15 years one-stop China custom CNC machining parts factory

1 |

Published by VMT at Dec 16 2025 | Reading Time:About 3 minutes

1 |

Published by VMT at Dec 16 2025 | Reading Time:About 3 minutes

If you choose magnesium for lightweight CNC machined parts without fully understanding its melting behavior, you risk warping, surface defects, or even safety hazards during processing. Magnesium’s low melting temperature can quickly become a problem when heat control is poor. When you understand the melting point of magnesium and its heat tolerance, you can machine it safely, control costs, and achieve consistent, high-quality results in CNC machining services.

Tip: Magnesium heats up quickly during machining. Poor temperature control can increase scrap rates and machining costs.

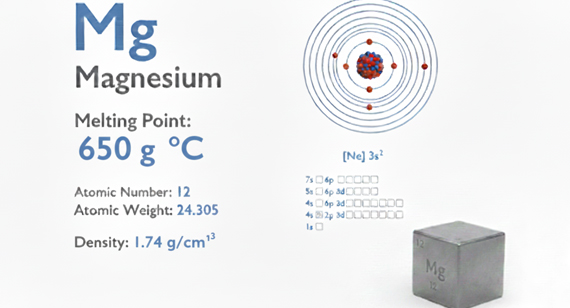

The melting point of magnesium is approximately 650°C (1,202°F). This magnesium melting temperature is lower than many structural metals, making magnesium easy to melt but sensitive to heat. In CNC machining, careful thermal control is required to prevent deformation, oxidation, or ignition.

Note: The magnesium fusion point and magnesium melt point refer to the same temperature range but may vary slightly in alloys.

Now that you understand the basic magnesium melting temperature, the next step is knowing what magnesium is and why its thermal behavior matters in real manufacturing. By understanding its structure, properties, and behavior at high temperatures, you can make better material decisions for CNC machining services and avoid costly processing mistakes. If you want deeper insight into lightweight metal machining, you can also explore related guides on CNC material selection within our CNC machining factory resources.

Tip: Choosing magnesium without understanding its thermal limits can increase tooling wear and safety risks.

Magnesium is a lightweight, silvery metal known for its low density, good machinability, and fast heat response. You often use it in CNC machined parts where weight reduction matters, such as aerospace and automotive components. Because magnesium heats up quickly, understanding its magnesium temperature for melting is critical when selecting cutting parameters and machining strategies.

Tip: Magnesium machines easily, but its low heat tolerance means you must avoid excessive spindle speeds and poor chip evacuation.

The melting point of magnesium is about 650°C (1,202°F) under standard atmospheric conditions. This magnesium melt point is significantly lower than steel and titanium, which explains why magnesium softens and melts quickly when exposed to heat. In CNC machining, staying well below the magnesium solidus temperature helps you maintain dimensional stability and surface quality.

Note: Pure magnesium has a stable melting temperature, but the melting point of magnesium alloy varies depending on composition.

You don’t calculate the melting point of magnesium from scratch during machining; you reference standardized material data. For pure magnesium, the melting temperature of magnesium is fixed at around 650°C. For alloys, you determine the magnesium solidus temperature and magnesium liquidus temperature from alloy specifications, which define the temperature range where melting begins and completes.

Tip: Always confirm alloy-specific data before machining. Assuming pure magnesium values for an alloy can lead to overheating and part failure.

When you machine magnesium, its physical and chemical properties directly affect heat control, tool life, and part quality. Magnesium’s low density, low melting temperature, and limited heat tolerance make it ideal for lightweight CNC machined parts—but only if you understand how each property behaves during cutting, heating, and post-processing in a CNC machining factory.

