mass production | Limited corrosion resistance |

Steel 1215 Performance

| Property |

Typical Value |

| Tensile Strength | 370–415 MPa |

| Yield Strength | 300 MPa |

| Elongation | 10% (in 50 mm) |

| Hardness (Brinell) | 120–180 HB |

| Machinability Rating | 136% (excellent) |

| Weldability | Poor |

| Corrosion Resistance | Low |

| Heat Treatability | Not suitable for hardening |

Steel 1215 Applications

| Industry |

Typical Uses |

| Automotive | Fasteners, pins, bushings, fittings |

| Machinery | Shafts, spacers, couplings |

| CNC Machining | High-volume precision components |

| Electronics / Hardware | Screws, bolts, and threaded parts |

Steel 4340

Steel 4340 is a nickel-chromium-molybdenum alloy steel known for its exceptional toughness, strength, and fatigue resistance. It maintains high mechanical properties even under severe stress and high-temperature conditions. Because of its ability to be heat-treated and hardened through its thickness, it’s widely used in aerospace, automotive, and tool-making industries.

In CNC machining, 4340 steel is valued for its high strength-to-weight ratio and dimensional stability, though it requires sharp tools, lower cutting speeds, and proper cooling due to its hardness.

Steel 4340: Advantages and Disadvantages

| Advantages |

Disadvantages |

| High tensile and yield strength | Difficult to machine in hardened condition |

| Excellent toughness and fatigue resistance | Relatively high material and processing cost |

| Good hardenability and heat-treat response | Requires controlled heat treatment to avoid cracking |

| Maintains strength at elevated temperatures | Moderate corrosion resistance (requires coating) |

Steel 4340 Performance

| Property |

Typical Value |

| Tensile Strength | 745–1860 MPa (depending on heat treatment) |

| Yield Strength | 470–1550 MPa |

| Elongation | 10–20% |

| Hardness (Brinell) | 217–460 HB |

| Machinability Rating | 50% (vs. AISI 1212) |

| Weldability | Fair (preheating required) |

| Corrosion Resistance | Moderate |

| Heat Treatability | Excellent |

Steel 4340 Applications

| Industry |

Typical Uses |

| Aerospace | Landing gear, shafts, fasteners |

| Automotive | Crankshafts, connecting rods, gears |

| Machinery | High-strength components, dies, and fixtures |

| CNC Machining | Precision parts requiring superior toughness |

A2 Tool Steel

A2 tool steel is an air-hardening, cold-work tool steel that belongs to the A-series family of steels. It offers a balanced combination of wear resistance, toughness, and dimensional stability during heat treatment. A2 tool steel is known for its ability to retain hardness after tempering and is easier to machine than many other high-alloy tool steels.

Because of these characteristics, A2 is a preferred choice for dies, punches, forming tools, and cutting components that demand both strength and durability. It’s also well-suited for precision CNC machining applications requiring tight dimensional control.

A2 Tool Steel: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Excellent dimensional stability during heat treatment | Moderate machinability (harder than O1) |

| Good balance of wear resistance and toughness | Not suitable for high-temperature applications |

| Air-hardening minimizes distortion and cracking | Requires controlled heat treatment |

| Holds a sharp edge and resists chipping | Higher cost compared to simple carbon steels |

A2 Tool Steel Performance

| Property |

Typical Value |

| Tensile Strength | ~1900 MPa (annealed) |

| Hardness (HRC) | 57–62 HRC (after heat treatment) |

| Toughness | Excellent for cold-work steel |

| Wear Resistance | High |

| Machinability Rating | ~65% (vs. AISI 1212) |

| Dimensional Stability | Excellent (air-hardening) |

| Corrosion Resistance | Low (requires coating or lubrication) |

| Heat Treatability | Excellent (air hardening minimizes distortion) |

A2 Tool Steel Applications

| Industry |

Typical Uses |

| Tool & Die Making | Punches, dies, shear blades |

| Manufacturing | Forming tools, trimming dies |

| Automotive | Molds, wear-resistant inserts |

| CNC Machining | Precision cutting tools and gauges |

O1 Tool Steel

O1 tool steel is an oil-hardening, cold-work tool steel that provides excellent dimensional accuracy, edge retention, and wear resistance after heat treatment. It contains moderate amounts of chromium, tungsten, and manganese, which enhance its hardness and machinability.

Compared to A2, O1 is easier to machine and heat treat, but it is less stable dimensionally and less wear-resistant. It is widely used in CNC machining, tool and die manufacturing, and precision cutting components that require fine surface finish and good toughness.

