15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 07 15

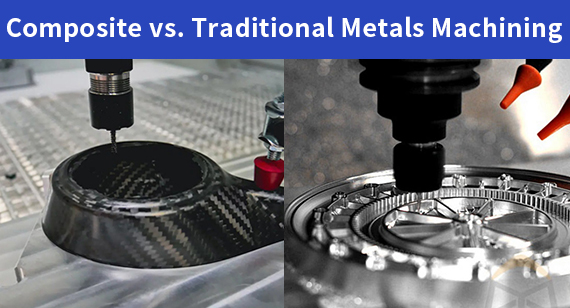

2025 07 15 Composite materials differ from traditional metal materials in CNC machining due to their structure, machinability, and performance characteristics. While metals offer high strength and thermal stability, composites provide lightweight properties, corrosion resistance, and customizability. Each material affects cutting techniques, tool wear, surface finish, and production cost — making material selection crucial for optimized CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2025 07 14

2025 07 14 2Cr13 and 3Cr13 are both martensitic stainless steels. The main difference lies in carbon content: 3Cr13 has higher carbon (≈0.3%) than 2Cr13 (≈0.2%), making it harder and more wear-resistant but slightly less corrosion-resistant. 2Cr13 is better for general machining; 3Cr13 suits tools requiring edge retention.

66

66

Read more

Read more

VMT

VMT  2025 07 12

2025 07 12 The primary difference between 3CR13 steel and 440C stainless steel lies in carbon and chromium content. 440C has higher carbon and chromium levels, offering greater hardness, wear resistance, and corrosion resistance than 3CR13, making it ideal for high-performance applications requiring strength and longevity.

66

66

Read more

Read more

VMT

VMT  2025 07 11

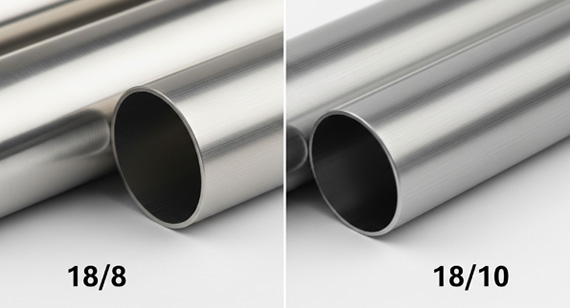

2025 07 11 18/8 stainless steel is a common informal designation for 304 stainless steel, indicating it contains approximately 18% chromium and 8% nickel. While 18/8 highlights the key alloying elements, 304 stainless steel is the official ASTM grade with precise compositional limits for all elements, ensuring consistent performance. Both are widely used in stainless steel CNC machining due to excellent corrosion resistance and formability.

66

66

Read more

Read more

VMT

VMT  2025 07 10

2025 07 10 18/8, 18/10, and 18/0 stainless steel differ mainly in their nickel content, affecting corrosion resistance, durability, and magnetic properties. 18/10 offers the highest corrosion resistance and shine, 18/8 balances cost and performance, while 18/0 is more affordable but less durable. Choosing the right grade depends on application, environment, and machining requirements.

66

66

Read more

Read more

VMT

VMT  2025 07 09

2025 07 09 18/8 stainless steel is generally more suitable for CNC machining than 18/10 due to its slightly lower nickel content, which improves machinability while still offering strong corrosion resistance. However, 18/10 provides superior durability and shine, making it ideal for parts requiring higher aesthetic value.

66

66

Read more

Read more

VMT

VMT  2025 07 08

2025 07 08 Composite materials are engineered by combining two or more distinct materials — typically a matrix and a reinforcement — to create a material with superior mechanical, thermal, or chemical properties. Composites are used across industries for lightweight, high-strength, and corrosion-resistant parts.

66

66

Read more

Read more

VMT

VMT  2025 07 07

2025 07 07 MIG/MAG welding are two arc welding methods widely used in CNC machining parts manufacturing. MIG uses inert gas for non-reactive shielding, ideal for non-ferrous metals, while MAG uses active gas suitable for ferrous metals. The key difference is the shielding gas type. Both offer high productivity and adaptability in welding CNC machining parts.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!