15 years one-stop China custom CNC machining parts factory

Client: Japanese

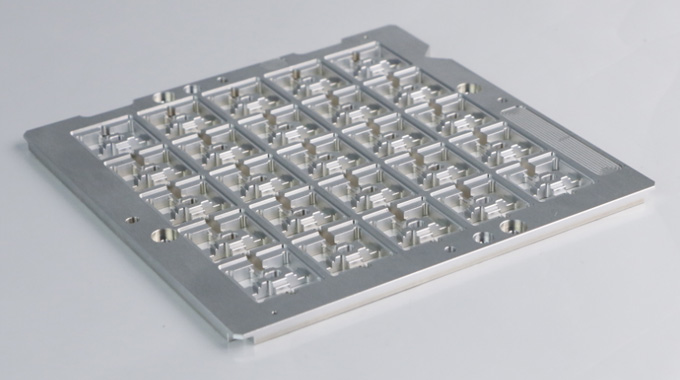

Product requirements: 5mm aluminum plate flatness needs to reach 0.02m

Quantity: 3 pieces

Material: Aluminum

CNC machining method: CNC CNC machining + surface grinding

Delivery time: 5 days

There are many factors to consider if the flatness of the 5MM thick aluminum plate can be controlled within 0.02MM. The first consideration is the material itself, because the material itself has stress, and the tolerance is measured on the machine when the stress is released after CNC machining. If it is within 0.02MM, it will deform if it is taken down and placed there, resulting in a tolerance of 1MM or more. Therefore, when we select materials, we must choose materials that have undergone stress relief treatment. Generally speaking, we will consider T651, followed by process planning. That is, the CNC machining sequence. We will finish the center hole first, then remove the stress after CNC machining go to the surface grinder for CNC machining, and then finish the size that all other grinders have not machined. In this way, the flatness can generally be controlled. Within 0.03MM, we tried this sample three times, and the final result flatness can be controlled. The customer placed an order on November 20, and we completed the confirmation of the first sample within a week.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!