15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 22 2026 | Reading Time:About 3 minutes

0 |

Published by VMT at Jan 22 2026 | Reading Time:About 3 minutes

You might be familiar with the "regulars" of the manufacturing world: the 6xxx series (like 6061 aluminum), which is strengthened by the Mg₂Si phase through Magnesium (Mg) and Silicon (Si) alloying. These alloys can be heat-treated to balance strength and toughness, making them highly machinable and ideal for CNC-machined structural parts. On the other hand, you might know the 3xxx series (like 3003 aluminum), where Manganese (Mn) provides a moderate strength boost over pure aluminum while retaining superior ductility—making it the go-to choice for sheet metal Machining.

But what about an alloy that sits perfectly between strength and ductility?

This article introduces “aluminum 5754”. It offers a balanced profile of strength and workability alongside "marine-grade" corrosion resistance. It is not only frequently formed into car body panels, floorings, and tanks through stamping, bending, or welding but also stands out as one of the most popular 5xxx series materials for CNC machining.

In practice, aluminum 5754 (EN AW-5754/AlMg3) is often confused with aluminum 5052 (AA 5052) because their properties are similar and they are often used interchangeably. However, 5754 aluminum is a distinct grade recognized in the Aluminum Association (AA) and European standards, commonly specified for automotive and high-end engineering. While both are Aluminum-Magnesium alloys, they differ slightly in chemical composition—specifically magnesium, manganese, and silicon content—subtle affecting their performance. Below table shows key differences between aluminum 5754 and aluminum 5052:

Table 1: Aluminum 5754 vs Aluminum 5052

| Property |

AA 5052 |

EN AW-5754 (AlMg3) |

| Main Alloying Elements |

Mg: 2.2% – 2.8%; Si ≤ 0.25%; Mn ≤ 0.10% | Mg: 2.6% – 3.6%; Si ≤ 0.40%; Mn ≤ 0.50% |

| Tensile Strength |

Relatively Lower | Relatively Higher |

| Hardness |

Higher | Relatively Lower (in comparable tempers) |

| Toughness |

Moderate | Higher, with better structural rigidity |

| Corrosion Resistance |

Excellent (Very good in seawater) | Superior (Best-in-class for seawater/industrial) |

| Weldability |

Very Good | Excellent |

| Typical Applications |

General sheet metal, appliances, electrical housings | Welded structures, pressure vessels, shipbuilding, automotive panels |

For A More Specific Mechanical,Thermal, Electrical Properties Data, You May Refer To Here: 5052 Aluminum vs. 5754 Aluminum

The differences in tensile strength, hardness, and toughness stem from fine-tuning their alloy elements. While both handle general forming and light structural tasks well, 5754 is highly recommended for environments requiring higher corrosion resistance and strength, such as pressure vessels and marine structures.

The magnesium content in aluminum alloy 5754 is roughly 25% higher than in aluminum alloy 5052. This increase enhances its tensile strength and resistance to harsh environments. Furthermore, the slightly higher manganese content leads to a faster work-hardening rate, meaning its strength increases significantly after cold working. The higher silicon content also directly improves its forging performance and corrosion limits.

To understand 5754 aluminum alloy, you must distinguish between temper designations.

A "T" prefix represents heat-treatment (like 6061-T6, achieved its max strength through heat treatment combination of solution and artificial aging). Numbers after T represent different heat treatment combinations to balance alloy’s mechanical properties.

In contrast, the "H" prefix indicates that the alloy is strengthened through “strain hardening” (physical cold working) rather than heat treatment. Numbers after H represent Machining and hard extent. This is also the primary way 5754 aluminum alloy achieves its properties finetuning. The following table compares the characteristics of 5754 across common tempers together with its annealed state:

Table 2: Properties of 5754 Across Common Tempers Together with its Annealed State

| Temper |

O (Annealed) |

H111 |

H22 |

H24 |

| Tensile Strength (MPa) |

190 – 240 | 200 – 250 | 230 – 280 | 240 – 290 |

| Yield Strength (MPa) |

≥80 | ≥100 | ≥150 | ≥180 |

| Elongation (%) |

14 – 18 | 12 – 15 | 7 – 10 | 5 – 8 |

| Machinability |

Poor (Too soft) | Fair | Good | Very Good |

| Forming/Bending |

Excellent | Good | Moderate | Limited |

| Best Use Case |

Complex deep drawing | General structural bending | Flat panels, tread plates | General rigid parts |

For A Full 5754 Aluminum Tempers(F,H12, H14, H16, H18, H22, H24,H26, H28, H32, H34,H36, H38,O ) Properties, You Can Refer To Here: 5754 (AlMg3, 3.3535, A95754) Aluminum.

