15 years one-stop China custom CNC machining parts factory

43 |

Published by VMT at Oct 15 2025 | Reading Time:About 3 minutes

43 |

Published by VMT at Oct 15 2025 | Reading Time:About 3 minutes

Your product’s success often hinges on a single, critical component. But when that part needs to precisely control light—whether for perfect clarity, diffused illumination, or complete obstruction—do you truly understand the hidden complexities that turn a design concept into flawless reality? The difference between transparent, translucent, and opaque goes far beyond simple definitions; it dictates your manufacturing choices, material performance, and ultimately, your market advantage. Many assume these distinctions are trivial, a mere surface-level observation, yet overlooking the profound engineering implications can lead to devastating project failures, costing both time and exorbitant sums. It's a risk we simply cannot tolerate, not when precision is the very bedrock of our craft!

Unraveling Light Interaction: Core Definitions

Understanding how materials interact with light is fundamental to selecting the correct CNC machining parts and manufacturing processes, especially when designing for specific optical or aesthetic outcomes. Transparent, translucent, and opaque—these terms, while commonly used, possess precise engineering implications crucial for product performance. The choice directly influences everything from light transmission to structural integrity, a veritable cascade of consequences!

Translucent materials permit light to pass through them, yet they scatter this light internally, preventing a clear image from being formed on the other side. Imagine a frosted window; you perceive light, certainly, but any distinct shapes or details remain gloriously indistinct. It’s a captivating dance between illumination and obscurity, truly!

Examples of Translucent Parts Materials

| Material Type | Common Translucency Applications | Key Characteristics |

| Frosted Acrylic | Light diffusers, display panels | Good impact resistance, excellent light diffusion |

| Polycarbonate | Automotive lenses, protective covers | High impact strength, good heat resistance |

| LDPE/HDPE | Bottles, containers, film | Flexible, chemical resistant |

| Silicone | Gaskets, seals, medical tubing | Flexible, high temperature stability, chemical resistance |

Transparent materials allow light to pass through them with minimal scattering or absorption, enabling objects on the opposite side to be seen clearly and distinctly. Think of a perfectly polished lens or a pristine pane of glass; visual information traverses the material with astonishing fidelity! It's a testament to material purity and surface perfection, wouldn't you say?

Examples of Transparent Parts Materials

| Material Type | Common Transparency Applications | Key Characteristics |

| Acrylic (PMMA) | Lenses, windows, displays | Excellent optical clarity, good rigidity |

| Polycarbonate | Safety shields, optical discs | Exceptional impact strength, good heat resistance |

| Optical PMMA | Precision optics, medical devices | Superior optical clarity, high surface hardness |

| Glass | Scientific instruments, mirrors | High hardness, excellent chemical resistance |

Opaque materials, in stark contrast, do not allow light to pass through them at all. They absorb or reflect all incident light, completely obstructing vision and creating a shadow. It’s a declaration of absolute blockage, a definitive barrier, ensuring privacy or protecting sensitive internal components from any stray illumination.

Examples of Opaque Parts Materials

| Material Type | Common Opaque Applications | Key Characteristics |

| Aluminum | Housings, structural components | Lightweight, high strength, corrosion resistant |

| Stainless Steel | Medical instruments, industrial parts | High strength, corrosion resistant, hygienic |

| ABS | Enclosures, consumer electronics | Good impact strength, easy to machine |

| Delrin (POM) | Gears, bearings, precision parts | Low friction, high stiffness, dimensional stability |

| Peek | Medical implants, aerospace parts | High strength-to-weight ratio, high temperature, chemical resistant |

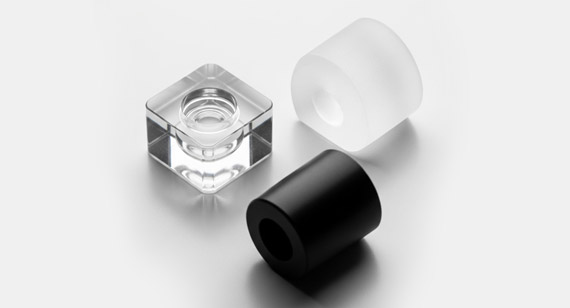

Transparent Components: Full Light Clarity

When we speak of truly transparent components, we're talking about maintaining the utter integrity of light—no distortion, no cloudiness, just pure, unadulterated vision. The paramount concern here is light transmission percentage, often coupled with an absolute minimum haze value; any deviation is, quite frankly, a catastrophic failure for optical applications. This pursuit of flawless transparency, often necessitating meticulous post-machining processes, is genuinely challenging!

