15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

201 |

Published by VMT at Apr 18 2022

201 |

Published by VMT at Apr 18 2022

How much is the CNC machining parts of aluminum alloy shell? There is no standard answer to this question. The factors that affect the price include the material, surface treatment, appearance requirement grade, dimensional accuracy, number of parts, etc. of CNC machined parts. Today we will explain these dimensions in detail.

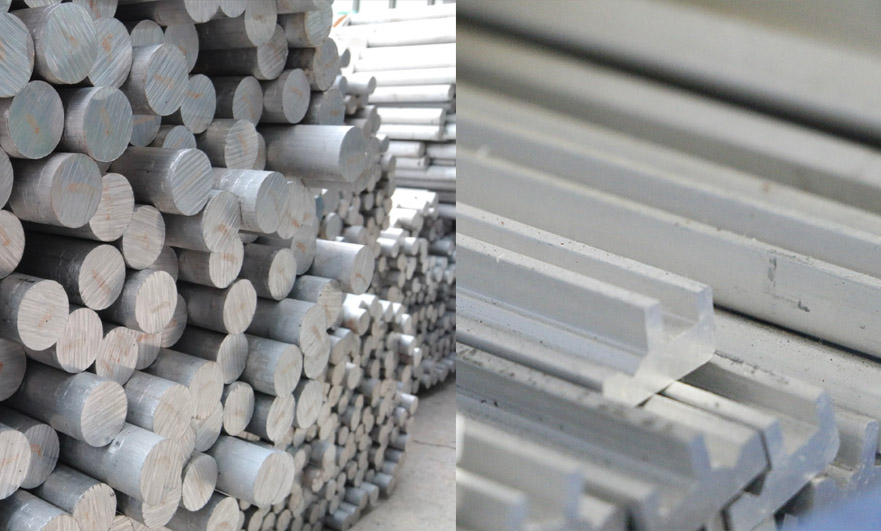

1. CNC Machining Parts Product Material

Aluminum has a variety of grades, the most commonly used grades are AL5052, AL6061, AL6063, AL7075.

1) AL5052 is generally used for sheet metal CNC machining parts in automation equipment, because its material is soft, it is easy to be bent, and cracks are not easy to appear at the bend.

2) AL6061, AL6063 are generally used for 3C electronic products, built-in parts of automation equipment, doors and windows, automobiles and other CNC machining parts.

3) AL7075 is generally used for aircraft, ships, gears, turbines, and aerospace CNC machining parts. The same is aluminum, but the prices of different grades are quite different. The above commonly used grades of AL5052 are the cheapest, AL6061 and AL6063 are in the middle, and AL7075 is the most expensive. The purity of the material is divided, and the material with less impurities is more expensive than the material with more impurities.

2. Surface Treatment of CNC Machining Parts

There are many surface treatment processes that can be done on aluminum. The commonly used surface treatment processes are oxidation, electroplating, electrophoresis, and spraying. Oxidation is the most commonly used process here, because oxidized CNC machining parts look more It has texture, a higher sense of grade, and the highest cost performance.

Of course, different customers have different needs. It is up to the customer to decide which surface treatment to do. We only provide suggestions.

In terms of price alone, according to the appearance standard of commonly used CNC machining parts, the price of spraying is cheaper than that of oxidation, that of oxidation is cheaper than that of electroplating, and that of electroplating is cheaper than that of electrophoresis.

3. Appearance Grade of CNC Machined Parts

From raw materials to beautiful finished products, a CNC machined part has to go through many processes, and each process may cause defects on the surface of CNC machined parts, such as scratches, bumps, gravure, batch edges, watermarks, sand holes, accumulation These common appearance problems such as tumor, chromatic aberration, etc.

CNC machining to manufacture high-quality parts, CNC machining parts manufacturers often have to invest more in material costs, personnel costs, quality control costs, process planning costs, packaging and transportation costs, so the stricter the customer's requirements for appearance, the corresponding result is The price of CNC machined parts will increase accordingly.

4.CNC Machining Parts Dimensional Accuracy

The application fields and performance of CNC machined parts are different, and the dimensional accuracy is also different. Parts with different dimensional accuracy requirements and high precision requirements are often difficult to process, have poor dimensional stability, and have a high scrap rate. The corresponding CNC machining and manufacturing costs are high. The higher the cost, the higher the price of CNC machined parts.

5. The Number of CNC Machining Parts

A CNC machining parts manufacturer manufactures a part, assuming that the quantity is 10 pieces, the CNC machining process requires a programmer, a machine adjuster, and a CNC machining machine. The CNC sample production time is generally about 2 days.

Parts with complex structures will take longer. The salary of personnel and the usage fee of CNC machining equipment are basically fixed. The cost of CNC machining parts is generally the salary of personnel + the usage fee of the machine. In this way, the unit price of CNC machining parts is will be high.

However, if the quantity is 10,000 pieces, and the above expenses are evenly amortized, it can be almost ignored. The factors that affect the price of the production of large-scale CNC machining parts are the materials, process planning, and CNC machining time.

Based on the above statements, I believe that everyone has a general reference standard for how much CNC machining parts of aluminum alloy casings generally cost. Well, today's topic is here, and you are welcome to place orders with VMT! Welcome to contact us so that you can better understand us.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!