15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Feb 01 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Feb 01 2026 | Reading Time:About 2 minutes

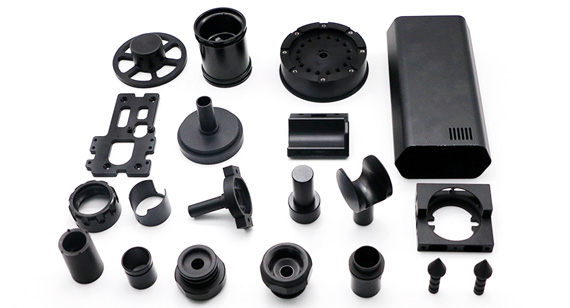

If you are looking for a surface finish for "blacked-out" components —not just about aesthetics, but also about performance, you'd have to understand the black electroless nickel (EN) plating. For industries like aerospace, medical devices, and defense, this black finish plays an important role on dimensional precision, corrosion resistance, and electrical conductivity of CNC machined parts. In this guide, you can gain a clear understanding of the black electroless nickel plating process, its key benefits and cost, black electroless nickel vs. traditional black nickel plating, and other alternative “black” surface finishes.

Black Electroless Nickel (Black Electroless Nickel Plating) is an advanced surface finishing process that combines the high-performance characteristics of traditional electroless nickel—such as exceptional thickness uniformity and wear resistance—with a sleek, non-reflective black appearance.

Unlike standard black nickel plating, which requires an electrical current (electrolytic), the electroless black nickel plating process is achieved through an autocatalytic chemical reaction. This allows the nickel-phosphorus alloy(low/mid/high phosphorus content affect the final performance, and you can check section 3.2) to deposit evenly across every surface of the part, regardless of its shape.

The two primary achieving methods of Black Electroless Nickel (BEN) process are:

Identifying the similar terms that:

Black Nickel Plating (Electrolytic)vs. Black Electroless Nickel Plating: They are different. Black nickel plating uses an electric current. While cheaper than black electroless nickel plating, it suffers from relatively poor thickness uniformity (the "dog-bone effect ":the metal deposits more heavily at the ends of the parts than in the middle, resulting in a thicker, bone-like shape.) and lower corrosion resistance compared to the electroless version.

CNC machining is a subtractive manufacturing process that utilizes computerized systems and specialized software to direct the movement of factory machinery. By precisely removing material from a solid block, CNC machines can produce highly complex parts with exceptional accuracy and repeatability, often achieving tolerances as tight as ±0.01mm.

If you are ordering CNC machined parts, black electroless nickel is a compatible finish for reasons that:

3.1 Key Benefits of Black Electroless Nickel Coating

Unmatched Uniformity

For CNC machined parts with complex geometries, threads, or deep blind holes, traditional electroplating fails because of "dog-boning" (thick edges and thin centers). Black electroless nickel provides a perfectly consistent thickness (typically 0.0002" to 0.0025"; the same as 5–60μm).

Good Hardness and Wear Resistance

After heat treatment, this coating can reach a hardness of 58 to 63 RC. This makes it highly resistant to scratches and abrasive wear, far exceeding the durability of black anodizing or black oxide.

Superior Corrosion Protection

By using a high-phosphorus base layer, black EN can withstand over 1,000 hours of salt spray exposure.

Low Reflectivity

With a light emissivity as low as 4-6%, it provides a deep matte finish that minimizes glare. Optical CNC machined parts prefer this low reflectivity property.

Electrical Conductivity

Specific conductive black electroless nickel processes (such as Black EN with a molecular-level sealer) utilize ultra-thin top layers that facilitate EMI shielding and electrical grounding.

3.2 Phosphorus Content of Black EN: The Key to Performance Selection

In Black Electroless Nickel (EN) plating, the phosphorus content of the underlying layer(base layer) is the single most important factor in determining the part’s final performance. For precision CNC machined components, we usually utilize duplex layers to ensure both aesthetic beauty and industrial-grade durability.