O1 Tool Steel: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Excellent machinability before hardening | Moderate dimensional changes during heat treatment |

| Good wear resistance and edge retention | Not suitable for high-impact or high-temperature use |

| Easy to heat treat with oil quenching | Can warp or crack if quenched improperly |

| Cost-effective for toolmaking | Requires protective coating to prevent corrosion |

O1 Tool Steel Performance

| Property |

Typical Value |

| Tensile Strength | ~1800 MPa (annealed) |

| Hardness (HRC) | 57–63 HRC (after heat treatment) |

| Toughness | Moderate |

| Wear Resistance | Good |

| Machinability Rating | ~90% (vs. AISI 1212) |

| Dimensional Stability | Fair (can distort slightly when oil-quenched) |

| Corrosion Resistance | Low |

| Heat Treatability | Excellent (simple oil quenching process) |

O1 Tool Steel Applications

| Industry |

Typical Uses |

| Tool & Die Manufacturing | Punches, dies, blanking tools |

| Machining & Fabrication | Gauges, bushings, fixtures |

| Woodworking | Chisels, plane blades |

| CNC Machining | Cutting tools, precision components requiring fine edges |

Steel 1020

Steel 1020 is a low-carbon mild steel with a carbon content of approximately 0.18–0.23%. It is known for its excellent weldability, ductility, and ease of machining, making it a common choice for general-purpose CNC machining. While it offers moderate strength, it cannot match the hardness or wear resistance of alloy or tool steels.

1020 steel is widely used in structural components, shafts, and low-stress mechanical parts, where cost-effectiveness and machinability are more important than high tensile strength.

Steel 1020: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Excellent machinability and weldability | Low tensile strength and hardness |

| Easy to form and fabricate | Limited wear resistance |

| Cost-effective and widely available | Poor corrosion resistance |

| Produces smooth surfaces for CNC milling | Not suitable for high-temperature applications |

Steel 1020 Performance

| Property |

Typical Value |

| Tensile Strength | 350–410 MPa |

| Yield Strength | 275 MPa |

| Elongation | 15–20% |

| Hardness (Brinell) | 120–180 HB |

| Machinability Rating | 70% (vs. AISI 1212) |

| Weldability | Excellent |

| Corrosion Resistance | Low |

| Heat Treatability | Can be case hardened, not for through-hardening |

Steel 1020 Applications

| Industry |

Typical Uses |

| Automotive | Shafts, gears, brackets |

| Machinery | Couplings, pins, low-stress components |

| Construction | Structural supports, fasteners |

| CNC Machining | Prototypes, fixtures, low-cost custom parts |

Steel 1045

Steel 1045 is a medium-carbon steel containing approximately 0.43–0.50% carbon, giving it higher strength and hardness than low-carbon steels like 1018 or 1020. It offers a good balance of machinability, strength, and wear resistance, making it suitable for CNC machined parts that require higher mechanical performance.

1045 steel can be heat-treated for increased hardness, making it a versatile choice for shafts, gears, and structural components.

Steel 1045: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Good balance of strength, hardness, and machinability | More difficult to weld than low-carbon steels |

| Can be heat-treated for higher hardness | Moderate corrosion resistance |

| Excellent wear resistance | Requires careful machining at higher speeds |

| Widely available and cost-effective | Not suitable for extreme high-temperature environments |

Steel 1045 Performance

| Property |

Typical Value |

| Tensile Strength | 585–700 MPa |

| Yield Strength | 310–530 MPa |

| Elongation | 12–16% |

| Hardness (Brinell) | 170–210 HB (annealed) |

| Machinability Rating | 60–65% (vs. AISI 1212) |

| Weldability | Fair (preheating recommended) |

| Corrosion Resistance | Low |

| Heat Treatability | Excellent (can be quenched and tempered) |

Steel 1045 Applications

| Industry |

Typical Uses |

| Automotive | Shafts, axles, gears, crankshafts |

| Machinery | Pins, couplings, bushings |

| Industrial | Rollers, dies, molds |

| CNC Machining | Structural components requiring moderate strength and wear resistance |

Steel 1060

Steel 1060 is a high-carbon steel with a carbon content of approximately 0.57–0.64%, giving it higher hardness, strength, and wear resistance than medium- or low-carbon steels. It is commonly used for CNC machined parts and tools where toughness and durability are required.

Because of its hardness and ability to hold an edge, 1060 steel is often used for springs, cutting tools, and high-strength components, but it can be more challenging to machine and weld compared to lower-carbon steels.

Steel 1060: Advantages and Disadvantages

| Advantages |

Disadvantages |

| High tensile strength and hardness | Lower machinability than low- and medium-carbon steels |

| Excellent wear resistance | Poor weldability without preheating |

| Holds shape and edge well | Prone to cracking if heat-treated incorrectly |

| Can be quenched and tempered for additional hardness | Requires careful handling to avoid warping |

Steel 1060 Performance

| Property |

Typical Value |

| Tensile Strength | 700–900 MPa |

| Yield Strength | 350–600 MPa |

| Elongation | 8–12% |

| Hardness (Brinell) | 190–250 HB (annealed) |

| Machinability Rating | ~50% (vs. AISI 1212) |

| Weldability | Poor (preheating required) |

| Corrosion Resistance | Low |

| Heat Treatability | Excellent (quench and temper) |

Steel 1060 Applications

| Industry |

Typical Uses |

| Automotive | Leaf springs, axles, high-strength fasteners |

| Industrial Machinery | Cutting tools, blades, knives |

| CNC Machining | Wear-resistant parts, high-strength components |

| Tool & Die | Punches, shear blades, dies |

Steel 1095

Steel 1095 is a high-carbon steel with approximately 0.90–1.03% carbon, known for its excellent hardness, wear resistance, and edge retention. It is commonly used in cutting tools, knives, and springs, where high strength and the ability to maintain a sharp edge are essential.