Translucent Materials: Diffused Light Transmission

Translucent materials are designed not to block light, but to sculpt it, to diffuse its harsh intensity into a softer, more uniform glow. Here, the critical parameters involve both light transmission and haze percentage, but paradoxically, a controlled amount of haze is precisely the objective. It is about crafting an intentional scattering, not merely accepting a deficiency, and that, my friends, requires a mastery of material science and surface texture that few truly possess.

Opaque Elements: Complete Light Blocking

Opaque elements, by their very nature, serve as impenetrable bastions against light. Their optical properties, or rather, their lack thereof, are a secondary consideration to their structural, mechanical, or thermal attributes. For these components, we are primarily concerned with strength, dimensional stability, thermal management, and—lest we forget—the aesthetic finish that often defines a product's first impression.

Engineering transparent parts is not for the faint of heart; it demands a profound understanding of material science and an almost obsessive attention to detail. I’ve seen projects derail because clients underestimated the unforgiving nature of light, how it exposes every microscopic flaw. Selecting the right material is merely the first, albeit critical, step in this intricate dance.

Key Properties Defining Transparent Performance

| Property | Description | VMT's Focus |

| Light Transmission | Percentage of light passing through | Maximizing for desired wavelength |

| Haze | Light scattering causing cloudiness | Minimizing to below industry standards |

| Refractive Index | How light bends when entering/exiting | Ensuring consistency for optical precision |

| Birefringence | Double refraction due to internal stresses | Controlling through stress-relieving processes |

| Surface Roughness (Ra) | Microscopic imperfections on the surface | Achieving ultra-low Ra values via polishing |

Common Transparent Materials for Precision Machining

For our discerning clientele seeking optical-grade CNC machining parts, the material choices are often quite specific. Acrylic, frequently referred to by its chemical name Polymethyl Methacrylate (PMMA), stands out for its exceptional clarity and ease of polishing, making it a perennial favorite for custom clear parts. Polycarbonate, on the other hand, while slightly less optically pure than PMMA, offers unparalleled impact resistance, a feature often indispensable in protective enclosures or robust lenses. Optical PMMA represents the zenith for many applications, delivering superior clarity where no compromise is permissible. We leverage our extensive experience across this spectrum, ensuring your transparent part manufacturing aligns perfectly with your performance requisites.

Design Challenges for Flawless Transparency

Achieving flawless transparency in precision plastic machining presents a labyrinth of design challenges. Streaks, internal bubbles, or sub-surface defects, even those imperceptible to the naked eye, can utterly ruin the optical performance of a component. Moreover, residual stresses from machining can lead to birefringence, distorting transmitted light—a truly unwelcome guest in any optical system. Designers must meticulously consider material thickness, radii, and exit points for tooling, all to mitigate stress and ensure uniform light passage. And don't even get me started on the relentless pursuit of an impeccable surface finish; it's a monumental undertaking, I tell you, demanding the absolute pinnacle of our CNC machining services!

Crafting translucent plastic machining components is an art form in itself, a delicate equilibrium where too much clarity is detrimental and too much opacity defeats the purpose. It’s not about absence of defects, but the intentional creation of a specific light-scattering characteristic, requiring a precise hand and an acute understanding of material behavior. Honestly, many factories get this wrong, either delivering cloudy mess or something too transparent; it's a pervasive problem.

