15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Dec 12 2025 | Reading Time:About 2 minutes

0 |

Published by VMT at Dec 12 2025 | Reading Time:About 2 minutes

A lens barrel is used to support and protect the camera lens, it usually asks for precision and good-looking appearance. If you are designing lens barrels for optical equipment such as cameras, telescopes and microscopes, and want to find a reliable manufacturer for mass production, it’s important for you to learn about the preferred materials and the manufacturing processes of lens barrels.

This article will guide you through what aluminum alloys grades are used, and machining processes of the lens barrels, and provide you with some useful references when considering manufacturing plans.

Aluminum alloy is lightweight, high strength, corrosion resistance, excellent machinability, and good thermal conductivity. These properties make aluminum alloys a cost-effective choice for precision optical instruments including lens barrels.

1.Lightweight yet Strong (Low Density, High Specific Strength)

Aluminum alloys have a density of approximately 2.7 g/cm³,and can provide good strength. This property allows lens barrels easy to handle, so it is quite good for handheld lenses and equipment that require portability and stable installation.

2.Excellent Machinability

Aluminum alloys can undergo casting, extrusion, forging , CNC precision cutting,etc. The plasticity of aluminum allows production of complex, precision structures if required, making them ideal for integrated lens barrel components.

3.Thermal Conductivity

Aluminum alloys dissipate heat effectively, reducing thermal expansion of lens barrels effects on optical cameras and helping maintain image stability.

4.Corrosion Resistance

In normal atmospheric conditions, aluminum alloys resist rust, extending the long-term service life of lens barrels.

5.Cost Effectiveness

Compared to stainless steel or magnesium alloys, aluminum alloys are more affordable, allowing manufacturers to reduce costs while maintaining performance.

6.Surface Finishes Options

Aluminum alloys are also compatible with various surface treatments, such as anodizing powder coating,electrophoretic coating (e-coating),etc, which are used for lens barrels.

Lens barrel material asks for good machinability (complex internal threads, grooves, and structures), adequate strength (without overdesign), lightweight, stable surface finish after anodizing, and cost efficiency. 6000 series alloys strike an ideal balance among these factors.

Basically, most lens barrels in the market are made of 6000 series aluminum alloys (6061, 6063, 6082). Among them, 6061-T6 is the most popular one for manufacturing lens barrels. Below is the comparison table of 6061 vs 6063 vs 6082.

Table 1: Comparison Table of Aluminum Alloys: 6061 vs 6063 vs 6082

| Property / Alloy |

6061 |

6063 |

6082 |

| Alloy Series |

6-series (Mg-Si) | 6-series (Mg-Si) | 6-series (Mg-Si) |

| Strength |

Medium-high (T6 yield ~276 MPa) | Medium-low (T6 yield ~214 MPa) | High (T6 yield ~310 MPa) |

| Machinability |

Good | Excellent, especially for extrusion | Good, slightly harder than 6063 |

| Corrosion Resistance |

Good | Very good, ideal for anodized appearance | Good |

| Typical Applications |

Lens barrels, outer housing, optical assemblies | Thin-wall exterior components, decorative or visible parts | Load-bearing lens barrel parts / internal barrel |

| Anodizing Finish |

Good | Excellent, smooth and uniform | Good |

| Weight |

Light | Lightest (suitable for thin-walled long sections) | Light, slightly heavier than 6063 |

| Remarks |

Most commonly used type is 6061-T6 | Preferred for extruded parts (6063-T5) | High-strength 6082-T6 used for high-load structural parts |

6061 Aluminum Alloy: Balances strength, machinability, and corrosion resistance, most commonly used in lens barrels and optomechanical components. Especially 6061-T6 holds high strength, good corrosion resistance, excellent weldability, and good machinability, widely used in applications requiring high strength and good surface treatment. It is the most widely used model for lens barrels, shells, and optomechanical components.

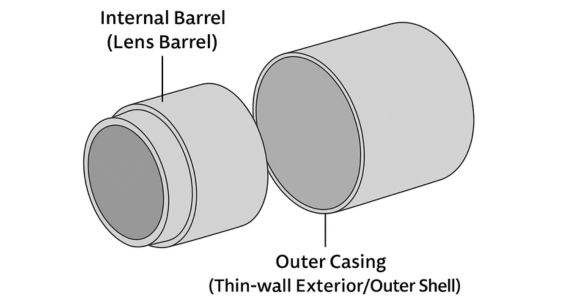

6063 Aluminum Alloy: Best machinability, easy to form extruded profiles, best corrosion resistance and anodizing effect. It is often used for thin-walled exterior/outer shell components(visible parts of the lens barrel or shell, mainly for protection and aesthetics; manufacturers generally consider thin-walled exterior components as part of the lens barrel) to meet requirements of appearance, lightweight, and strength.

6082 Aluminum Alloy: Highest strength, good fatigue resistance (the material's ability to resist fracture or performance degradation under long-term repeated loads), suitable for Internal Barrel bearing large loads, but its machinability is slightly lower than 6061/6063.

Manufacturing a precision lens barrel requires high-accuracy machining, strict tolerance control, and high-quality surface finishing to ensure proper alignment, smooth mechanical operation, and long-term stability of the optical assembly. The complete process is outlined below:

1. Design & Engineering Preparation

Before manufacturing begins, engineers create a detailed 3D CAD model of the lens barrel and conduct feasibility evaluations on materials, machining strategies, and required tolerances. CAM programming, machining simulation, and fixture design are also completed at this stage.