Due to its high carbon content, 1095 steel can be challenging to machine and weld, and it requires careful heat treatment to avoid cracking or warping. It is ideal for CNC machined parts where hardness and durability are critical.

Steel 1095: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Very high hardness and wear resistance | Difficult to machine compared to low/medium-carbon steels |

| Excellent edge retention | Poor weldability |

| Can be heat-treated to very high hardness | Susceptible to corrosion without coating |

| Ideal for blades, springs, and cutting tools | Lower ductility |

Steel 1095 Performance

| Property | Typical Value |

| Tensile Strength | 750–1000 MPa |

| Yield Strength | 500–700 MPa |

| Elongation | 6–10% |

| Hardness (Brinell) | 200–280 HB (annealed) |

| Machinability Rating | ~45% (vs. AISI 1212) |

| Weldability | Poor (preheating required) |

| Corrosion Resistance | Low |

| Heat Treatability | Excellent (quench and temper) |

Steel 1095 Applications

| Industry |

Typical Uses |

| Cutting Tools | Knives, blades, saws, shears |

| Automotive | Springs, high-strength fasteners |

| Industrial Machinery | Wear-resistant components |

| CNC Machining | High-hardness parts, cutting dies |

Steel 8620

Steel 8620 is a low-alloy, case-hardening steel containing nickel, chromium, and molybdenum. It is known for its excellent hardenability, toughness, and fatigue resistance. Unlike high-carbon steels, 8620 is typically used for carburizing (surface hardening), providing a hard, wear-resistant exterior while maintaining a tough, ductile core.

This makes it ideal for CNC machined parts like gears, shafts, and automotive components, where both surface wear resistance and core strength are critical.

Steel 8620: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Excellent toughness and fatigue resistance | Requires carburization for high surface hardness |

| Good wear resistance after case hardening | Moderate machinability in annealed state |

| Maintains core ductility | Limited corrosion resistance |

| Cost-effective alloy steel | Heat treatment adds extra processing time |

Steel 8620 Performance

| Property |

Typical Value |

| Tensile Strength | 585–745 MPa (annealed) |

| Yield Strength | 350–515 MPa |

| Elongation | 15–20% |

| Hardness (Brinell) | 170–217 HB (annealed) |

| Machinability Rating | 60% (vs. AISI 1212) |

| Weldability | Good (preheating recommended) |

| Corrosion Resistance | Low |

| Heat Treatability | Excellent (carburizing, quench, and temper) |

Steel 8620 Applications

| Industry |

Typical Uses |

| Automotive | Gears, crankshafts, camshafts |

| Aerospace | Landing gear components, shafts |

| Industrial Machinery | High-strength, wear-resistant parts |

| CNC Machining | Precision parts requiring surface hardness and tough core |

D2 Tool Steel

D2 tool steel is a high-carbon, high-chromium cold-work tool steel known for its excellent wear resistance, hardness, and dimensional stability. Unlike air- or oil-hardening tool steels, D2 is semi-air-hardening and can achieve very high surface hardness, making it ideal for cutting, forming, and die applications.

In CNC machining, D2 is often used for dies, punches, and precision tooling, especially where abrasion resistance and long tool life are critical.

D2 Tool Steel: Advantages and Disadvantages

| Advantages |

Disadvantages |

| Exceptional wear resistance | Difficult to machine compared to low-carbon steels |

| High hardness (up to 62 HRC) | Poor toughness (can chip under impact) |

| Excellent dimensional stability | Requires careful heat treatment |

| Retains edge for long periods | Limited corrosion resistance |

D2 Tool Steel Properties

| Property |

Typical Value |

| Tensile Strength | 700–900 MPa |

| Yield Strength | 450–700 MPa |

| Elongation | 8–12% |

| Hardness (HRC) | 55–62 HRC (after heat treatment) |

| Machinability Rating | ~40–50% (vs. AISI 1212) |

| Wear Resistance | Very High |

| Corrosion Resistance | Low |

| Heat Treatability | Excellent (requires precise heating and tempering) |

D2 Tool Steel Applications

| Industry |

Typical Uses |

| Tool & Die | Cutting dies, shear blades, punches |

| Industrial Machinery | Wear-resistant components, knives |

| Automotive | High-wear components |

| CNC Machining | Precision tooling, cutting instruments |

When choosing a material for CNC machining, it’s important to compare steel alloys with other commonly used metals like aluminum, titanium, and brass. Each metal offers unique combinations of strength, machinability, cost, and corrosion resistance, which determine its suitability for specific industrial applications.