Defining Haze and Light Diffusion Requirements

Haze, in the context of translucent materials, describes the proportion of transmitted light that deviates from the incident beam by more than 2.5 degrees, effectively scattering it. For many applications, this controlled scattering is the very objective! It dictates how light is softened, how hot spots are eliminated, and how a uniform glow is achieved across a surface. Therefore, specifying an acceptable haze percentage—and ensuring our translucent CNC machining parts meet it—is absolutely paramount. It’s a design parameter, not a manufacturing flaw, a truly crucial distinction.

Material Choices for Specific Translucency Effects

Materials like frosted acrylic, certain grades of polycarbonate, and even some specialized silicones are frequently employed for their inherent light-diffusing properties or their ability to be modified to achieve specific translucency. The choice hinges on the desired level of diffusion, the color temperature of the light source, and—of course—the mechanical performance requirements. A medical device diffuser will demand different material rigor than a decorative lighting panel, an unbelievably important consideration. Our factory guides you through this complex selection, ensuring the optimal material for your translucent component fabrication.

Achieving Desired Translucency in Manufacturing

Achieving the desired translucency in manufacturing involves more than just material selection; it's about surface texture and internal additives. Sandblasting, chemical etching, or specific mold textures can create diffusion on clear materials. Alternatively, pigments or microscopic particles dispersed within the material itself can produce the desired light scattering. The precision of our CNC machining services ensures that these surface finishes are uniform and repeatable, whether it’s a specific grit blast for a frosted look or a finely textured pattern to break up light, allowing for exact control over light transmission and diffusion characteristics.

Opaque component fabrication might seem simpler than its transparent or translucent counterparts, lacking the optical complexities, but this assumption is unbelievably foolish. It brings its own distinct set of engineering challenges, primarily centered around mechanical performance, thermal management, and, critically, impeccable surface aesthetics. We're talking about components that define robustness and visual appeal!

Beyond Optical Properties: Mechanical Strength & Finish

With opaque parts, the focus shifts dramatically from light interaction to the unyielding demands of structural integrity, wear resistance, and the ability to withstand harsh environmental conditions. Tensile strength, impact resistance, hardness, and thermal expansion coefficients become the veritable stars of the show. Yet, we cannot, for a second, neglect the exterior. A high-quality surface finish, whether a satin matte, a brushed texture, or a vibrant anodized color, is often paramount for both functionality and brand perception. It is the palpable essence of a premium product, after all.

Diverse Opaque Materials and Their Industrial Uses

The spectrum of opaque materials VMT CNC Machining Factory works with is vast, reflecting the myriad applications for these components. Metals like aluminum—lightweight and corrosion-resistant—are staples for enclosures and structural elements. Stainless steel, with its incredible strength and hygiene properties, dominates medical and food processing sectors. Engineering plastics such as ABS, Delrin (POM), and PEEK offer excellent mechanical properties, chemical resistance, and often a more economical choice for specific applications, ranging from consumer electronics to high-performance aerospace components. Each material selection is a strategic decision, fraught with trade-offs between cost, performance, and manufacturability.

Surface Finish & Color Considerations for Opaque

For opaque CNC machining parts, surface finish is less about optical clarity and more about tactile feel, durability, and aesthetic presentation. Achieving the correct Ra value, ensuring uniform texture, and applying precise coatings—such as anodizing for aluminum or painting for plastics—are critical. Consider the subtle texture of a high-end electronic device enclosure, or the perfectly smooth, anti-glare finish of an industrial control panel; these are not accidents, but the result of meticulously planned manufacturing and finishing processes. Color consistency, especially across multiple batches, is another absolutely irreplaceable truth we diligently uphold.

At VMT CNC Machining Factory, our expertise isn't merely theoretical; it is forged in the relentless pursuit of perfection across all three optical categories. We approach transparent part manufacturing, translucent plastic machining, and opaque component fabrication with the same unwavering commitment to precision and quality. It’s a core philosophy, an undeniable truth that guides every cut and every polish.

