15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Feb 02 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Feb 02 2026 | Reading Time:About 2 minutes

Bronze—metallic brown color—you can often see it from celebrity statues in many museum; Silicon—the most abundant elements in nature composed of the earth under our feet. But what about silicon bronze? This material is what we will discuss—it isn’t bronze with silicon, but at least 94% copper with 1-4% silicon and other trace elements (bronze is 89-92% copper with 5.5-7.0% Tin). Thus, the color of silicon bronze is mainly similar to copper— a reddish-brown color.

This article will introduce this widely used high strength, corrosion-resistant material —silicon bronze—from its types and common grades, properties and manufacturability and pros and cons, giving you a worthwhile engineering insight of this material.

Silicon bronze is copper alloy that typically consists of 94–96% copper, with the remainder being silicon and small amounts of manganese, tin, iron, or zinc. Silicon bronze's composition allows it to maintain the excellent corrosion resistance of copper, while the addition of silicon significantly enhances its strength and toughness. However, it is important to note that while copper is a great conductor, silicon bronze has relatively low thermal conductivity(The alloying process will drastically reduce this property) compared to other copper alloys, which makes it exceptionally well-suited for welding. Silicon content from 1% to 2.5% can consider it as low silicon bronze while 2.5% to 4% can think of it as high silicon bronze, along with other elements affect the materials’ property.

You may also hear silicon bronze referred to by other names such as Siliconized Bronze; trade names of Everdur (US) and Cusilman (AU); EN Designation of CW116C (CuSi3Mn1).

History of Silicon Bronze

Silicon bronze gained prominence in the early 20th century as a good alternative to tin bronze and steel for specific applications. Its development was driven by the need for a non-magnetic material that could resist "saltwater rot." During WWII, it became emerge used for naval fasteners and chemical processing equipment. Its non-magnetic property also makes it advantageous in the manufacture of mine-clearing equipment. Evolving with modern industry, silicon bronze remains a good material for high-strength, corrosion-resistant marine applications. Its lead-free environmental profile, ease of welding, and aesthetic oxidized patina also make it a preferred material for architectural and plumbing uses.

Complementary Table of Chemical Composition and Elemental Roles

Table 1: Silicon Bronze Chemical Composition and Elemental Roles

| Element |

Typical % |

Key Role in the Alloy |

| Copper (Cu) |

94% - 96% | Serves as the base metal; provides exceptional corrosion resistance and durability. |

| Silicon (Si) |

1.0% - 4.0% | Primary alloying element; significantly increases tensile strength and hardness while improving fluidity for casting. |

| Manganese (Mn) |

0.5% - 1.5% | Acts as a deoxidizer; enhances grain refinement, high-temperature strength, and wear resistance. |

| Zinc (Zn) |

1.0% - 5.0% | Improves castability and surface finish; helps balance material costs in high-volume production. |

| Iron (Fe) |

< 0.8% | (Trace element) Increases hardness and prevents grain growth during heat treatment. |

| Lead (Pb) |

< 0.05%(can be considered none) | Maintained at trace levels to comply with "Lead-Free" environmental standards and health regulations.USA Safe Drinking Water Act defines non-lead as lead ≤ 0.25%. |

Silicon bronze is a family of copper-based alloys typically containing 1% to 4% silicon. It is renowned for its excellent corrosion resistance, high strength, and superior weldability, making it a preferred choice for marine, industrial, and artistic applications. We can categorize silicon bronze into high and low silicon bronze according to its silicon content while it can also be categorized into wrought or cast silicon bronze according to its processing way. The following show different types with corresponding grades:

1. Wrought Silicon Bronze

Wrought alloys are shaped through mechanical processes like rolling, forging, or drawing. They are characterized by high structural integrity and ductility.

Low-Silicon Bronze B (UNS C65100)

This alloy contains approximately 1.5% silicon, and the grade UNS C65100 is the most ductile of the silicon bronzes and is specifically designed for cold-forming processes like cold heading, bending, and swaging. Suggested applications of UNS C65100 include hydraulic pressure lines and heat exchanger tubes,U-bolts and pole line hardware, fastens and bolts.

High-Silicon Bronze A (UNS C65500)

It contains approximately 3.0% silico and high-silicon bronze a is the industry standard for CNC machining and structural components requiring high strength. Its strength levels comparable to mild steel, and it has superior fatigue resistance, and excellent weldability (TIG/MIG). Applications of the high-silicon bronze a include marine hardware like propeller shafts, rudder pins, and hull fasteners; industrial uses like valve stems, pump shafts, and heavy-duty gears; pressure vessels and chemical handling equipment can also be made of this alloy.