In general:

Below is a comparison chart highlighting key properties among these materials:

Comparison Table: Steel Alloys vs. Other Metals

| Property / Metal Type |

Steel Alloys (e.g., 4140, 8620, D2) |

Aluminum Alloys (e.g., 6061, 7075) |

Titanium Alloys (e.g., Ti-6Al-4V) |

Brass (e.g., C360) |

| Density (g/cm³) | 7.8 | 2.7 | 4.5 | 8.5 |

| Tensile Strength (MPa) | 500–2000 | 200–600 | 900–1200 | 300–600 |

| Hardness (HRC) | 20–65 | 15–25 | 30–40 | 20–25 |

| Machinability | Moderate to Difficult | Excellent | Difficult | Excellent |

| Corrosion Resistance | Moderate (improved by coatings) | Good | Excellent | Excellent |

| Thermal Conductivity (W/m·K) | 40–60 | 150–200 | 20 | 120 |

| Cost (Relative) | Medium | Low | Very High | Medium |

| Weight (Relative) | Heavy | Very Light | Light | Heavy |

| Applications | Machinery, Tools, Automotive Parts | Aerospace, Automotive, Prototypes | Medical, Aerospace, High-end Components | Fittings, Valves, Decorative Parts |

Steel can be machined through a variety of CNC processes, each designed to achieve specific shapes, tolerances, and surface finishes. The choice of process depends on the part geometry, steel grade, and required precision. Modern CNC technology allows for efficient production of both simple and complex steel components, ensuring consistency, accuracy, and repeatability across batches.

Below are the most common CNC machining processes used for steel.

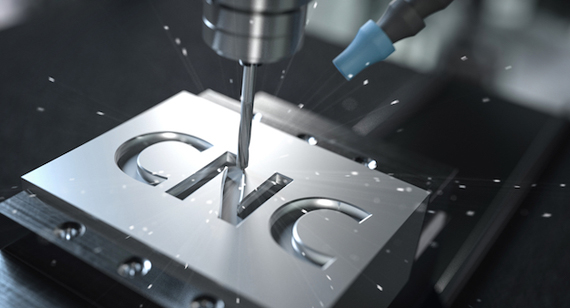

1. CNC Milling

CNC milling is one of the most common machining methods for steel. It involves rotating cutting tools that remove material from a solid workpiece to create slots, holes, pockets, and complex 3D contours.

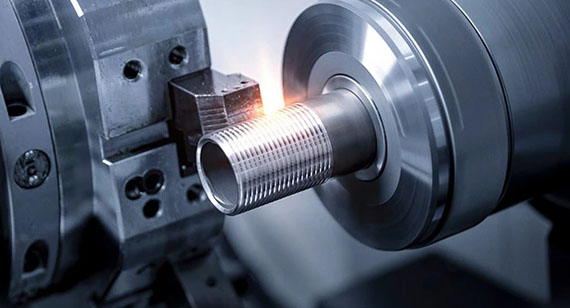

2. CNC Turning

CNC turning rotates the steel workpiece while a fixed cutting tool removes material to create cylindrical shapes. It’s ideal for producing shafts, pins, and bushings with high precision.

3. Turning (Manual or Semi-Automated)

While CNC turning is automated, manual turning is still used for prototyping or low-volume production. Skilled machinists can make quick dimensional adjustments and create custom one-off steel parts.

4. CNC Drilling

CNC Drilling is used to create round holes in steel parts, either standalone or as part of a CNC milling operation. High-speed steel (HSS) or carbide drills are commonly used.

5. Threading

Threading involves cutting internal or external helical grooves into steel parts to create fastener interfaces. CNC machines can perform threading using taps, dies, or thread milling cutters.

Laser cutting uses a high-powered laser beam to slice through steel with exceptional precision. It’s ideal for producing intricate shapes and thin components with clean edges.

7. Grinding

Grinding is used to achieve extremely tight tolerances and mirror-like surface finishes. It removes small amounts of material using abrasive wheels or belts.

8. EDM (Electrical Discharge Machining)

EDM uses electrical discharges (sparks) to erode material from hardened steel. It’s especially useful for parts that are too hard to machine conventionally.

9. Water Jet Cutting

Water jet cutting uses a high-pressure jet of water (with or without abrasives) to cut steel precisely without generating heat.

Steel is not inherently difficult to CNC machine, but its machinability varies greatly depending on the grade, hardness, and heat treatment. Some steels—like A36, 1018, or 1215—are relatively easy to cut, while high-carbon steels and tool steels (e.g., D2, A2, or 1095) can be challenging due to their hardness, strength, and tendency to cause tool wear.

Key Factors Affecting Steel Machinability

Carbon Content:

Alloying Elements:

Heat Treatment:

Tool Material and Coating:

Coolant and Lubrication:

Overall Assessment

Conclusion:

Steel can be CNC machined effectively with the right combination of tooling, feeds, speeds, and coolant. For high-performance parts, choosing a CNC machining factory experienced in working with various steel grades ensures precision, efficiency, and cost control.