Why are O (Annealed), H111, H22, and H24 the most common states for Machining EN AW-5754?

These specific tempers are favored because they allow manufacturers to strategically leverage the "Work Hardening" property of Aluminum 5754 without the need for heat treatment. The O (Annealed) state provides the maximum baseline ductility for extreme shaping. The H-series (H111, H22, H24) tempers represent a typical spectrum of "strain hardening" where the material has been physically strengthened through rolling or leveling. By selecting one of these states, engineers can find the precise "Goldilocks zone".

What are the most suitable manufacturing methods for each of them?

Each temper of EN AW-5754 dictates a specific "best-fit" fabrication path.

What are common examples used for each of them?

Precision Bending and Folding

Thanks to its excellent ductility, 5754 is a premier material for air bending and folding. In the O or H111 state, it can achieve tight bend radii without surface cracking, making it ideal for manufacturing complex brackets and chassis. A key Machining point is accounting for springback; while 5754 is ductile, its work-hardening nature means technicians must slightly over-bend the part to achieve the final desired angle, especially in higher H-tempers.

Stamping and Deep Drawing

Aluminum 5754 is frequently used in stamping for automotive body panels and internal structures. Its ability to flow under pressure without tearing makes it suitable for "deep drawing" applications like fuel tanks or specialized containers. The Machining essential here is the use of high-quality lubricants to prevent galling (material transfer) on the die, ensuring a smooth surface finish and prolonged tool life.

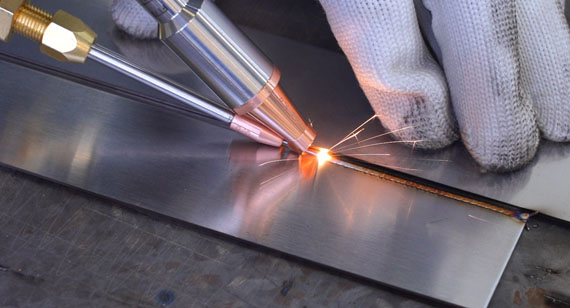

As a 5xxx series alloy, 5754 is considered one of the most weldable aluminum alloys. It maintains much of its strength in the Heat Affected Zone (HAZ) and is not prone to the "hot cracking" issues seen in some 6xxx series. It is widely used in shipbuilding and pressure vessels where leak-proof, high-strength joints are required. The key is using matching filler rods (such as 5356 or 5183) to maintain the corrosion resistance of the weld seam.

While 5754 is often associated with sheet metal, it is frequently CNC-milled for marine components and structural blocks. Compared to the "gummy" 3003, 5754 offers better chip control. It is used when a part requires both complex geometry and high corrosion resistance. The Machining key belongs to tool selection: using polished, un-coated carbide tools with large flute volumes helps evacuate the long, continuous chips characteristic of 5xxx alloys, preventing chip re-cutting and "built-up edge" (BUE).

Turning 5754 is common for manufacturing specialized fittings, nozzles, and marine fasteners. It provides a clean surface finish when the correct feed rates are applied. Because 5754 work-hardens, it is vital to keep the tool constantly engaged with the material; dwelling or rubbing instead of cutting will harden the surface, making subsequent passes more difficult and increasing tool wear.

Precision Drilling and Tapping

5754 is often drilled for assembly holes in structural frames. When tapping (or threading), it is generally recommended to use roll taps (form taps) rather than cutting taps. Since 5754 is highly ductile, roll tapping displaces the material to form threads rather than cutting it, resulting in stronger threads and zero chip debris inside blind holes.

The main benefits of surface treatment for 5754 aluminum alloy include improved corrosion resistance, wear resistance, aesthetics, and enhanced adhesion with coatings and adhesives. In other words, the performance and aesthetic appearance of your products can be upgraded through surface treatment.

For the most used surface finished of 5754 aluminum, I recommend that:

Below table shows a more detailed information about 5754 aluminum surface finishes options:

Table 3: 5754 Aluminum Surface Finishes Options

| Treatment |

Process Description |

Effect |

Common Applications |

| Anodizing (Clear/Color) |

Electrochemical oxidation of the surface. | Increases hardness and adds vivid colors while protecting against wear. | Architectural panels, consumer electronics. |

| Hard Anodizing |

Low-temperature electrochemical process. | Creates a thick, extremely hard ceramic-like layer. | Marine engine parts, abrasive environments. |

| Powder Coating |

Electrostatic spray of polymer powder followed by heat curing. | Provides a thick, durable, and colorful protective layer. | Automotive trim, outdoor furniture, signage. |

| Chromate Conversion |

Chemical immersion (e.g., Alodine). | Improves paint adhesion and provides basic corrosion protection. | Aerospace internals, base layer for painting. |

| Brushing/Sandblasting |

Mechanical abrasion of the surface. | Creates a matte or directional "satin" texture to hide fingerprints/scratches. | Decorative trims, industrial control panels. |