2. Cast Silicon Bronze

Cast grades are specifically formulated for foundries. They often contain additional elements like zinc or manganese to improve molten metal flow. Foundry silicon bronze (UNS C87300 / C87600) often referred to by the trade name "Everdur," these grades are well-suited for intricate casting. Cast silicon bronze UNS C87300 and C87600 is highly corrosion resistant and has high fluidity and self-lubrication. Suitable applications of this alloy include pump housings, marine fittings, intricate sculptures, commemorative plaques, and decorative gates.

3.Mechanical and Physical Properties of Common Silicon Bronze Grades

Below table is a complementary of above mentioned grades including their main phsical and machanical properties:

Table 2: Mechanical and Physical Properties of Common Silicon Bronze Grades

| Property |

C65100 |

C65500 |

C87300 |

C87600 |

| Tensile Strength |

40k – 95k psi 276 – 655 MPa |

56k – 108k psi 386 – 745 MPa |

45k – 55k psi 310 – 380 MPa |

60k – 72k psi 414 – 496 MPa |

| Yield Strength |

15k – 65k psi 103 – 448 MPa |

21k – 60k psi 145 – 414 MPa |

18k – 25k psi 124 – 172 MPa |

30k – 35k psi 207 – 241 MPa |

| Elongation (% in 2") |

11% – 55% | 15% – 60% | 20% – 30% | 16% – 25% |

| Hardness |

60 – 95 HRB | 70 – 95 HRB | 70 – 85 HB | 75 – 90 HRB |

| Density |

0.316 lb/in³ 8.75 g/cm³ |

0.308 lb/in³ 8.53 g/cm³ |

0.302 lb/in³ 8.36 g/cm³ |

0.300 lb/in³ 8.30 g/cm³ |

| Melting Point |

1890 °F 1032 °C |

1880 °F 1027 °C |

1780 °F 971 °C |

1740 °F 949 °C |

| Elec. Conductivity |

12% IACS | 7% IACS | 6.7% IACS | 5.5% IACS |

| Thermal Conductivity |

33 Btu/ft·h·°F 57 W/m·K |

21 Btu/ft·h·°F 36 W/m·K |

18.2 Btu/ft·h·°F 31.5 W/m·K |

16.4 Btu/ft·h·°F 28.4 W/m·K |

| Machinability Rating |

30% | 30% | 40% | 50% |

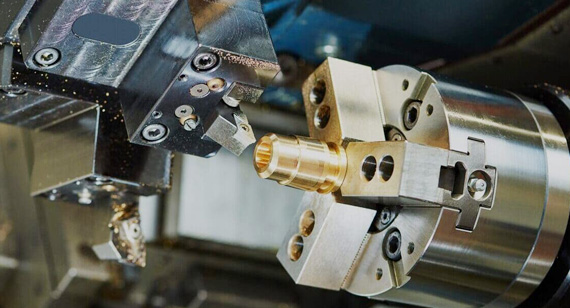

Precise CNC Machining Strategies

Silicon bronze is highly valued in modern manufacturing, though it presents unique challenges compared to free-cutting brass. With a machinability rating typically ranging from 30% to 50%, the alloy is notably "gummy," often producing long, stringy chips that can interfere with automated tooling. To achieve high-quality finishes in CNC environments, carbide tooling with sharp rake angles is essential to shear the metal effectively rather than pushing or dragging it. Furthermore, it is critical to use high-pressure, sulfur-free synthetic coolants; sulfur-based additives can permanently stain the copper surface, compromising the aesthetic and structural integrity of the part. By maintaining lower cutting speeds—typically between 200 and 400 SFM—and moderate feed rates, machinists can effectively manage heat and ensure dimensional accuracy.

Welding and Joining

Often cited as the easiest copper-based alloy to weld, silicon bronze simplifies the fabrication process by eliminating the need for preheating in most applications. The gold standard for joining this material is TIG (GTAW) welding using an ERCuSi-A filler metal; the silicon content acts as an efficient deoxidizer, significantly reducing porosity in the weld pool. For thicker structural plates, MIG (GMAW) welding with Argon shielding provides excellent results. While oxy-acetylene welding is possible, it is generally discouraged due to the risk of "hot shortness"—a metallurgical state where the metal becomes brittle and prone to cracking if overheated. This ease of joining makes silicon bronze a good choice for complex assemblies where structural strength and leak-proof seals are required.

When high-impact shaping is required, silicon bronze grades like C65500 offer excellent hot-working ratings, provided the temperature remains within a specific range that lies between 1300°F and 1600°F (700°C – 870°C), allowing for significant deformation(such as hot forging, hot pressing, or hot extrusion) without compromising the alloy's internal structure. However, fabricators must be vigilant as the material cools; if worked near or below the 1200°F threshold, the alloy becomes susceptible to hot shortness. Ceasing operations once the temperature drops below this limit is vital to prevent brittle fractures and ensure the longevity of the forged component.