Here’s a comparison table showing the relative machinability of common steel grades used in CNC machining, along with brief comments to help readers understand performance differences:

Steel Machinability Comparison Table

| Steel Grade | Type | Machinability Rating (% of 1212 = 100%) | Relative Difficulty | Comments / Notes |

| 1215 | Free-machining carbon steel | 100% | ★☆☆ (Easy) | Excellent machinability due to added sulfur and lead; ideal for high-speed CNC turning. |

| 1018 | Low-carbon steel | 70–80% | ★★☆(Moderate) | Good surface finish and dimensional accuracy; suitable for general machining. |

| 1020 | Low-carbon steel | 65–75% | ★★☆ (Moderate) | Slightly softer than 1018; easy to cut but offers lower strength. |

| 1045 | Medium-carbon steel | 55–60% | ★★★(Challenging) | Balanced strength and machinability; commonly used in shafts and gears. |

| 1060 | High-carbon steel | 40–50% | ★★★☆ (Hard) | Increased hardness and strength reduce machinability; preheating recommended. |

| 1095 | High-carbon steel | 35–45% | ★★★★ (Hard) | Very hard and wear-resistant; requires carbide tools and slower speeds. |

| 4130 | Alloy steel (chromium-molybdenum) | 65% | ★★★ (Challenging) | Strong and tough; heat-treated parts require specialized tooling. |

| 4140 | Alloy steel (chromium-molybdenum) | 55–60% | ★★★☆ (Hard) | Known for toughness and strength; often requires coated carbide tools. |

| 4340 | Nickel-chromium-molybdenum steel | 50–55% | ★★★★ (Hard) | Very strong and tough; limited machinability in hardened condition. |

| 8620 | Low-carbon alloy steel | 65–70% | ★★☆ (Moderate) | Good machinability before case hardening; popular for gears and pins. |

| A2 Tool Steel | Air-hardening tool steel | 40–45% | ★★★★ (Hard) | Wear-resistant; best machined before hardening. |

| O1 Tool Steel | Oil-hardening tool steel | 50% | ★★★★ (Hard) | Stable and precise, but slow machining speeds required. |

| D2 Tool Steel | High-carbon, high-chromium steel | 35–40% | ★★★★★ (Very Hard) | Very abrasion-resistant; machining requires CBN or carbide tools. |

| A36 | Structural steel | 70% | ★★☆ (Moderate) | Widely used; acceptable machinability for structural parts. |

Summary Insight

Recommendation:

For efficient production, match the steel grade to your performance needs and machining capabilities. Complex or hardened alloys should be handled by an experienced CNC machining factory with high-precision equipment and appropriate tooling.

Choosing the Right Steel for CNC Machining Projects

Selecting the right steel grade for CNC machining depends on your part requirements, strength needs, and production goals. For example, Steel 1215 and 1018 are ideal for high-volume machining where speed and surface finish are priorities, while 4140 or 4340 offer higher strength for heavy-duty mechanical components. Tool steels like A2, O1, and D2 are preferred when wear resistance and dimensional stability are critical.

When balancing machinability, cost, and performance, partnering with a skilled CNC machining factory ensures the correct tooling, cutting speeds, and heat treatments are applied—maximizing part accuracy, tool life, and overall production efficiency.

While steel is one of the most widely used materials in CNC machining, it also presents several milling challenges that can impact tool performance, surface quality, and production efficiency. Understanding these common problems helps machinists and engineers optimize processes, minimize downtime, and improve part accuracy during steel milling operations.

1. Shortened Tool Life

Steel, especially high-carbon and alloy grades, tends to generate significant heat and friction during milling. This leads to rapid tool wear, especially when using improper cutting parameters or uncoated tools.

2. Machining Difficulty

Certain steels, such as 4140, 4340, and D2, have high strength and hardness, making them difficult to machine. They often require specialized cutting tools, slower speeds, and multiple passes to achieve precise tolerances.

3. Poor Cutting Control

When machining steels with uneven hardness or inclusions, chip control and cutting stability can become problematic. This results in chatter, vibration, and poor surface finish.

4. Hardness

The inherent hardness of steel, especially after heat treatment, makes it more resistant to cutting forces. This increases tool stress, power consumption, and thermal load, reducing efficiency.

Summary:

Steel milling requires precise control over cutting parameters, tooling, and cooling strategies. By understanding the challenges of shortened tool life, machining difficulty, cutting instability, and hardness, manufacturers can improve productivity, extend tool longevity, and achieve superior part quality in steel CNC machining.

Steel CNC milling can be complex due to hardness, heat generation, and tool wear. However, with the right techniques, you can simplify the process, enhance part accuracy, and extend tool life. The following key tips help you optimize performance and avoid costly machining errors during steel CNC machining.

1. Selecting High-Quality Materials

Always start with high-quality, consistent-grade steel. Low-quality or impure materials often contain inclusions that cause tool chipping, poor surface finish, and unpredictable machining behavior.

Note: Using verified steel materials helps maintain tight tolerances and reduces tool wear.

2. Work Hardening

Steel tends to harden during machining due to friction and heat, making subsequent cuts more difficult.

Note: Proper feed control prevents unnecessary strain on tools and extends their lifespan.

3. Rigid Tools

A rigid setup ensures stability and reduces vibration during steel milling. Even minor tool deflection can cause dimensional inaccuracies and surface defects.

Note: Vibration-free setups not only improve finish but also protect expensive tooling.

4. Tool Materials

Choose tools that match the steel’s hardness and cutting conditions.

Note: The right tool material dramatically improves cutting speed and surface finish.