2. Rough Machining:CNC Machining or 3D Printing

Rough machining is usually done by CNC machining or 3D printing. Choice between CNC machining and additive manufacturing depends on design complexity, material selection, and production volume. CNC is preferred when you need consistent accuracy, fine surface finish, and clean internal features. Additive manufacturing is better for complex internal structures or fast prototype iterations.For high-volume manufacturing, companies often form the initial blanks through extrusion or forging. These blanks are then finished with CNC machining to achieve the final tolerances and surface quality required for optical components.

Because lens barrels require very tight tolerances and high surface quality—often at the micron level—CNC machining is the primary method used in both prototyping and mass production. It provides consistent dimensional accuracy, smooth internal surfaces, and precise threads.

CNC machining is widely used to produce aluminum lens barrels with good dimensional accuracy, smooth surfaces. Its typical workflow is : CAD → CAM Programming → Workpiece Setup → Machining (turning, milling, drilling).

This manufacturing way (CNC machining) is using cutting tools (usually lathe,3-axis, 4-axis, or 5-axis CNC milling) to cut a workpiece( a complete piece of material) into the shape you want. It achieves:

3D printing is helpful for early prototypes or for creating complex, lightweight structures. However, printed parts usually need secondary machining to meet optical requirements. During the prototype stage, parts are typically made entirely by CNC machining or 3D printing. Once production scales up, cost and material efficiency become more important. 3D printing is suitable for lens barrels with complex internal structures, lightweight designs, or when rapid prototyping is needed.

3D printing builds the parts layer by layer, using methods such as powder-based laser sintering (SLS/SLM), stereolithography (SLA), or fused deposition modeling (FDM).In powder-based processes, a laser selectively fuses material powders to form each layer, which is repeated until the complete part is formed, often followed by post-processing like sintering, curing, or polishing to achieve the required strength and surface quality.

3. Grinding and Polishing

Grinding and polishing are used to improve smoothness of lens barrels. Grinding removes material to achieve nominal dimensions and smooth interfaces, while polishing(is sort of surface fishish) further reduces surface roughness, improving mechanical feel and preventing binding .

Surface finishing enhances durability, appearance, and optical performance by reducing unwanted reflections inside the lens barrel.

Common finishing options include:

These treatments help maintain mechanical stability and minimize internal reflections that degrade image quality.

Heat treatment can improve strength and hardness of aluminum alloys (e.g., 6061-T6, 6082-T6), but is not essential for most lens barrels, since mechanical loads are moderate.It may be applied in cases where higher stiffness or wear resistance is required, such as telephoto lenses and large-aperture lenses, to reduce minor deformations during optical focusing or rotation rings and ensure imaging stability.

6.Assembly

After the CNC machining plant completes grinding, polishing, milling, turning, etc., to ensure that the dimensions and precision meet your lens barrel design requirements, you (the brand owner or optical assembly plant) need to complete the final assembly.

You may assure that:

7.Final Quality Assurance (QA/QC)

Final Quality Assurance (QA/QC) involves comprehensive testing to ensure the finished lens barrel meets all optical, mechanical, and cosmetic specifications. This includes dimensional verification using CMMs, interferometry and alignment measurements, coaxiality and thread-quality inspection, and mechanical durability checks to confirm smooth operation and consistent torque. Surface finish and coating uniformity are examined through detailed visual inspection. Only after passing all of these tests is the lens barrel approved for final integration into the optical system.

At VMT CNC machining factory, we utilize industry-leading CNC machining equipment (3-5 axes) and rigorous quality control processes to ensure that every lens barrel meets requirements for dimensional accuracy and aesthetically pleasing surface finishes. VMT also provides DFM analysis and prototype-to-volume production support, producing high-quality, durable lens barrels that meet performance and cost goals. From prototyping to mass production, we provide fast, reliable, and consistent manufacturing support to numerous customers in the optics, precision instrumentation, and industrial optics applications.

Not sure how to manufacture lens barrels? VMT engineers will advise you on manufacturability, surface finishes, and optimized structural design to ensure your lens barrels meet performance, budget, and long-term reliability objectives. Contact a VMT expert today for a free consultation or quote!

1.What are the disadvantages of aluminum alloys compared to steel?

Aluminum alloys have lower strength and wear resistance compared to steel, and they require surface treatments because the surface is relatively soft.

2.Why aren’t lens barrels typically made from stainless steel?

Stainless steel is heavy, costly to machine, and adds unnecessary weight to optical systems, so it’s used only for small high-strength components.

3.Can magnesium alloy be used for lens barrels?

Yes, but less commonly. It is mainly used in high-end lenses from brands like Canon, Nikon, Sony, and Fuji due to its light weight and high strength, though it is more expensive and requires stricter corrosion protection.

4.What are some well-known lens barrel brands?

Thorlabs, Edmund Optics, Newport, Qioptiq (Excelitas), etc.

5.What other materials can be used to make lens barrels besides aluminum alloys?

Most lens barrels are made from aluminum alloys, while magnesium alloys and engineering plastics are used in smaller proportions.

6. What surface finishes are commonly used for lens barrels?

Common finishes include anodizing, hard anodizing, bead-blasting with anodizing, black matte coating, and chemical conversion coatings.