15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 31 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 31 2026 | Reading Time:About 2 minutes

Have you been looking for an alloy with a good balance of strength, hardness, and durability, combined with excellent casting performance and high thermal stability? A380 aluminum alloy is exactly such an aluminum die-casting alloy widely used in automotive parts (brackets, engine housings), electronic housings, and tools. Its excellent fluidity and pressure tightness provide it with superior casting properties; and its universal in die-casting parts makes the aluminum a380 material cost affordable. This article will focus on a380 aluminum material properties, applications, as well as its manufacturability and comparison with non-castable wrought aluminum alloys 6061 and 7075 (wrought vs. casting ).

A380 (specifically A380.0) is the industry standard and most widely specified material for die casting. This is because its exceptional balance of castability, mechanical performance, and cost-effectiveness. While specialized alloys may outperform it in specific niches—such as A356-T6 for higher yield strength or A383 for superior corrosion resistance—A380 remains the premier general-purpose choice. Its high fluidity, pressure tightness, and resistance to hot cracking allow for the mass production of intricate, durable components like engine cases and electronic housings.

When sourcing this material globally, it is helpful to know the aluminum alloy a380 equivalent designations:

Alloying elements of a380 aluminum alloy composition, particularly Silicon and Copper, contribute to the alloys balance of fluidity and strength; The high Silicon content ensures the metal flows easily into intricate mold cavities, while Copper ensures the finished part can withstand mechanical stress. Below table shows a380 aluminum chemical composition and each element’s role:

Table 1: A380 Aluminum Chemical Composition

| Element |

Percentage (%) |

Role in the Alloy |

| Silicon (Si) |

7.5 – 9.5 | Improves fluidity and reduces shrinkage during casting. |

| Copper (Cu) |

3.0 – 4.0 | Increases tensile strength and hardness; improves machinability. |

| Iron (Fe) |

1.3 (Max) | Prevents the alloy from sticking to the die (soldering). |

| Magnesium (Mg) |

0.1 (Max) | Enhances strength through age hardening. |

| Aluminum (Al) |

Balance | Base metal. |

Understanding a380 aluminum mechanical, physical and thermal properties is essential for the products manufacturing and design considerations. The mechanical properties of A380 provide the necessary strength and stiffness, its physical properties offer weight efficiency, and its thermal properties ensure heat management and casting precision. Below table shows a380 aluminum’s detailed mechanical, physical and thermal properties:

Table 2: A380 Aluminum Alloy Property

| Category |

Property |

Metric Value |

Imperial Value |

| Mechanical |

Ultimate Tensile Strength | 324 MPa | 47 ksi |

| Yield Strength | 159 MPa | 23 ksi | |

| Modulus of Elasticity | 71 GPa | 10.3 x $10^6$ psi | |

| Fatigue Strength | 138 MPa | 20 ksi | |

| Shear Strength | 190–210 MPa | 28–31 ksi | |

| Hardness (Brinell) | 80 HB | 80 HB | |

| Elongation at Break | 3.5% | 3.5% (in 50mm) | |

| Poisson's Ratio | 0.33 | 0.33 | |

| Physical |

Density | 2.71 g/cm³ | 0.098 lb/in³ |

| Electrical Conductivity | 27% IACS | 27% IACS | |

| Machinability | Good | ~50% Benchmark | |

| Thermal |

Thermal Conductivity | 96.2 W/m-K | 55.6 BTU/ft-hr-°F |

| Melting Range | 540–595 °C | 1000–1100 °F | |

| Coefficient of Thermal Expansion | 21.8 µm/m-K | 12.1 µin/in-°F | |

| Specific Heat Capacity | 963 J/kg-K | 0.230 BTU/lb-°F |

Die Casting A380

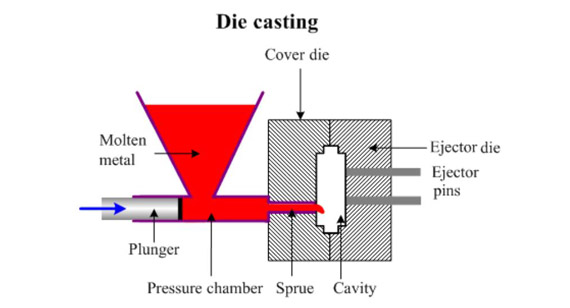

Die casting is a manufacturing process where molten metal is injected under high pressure into a reusable steel mold, known as a "die." Think of it like a high-precision, metallic version of injection molding. It is used to produce high volumes of complex metal parts with excellent dimensional consistency. A380 is the gold standard for a380 aluminum die cast processes. Its excellent hot-crack resistance means that as the metal cools and shrinks inside the steel mold, it is less likely to develop micro-cracks. This makes it ideal for thin-walled parts and complex geometries. When you are operating the a380 aluminum die cast processes, please consider:

CNC machining is a subtractive manufacturing process, and it uses computerized machines (like drills, mills, and lathes) to remove material from a solid block or a cast part to achieve an incredibly high level of precision—even down to 0.01mm. As a380 offers excellent machinability, its die cast parts can be further CNC machined for high-speed production of tight-tolerance features like bearing seats, threaded holes, and mating surfaces.

When and Why Should You CNC Machining A380 Castings?