Tip: Ignoring magnesium’s thermal and chemical properties can increase fire risk and scrap costs during CNC machining services.

| Property | Value / Description | Relevance to CNC Machining |

| Atomic Number | 12 | Indicates a simple atomic structure, contributing to low density and easy machinability |

| Boiling Point | ~1,091°C (1,996°F) | Much higher than the magnesium melting temperature, allowing controlled machining below vaporization |

| Electronegativity | 1.31 (Pauling scale) | Low electronegativity makes magnesium chemically active and prone to oxidation |

| Density | ~1.74 g/cm³ | Extremely lightweight, ideal for weight-sensitive CNC machined parts |

| Melting Point | ~650°C (1,202°F) | Defines the magnesium melt point and sets strict thermal limits during machining |

| Corrosion Resistance | Poor without protection | Requires coatings or alloying to prevent corrosion in humid or salty environments |

| Heat Treatment | Limited effectiveness | Heat treatment improves strength slightly but must stay below magnesium solidus temperature |

Note: For magnesium alloys, the magnesium alloy melting temperature may vary between solidus and liquidus values, so always refer to alloy-specific data sheets before machining.

The melting point of magnesium is not always a fixed number in real manufacturing. When you work with magnesium in CNC machining services, factors such as alloy composition, processing method, and thermal history can shift the magnesium fusion point and melting behavior. Understanding these influences helps you control heat input, avoid deformation, and reduce risk in a CNC machining factory.

The melting point of magnesium changes significantly depending on the alloying elements used. Commonly, magnesium is alloyed with aluminum, zinc, manganese, and rare earth metals. These elements alter the magnesium solidus temperature and magnesium liquidus temperature, creating a wider or narrower melting range. When you select magnesium alloys for CNC machined parts, always check the alloy-specific melting point to ensure thermal stability during processing.

Aluminum is the most common alloying element in magnesium. Increasing aluminum content generally raises the magnesium alloy melting temperature, improving high-temperature strength. For example, AZ91 (9% aluminum) melts at a higher temperature than AM60 (6% aluminum). Knowing aluminum content helps you plan machining parameters and prevent excessive softening or melting during CNC milling or turning.

The way magnesium parts are produced—casting, extrusion, or additive manufacturing—affects the melting behavior. Casting may introduce microsegregation, slightly lowering the magnesium melt point locally, while extrusion can create more uniform microstructures, maintaining consistent melting characteristics. Understanding your part’s manufacturing history helps you adjust the magnesium temperature for melting safely during CNC machining.

Cooling rates after heating or solidification directly influence the magnesium solidus and liquidus temperatures. Rapid cooling can create residual stresses and lower localized melting points, while slow cooling allows for stable crystalline structures. Controlling temperature and cooling in CNC machining ensures the part retains dimensional stability and avoids unexpected soft spots.

Porosity, common in cast magnesium alloys, can affect how heat distributes in the material. Areas with high porosity may heat faster, locally reducing the effective magnesium melt point. This can cause warping or incomplete machining if not accounted for in tool paths or cutting speeds.

Other minor factors, such as trace alloying elements, surface oxidation, and environmental humidity, can slightly shift the magnesium melting temperature. Even small variations can impact CNC machining, especially in thin-walled or heat-sensitive components.

Magnesium alloys are widely used in CNC machined parts because they combine light weight with improved mechanical strength. Each alloy has a specific melting point range determined by its composition, especially aluminum, manganese, and zinc content. Understanding these magnesium alloy melting temperatures allows you to select the right alloy for your CNC machining services while preventing overheating, deformation, or other heat-related issues.

| Alloy | Melting Point Range (°C) | Melting Point Range (°F) | Notes |

| Magnesium-Aluminum (Mg-Al) | 900°C – 1040°C | 1652°F – 1904°F | Common lightweight alloy with moderate heat tolerance |

| Magnesium-Manganese (Mg-Mn) | 620°C – 650°C | 1148°F – 1202°F | Enhanced corrosion resistance with minor melting point variation |

| Magnesium-Zinc (Mg-Zn) | 590°C – 630°C | 1094°F – 1166°F | Offers improved strength at elevated temperatures |

| AZ91 Magnesium Alloy |

533°C – 536°C |

997°F |

9% aluminum, 1% zinc; widely used in automotive and aerospace CNC machined parts |

| AM60 Magnesium Alloy |

Solidus (Starts to melt): ~435°C Liquidus (Fully liquid): ~615°C - 620°C |

Solidus (Starts to melt): 815°F Liquidus (Fully liquid): 1140°F - 1148°F) |

6% aluminum, 0.13% manganese; more ductile and easier to machine |

| AZ31 Magnesium Alloy | 605°C – 630°C | 1120°F – 1170°F | Lightweight, good corrosion resistance, commonly used for thin-walled parts |

| AZ91D Magnesium Alloy | 470°C – 598°C | 875°F – 1108°F | Improved casting alloy version of AZ91 with better corrosion resistance |