Advanced Machining for Optical-Grade Parts

For optical clarity parts, our advanced CNC machining capabilities are absolutely pivotal. We utilize multi-axis machines, employing specialized tooling geometries and meticulously controlled feed rates to minimize material stress and achieve initial surface finishes that dramatically reduce post-processing requirements. But, truth be told, that's only the beginning! For true optical grade, we then employ multi-stage polishing techniques—from mechanical to chemical methods—to reach astonishingly low surface roughness values, often in the nanometer range, erasing any trace of tool marks. This level of precision is, quite frankly, a mind-blowing miracle of modern engineering, directly contributing to our reputation for custom clear parts.

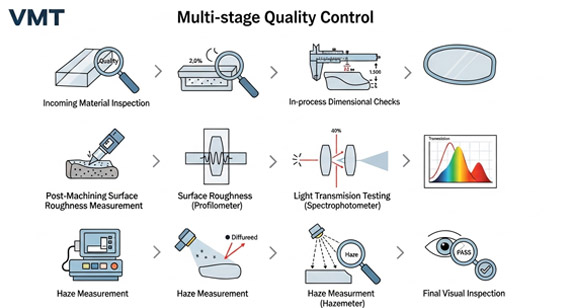

Quality Control for Guaranteed Part Performance

Our quality control protocols are nothing short of stringent, an ironclad guarantee of part performance. For transparent and translucent components, we employ sophisticated optical measurement tools, including spectrophotometers for light transmission, hazemeters for diffusion, and profilometers for surface roughness. Each batch of precision plastic machining parts undergoes rigorous visual inspection under controlled lighting conditions to detect even the most minute defects—scratches, inclusions, or streaks. For opaque parts, dimensional accuracy, mechanical property testing, and consistent surface finish verification are meticulously performed. This holistic approach ensures every component, regardless of its optical characteristic, meets or exceeds your specifications. We leave absolutely nothing to chance, after all.

Transparent Pricing for Complex Part Production

We firmly believe that superior quality, especially for complex part production like transparent part manufacturing or translucent component fabrication, should not be shrouded in mystery. VMT CNC Machining Factory champions transparent pricing because you deserve to understand the value behind every single process step. Our quotes meticulously detail material costs, machining time, specialized tooling, and—crucially—the often significant labor and expertise involved in post-processing for optical finishes. This clarity empowers you to make informed decisions, ensuring you receive the high-quality parts you need without any unwelcome financial surprises.

Choosing between transparent, translucent, and opaque components isn't just a material decision; it's a fundamental design choice that impacts functionality, aesthetics, and user experience. It's a choice that can make or break a product, a downright catastrophic oversight if mishandled.

Application Examples Across Optical Properties

| Optical Property | Typical Applications | Primary Function | Example Materials |

| Transparent | Lenses, display screens, windows | Clear vision, precise light focus | Acrylic, Optical PMMA |

| Translucent | Light diffusers, frosted panels | Soft, even illumination, privacy | Frosted Polycarbonate, Silicone |

| Opaque | Housings, structural brackets, gears | Light blocking, structural support | Aluminum, ABS, PEEK |

Design for Manufacturability (DFM) Insights for Success

Implementing Design for Manufacturability (DFM) principles is absolutely essential for mitigating risks and optimizing cost and lead time, especially with custom clear parts. For optical components, this means designing with tooling access in mind, minimizing sharp internal corners that can trap stress, and specifying realistic surface finish requirements. Honestly, a perfectly polished internal cavity with an impossible aspect ratio is not just difficult; it's often genuinely unmanufacturable without astronomical costs. Conversely, for opaque components, DFM focuses on optimizing material utilization, reducing complex setups, and ensuring robust features for assembly. We collaboratively review your designs, offering invaluable insights to streamline production and elevate part quality.

Wait, I need to clarify that point—the "impossible aspect ratio" for optical parts. What I mean is, while our VMT CNC Machining Factory team possesses unparalleled expertise in transparent part manufacturing, there are still physical limits to what can be polished effectively. Very deep, narrow channels or exceptionally sharp internal corners cannot be reached by standard polishing tools without risking surface degradation or compromising clarity, and that requires designers to be mindful of these constraints during their initial conceptualization stages. It’s about smart design, not just pushing boundaries!