About Duplex Layers of Black Electroless Nickel

To achieve a finish that is both deep black and highly functional, a two-step process is typically employed:

Choosing the Right Phosphorus Level of Black Electroless Nickel

Depending on your application, you must specify the phosphorus content of the base layer:

1.High-Phosphorus (10–13% P) — Maximum Corrosion Resistance

2.Mid-Phosphorus (5–9% P) — The Balanced All-Rounder

3.Low-Phosphorus (1–4% P) — Hardness & Conductivity

Below table shows property differences of black electroless nickel when the base layer with different phosphorus level:

Table 1: Phosphorus Content vs. Properties of Black Electroless Nickel Plating

| Base Layer Type |

Salt Spray (NSS) |

Magnetism |

Conductivity |

Color Consistency |

| High-Phos (10-13%) |

100 - 1,000+ Hours | Non-Magnetic | Moderate | Excellent (Deepest Black) |

| Mid-Phos (5-9%) |

48 - 96 Hours | Slightly Magnetic | Good | Good (Consistent) |

| Low-Phos (1-4%) |

< 24 Hours | Strongly Magnetic | Excellent | Difficult (Matte Grey/Black) |

Engineering Recommendations for Designers

When you are specifying Black Electroless Nickel on your CNC drawings, consider these three common scenarios:

For Aesthetics & General Protection:

Specify: Mid-Phosphorus EN (5–9μm) + Black EN (2–5μm). This is the most cost-effective way to get a professional "blacked-out" look for internal machinery or handheld devices.

For Medical or Harsh Marine Environments:

Specify: High-Phosphorus EN Base (>10μm) + Black EN Topcoat. Without the High-Phos base, the black layer may tarnish or develop "pitting" corrosion when exposed to sterilization chemicals or salt air.

For Electrical Shielding & Grounding:

Specify: Low or Mid-Phosphorus Black EN and require a surface contact resistance test. For these applications, the blackening process must be tightly controlled to ensure the oxide film remains conductive enough for EMI/RFI grounding.

Black electroless nickel can be applied to a wide variety of materials, including both conductive metals and certain non-conductive substrates like plastics. Below table show the materials that can be black electroless nickel plating:

Table 2: Common Materials That Can Be Black Electroless Nickel Plated

| Category |

Material Names |

Application Notes |

| Aluminum Alloys |

All grades (1000–7000 series), cast, and die-cast aluminum | Most common substrate; widely used in optical and aerospace components. |

| Ferrous Alloys |

Mild steel, carbon steel, stainless steel, and tool steel | Provides excellent hardness and corrosion resistance for industrial parts. |

| Copper Alloys |

Pure copper, brass, bronze, and beryllium copper | Frequently used for electrical connectors, RF components, and telecommunications. |

| Iron |

Standard iron and various cast iron grades | Used for heavy industrial parts to provide a uniform black protective layer. |

| Exotic Metals |

Titanium, tungsten, molybdenum, cobalt-chrome, and silver | Used in medical devices, semiconductor equipment, and high-tech defense. |

| Non-Metals |

Polycarbonate, nylon, and certain ceramics | Requires surface activation; used for lightweight EMI/RFI shielding. |

Black Electroless Nickel (BEN) is a high-performance functional coating valued for its black aesthetics, exceptional corrosion resistance, and low reflectivity. Unlike traditional blackening processes, BEN provides a uniform thickness even on complex geometries, making it indispensable across several high-tech industries. Common uses examples include:

Black electroless nickel (EN) plating is a high-end surface treatment technology, with costs typically 25%–50% higher than standard electroless nickel. The premium pricing is primarily driven by the expensive chemistry and shorter life of the black plating bath. Furthermore, achieving a deep black finish usually requires a "duplex process" (a nickel base layer followed by a black nickel topcoat), which increases both processing time and operational complexity.

The specific pricing for Black EN is influenced by several core factors. First is part complexity: components with precision threads, blind holes, or intricate geometries demand more meticulous control, thus driving up costs. Second are thickness and performance specifications; costs escalate when meeting stringent salt spray test standards or specific low-reflectivity optical requirements. Although Black EN is significantly more expensive than powder coating, it remains irreplaceable for specialized functional requirements in the aerospace, medical, and precision electronics industries due to its superior performance in EMI shielding, optical absorption, and dimensional tolerance control.

Expcept for black electroless nickel coating, if you are seeking other black surface finishing, here are other alternatives with pros and cons listed in below table:

Table 3: Alternatives for a Black Appearance

| Process |

Best For |

Pros |

Cons |

| Black Anodizing |

Aluminum | Cheapest, very deep black. | Non-conductive, lower wear resistance. |

| Black Oxide |

Steel/Copper | Very low cost, no dimensional change. | Poor corrosion resistance (needs oil). |

| Black Chrome Plating |

Automotive/Tactical | Extreme durability, premium look. | Very expensive, environmental concerns. |

| QPQ (Nitriding) |

Steel Parts | Best for wear/hardness. | High heat can warp precision CNC parts. |

If your CNC machined parts require a professional non-reflective black aesthetic, the ability to fit into tight tolerances (±0.01mm), electrical grounding, and wear resistance to environments, then black electroless nickel plating is a ideal solution.

