15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 30 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 30 2026 | Reading Time:About 2 minutes

For aluminum parts manufacturing through CNC machining and industrial extrusion, 6060 aluminum alloy stands out as the good choice when aesthetics, complex geometry, and superior surface finish are non-negotiable. As a heat-treatable 6xxx series (Al-Mg-Si) alloy, it becomes a highly valued material in both aesthetic engineering and architectural extrusion because of its excellent formality, good corrosion resistance, moderate strength, and surface treatments suitability.

This guide provides an in-depth look at 6060 aluminum properties and uses, its advantages over 6061, manufacturability, helping you determine whether it is a suitable material for your manufacturing or design needs.

Aluminum 6060 is a medium-strength alloy known for its exceptional corrosion resistance and "extrudability." It is specifically designed to be pushed through dies to create intricate cross-sections that would be impossible with harder alloys.

Key Highlights:

The performance of aluminum alloy 6060 is dictated by its chemical balance, which is mainly affected by it Magnesium and Silicon content. By tightly controlling Magnesium and Silicon, the alloy forms Mg2Si precipitates during heat treatment; This helps enhance the alloy’s strength and achieve moderate strength while maintaining good extrusion performance. Below table shows 6060 aluminum alloy’s chemical composition:

Table 1: 6060 Aluminum Chemical Composition (Weight %)

| Element |

Symbol |

Min |

Max |

| Aluminum |

Al | Remainder | Remainder |

| Magnesium |

Mg | 0.35% | 0.60% |

| Silicon |

Si | 0.30% | 0.60% |

| Iron |

Fe | 0.10% | 0.30% |

| Copper |

Cu | - | 0.10% |

| Manganese |

Mn | - | 0.10% |

| Chromium |

Cr | - | 0.05% |

| Zinc |

Zn | - | 0.15% |

| Titanium |

Ti | - | 0.10% |

Mechanical Properties and Temper Conditions of 6060 Aluminum

The mechanical properties of 6060 aluminum alloy vary under different tempering conditions. Below table is based on EN 755-2 standards for profiles with wall thickness ≤ 15mm.

Table 2: 6060 Aluminum Mechanical Properties By Temper

| Temper |

Tensile Strength(MPa) |

Yield Strength(MPa) |

Elongation (%) |

Hardness (HBW) |

| 6060 T4 |

≥ 120 | ≥ 60 | ≥ 16% | ~ 45 |

| 6060 T5 |

≥ 160 | ≥ 120 | ≥ 8% | ~ 60 |

| 6060 T6 |

≥ 190 | ≥ 150 | ≥ 8% | ~ 70 |

| 6060 T66 |

≥ 215 | ≥ 160 | ≥ 8% | ~ 75 |

6060 T4 Aluminum(Naturally Aged)

It is solution heat treated followed by natural aging at room temperature. In this state, the 6060 aluminum has lower strength but offers extremely high plasticity and ductility (typically with an elongation rate of ≥ 16%). It is the most suitable temper for parts requiring secondary cold deformation, such as deep bending, stamping, or flanging.

6060 T5 Aluminum (Artificially Aged)

It is cooled from an elevated temperature shaping process and then artificially aged. This temper is suitable for parts with standard strength requirements that need good dimensional stability and high surface quality (such as standard window frames).

6060 T6 Aluminum(Solution Heat Treated + Artificially Aged)

It offers higher strength than T5. It generally requires a separate quenching process and can be used for structural components with moderate load-bearing requirements.

6060 T66 Aluminum (Enhanced T6)

This is achieved by precisely controlling extrusion temperatures and cooling rates. It provides the highest yield strength for the 6060 alloy without sacrificing formability.T66 has become the preferred choice for high-performance curtain walls and precision industrial aluminum.

Physical Properties of 6060 Aluminum

The physical properties of 6060 aluminum alloy are not affected by heat treatment. Its physical properties include:

From Profile to Part : Extrusion and CNC Machining

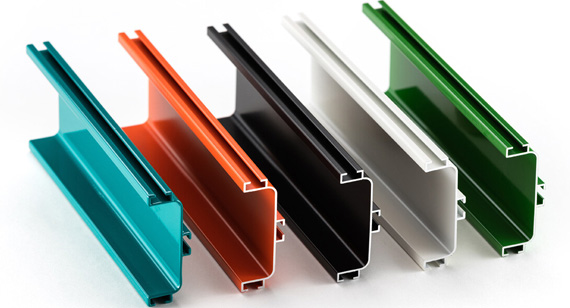

While most products start as 6060 aluminum extrusion profiles (windows, rails, frames), they often require CNC Machining to become finished components.