For 5754 aluminum’s balance of strength, and formability, excellent seawater corrosion resistance, and good adaptability to forming Machining and machining manufacturing, it is widely used in applications such as:

Aluminum 5754 represents the "sweet spot" of the aluminum family. It bridges the gap between the ultra-ductile 3xxx series and the high-strength 6xxx series, offering a unique combination of structural integrity and exceptional formability. What’s more, it also boasts excellent weldability and marine-grade corrosion resistance. Whether you are stamping a car door, welding a ship hull, or CNC machining a high-precision marine valve, aluminum 5754 provides the reliability and chemical stability.

An Electric Vehicle (EV) startup required a durable, lightweight battery module tray to serve as a primary structural enclosure. The component needed to withstand harsh road salt environments, maintain structural rigidity to protect battery cells, and provide sub-millimeter precision for internal mounting points. The material specification was 5754-H111 aluminum sheet, 3.0 mm thickness.

VMT conducted a comprehensive Design for Manufacturing (DFM) review. We identified that achieving the required ±0.02mm tolerance on internal mounting pedestals solely through sheet metal bending was impossible due to the natural springback of 5754. Our engineers proposed an integrated approach: laser-cutting and bending the primary "tub" structure first, followed by a secondary CNC machining operation. We also optimized the bend relief notches to prevent stress concentration at the corners, ensuring long-term structural integrity under vehicle vibration.

To solve the precision challenge, the bent trays were loaded into a custom-engineered 4-axis CNC milling fixture. This allowed us to machine the mounting pedestals and drill alignment holes after the stresses of bending had been released. We used high-speed, single-flute carbide end mills to achieve a mirror-like finish on the contact surfaces.

Given the exposure to road debris and moisture, the trays underwent a multi-stage surface treatment. We applied a Yellow Chromate Conversion Coating (Alodine) to enhance the already superior corrosion resistance of the 5754 alloy, followed by a durable structural powder coating. Before full-scale production, we performed salt spray testing to verify that the 5754/coating combination met the 1,000-hour industry standard.

The final assembly passed all dimensional and pressure tests. By choosing the "Forming + CNC" hybrid route rather than machining the tray from a solid billet, VMT reduced material waste by 65% and total production costs by 40%. Despite the complex forming, we maintained a critical tolerance of ±0.02mm at the cell mounting points, and a seamless battery module integration was achieved.

1. 5754 vs. 3003: Which should I choose for strength?

While both are excellent for formability, 5754 offers significantly higher strength and better fatigue resistance than 3003. 3003 is typically used for general-purpose sheet metal work like kitchenware or heat exchangers, whereas 5754 is the preferred choice for structural automotive components and flooring due to its superior mechanical properties.

2. 5754 vs. 6061: How do they differ in Machining?

The primary difference lies in heat treatability. 6061 is a heat-treatable alloy (often used in T6 temper) providing higher peak strength, while 5754 is non-heat-treatable and gains strength through work hardening. 5754 offers superior corrosion resistance in marine environments and is generally easier to weld without the risk of hot cracking associated with 6000-series alloys.

3. Is 5754 aluminum fully recyclable?

Yes, 5754 aluminum is 100% recyclable without any loss in its physical properties. In fact, many modern automotive manufacturers now use specialized versions like RC5754, which contains high percentages of recycled content to support "Closed-Loop" recycling initiatives and reduce the carbon footprint of vehicle production.

4. What is the difference between AW 5754 and AW 5052?

These two are very similar, but 5754 has a slightly higher Magnesium content and stricter control over impurities compared to 5052. This makes 5754 slightly stronger and provides better resistance to atmospheric and seawater corrosion, which is why 5754 is the dominant standard in European automotive and marine industries.

5. What is the difference between 5754 and 5083 aluminum?

5083 is a high-strength alloy with higher Magnesium content (up to 4.9%), making it much stronger than 5754. However, 5754 is easier to form and more cost-effective. While 5083 is reserved for extreme stress applications like pressure vessels and large ship hulls, 5754 is the "Goldilocks" solution for medium-strength structural panels and automotive parts.

6. Why is 5754 often called "Marine Grade" aluminum?

It earns this title because of its exceptional resistance to salt-water corrosion. Even without painting or protective coatings, 5754 remains stable and maintains its structural integrity in harsh maritime environments. It is the industry standard for manufacturing deck fixtures, hulls, and other components exposed to constant sea spray.