Note: The ranges reflect magnesium solidus temperature to magnesium liquidus temperature for each alloy. Machining should always be done below the solidus temperature to maintain dimensional stability.

Tip: Using a magnesium alloy outside its recommended temperature range can cause warping, surface defects, or reduced mechanical performance.

When you select materials for CNC machined parts, understanding how magnesium’s melting point compares to other metals is essential. Magnesium melts at a relatively low temperature (~650°C / 1,202°F), which makes it lightweight and easy to machine but also more sensitive to heat than most structural metals. Comparing it with metals like aluminum, steel, copper, and tungsten helps you plan thermal control, tooling, and machining strategies effectively.

| Metal | Melting Point (°C) | Melting Point (°F) | Notes / Relevance to CNC Machining |

| Melting Point of Magnesium | 650°C | 1,202°F | Low melting point; lightweight and easy to machine |

| Melting Point of Aluminum | 660.3°C | 1,220.5°F | Slightly higher than magnesium; common in lightweight parts |

| Melting Point of Titanium | 1,668°C | 3,034°F | Very high melting point; requires specialized CNC machining techniques |

| Melting Point of Stainless Steel | 1,400°C–1,530°C | 2,552°F–2,786°F | High melting point; durable but harder to machine than magnesium |

| Melting Point of Steel (Carbon) | 1,370°C–1,540°C | 2,498°F–2,804°F | High melting point; suitable for structural parts but heavy |

| Melting Point of Red Copper | 1,085°C | 1,985°F | Moderate melting point; higher thermal conductivity affects machining |

| Melting Point of Iron | 1,538°C | 2,800°F | Very high melting point; machining generates more heat |

| Melting Point of Copper | 1,085°C | 1,985°F | Same as red copper; good conductivity, needs careful heat control |

| Melting Point of Tin | 232°C | 450°F | Very low melting point; easy to melt but soft for structural applications |

| Melting Point of Tungsten | 3,422°C | 6,192°F | Extremely high melting point; nearly impossible to melt in standard CNC setups |

| Melting Point of Silver | 962°C | 1,764°F | Low-to-moderate melting point; excellent conductivity, watch for oxidation |

| Melting Point of Zinc | 420°C | 788°F | Low melting point; caution for heat-sensitive machining |

Tip: Always match the machining process and tooling to the material’s melting point to avoid deformation, oxidation, or fire risks.

Magnesium’s relatively low melting point (~650°C / 1,202°F) and light weight make it a versatile material across multiple industries. Its thermal behavior affects casting, CNC machining, and heat-sensitive applications. By understanding the magnesium temperature for melting and heat tolerance, you can optimize processes, improve part quality, and reduce manufacturing risks in diverse industrial sectors.

Magnesium alloys are extensively used in aerospace for lightweight components such as seat frames, instrument panels, and gear housings. The low magnesium melt point allows precision casting and CNC machining without excessive energy consumption. Controlling heat during processing ensures dimensional accuracy and prevents material weakening.

In the automotive sector, magnesium alloys are popular for engine blocks, transmission cases, and chassis components. Their low density helps reduce vehicle weight and improve fuel efficiency. Knowledge of the magnesium alloy melting temperature allows precise casting and CNC machining while avoiding thermal deformation or surface defects.

Magnesium is used in electronics for laptop casings, smartphone frames, and camera components, where lightweight and thermal dissipation are critical. The low magnesium melt point facilitates microcasting and thin-walled CNC machining, ensuring parts are both strong and lightweight.