5. Using Sharp Tools

Sharp cutting edges help reduce cutting forces and heat buildup, resulting in cleaner surfaces and longer tool life.

Note: Dull tools can double machining time and degrade precision.

6. Lubricants

Proper lubrication reduces friction and heat, especially in high-speed or deep cutting operations.

Note: Using the right lubricant extends both tool and machine life, ensuring smooth, cost-effective CNC steel milling.

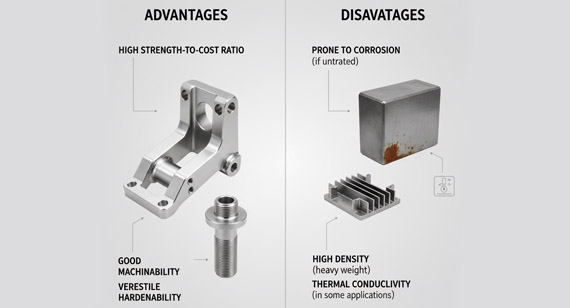

Steel remains one of the most widely used materials in CNC machining because of its strength, durability, and cost-effectiveness. However, it also comes with certain challenges that can affect production efficiency and tooling performance. Understanding both sides will help you make the best material choice for your CNC machining projects.

What Are the Advantages of Steel for Machining?

Steel offers a strong balance between performance, machinability, and cost, making it ideal for parts that require strength and precision.

| Advantages |

Description |

| High Strength and Toughness | Steel provides excellent mechanical properties for parts exposed to stress, impact, or load. |

| Wide Material Selection | You can choose from various grades—carbon steel, alloy steel, and tool steel—depending on project requirements. |

| Good Machinability (Certain Grades) | Grades like 1215 or 12L14 offer superior machinability, reducing tool wear and cutting time. |

| Excellent Surface Finish | Steel allows for smooth finishing and can be polished, plated, or coated easily. |

| Heat Treatability | Many steels can be hardened and tempered for added strength and wear resistance. |

| Cost-Effective | Compared to titanium or Inconel, steel offers high strength at a lower cost. |

What Are the Disadvantages of Steel for Machining?

Despite its benefits, steel can present difficulties that affect productivity and tool longevity.

| Disadvantages |

Description |

| Tool Wear | Hard and alloy steels can quickly dull tools, increasing maintenance and costs. |

| Work Hardening | Steel surfaces can harden during machining, making subsequent cuts more difficult. |

| Heat Generation | High friction during cutting produces heat that can cause warping or reduced dimensional accuracy. |

| Corrosion Risk | Carbon steels are prone to rust without protective coatings. |

| Machinability Variation | Machinability differs widely among steel grades, requiring parameter adjustments. |

| High Cutting Forces | Some steels require more power and rigid setups for stable machining. |

Summary:

Steel is a versatile and cost-efficient choice for CNC machining, but success depends on selecting the right grade and process parameters. By understanding its pros and cons, you can achieve higher precision, lower costs, and better overall machining efficiency in your CNC projects.

The cheapest steel for machining is typically Steel 1215, also known as free-machining steel. It’s specifically engineered for easy and fast machining with minimal tool wear, making it an excellent choice for high-volume CNC production where efficiency and cost control are priorities.

| Steel Grade |

Description |

Relative Cost |

Machinability Rating (100 = best) |

| Steel 1215 |

Free-machining low-carbon steel with added sulfur for improved chip breaking and surface finish. | ★★☆☆☆ (Very Low) | 100 |

| Steel 12L14 |

Similar to 1215 but with lead added for even smoother cutting. Common in high-speed turning and milling. | ★★☆☆☆ (Low) | 100+ |

| Steel 1018 |

Low-carbon steel offering a balance of cost, machinability, and weldability. | ★★★☆☆ (Moderate) | 70 |

| Steel A36 |

Structural-grade steel, inexpensive but less precise for tight-tolerance machining. | ★★☆☆☆ (Low) | 60 |

After CNC milling, steel parts often require surface finishing to enhance appearance, durability, and corrosion resistance. Choosing the right finish depends on your part’s functional needs—such as wear resistance, conductivity, or aesthetic appeal. Below are the most common surface finishing options for CNC machined steel parts, explained briefly and shown in a comparison table.

1. Passivation

Passivation removes free iron and contaminants from the steel surface using an acid bath, forming a thin protective oxide layer that prevents corrosion. It’s ideal for stainless steels and improves the material’s natural resistance to rust.

2. Galvanizing

This process coats steel with a layer of zinc to prevent corrosion. It’s widely used in construction and outdoor applications where long-term exposure to moisture is common.

3. Nickel / Electroless Nickel Plating

Nickel plating provides a smooth, wear-resistant, and corrosion-resistant surface. Electroless nickel plating ensures even coating thickness, making it suitable for complex CNC parts with tight tolerances.

4. Blackening / Bluing

This chemical conversion process creates a dark oxide layer that enhances appearance and offers mild corrosion resistance. It’s often used for tool steels and decorative components.

5. Chrome Plating

Chrome plating delivers a mirror-like finish with superior hardness and wear resistance. It’s ideal for parts requiring low friction and aesthetic appeal, such as pistons, shafts, and molds.