Surface Finishing: The Anodizing Standard

6060 aluminum alloy is an ideal 6xxx-series grade for anodizing due to its low iron (Fe) content and strictly controlled impurities to gain a good surface. It is an electrochemical process that converts the aluminum surface into a uniform aluminum oxide layer in a sulfuric acid electrolyte. Because this oxide layer is integrated with the substrate at a molecular level, it eliminates risks of peeling or flaking common with physical coatings. The resulting film provides good transparency, clearly displaying the metal's natural texture while allowing for stable color absorption through its microporous structure.

Surface Protection and Visual Performance

Anodizing improves the surface hardness and wear resistance of 6060 alloy components. By combining this process with mechanical treatments such as brushing, sandblasting, or polishing, parts can achieve various industrial finishes ranging from matte to high-gloss with various colors options. This method maintains the metallic feel of the aluminum, making it suitable for electronic components and architectural segments that require both dimensional precision and surface durability.

Other Treatment Options and Cost Considerations

While anodizing is the standard choice for aluminum 6060, other treatments offer specific advantages:

In terms of cost, anodizing typically sits between powder coating and PVDF coating.

Welding 6060 Aluminum

6060 aluminum has good weldability. When welding 6060 aluminum, both MIG and TIG welding provide reliable results. However, filler metal selection depends on whether the part will undergo further surface treatment:

Aluminum alloy 6060 is a common grade under the European Standard (EN), whereas 6063 is the primary grade under the American Standard (ASTM). Both are widely used for architectural extrusions and are very similar in application. Although they are often interchangeable due to shared properties—such as good corrosion resistance, excellent formability, medium strength, and suitability for anodizing—there are still some differences in these characteristics:

Table 3: Comparison of 6060 Aluminum Vs 6061 Aluminum

| Property |

6060 Aluminum (EN 573-3) |

6063 Aluminum (ASTM B221) |

Impact on Application |

| Main Composition |

Mg: 0.35-0.6%, Si: 0.3-0.6% | Mg: 0.45-0.9%, Si: 0.2-0.6% | 6063 has higher Magnesium, offering a higher strength ceiling. |

| Iron (Fe) Content |

Lower (≤ 0.30%) | Higher (≤ 0.35%) | 6060 provides a more refined and transparent surface after anodizing. |

| Tensile Strength (T6) |

Approx. 190 - 215 MPa | Approx. 215 - 245 MPa | 6063 has a slight advantage in load-bearing structures. |

| Yield Strength (T6) |

Approx. 150 - 160 MPa | Approx. 170 - 190 MPa | 6063 offers slightly better resistance to permanent deformation. |

| Extrusion Performance |

Excellent (Highest) | Great | 6060 is better suited for thin walls and complex profiles. |

| Anodizing Quality |

Premium (High color consistency) | Excellent | 6060 is the preferred choice for high-end decorative parts. |

| Relative Cost |

Slightly Higher | Standard | 6060 often carries a slight higher price due to stricter impurity control. |

Due to its excellent extrusion performance and superior anodizing aesthetics, 6060 aluminum alloy is widely used in industries that require high surface precision and complex structural configurations. Here are a few of its use examples:

6060 aluminum alloy is the perfect synthesis of form and function. Whether you are designing a sleek architectural facade or a precision electronic casing, understanding extrusion aluminum 6060, properties and its compatibility with CNC machining and anodizing can elevate your product's quality.

A premium smart home manufacturer required a 0.8mm thin-wall motor housing for an automated curtain system. The component serves as both a structural frame and a heat sink, requiring a high-precision matte titanium-gray finish with high surface uniformity and no visible machining marks.

VMT CNC Machining Factory Solutions:

Q1: What are the equivalent grades for Aluminum 6060?

The closest equivalent is 6063. In the ISO system, it is known as Al-Mg-Si0.5.

Q2: What is the typical 6060 aluminum price?

It is generally very cost-effective due to high production speeds. However, prices vary based on the complexity of the extrusion and the specific temper (T66 usually carries a small premium).

Q3: Can I get 6060 aluminum plate?

While 6060 aluminum plate exists, this alloy is predominantly used for extrusions. If you need a sheet for machining, 6061 or 5052 are often more readily available in plate form.

Q4: Is 6060 aluminum good for saltwater environments?

It has good corrosion resistance, but for direct marine contact, 5083 or 6061 with high-thickness anodizing are usually preferred.

Q5: What is E6060 aluminum sheet?

The "E" prefix often designates "Electronic" or "Exquisite" grade, signifying a material with even higher purity and tighter tolerances for premium decorative anodizing.

Q6: Why use T66 instead of T6 for 6060?

T66 is the "super-charged" version of T6. Choose T66 if your part is a load-bearing architectural component that needs maximum stiffness without increasing wall thickness.