Partnering for Optimal Part Solutions

Choosing the right partner for your CNC machining needs, whether for transparent part manufacturing, translucent plastic machining, or opaque component fabrication, is a decision of paramount importance. Our factory, VMT, is not merely a supplier; we are an extension of your engineering team, a trusted advisor for precision plastic machining. We bring deep technical expertise, state-of-the-art facilities, and an unwavering commitment to quality and transparent pricing. Partner with us, and gain the confidence that your vision will be transformed into flawless physical reality, every single time. It's a partnership built on trust, precision, and mutual success!

This article has dissected the critical distinctions between transparent, translucent, and opaque materials, emphasizing their unique light interaction properties and the profound implications for precision CNC machining parts. We've explored common materials for each category, delved into specific engineering challenges from optical clarity to surface aesthetics, and highlighted VMT CNC Machining Factory's expertise in delivering high-quality, meticulously engineered components across the spectrum. Understanding these nuances is crucial for successful product development and selecting the optimal manufacturing partner.

1. What defines the difference between a transparent and a translucent material?

Transparent materials permit light to pass through without scattering, allowing clear images to be seen through them. Translucent materials also allow light to pass, but they scatter it internally, preventing a clear image and instead creating a diffused effect. The primary difference lies in the clarity of vision through the material; transparent offers clear vision, translucent offers diffused light without clear vision.

2. Why is surface finish so critical for transparent CNC machining parts?

For transparent parts, surface finish is incredibly critical because any microscopic imperfections—scratches, tool marks, or roughness—can scatter light, leading to haze, distortion, and a reduction in overall optical clarity. Achieving an ultra-smooth, optically polished surface is essential to maximize light transmission and ensure the part performs as a precision optical component.

3. Can the same material be both transparent and translucent?

Yes, absolutely! Many materials, such as acrylic or polycarbonate, are inherently transparent. However, they can be processed or treated to become translucent. This is often achieved through surface texturing (like frosting or sandblasting), internal additives (pigments or diffusing particles), or specific manufacturing techniques that introduce controlled internal scattering.

4. What are common challenges when machining custom clear parts?

Machining custom clear parts presents several challenges, including preventing surface scratches and marks during processing, minimizing internal stresses that can lead to birefringence, eliminating internal bubbles or inclusions, and achieving extremely low surface roughness values through post-machining polishing. Material selection, tool path optimization, and meticulous handling are paramount.

5. How does VMT CNC Machining Factory ensure the quality of optical clarity parts?

VMT ensures the quality of optical clarity parts through a multi-faceted approach. This includes advanced multi-axis CNC machining to reduce initial surface imperfections, specialized multi-stage polishing techniques to achieve ultra-smooth finishes, and stringent quality control using instruments like spectrophotometers (for light transmission), hazemeters (for light scattering), and profilometers (for surface roughness), alongside rigorous visual inspections.

6. What role does Design for Manufacturability (DFM) play for these part types?

DFM is crucial for all part types. For transparent and translucent components, DFM helps optimize geometries to allow for proper tooling access for polishing, minimizes stress concentration points, and guides realistic surface finish specifications. For opaque parts, DFM focuses on material efficiency, robust design for mechanical integrity, and simplifying features for cost-effective production, ensuring optimal performance and manufacturability.

7. What kind of lead times can I expect for precision plastic machining, especially for optical parts?

Lead times for precision plastic machining, particularly for optical-grade parts, can vary significantly depending on material availability, part complexity, required post-processing (e.g., multi-stage polishing), and order volume. While standard machining might have shorter lead times, achieving flawless optical clarity requires additional specialized processes, which naturally extend the timeline. We provide transparent lead time estimates during the quoting process, reflecting the true scope of work.

8. Why should I choose VMT as my source manufacturer for transparent, translucent, or opaque components?

Choosing VMT as your source manufacturer guarantees unparalleled precision, deep technical expertise across all material types, and unwavering commitment to quality. As a direct factory, we offer transparent pricing, streamlined communication, and the ability to handle complex projects from prototype to high-volume production. Our dedication to solving your design challenges and delivering flawless physical reality for your transparent, translucent, or opaque components is our core promise.