15 years one-stop China custom CNC machining parts factory

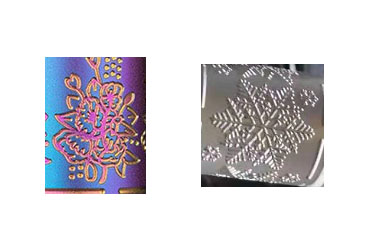

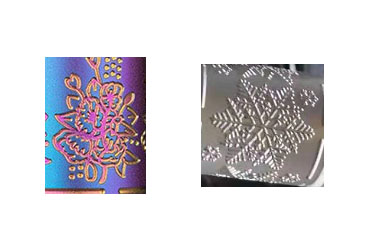

CNC Machining Titanium Flashlight Shell: Etching Surface Treatment

Customer requirements: A depth of 0.2 or more makes the product more textured

Quantity: 12000 pieces

Material: Titanium Alloy TA2

CNC machining method: CNC turning-CNC machining-cleaning-electrophoresis-laser engraving-corrosion-deoiling-polishing-PVD electroplating-AF oil

Delivery time:40 days

The prices and styles of flashlights in the current market are going up, and the CNC machining technology is also slowly advancing.

In December, a Norwegian customer found us through a Google search for a CNC machining titanium alloy flashlight shell factory. They developed a titanium alloy flashlight shell. In order to attract consumers' attention and market demand, they wanted to make a pattern on the side. Generally, the shell of the ordinary flashlight is processed by traditional CNC turning, and this titanium alloy flashlight shell adopts a surface etching process. Titanium alloy etching is rarely touched in the CNC machining industry.

Common corrosions are generally stainless steel and brass parts. Titanium alloy corrosion and round product corrosion are rarely done. In order to meet market demand and show uniqueness, customers choose titanium alloys for corrosion patterns.

Through various tests (selection of machinery and equipment, debugging of syrup), we finally broke through various problems to meet the requirements of the product. A depth of 0.2 or more made the product more textured and completed the delivery.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!