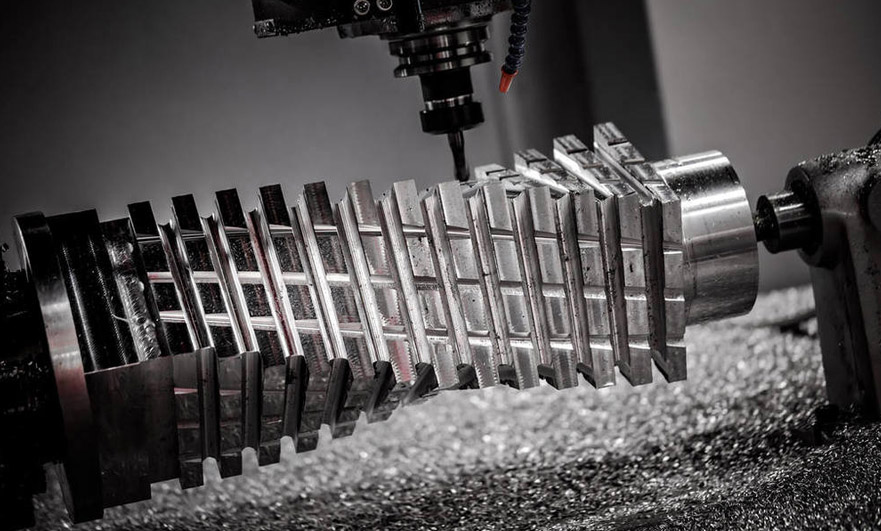

15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

133 |

Published by VMT at Oct 14 2021

133 |

Published by VMT at Oct 14 2021

In fact, we have entered the era of Industry 4.0. Unlike other industrial revolutions, we have entered the era of intelligence. Compared with the 3.0 industrial technology information era, 4.0 uses higher technology and efficient processes. The use of big data expands and strengthens manufacturing. Gradually custom CNC machining services also need to start preparing for transformation, so as to facilitate future and current market competition. What is Industry 4.0? What is the impact on custom CNC machining service manufacturing? Let's discuss with us below!

What is Industry 4.0?

Industry 4.0 is based on Industry 3.0 to use intelligence to centrally process information in the automation industry. It has the feature of using automated systems to replace part of the human thought process, so the connection between humans and technology is getting closer and closer.

Industry 4.0 is the fourth industrial revolution. This revolution uses data and cloud computing in production and manufacturing. The Internet of Things, especially the Industrial Internet of Things (IIoT), as well as artificial intelligence and computer integration, are the core components of Industry 4.0.

Due to the rise of 4.0, new technologies have been continuously developed to automate many manufacturing processes. Since each system can communicate with each other and share data, turnaround time and costs are reduced.

The Impact of Industry 4.0 on custom CNC machining services

The most direct impact of Industry 4.0 on custom CNC machining services is that it will change the daily operations of CNC machining workshops, such as reducing downtime. The reason for the growth is the increasing need to reduce operating costs, increase efficiency, and significantly reduce the possibility of component errors.

The integration of CNC machining machinery and CAM (Computer Aided Manufacturing) helps to shorten manufacturing time and ensure the production of defect-free parts. Leading commercial enterprises and large manufacturers need more and more advanced CNC hardware and software. Therefore, the continuous development of custom CNC machining service technology is promoted.

Machining advantages of Industry 4.0

1. Continuous operation: With the powerful performance and real-time data flow of Industry 4.0, custom CNC machining service solutions can even build predictive models and algorithms that can be used to identify potential failure points, otherwise many failure points will be invisible to the naked eye. All of these make machines and equipment run continuously without failure, and the efficiency is higher than ever.

2. Energy and operation saving:

With Industry 4.0 solutions, you can better manage resource usage. Incoming data collected by IoT sensors and platforms can be used to better inform operations. Smart meters can be placed to effectively manage energy flow. custom CNC machining service equipment can be automated or appropriately powered to reduce the impact on the environment and resources.

3. Real-time quality assurance:

Industry 4.0 and related technologies will revolutionize this process through real-time QA such as automatic virtual metering (AVM) systems. Essentially, data about conditions, quality, and status are collected and combined with information about machines and processes. It provides a more complete overview of operations and provides real-time elements for quality inspection.

4. Better man-machine interface:

The future mechanical workshop or custom CNC machining service factory workshop will be very efficient, because people, machines and robots can work side by side in a stable and safe environment. In order to achieve this goal, a lot of improvements to the man-machine interface are needed. Technicians will be able to remotely operate the equipment and send commands immediately. The reporting system will provide operators with real-time alerts and insights, no matter where they are.

In conclusion:

Industry 4.0 is the latest wave of change in the entire custom CNC machining service manufacturing industry and commerce. But it will not worry about this change because of the elimination of workers, but will bring new efficiency and improvement opportunities to the existing process.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!