Cold forming is where silicon bronze truly excels, particularly in the production of high-strength fasteners and precision tubing. The alloy possesses a high rate of work-hardening, meaning it gains substantial tensile strength and hardness as it is shaped at room temperature. This makes it an ideal option for cold-forming processes such as stamping, bending, cold heading, drawing, and roll threading. For extensive forming processes that may lead to excessive brittleness, a stress-relief anneal between 900°F and 1250°F (480°C - 675°C) can be utilized to restore ductility without losing the structural benefits of the shaping process.

Surface Treatments and Finishing

Beyond its mechanical prowess, silicon bronze is world-renowned for its aesthetic versatility and natural corrosion resistance. The material can be mechanically polished to a brilliant luster ranging from "rose gold" to "bright gold," or it can be chemically treated to achieve specific artistic visions. While the material naturally forms a protective oxide film that passivates the surface for marine and industrial use, architectural applications often employ specialized waxes or clear coats to preserve a specific stage of oxidation or a high-polish shine.

Silicon bronze is often selected when standard brass or bronze falls short. Its unique metallurgical profile offers several distinct benefits:

Exceptional Corrosion Resistance & Anti-Fouling

Unlike brass, which can suffer from "dezincification" in saltwater, silicon bronze is nearly immune to this type of corrosion. Additionally, its high copper content provides natural anti-fouling properties, preventing the growth of algae, barnacles, and marine organisms—a critical advantage for underwater components.

High Strength-to-Weight Ratio

In its wrought form (like C65500), silicon bronze achieves a tensile strength comparable to mild steel (55,000–100,000psi). This allows engineers to design parts that are as strong as steel but with the added benefit of superior environmental resistance.

Non-Magnetic & Non-Sparking

Silicon bronze is completely non-magnetic. This makes it essential for sensitive electronic enclosures, MRI equipment, and naval mine-sweeping applications. Furthermore, it is non-sparking, making it the safest choice for tools and components used in explosive or volatile environments.

Silicon bronze has limitations that must be considered during the budgeting and design phases.

Lower Machinability Compared to Brass

The biggest hurdle for manufacturers is its machinability rating of 30-50% . For comparison, C360 Free-Cutting Brass is rated at 100%.The presence of silicon makes the alloy "gummy" and abrasive. It also creates more heat during cutting, leads to faster tool wear, and requires slower spindle speeds, which increases the overall machining time and cost.

Higher Material Cost

Silicon bronze is significantly more expensive than standard yellow brass or carbon steel, and it is typically priced 20–40% higher than common brass alloys. The high copper purity (95%+) and the cost of alloying elements like silicon and manganese drive the price up.

Susceptibility to Stress Corrosion Cracking (SCC)

Although silicon bronze performs exceptionally well in seawater, atmospheric conditions, and most acidic environments, in specific environments involving concentrated ammonia or certain mercury compounds, silicon bronze can be prone to stress corrosion cracking. You’d have to ensure the environment is compatible before specifying this alloy for chemical processing.

Limited High-Temperature Use

Silicon bronze can become "hot short" (brittle) at elevated temperatures. It is generally not recommended for use in environments exceeding 200°C200°C200°C (392°F392°F392°F) for prolonged periods, as its mechanical strength begins to degrade.

Whether you are choosing a grade like C65500 for its structural integrity or C87300 for its intricate casting fluidity, Silicon Bronze remains one of the most versatile materials in your parts design lists. In addition, its role in sustainable, "lead-free" infrastructure and high corrosion resistance also contributes to lots of modern industries.

A client required a custom-designed underwater sensor housing with tight tolerances (±0.01mm) made from C65500 Silicon Bronze. The material's tendency to work-harden caused premature tool wear for their previous supplier.

Our Solution:

The Result: We achieved a surface finish of Ra 0.8 and delivered 500 units with 0% rejection. The client saw a 15% reduction in total part cost due to our optimized cycle times.

Silicon bronze vs. Brass: What is the difference?

The main difference is the alloying element. Brass uses Zinc, while Silicon Bronze uses Silicon. Silicon bronze is significantly stronger and has much better corrosion resistance in saltwater.

Is silicon bronze stronger than steel?

It is comparable in strength to low-carbon (mild) steel. However, it is not as strong as heat-treated alloy steels or stainless steels like 17-4 PH.

Is silicon bronze the same as copper?

No. It is a copper-based alloy (usually 95% copper). Pure copper is softer and much more conductive, but silicon bronze is much harder and more durable.

Does silicon bronze turn green?

Yes, over time and when exposed to moisture and oxygen, it develops a green protective layer called a patina (verdigris). This layer actually protects the underlying metal from further corrosion.

What is the machinability of silicon bronze?

It is rated at 30 to 50% (where Free Cutting Brass is 100). This means it requires slower speeds and more rigid setups than standard brass or aluminum.

What is the color of silicon bronze?

When freshly machined, it has a warm, reddish-gold or "rose-gold" hue, darker than yellow brass but lighter than pure red copper.