A European customer recently reached out to VMT seeking a manufacturing solution for optical sensor lens barrel mounts used in high-precision medical imaging equipment. These components, machined from AL6061-T6 aluminum alloy, had previously been treated with black anodizing by another supplier. However, the anodizing process caused significant quality issues: the uneven coating on M1.5 fine threads resulted in an assembly pass rate of less than 70%, while the insulative properties of the anodic oxide layer blocked the essential EMI shielding and grounding required for sensitive electronics. Most critically, a high surface reflectivity of 15% produced stray light that interfered with the imaging sensors, directly compromising the diagnostic quality of the final medical device.

The VMT team addressed these complex requirements through an integrated "Machining + Surface Treatment" approach. During the initial 5-axis CNC machining phase, we implemented a precise compensation of 5μm to 8μm to account for the thickness of the subsequent nickel layer, ensuring that final tolerances remained strictly within ±0.01mm. Moving away from traditional electrolytic methods, we utilized a specialized autocatalytic black electroless nickel process. By employing a "mid-phosphorus nickel base + black nickel topcoat" duplex technique, we leveraged the inherent uniformity of electroless plating to ensure that the coating thickness and appearance remained perfectly consistent across both the micro-fine threads and the internal walls of deep bores.

The results of this refined process represented a total transformation in component performance. The assembly pass rate for the fine threads surged from 70% to 99.8%, effectively eliminating previous tolerance failures. On the optical front, surface reflectivity was successfully reduced to 5% or less, effectively suppressing stray light and light flares. Electrically, the surface contact resistance was maintained below 0.1 Ohm, providing perfect EMI shielding and grounding. Furthermore, the components passed a rigorous 96-hour salt spray test, ensuring exceptional durability even in medical environments subjected to frequent disinfection and sterilization.

Can nickel plating be black?

Yes, nickel plating can achieve a black finish through either electrolytic or electroless processes. While standard nickel is known for its bright, metallic appearance, specialized chemical baths incorporate secondary metals or oxidative treatments to create a charcoal to jet-black surface.

Is black electroless nickel conductive?

Yes, it can be engineered to be highly conductive. Unlike black anodizing which is an insulator, specific "thin-film" black electroless nickel processes maintain excellent surface conductivity, making them ideal for components requiring EMI/RFI shielding and electrical grounding.

How do you blacken electroless nickel?

The most common method involves a two-step "etching" or "oxidizing" process. A standard nickel-phosphorus layer is first deposited as a base, followed by immersion in a specialized acid bath that modifies the surface structure to trap light, creating the black appearance.

What color is electroless nickel?

Standard electroless nickel has a metallic silver or slightly yellowish stainless-steel appearance. In contrast, Black EN offers a spectrum of finishes depending on the process, ranging from a semi-gloss charcoal grey to a deep, non-reflective matte jet black.

What is the difference between nickel and black nickel?

Traditional nickel plating is primarily used for its brightness, wear resistance, and corrosion protection. Black nickel, while retaining many of those protective qualities, is specifically chosen for its functional optical properties, such as light absorption, glare reduction, and aesthetics.

Is black electroless nickel more expensive than black anodizing?

Generally, yes. Black electroless nickel is more expensive because it is a more complex, multi-stage chemical process that often requires a duplex layer (base nickel plus a black topcoat), whereas black anodizing is a standard electrochemical treatment for aluminum with lower material and processing costs.

What’s the difference between black electroless nickel plating and black nickel plating?

Black electroless nickel plating is a nickel-phosphorus alloy coating deposited through a chemical reaction without external current. It offers excellent uniformity, corrosion resistance, and wear resistance, making it suitable for complex shapes, but it is relatively more expensive. Black nickel plating, on the other hand, usually refers to electroplating nickel followed by a blackening treatment (such as blackening/bluing), or electroplating nickel followed by the deposition of a black chemical coating. It requires electrical current, and its corrosion resistance is inferior to electroless nickel plating, and the thickness is less uniform than black electroless nickel plating. It is slightly inferior in terms of corrosion and wear resistance, and its application is limited on complex, high-precision parts, but it is relatively less expensive.