15 years one-stop China custom CNC machining parts factory

Client: Fangda Zhichuang Technology Co., Ltd.

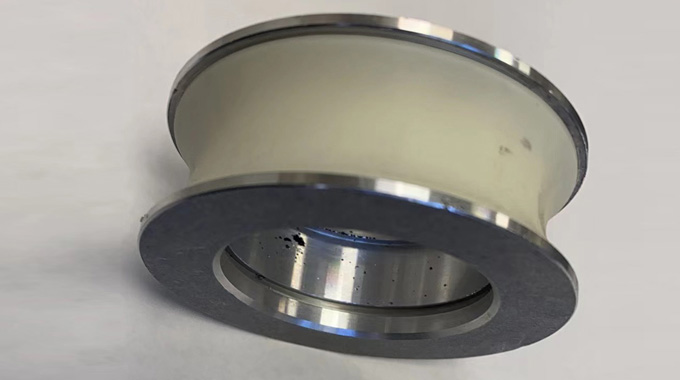

Product requirements: The concentricity of the outer circle of the bearing and the outer circle of the wheel must be guaranteed

Quantity: 20000 pieces

Material: Aluminum alloy in-mold injection molding

machining method: CNC machining

Delivery time: 20 days

Fangda Zhichuang Technology Co., Ltd. has made a lot of innovations in the subway screen door in order to ensure public safety. They have up to 386 innovation patents in this industry. The major impact on the quality of the screen door is the aluminum alloy roller. Just imagine this If the door is not smooth and Carmen will bring hidden dangers to the society? So no matter the strength of the wheel and the size of the extra, no slight error is allowed.

Weimat is fortunate to participate in this project and undertake the work of machining aluminum rollers for subway screen doors. Because the bearings are assembled and then installed on the screen doors, the bearing hole size tolerance affects the tightness of the bearing and the wheel, and it must be ensured at the same time. The concentricity of the outer circle of the bearing and the outer circle of the wheel, so that the wheel can run smoothly and safely. For this reason, we have gone through many trials. So far, we have improved all the problems before starting mass production.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!