While die casting produces a "near-net shape," it often cannot achieve the extreme precision required for mechanical assemblies. CNC machining is used on A380 parts when:

A380 Post-Processing: Anodizing and Heat Treatment

While A380 aluminum has excellent properties right out of the mold, post-processing is often necessary to meet specific engineering requirements. Whether it is to enhance the surface's aesthetic looks or to enhance the parts' internal stabilization. That is, in its raw "as-cast" state, A380 parts may have microscopic surface porosity or internal residual stresses from the high-pressure injection process, and post-processing can be used to:

Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish; and clear or colors of the parts surface can be achieved by this process usually. But it's special for a380 aluminum that the alloy does not take "decorative" color anodizing well due to its high silicon content (7.5% - 9.5%). Anodizing a380 aluminum typically results in a dark grey, charcoal, or mottled matte appearance; So, a380 is usually subjected to functional hard anodizing (Type III). This creates a thick, sapphire-hard ceramic layer that is perfect for industrial components that face heavy friction.

But if you want to achieve decorative aesthetics for a380 aluminum products, here are some other common finishes for a380:

Heat treatment involves heating the aluminum casting to a specific temperature, holding it there, and then cooling it at a controlled rate to alter its physical and mechanical properties. Most A380 parts are used in the "as-cast" (F temper) condition to save costs. However, heat treatment is applied when:

A380 aluminum alloy is the premier choice for die-cast components across various industries, primarily where a balance of superior castability, mechanical strength, and thermal efficiency is required. Beyond its structural integrity, its ability to provide EMI (Electromagnetic Interference) shielding and efficient heat dissipation makes it indispensable in modern engineering. Here I list a few of a380 aluminum use examples:

A380 (casting) and 6061/7075 (wrought) alloys are all can be used in similar industries such as automotive uses and electronic uses. Below table shows the comparison of aluminum alloy a380 vs 6061 vs 7075:

Table 3: Comparison of Aluminum Alloy A380 vs 6061 vs 7075

| Feature |

A380 (Cast) |

6061 (Wrought) |

7075 (Wrought) |

| Primary Use |

Complex die-cast parts | Structural extrusions/plates | High-stress aerospace parts |

| Complexity |

High (intricate shapes) | Moderate (machined) | Moderate (machined) |

| Yield Strength |

Low (~160 MPa) | Medium (~270 MPa) | High (~500+ MPa) |

| Corrosion |

Moderate | High | Low |

Manufacturing vs. Material Integrity

The primary difference lies in how these alloys are formed. A380 is a "casting" alloy, engineered with high silicon content (approx. 8.5%) to ensure it flows like water into complex molds. This allows for "net-shape" manufacturing, where a single die-casting cycle produces a finished part with intricate cooling fins or internal brackets that would be nearly impossible to machine. In contrast, 6061 and 7075 are "wrought" alloys, meaning they are designed to be worked in a solid state (like rolling or forging). While they offer superior grain structure and higher yield strength, using them for complex parts requires extensive CNC machining, which leads to significant material waste and higher labor costs.

Strength and Specialized Utility

When strength is an absolute priority, wrought alloys take the lead. 7075 aluminum is often referred to as "aircraft-grade" because its yield strength is nearly triple that of A380, making it essential for high-stress aerospace components. 6061 aluminum serves as the "versatile structural uses," offering excellent weldability and corrosion resistance for structural frames. However, A380 dominates the high-volume market because most general-purpose parts—like engine housings or electronic boxes—do not require the high tensile strength of 6061 or 7075. For these applications, A380 provides "good enough" mechanical properties at a fraction of the production cost, striking the perfect balance for mass-market automotive and consumer electronics.

In summary, a380 aluminum stands out as one of the most practical and economical solution for high-volume die casting aluminum products manufacturing. While it may not reach that high tensile strengths of wrought alloys, its superior fluidity, thermal stability, and pressure tightness make it highly valued for complex, net-shape die casting.

A leading automotive supplier approached VMT CNC Machining Factory with a complex engine bracket design. The client was originally CNC machining the part from 6061-T6 aluminum blocks. However, they faced two major hurdles:

VMT Solution: Transitioning to Die Casting + Precision CNC

VMT’s engineering team conducted a DFM (Design for Manufacturing) analysis and proposed switching the material to A380 Aluminum Die Casting Alloy.

By partnering with VMT and leveraging a380’s properties, optimal results were achieved:

What is the difference between A380 and 380 aluminum?

In practical terms, they are often used interchangeably. However, "A380" usually refers to the commercial standard with specific impurity controls, whereas "380" is the broader alloy designation.

Can A380 aluminum be welded?

Welding A380 is difficult due to the high silicon and copper content, which can lead to brittleness and cracking. It is much better suited for mechanical fastening or adhesive bonding.

Is A380 aluminum corrosion-resistant?

It has moderate corrosion resistance. While the aluminum base forms a protective oxide layer, the 3-4% copper content makes it more susceptible to corrosion than copper-free alloys like A360.

Why is the aluminum a380 price so competitive?

A380 is often produced from recycled aluminum scrap, making it more environmentally friendly and cost-effective than "primary" alloys Also, its chemical composition relatively simple and not expensive. Its processing efficiency leads to much supply in the market, making its price competitive.

Does A380 provide EMI shielding?

Yes. A380 is excellent for electronic enclosures because it provides natural electromagnetic interference (EMI) and RFI shielding for sensitive internal components.

Where can I find A380 aluminum for sale?

A380 is typically sold in a380 aluminum ingot form to die casters. As a customer, you usually purchase A380 as a finished "die-cast + machined" part from a full-service provider.