Magnesium alloys are applied in medical devices such as orthopedic implants and biodegradable stents. Their low melting temperature enables precise shaping and CNC machining for customized parts. Understanding magnesium heat tolerance is crucial for ensuring biocompatibility and structural integrity during processing.

Magnesium is also used in sports equipment, defense components, and energy-efficient machinery. Its low density and controlled melting point allow designers to create lightweight, complex parts with CNC machining services. Proper thermal management ensures longevity and safety in these applications.

Recent research on magnesium focuses on understanding its thermal behavior, ignition risks, and process optimization for CNC machining and additive manufacturing. Magnesium’s low melting point (~650°C / 1,202°F) presents both opportunities for lightweight component production and challenges in controlling heat during machining. Studying ignition points, properties at melting, SLM (Selective Laser Melting) challenges, and process parameters helps engineers improve part quality and safety.

| Topic | Key Findings | Description |

| Ignition Point | Magnesium ignites at ~473–600°C in air | Low ignition temperature requires strict temperature control and protective atmospheres during machining or melting |

| Properties at Melting Point | Softens rapidly near 650°C | Understanding magnesium solidus and liquidus temperatures helps prevent deformation and maintain CNC machined part dimensions |

| SLM Process Challenges | High reflectivity and porosity risk | Laser-based additive manufacturing can create defects unless scanning speed, power, and layer thickness are optimized for magnesium alloys |

| Process Parameter Optimization | Cooling rate, laser power, and alloy selection are critical | Careful adjustment of machining or additive parameters ensures consistent mechanical properties, dimensional stability, and surface finish |

Understanding the melting point of magnesium is essential for safely and efficiently machining or casting magnesium and its alloys. With a relatively low melting temperature (~650°C / 1,202°F), magnesium offers lightweight advantages for aerospace, automotive, electronics, and medical applications—but also demands careful thermal management.

Key points to remember:

Tip: Always refer to alloy-specific melting temperatures and research updates when designing or machining magnesium components to ensure consistent quality and safety.

1. Is magnesium easy to melt?

Yes, magnesium is relatively easy to melt due to its low magnesium melting temperature (~650°C / 1,202°F). Its low density and thermal conductivity make magnesium alloys convenient for casting and CNC machining, but careful heat control is essential to avoid fire hazards or deformation.

2. Why does magnesium have a low melting point?

Magnesium has a low melting point because of its simple atomic structure and weak metallic bonding compared to heavier metals like titanium or tungsten. Alloying elements like aluminum, manganese, and zinc can slightly adjust the magnesium alloy melting temperature, but the base magnesium remains relatively low in heat tolerance.

3. Is magnesium heat resistant? Why does magnesium melt at low temperatures?

Magnesium is not highly heat resistant. Its magnesium solidus temperature is low, so it softens and melts quickly under heat. This is advantageous for lightweight CNC machined parts but requires precise thermal management to prevent warping or ignition during machining.

4. Does magnesium rust?

Magnesium does not rust like iron, but it can corrode, especially in humid or salty environments. Protective coatings, alloying, or controlled atmospheres are used in CNC machining to maintain magnesium heat tolerance and surface integrity.

5. Which metal is the most difficult to melt?

Tungsten is the most difficult to melt, with a melting point of 3,422°C (6,192°F). Compared to magnesium, tungsten requires specialized high-temperature processes and is far less practical for standard CNC machining applications.

6. Why is the melting point of magnesium lower than that of calcium?

Magnesium has a smaller atomic radius and weaker metallic bonding than calcium, which lowers its magnesium fusion point. This makes magnesium easier to melt and machine, but also more sensitive to heat during processing.

7. Which metal takes the longest to melt?

Tungsten again takes the longest to melt due to its extremely high melting temperature. Metals like titanium and stainless steel also require high temperatures, whereas magnesium melts quickly, making it ideal for lightweight, low-heat applications in CNC machined parts.

Tip: When machining or casting magnesium, always account for magnesium melt point, solidus and liquidus temperatures, and alloy composition to maintain safety, quality, and process efficiency.