6. Powder Coating

Powder coating applies a dry powder layer electrostatically, then cures it under heat. The result is a tough, colorful, and protective coating resistant to impact, abrasion, and corrosion.

7. Oil Spraying

Oil spraying creates a temporary corrosion barrier for short-term protection during storage or transport. It doesn’t change part dimensions or surface texture.

Comparison Table of Surface Finishes for CNC Milled Steel Parts

| Surface Finish |

Protection Level |

Appearance |

Main Benefits |

Common Applications |

| Passivation | Moderate | Natural metal | Removes contaminants, enhances corrosion resistance | Stainless steel components |

| Galvanizing |

High | Matte gray | Long-term rust protection, durable | Construction, outdoor parts |

| Nickel / Electroless Nickel Plating |

High | Bright silver | Uniform coating, wear and corrosion resistance | Aerospace, precision tools |

| Blackening / Bluing |

Low–Moderate | Dark gray/black | Aesthetic finish, mild rust resistance | Tools, decorative parts |

| Chrome Plating |

Very High | Mirror-bright | Hard surface, low friction, aesthetic | Shafts, molds, machinery |

| Powder Coating |

High | Colored | Strong impact and corrosion protection | Automotive, machinery housings |

| Oil Spraying |

Low (Temporary) | Oily sheen | Easy, cost-effective short-term protection | Stored or transport parts |

Summary:

Choosing the right surface finish for your CNC milled steel parts enhances both performance and longevity. For long-term durability, go with nickel plating or galvanizing; for appearance, choose chrome or black oxide; and for temporary protection, oil spraying offers a cost-effective solution.

Steel is one of the most widely used materials in CNC machining due to its high strength, durability, and versatility. Different grades of steel can be machined to produce components for various industries, from automotive and aerospace to energy and medical devices. Its combination of machinability and performance makes it ideal for both structural and precision-engineered parts.

Applications of CNC Machined Steel Parts

| Industry | Common CNC Machined Steel Components | Key Benefits |

| Automotive |

Gears, shafts, engine blocks, brake components, suspension parts | High strength, wear resistance, and dimensional stability under stress |

| Aerospace |

Landing gear parts, brackets, engine mounts, fasteners | Excellent fatigue resistance, high-temperature tolerance |

| Industrial Machinery and Automation |

Bearings, couplings, rollers, precision tooling, hydraulic components | High load-bearing capacity and long service life |

| Oil and Gas |

Valve bodies, drill collars, flanges, pipe fittings | Corrosion and pressure resistance in harsh environments |

| Construction and Infrastructure |

Bolts, beams, rebar connectors, brackets | Structural reliability and cost-effective production |

| Energy |

Turbine shafts, generator components, heat exchangers | Strength, heat resistance, and good machinability |

| Medical Devices |

Surgical tools, implants, diagnostic equipment housings | Biocompatibility (for stainless steels) and high precision |

| Military |

Armor components, weapon parts, tactical gear fittings | Toughness, impact resistance, and durability in extreme conditions |

CNC machining steel requires not only precision machines but also specialized tools and equipment designed to handle the material’s hardness and toughness. The correct combination of CNC machinery, cutting tools, cooling systems, and measuring devices ensures accuracy, consistency, and cost-effective production during steel processing.

CNC Machines

High-performance CNC milling machines and CNC turning centers are essential for machining steel components. These machines provide the rigidity, power, and precision required to cut hard metals. Multi-axis CNC machines (3-, 4-, or 5-axis) allow complex geometries and tight tolerances to be achieved efficiently.

Cutting Tools

Steel machining requires durable cutting tools made from carbide, high-speed steel (HSS), cobalt alloys, or ceramic composites. Carbide tools are preferred for their superior hardness and heat resistance, which enable higher cutting speeds and longer tool life. Coated tools (e.g., TiAlN, TiCN) further enhance wear resistance and reduce friction.

Coolant Systems

Effective coolant and lubrication systems are vital to prevent overheating and tool wear. Coolants such as emulsified oils or synthetic fluids help dissipate heat, improve surface finish, and extend tool life. In high-speed operations, through-tool coolant delivery ensures efficient temperature control at the cutting edge.

Toolholders and Accessories

High-quality toolholders, collets, and chucks ensure cutting tools remain stable and properly aligned. Precision toolholding reduces vibration, enhances accuracy, and minimizes tool runout—critical for machining hard steels and achieving consistent dimensional accuracy.

Workholding

Reliable workholding systems—such as vises, clamps, magnetic chucks, and custom fixtures—are necessary to secure steel workpieces during machining. Rigid workholding minimizes movement and vibration, which helps maintain accuracy, safety, and optimal surface finish.

Measuring Tools

Precision metrology equipment like micrometers, calipers, coordinate measuring machines (CMM), and height gauges is used to verify part accuracy. Continuous inspection ensures that machined steel components meet exact dimensional tolerances and quality standards.

Safety Equipment

Machining steel generates heat, sharp chips, and noise. Operators must use proper personal protective equipment (PPE)—including safety glasses, gloves, hearing protection, and protective footwear—to maintain a safe working environment.

