15 years one-stop China custom CNC machining parts factory

VMT has been helping numerous customers across various industries realize their manufacturing and prototyping needs and requirement. Explore our successful cases below.

Get an Instant QuoteBecause the batch is only 300 sets, the customer wants to use CNC machining to produce it like a prototype. We found that many curved surfaces on the arrow should be completed in 3D during the review stage. After our Engineer was reviewed with DMF, we recommended that the customer analyze the cost of this project.

66

66

Read more

Read more

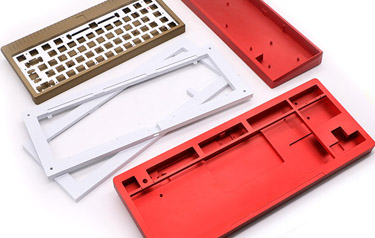

This kind of mechanical keyboard is not standard design, like GH60 GK61 , DIY TKL , 65, it is mainly sold to niche fans. Because it is taking the mid-to-high-end route, customers have strict requirements on the appearance and cannot have any defects on aluminum mechanical keyboard case. According to customer requirements by custom cnc machining, our engineers formulate corresponding special tools, fixtures and reasonable tool paths, and finally meet the customer's quality requirements.

66

66

Read more

Read more

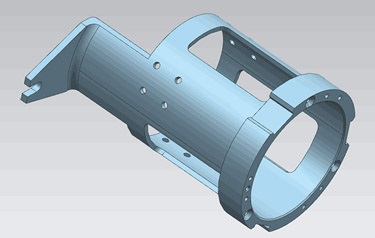

Our engineers conduct a process review according to the customer's drawings. During the review, it is found that it is an irregular eccentric shaped part. According to the traditional processing method, it can only be produced by a 5-axis machine, and the material that needs to be purchased must be twice the outer diameter of the parts. The processing area is large, the time is long, and materials are wasted.

66

66

Read more

Read more

The customer of Industrial Controller found 5 CNC milling suppliers for quotations. Because the quantity is only 1,000 pieces, the quotations of other suppliers are higher than the customer's cost budget.In the end, customers find us, and our company insists that there is no difference between big and small customers. After the engineer analyzed the product structure, it was determined that the extrusion + CNC machining met the customer's requirements, and the cost was reduced, and the quality was also recognized by the customer.

66

66

Read more

Read more

When making the main shell of this microphone at the beginning, the process was bar material + CNC machining, which was a waste of material and long milling time.After mass production, in order to meet customer needs, our engineers changed the process to extrusion + CNC milling. The cost was directly reduced by 50%, and the quality reached the customer's requirements.

66

66

Read more

Read more

Galvanometer of laser machine parts are machined with square solid materials, and CNC machining takes 35 minutes, which wastes materials and the mahining cost is beyond the customer's acceptable range.In order to reduce costs, our engineers use cold forging, the machining time is reduced to 12 minutes, and the cost is reduced by 60%.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!