CNC Programming Software

Advanced CAM (Computer-Aided Manufacturing) software enables precise toolpath generation and simulation. It optimizes cutting parameters, reduces cycle times, and prevents collisions. Software like Mastercam, Fusion 360, and Siemens NX is commonly used to streamline CNC machining workflows for steel.

At VMT CNC Machining, we understand that every steel part project is unique—whether it’s a precision automotive component, a durable industrial fitting, or a complex aerospace assembly. From material selection to final finishing, our goal is to provide high-quality, custom CNC steel machining services that meet your performance, cost, and delivery requirements.

1. Share Your Design and Requirements

Start by sending us your 3D CAD files (STEP, IGES, or STL) and technical drawings. Include essential details such as material grade (e.g., 1045, 4140, or 316), surface finish requirements, tolerances, and any special machining or heat treatment needs. Our engineering team will review your design for manufacturability and suggest optimizations to reduce cost and lead time.

2. Receive an Instant Quotation

Once your design is reviewed, VMT provides a fast, accurate quotation based on machining complexity, material type, and finishing requirements. You’ll receive a detailed cost estimate and production schedule—ensuring transparency from the very beginning.

3. Prototype or Full Production

Whether you need a single prototype for testing or mass production of CNC steel parts, VMT’s flexible manufacturing capabilities can meet your needs. We utilize multi-axis CNC milling, CNC turning, and precision grinding to ensure your parts meet tight tolerances and consistent quality standards.

4. Surface Finishing and Quality Assurance

VMT offers a wide range of surface treatments for steel CNC machined parts, including passivation, nickel plating, black oxide, and powder coating. Every component undergoes strict quality control using CMM inspection, hardness testing, and dimensional verification before shipment.

5. Global Delivery and After-Sales Support

Our efficient logistics system ensures on-time global delivery. VMT’s dedicated support team provides after-sales assistance, helping customers resolve technical or production-related questions quickly and efficiently.

Partner with VMT for Reliable Steel CNC Machining Services

With over a decade of experience in CNC machining steel and other metals, VMT is your trusted partner for precision, performance, and reliability. From concept to completion, we deliver CNC milled steel parts that exceed expectations in both quality and value.

Contact us today to start your CNC steel machining project and experience the professional service, advanced equipment, and technical expertise that make VMT a leading CNC machining factory.

Steel remains one of the most versatile and widely used materials in CNC machining. From low-carbon grades like A36 and 1020 for cost-effective fabrication to high-strength alloys like 4340 and 8620, and tool steels such as D2, A2, and O1, each type offers a unique balance of machinability, hardness, and performance. Understanding these characteristics allows engineers and manufacturers to choose the right steel for each specific application—whether it’s precision components for aerospace, automotive shafts, or heavy-duty industrial tools.

However, machining steel comes with challenges such as tool wear, work hardening, and cutting control issues. By using rigid setups, high-quality tooling, proper lubrication, and optimized CNC parameters, these problems can be significantly reduced. Pairing this with appropriate surface finishes like passivation, plating, or powder coating ensures long-term performance and corrosion resistance of steel CNC machined parts.

At VMT CNC Machining, we specialize in transforming various grades of steel into high-precision, custom CNC machined parts that meet the strictest quality standards. With advanced CNC milling, turning, and finishing capabilities, we provide complete solutions from material selection and prototyping to full-scale production and finishing.

Whether you need durable automotive components, aerospace fittings, or industrial tools, VMT is your trusted partner for reliable, efficient, and cost-effective steel CNC machining services.

Contact VMT today to start your steel machining project and experience the difference that precision, expertise, and quality craftsmanship can make.

1. What is the difference between milling and grinding?

Milling is a machining process that removes material using rotary cutters to create precise shapes, holes, or surfaces. Grinding, on the other hand, uses an abrasive wheel to achieve a fine surface finish or tight dimensional tolerance. Milling focuses on shaping and removing bulk material, while grinding is typically used for finishing and precision work.

2. Is milling the same as drilling?

No. Milling involves cutting along multiple axes to create complex shapes, slots, and profiles, whereas drilling is a single-axis operation that produces round holes using a drill bit. Milling tools can move laterally and vertically, while drilling is limited to a straight downward motion.

3. What is the difference between milling and welding?

Milling is a subtractive process—it removes material to form a part—while welding is an additive process that joins two or more pieces of metal together by melting and fusing them. Milling is used for shaping and machining parts, whereas welding is used for assembly and structural joining.

4. What is the milling process?

The milling process involves securing a workpiece on a table and using a rotating cutting tool to remove material layer by layer. CNC (Computer Numerical Control) milling uses automated programming to control cutter movement across multiple axes, producing complex parts with high accuracy and consistency.

5. What is the purpose of milling?

The purpose of milling is to produce precision components with specific dimensions, shapes, and surface finishes. It is used to create parts with slots, holes, contours, threads, or flat surfaces across industries such as automotive, aerospace, and manufacturing.

6. What are the disadvantages of milling?

7. What are the advantages of milling?

8. What metals are used for milling operations?

Common metals used in milling include:

Each metal requires different cutting speeds, feed rates, and tooling materials to achieve optimal machining performance.